Low-smoke, halogen-free and flame-retardant polyester elastomer thin-wall insulating material and preparation method thereof

A flame-retardant polyester, thin-wall insulation technology, applied in the field of wire and cable materials and their preparation, can solve the problems of poor processing safety, low volume resistivity, unqualified aging performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

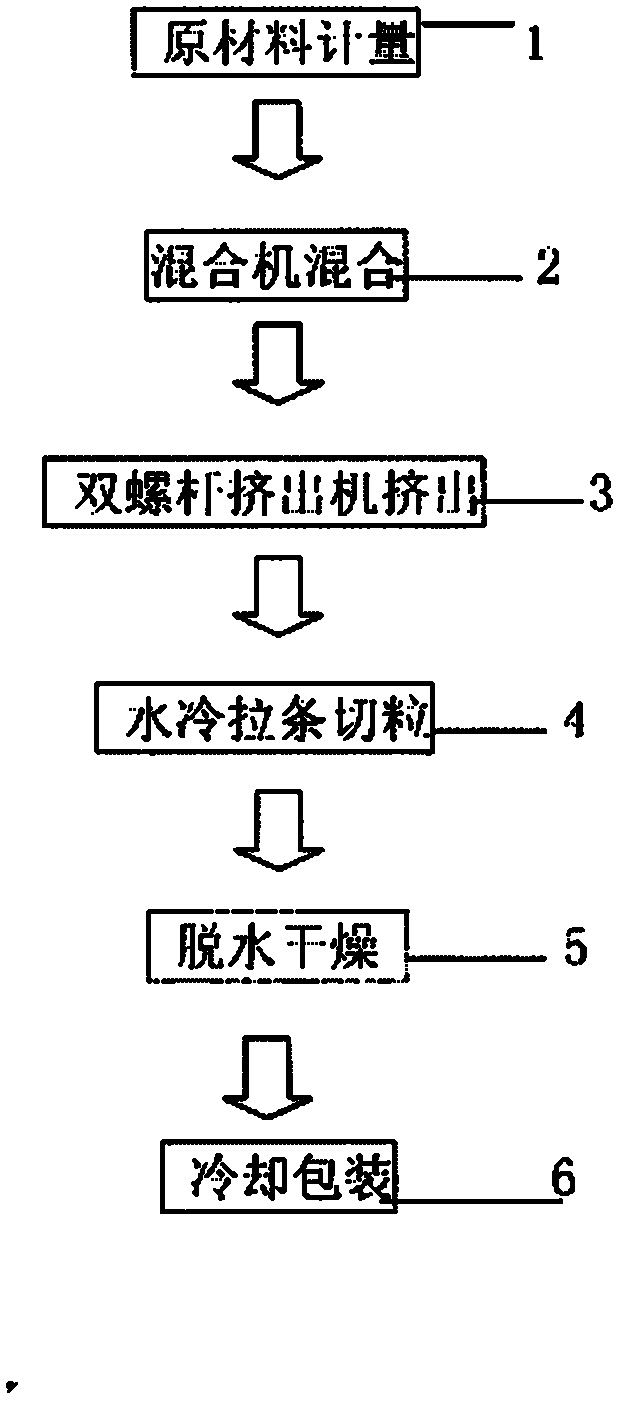

[0028] Taking low-smoke halogen-free flame-retardant polyester elastomer thin-wall insulating material and its preparation method as an example, combined with figure 1 The present invention is described in further detail, but not limited thereto. The raw materials used in the following examples are commercially available industrial products.

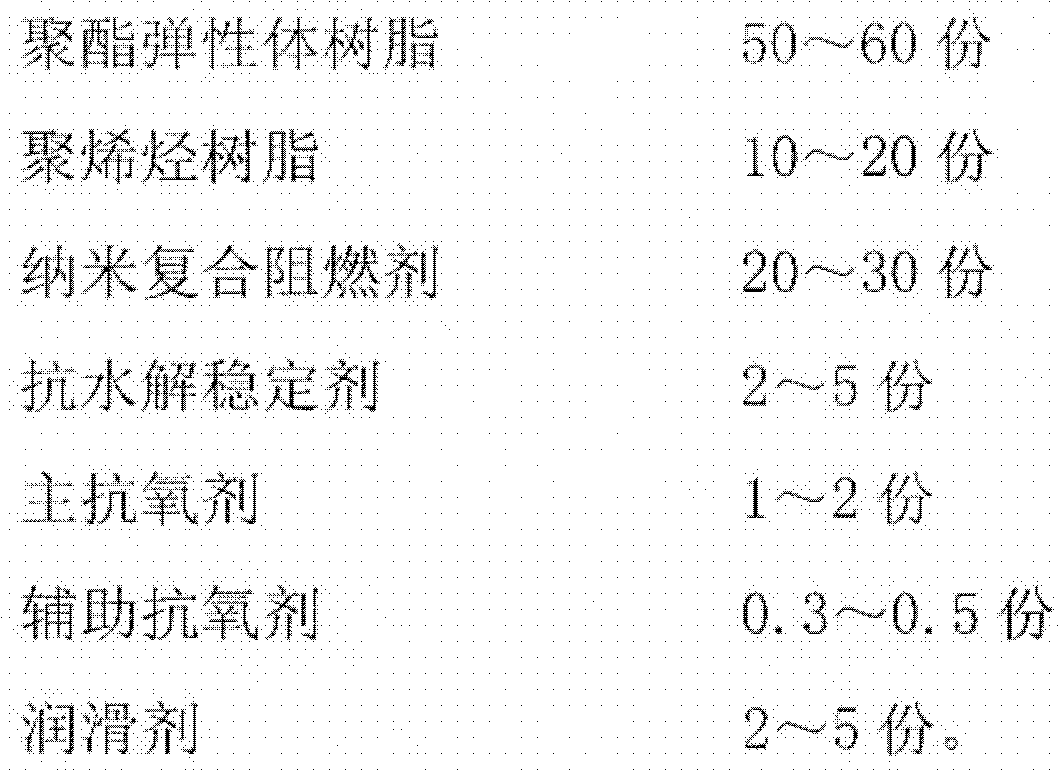

[0029] Embodiment is formulated according to the parts by weight shown in each component in table 3:

[0030] table 3

[0031] project

Implementation recipe

polyester elastomer

70

10

Nanocomposite flame retardant

20

Anti-hydrolysis stabilizer

2

0.5

0.3

3

[0032] Preparation:

[0033] The preparation process steps of the present invention are as follows, according to the raw material metering 1, that is, according to the weight parts in the table, the raw material is adde...

PUM

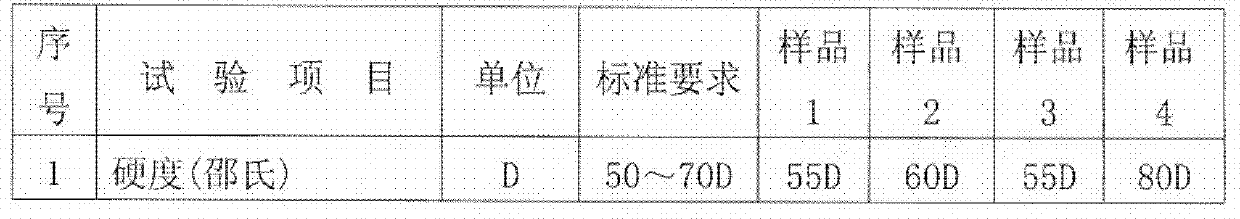

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com