Infrared heating testing device and testing method for bituminous pavement

A heating test, asphalt pavement technology, applied in the field of highway engineering, can solve the problems of immature asphalt pavement technology, reduced asphalt recyclability, reduced work efficiency, etc., to avoid incomplete heating, less consumption, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

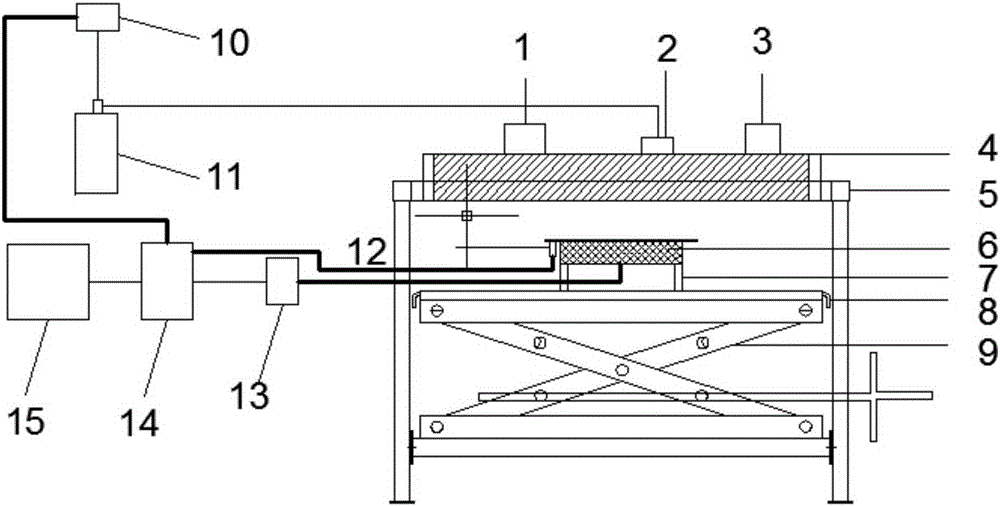

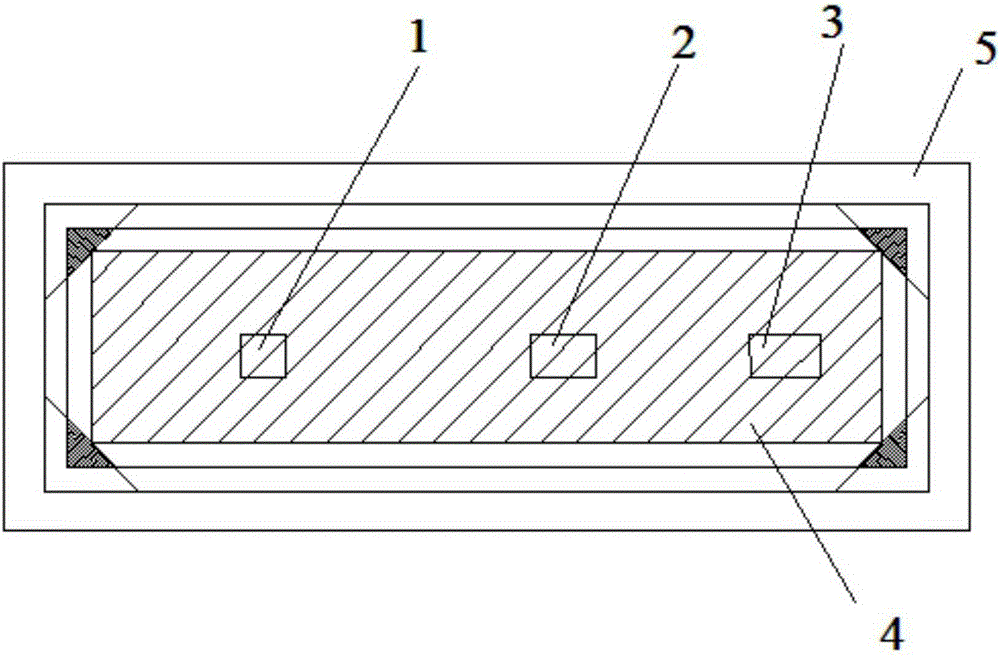

[0036] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

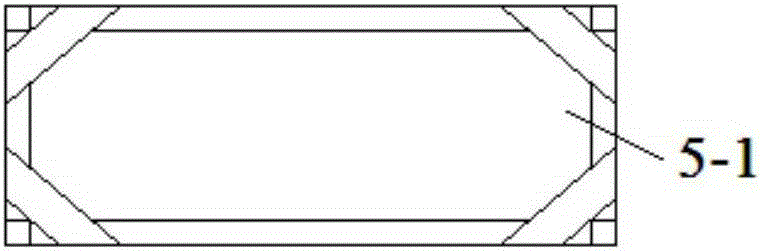

[0037] see figure 1 and figure 2 , the device of the present invention includes an infrared generation controller 1, a liquefied petroleum gas intake control valve 2, a frequency conversion blower 3, an infrared generating device 4, a test bench frame 5, a test block tray 7, an insulating water tank 8, a lifting device 9, a load Sensor 10, petroleum liquefied gas storage tank 11, infrared radiation flow sensor 12, thermocouple temperature compensation block 13, data acquisition instrument 14 and computer 15, wherein, infrared generation controller 1 controls the start and stop of infrared generation device 4; petroleum liquefaction Air intake control valve 2 controls the intake of liquefied petroleum gas; variable frequency blower 3 controls the intake of air; the asphalt test block 6 is installed on the test block tray 7 during the test, between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com