Mechanical seal chemical pump and using method thereof

A mechanical seal and chemical pump technology, applied in the field of chemical pumps, can solve the problems of no heat resistance, chemical corrosion resistance, aging resistance, mildew resistance, poor sealing performance of chemical centrifugal pumps, and short service life of chemical centrifugal pumps. , to achieve the effect of improving strength and electrical properties, improving light decomposition resistance, and improving thermal decomposition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

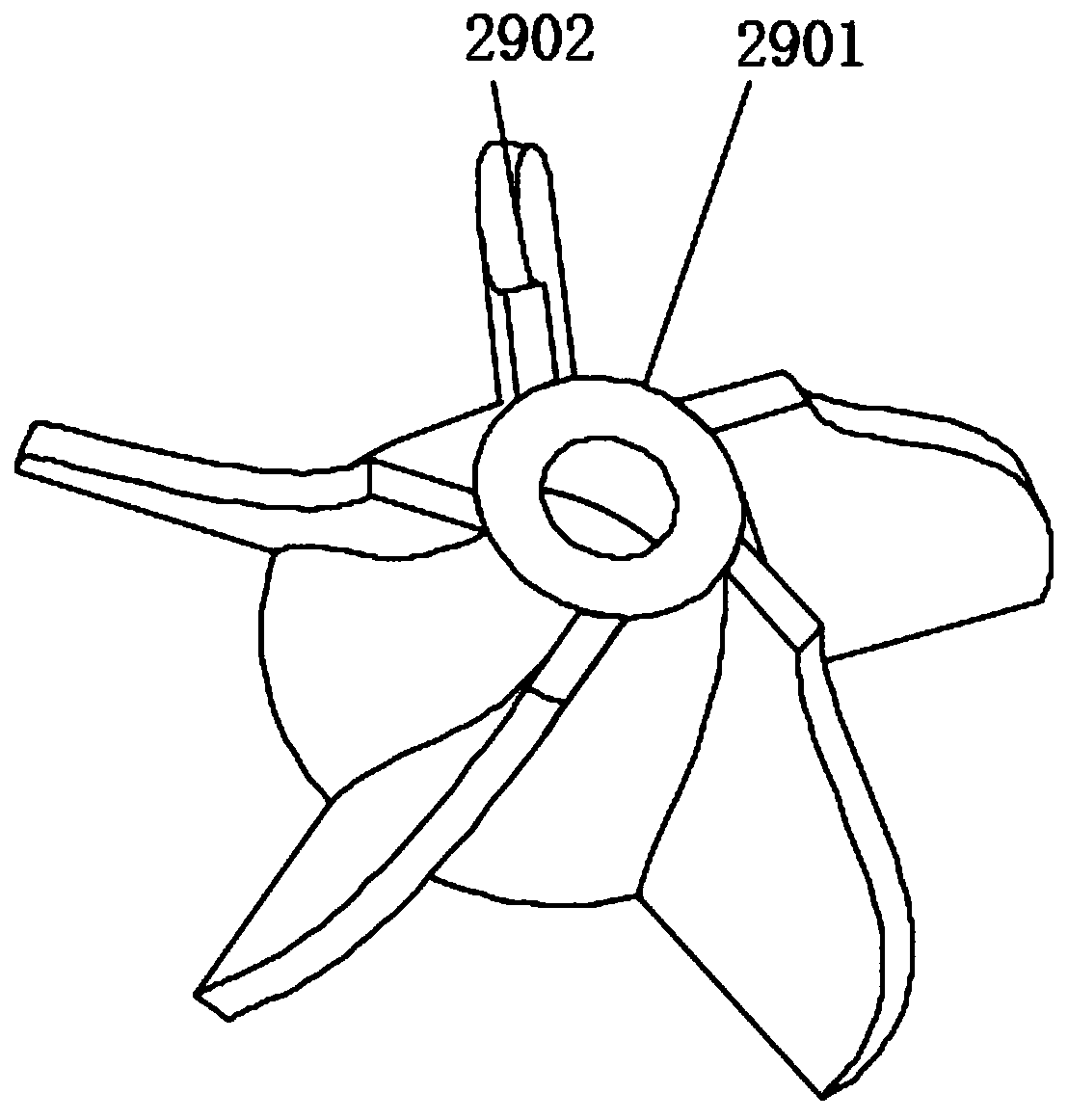

[0029] The preparation method of the impeller 29 is: mix AS resin, mica, the first silane coupling agent, and the second silane coupling agent in a high mixer for 10-15min; place them in the main feeding port of the twin-screw extruder , add glass fiber, carbon fiber and other additives from the side feed port, melt and extrude, cool in a water tank, cut into pellets, and then mix after drying to obtain injection molding pellets; add injection molding pellets to an injection molding machine for injection molding to obtain an impeller 29;

