Ceramic composite electronic cigarette heating pipe and electronic cigarette atomizing core employing same

A ceramic composite, electronic cigarette technology, applied in the direction of smoker's products, applications, tobacco, etc., can solve the problems of carbonization of liquid-conducting cotton 102, reduction of heat conduction capacity, leakage of electronic cigarette liquid, etc., so as to eliminate the trouble of liquid leakage and avoid The effect of wasting resources and increasing usage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

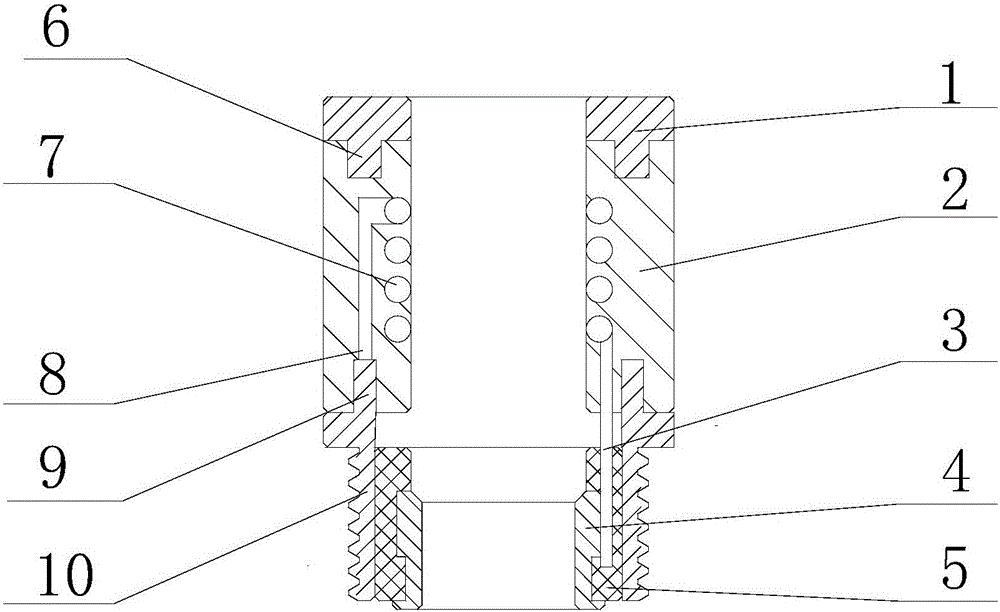

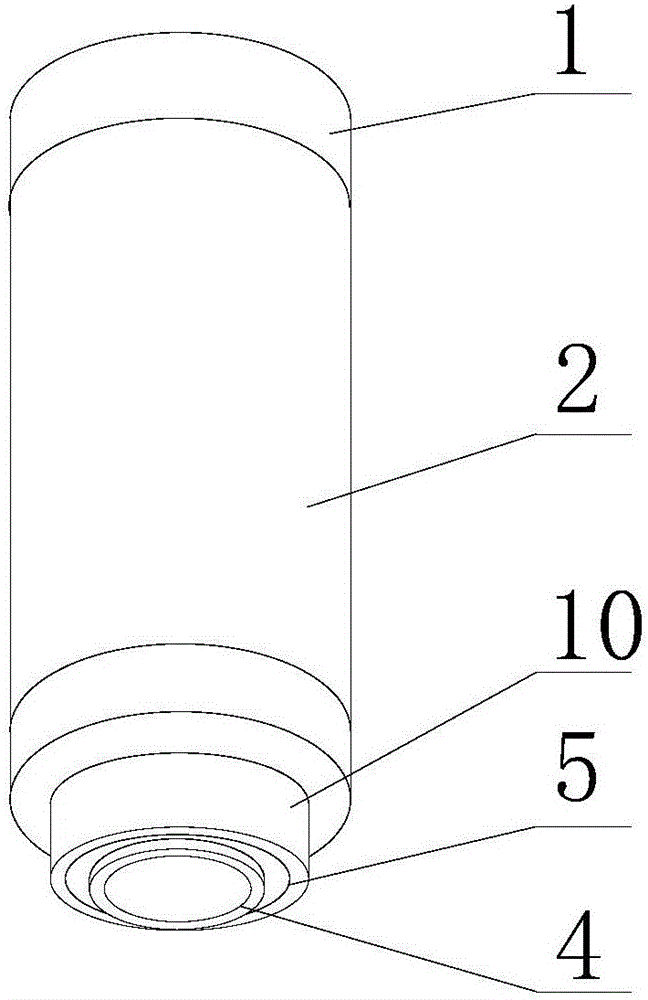

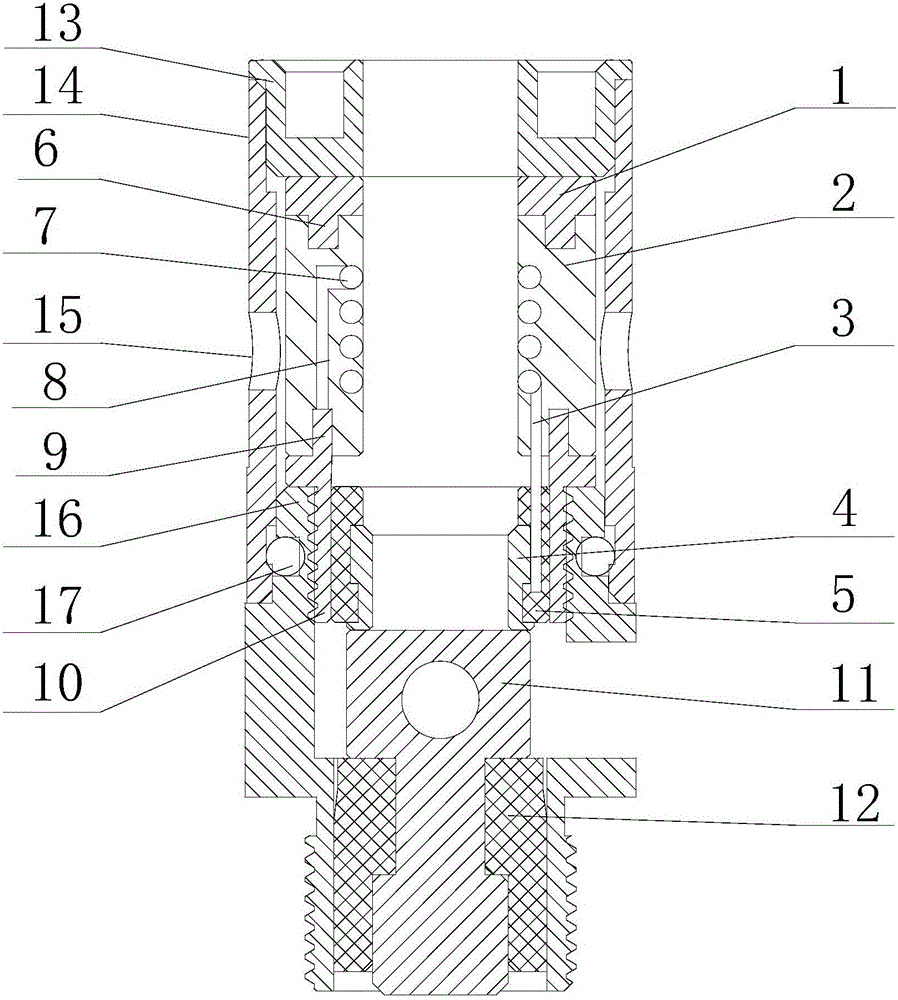

[0032] Such as figure 1 Shown is a schematic cross-sectional structure diagram of the ceramic composite heating tube of this embodiment. The ceramic composite heating tube includes two parts, one part is a heating wire 7 for heating, and the other part is a microporous ceramic tube 2 for fixing and embedding the heating wire 7 . The microporous ceramic tube 2 has a cylindrical structure, and the heating wire 7 itself is wound into a spiral shape. The spiral heating wire 7 is located at the inner tube wall of the microporous ceramic tube 2 and protrudes from the inner tube wall of the microporous ceramic tube 2 The purpose of this is to realize that the temperature of the ceramic composite heating tube gradually rises from the outer wall to the inner wall, and the temperature at the inner wall is the highest, and the inner wall is the smoke suction pipe, which will increase the atomization effect.

[0033] Such as figure 1 , figure 2 As shown, the two ends of the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com