Acid-adjusting hydrolysis process for preparing levulinic acid

A technology for adjusting levulinic acid and acid, which is applied in the preparation of carboxylate salts, chemical instruments and methods, and the preparation of organic compounds. Effects of increasing production cost and technical difficulty, shortening hydrolysis time, and increasing cellulose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

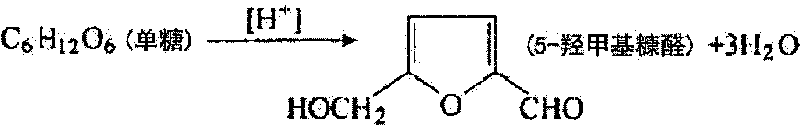

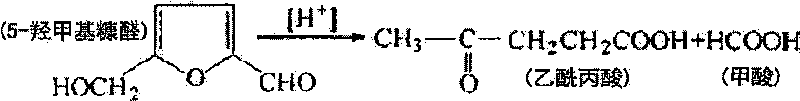

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Raw materials: cellulose 40.13% corn stalks; sulfuric acid 98%, analytically pure.

[0021] 2. Preparation:

[0022] (1) Raw material pretreatment: Air-dry the corn stalks, pulverize them, and pass through a 30-mesh sieve. (3) Hydrolysis: use dilute sulfuric acid as a catalyst, add 2000ml of dilute sulfuric acid solution with a mass concentration of 3.8%, add corn stalks at a solid-to-liquid ratio of 1:19.5, stir evenly, and let stand at room temperature for 30 minutes to fully mix the feed liquid. Heating to 239.5°C within 3.2 minutes, reacting at 239.5°C and 2.4mPa pressure for 34.3 minutes, with a rotation speed of 100r / min. (4) Acid adjustment: quickly cool down to 50°C, reduce to normal pressure, reduce the rotating speed to 70r / min, inject 20ml of 20% sulfuric acid solution, then rapidly raise the temperature to 205°C, rotate at 160r / min, reaction pressure 2.2mPa, reaction time 20 minutes. (5) Detection of the target product: after the reaction is completed,...

Embodiment 2

[0024] 1. Raw materials: rice straw with 36.2% cellulose; 98% sulfuric acid, analytically pure.

[0025] 2. Preparation:

[0026] (1) raw material pretreatment: air-dry rice straw, pulverize, pass 30 mesh sieves; (3) hydrolysis: take dilute sulfuric acid as catalyst, add the dilute sulfuric acid solution 2000ml of mass concentration 3.9%, add rice straw according to solid-liquid ratio 1: 17.4 Straw, stir evenly, stand at room temperature for 30 minutes so that the feed liquid is fully mixed. Heating to 241.2°C within 3.5 minutes, reacting at 241.2°C and 2.4mPa pressure for 34.5 minutes, with a rotation speed of 120r / min. (4) Acid adjustment: quickly cool down to 50°C, reduce to normal pressure, reduce the rotating speed to 70r / min, inject 20ml of 20% sulfuric acid solution, then rapidly raise the temperature to 205°C, rotate at 160r / min, reaction pressure 2.2mPa, reaction time 20 minutes. (5) Detection of the target product: the reaction is completed, the solid-liquid is fi...

Embodiment 3

[0028] 1. Raw materials: Combined raw materials: corn stalks account for 40% of raw materials, rice stalks account for 40% of raw materials, and rice husks account for 20% of raw materials. The average cellulose content after mixing is 35.15%; sulfuric acid is 98%, analytically pure.

[0029] 2. Preparation:

[0030] (1) Raw material pretreatment: air-dry and pulverize corn stalks, rice stalks and rice husks, pass through a 30-mesh sieve, and combine the three raw materials in a ratio of 2:2:1. (3) Hydrolysis: take dilute sulfuric acid as a catalyst, add 2000ml of dilute sulfuric acid solution with a mass concentration of 3.7%, add combined raw materials by solid-liquid ratio 1: 17.9, stir evenly, and leave standstill at room temperature for 30 minutes to fully mix the feed liquid. Heating to 233.1°C within 3.8 minutes, reacting for 32.1 minutes under the conditions of 233.1°C and 2.3mPa pressure, with a rotation speed of 110r / min. (4) Acid adjustment: quickly cool down to 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com