Oblique flow fan blade and preparation method thereof

A technology of flow air and antioxidant, applied in the field of fan blades and its preparation, can solve problems such as easy deformation, insufficient rigidity and high temperature resistance, increased vibration and noise, etc., to increase material toughness, improve aging performance, and improve flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

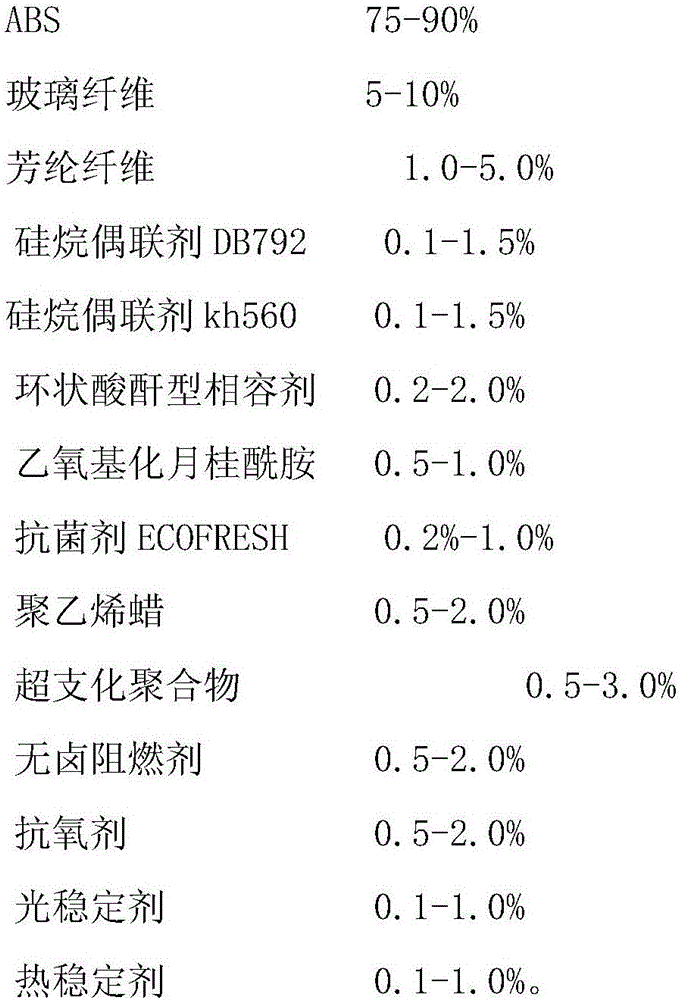

[0019] A kind of oblique flow blade, the oblique flow blade is injection molded from the following materials in terms of mass percentage:

[0020]

[0021] The preparation method of the above-mentioned oblique flow air blade, the method comprises the following steps: mixing ABS resin, silane coupling agent DB792, and silane coupling agent kh560 in a high mixer for 10-15min; In the feeding port, glass fiber, aramid fiber and other additives are added from the side feeding port, melted and extruded, cooled in a water tank, pelletized, and then dried and mixed to obtain injection molding pellets; injection molding pellets are added to the injection molding machine Injection molding is carried out to obtain the oblique flow fan blade.