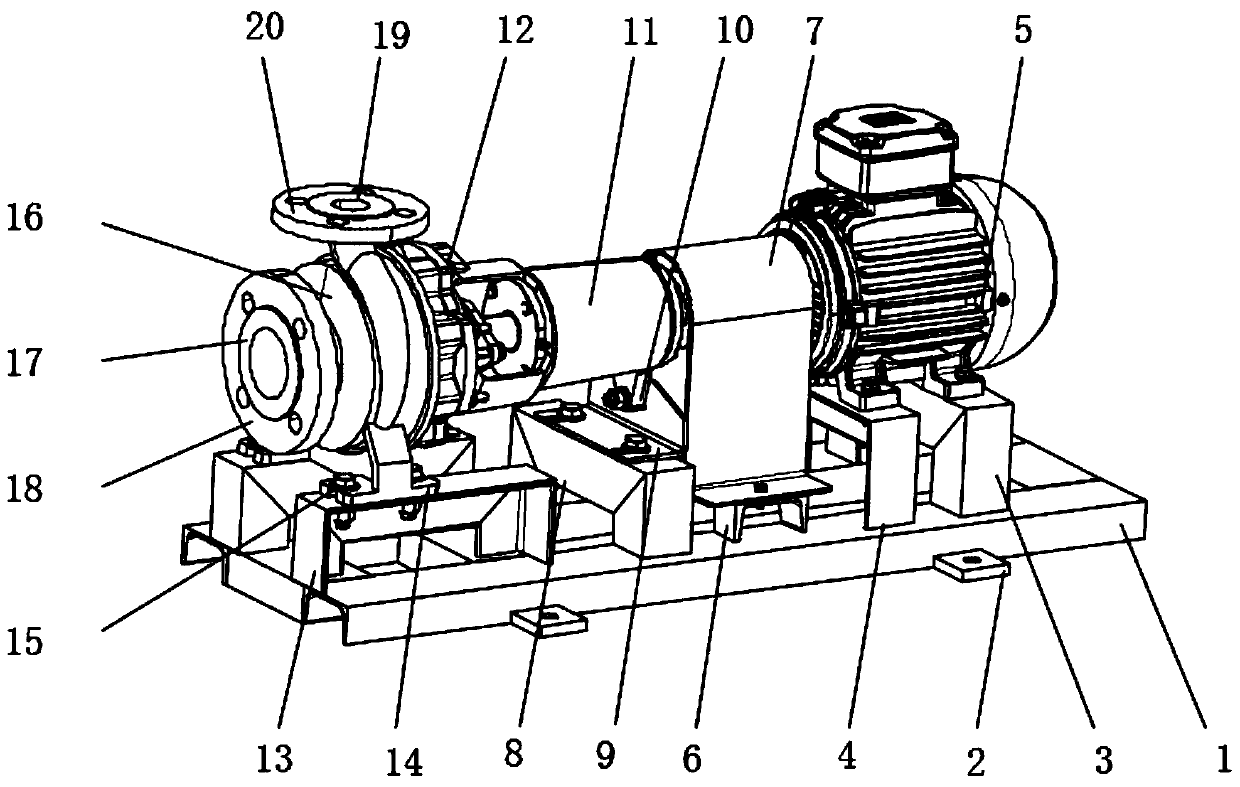

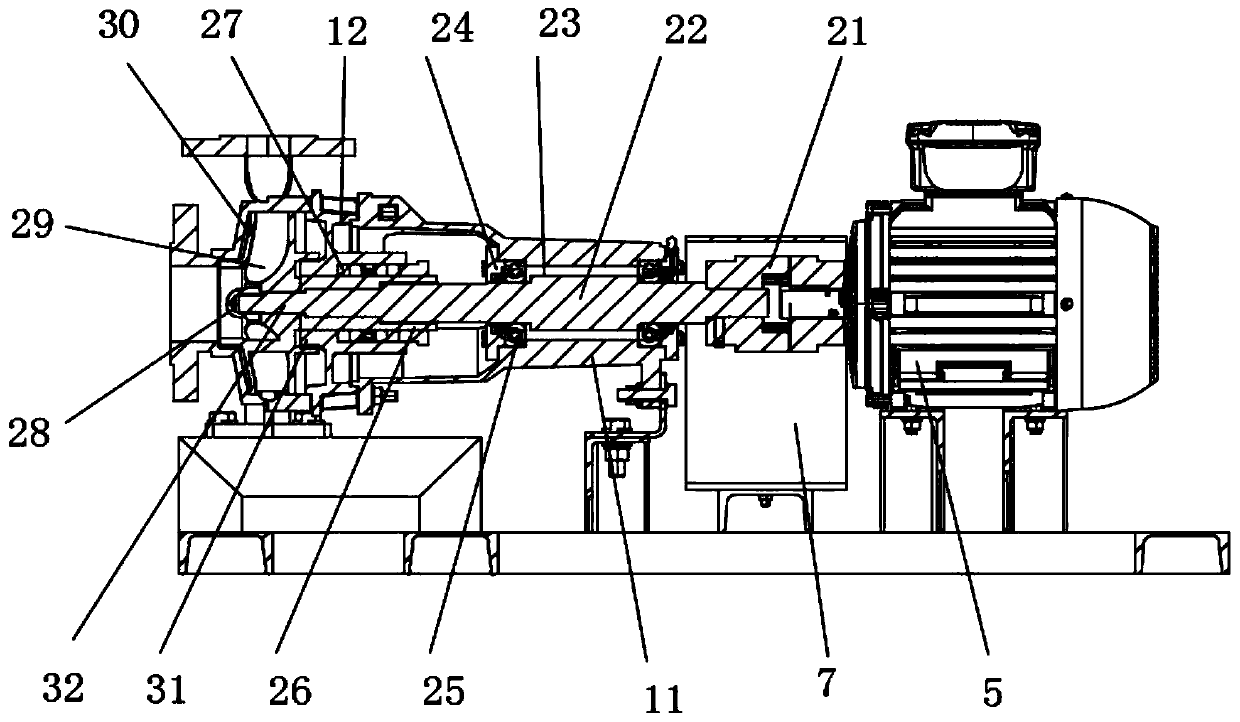

[0030] The inside of the pump cover 16 is provided with a second cavity 30, the second cylinder 12 is fixedly installed between the pump cover 16 and the first cylinder 11, and an inlet is fixedly installed on one side surface of the pump cover 16. Material port 17, the first flange seat 18 is fixedly installed on the arc side of the feed port 17, the upper end of the pump cover 16 is fixedly equipped with a discharge port 19, and the arc si...

Embodiment 1

[0035] The impeller 29 is made up of the following materials by mass percentage: 80% of AS resin, 15% of glass fiber, 1.0% of carbon fiber, 5% of mica, 0.1% of the first silane coupling agent, 0.1% of the second silane coupling agent, cyclic anhydride Type compatibilizer 0.2%, ethoxylated lauramide 0.5%, antibacterial agent 0.2%, ethylene bis stearamide 0.5%, EVA 0.5%, halogen-free flame retardant 0.5%, antioxidant 0.5%, light Stabilizer 0.1%, heat stabilizer 0.1%; Described antioxidant selects one kind of mixing in antioxidant 1010, antioxidant 1076, antioxidant CA, antioxidant DNP and antioxidant MB to mix, Halogen-free flame retardants use nitrogen-based flame retardants or nitrogen-phosphorus intumescent flame retardants, light stabilizers