A kind of biodegradable straw and preparation method thereof

A straw and biological technology, applied in the fields of biodegradable straws and its preparation, straw materials and its preparation, can solve the problems of poor mechanical properties, low heat resistance, easy degradation, and easy breeding of harmful microorganisms, etc., to improve strength and increase Compatibility, effect of reducing hydrolysis phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

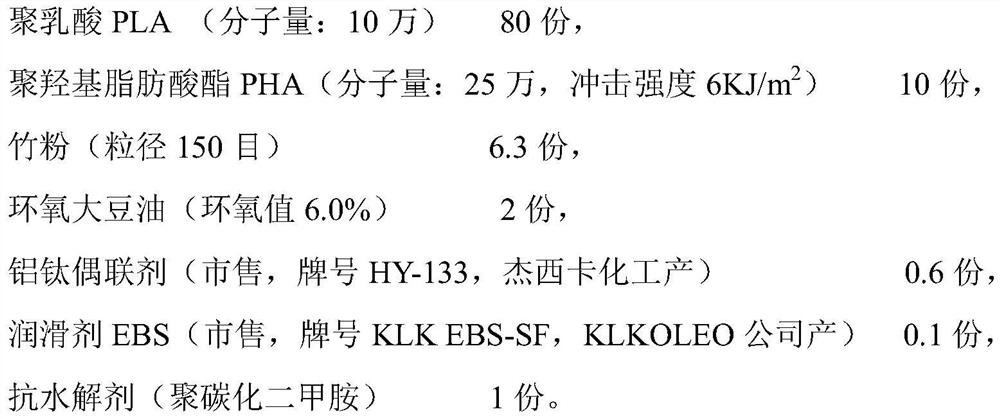

[0019] The weight content of each raw material component in the biodegradable straw is:

[0020]

[0021] The preparation process of biodegradable straws is as follows:

[0022] (1) Add 6.3 parts of bamboo powder to the high-speed mixer, set the equipment temperature to 80°C, and set the stirring speed to 500r / min. After turning on the equipment, slowly add 0.6 parts of aluminum-titanium coupling agent from the feeding port and continue stirring After 10min, close the equipment to form bamboo powder pretreatment material.

[0023] (2) Do the ingredients according to the set ratio, first add 80 parts of PLA and 10 parts of PHA to the high-speed mixer, set the stirring speed to 100r / min, after turning on the equipment, first add 2 parts of epoxy soybean oil, and then Add bamboo powder pretreatment material, lubricant and anti-hydrolysis agent, and continue to stir for 10 minutes to form a polylactic acid mixture.

[0024] (3) Add the polylactic acid mixture to the twin-scre...

Embodiment 2

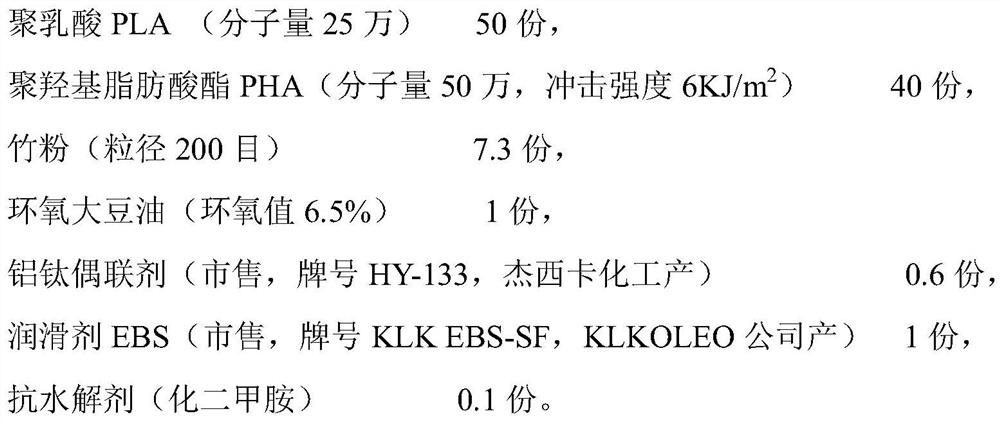

[0026] The weight content of each raw material component in the biodegradable straw is:

[0027]

[0028] The biodegradable straw is prepared with reference to the preparation process of Example 1, the difference is:

[0029] (1) Stirring temperature is 100 DEG C in step 1, and stirring speed is 1000r / min, after adding aluminum-titanium coupling agent, continue to stir for 15min to form bamboo powder pretreatment material;

[0030] (2) In step 3, the extrusion temperature is 150° C., the die head temperature is 160° C.; the cooling temperature is 42° C.; the pulling speed is 1.5 m / s.

Embodiment 3

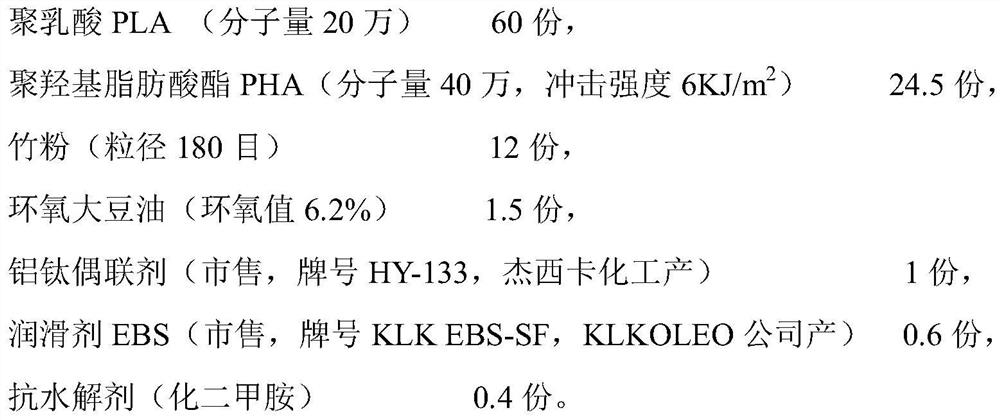

[0032] The weight content of each raw material component in the biodegradable straw is:

[0033]

[0034] The biodegradable straw is prepared with reference to the preparation process of Example 1, the difference is:

[0035] (1) Stirring temperature is 90 DEG C in step 1, and stirring speed is 600r / min, after adding aluminum-titanium coupling agent, continue to stir for 12min to form bamboo powder pretreatment material;

[0036] (2) In step 3, the extrusion temperature is 160° C., the die head temperature is 200° C.; the cooling temperature is 50° C.; the pulling speed is 1 m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com