Embodiment 2

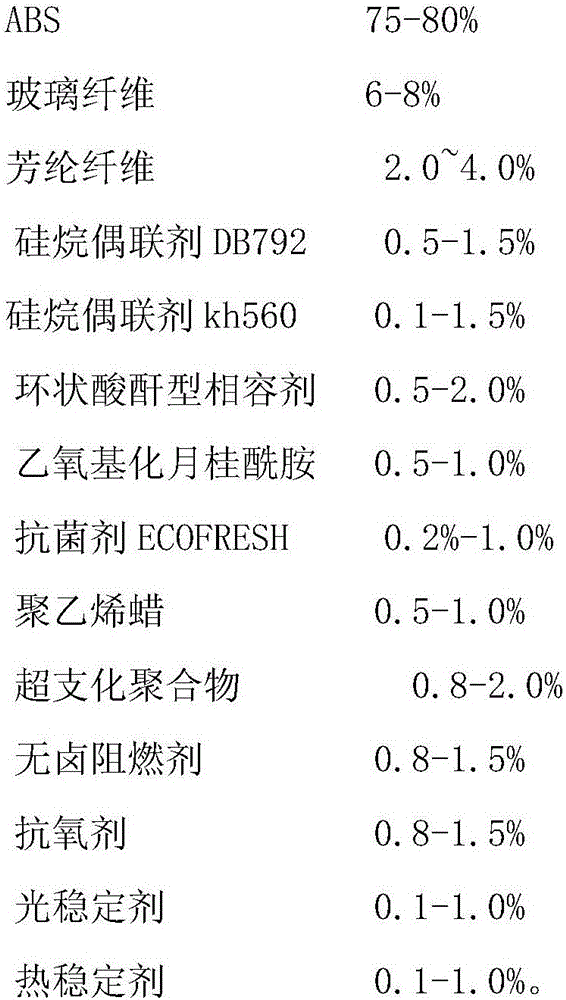

[0023] A kind of oblique flow blade, the oblique flow blade is injection molded from the following materials in terms of mass percentage:

[0024]

[0025]

[0026] The preparation method of the above-mentioned oblique flow air blade, the method comprises the following steps: mixing ABS resin, silane coupling agent DB792, and silane coupling agent kh560 in a high mixer for 10-15min; In the feeding port, glass fiber, aramid fiber and other additives are added from the side feeding port, melted and extruded, cooled in a water tank, pelletized, and then dried and mixed to obtain injection molding pellets; injection molding pellets are added to the injection molding machine Injection molding is carried out to obtain the oblique flow fan blade.

Embodiment 3

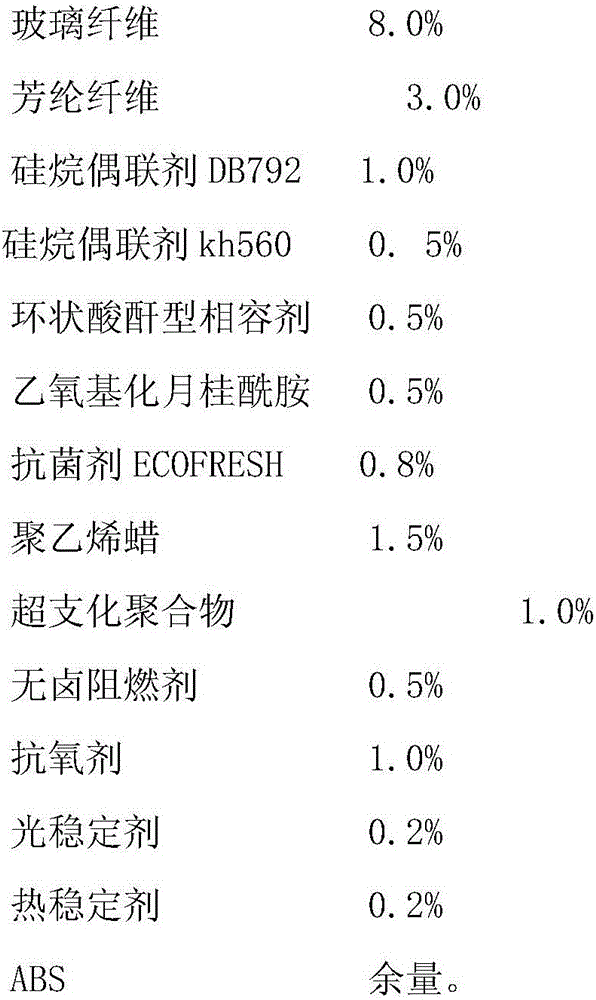

[0028] A kind of oblique flow blade, the oblique flow blade is injection molded from the following materials in terms of mass percentage:

[0029]

[0030]

[0031] The preparation method of the above-mentioned oblique flow air blade, the method comprises the following steps: mixing ABS resin, silane coupling agent DB792, and silane coupling agent kh560 in a high mixer for 10-15min; In the feeding port, glass fiber, aramid fiber and other additives are added from the side feeding port, melted and extruded, cooled in a water tank, pelletized, and then dried and mixed to obtain injection molding pellets; injection molding pellets are added to the injection molding machine Injection molding is carried out to obtain the oblique flow fan blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com