use hindered amine light stabilizers and benzothiazole ultraviolet absorbers, heat stabilizers use calcium-zinc stabilizers; The silane coupling agent and the second silane coupling agent are silane coupling agent kh560 and silane coupli...

Embodiment 2

[0038] The impeller 29 is made up of the following materials by mass percentage: AS resin 55%, glass fiber 25%, carbon fiber 5.0%, mica 10%, the first silane coupling agent 1.5%, the second silane coupling agent 1.5%, cyclic anhydride Type compatibilizer 2.0%, ethoxylated lauramide 1.0%, antibacterial agent 1.0%, ethylene bisstearamide 2.0%, EVA 3.0%, halogen-free flame retardant 2.0%, antioxidant 2.0%, light Stabilizer 1.0%, heat stabilizer 1.0%; antioxidant selected from antioxidant 1010, antioxidant 1076, antioxidant CA, antioxidant DNP and antioxidant MB mixed with a variety of mixtures, halogen-free The flame retardant is nitrogen-based flame retardant or nitrogen-phosphorus intumescent flame retardant, the light stabilizer is hindered amine light stabilizer and benzothiazole ultraviolet absorber, the heat stabilizer is calcium-zinc stabilizer; the first silane coupler The coupling agent and the second silane coupling agent are silane coupling agent kh560 and silane coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com