Down-flow gas semi-coke activated pulverized coal pyrolysis system and method

A semi-coke and coal gas technology, applied in the field of coal chemical industry, can solve the problems of large amount of gas heat carrier, difficulty in dust removal of raw coal gas, easy carbon deposition, etc., achieve low energy consumption, improve coal pyrolysis efficiency, and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

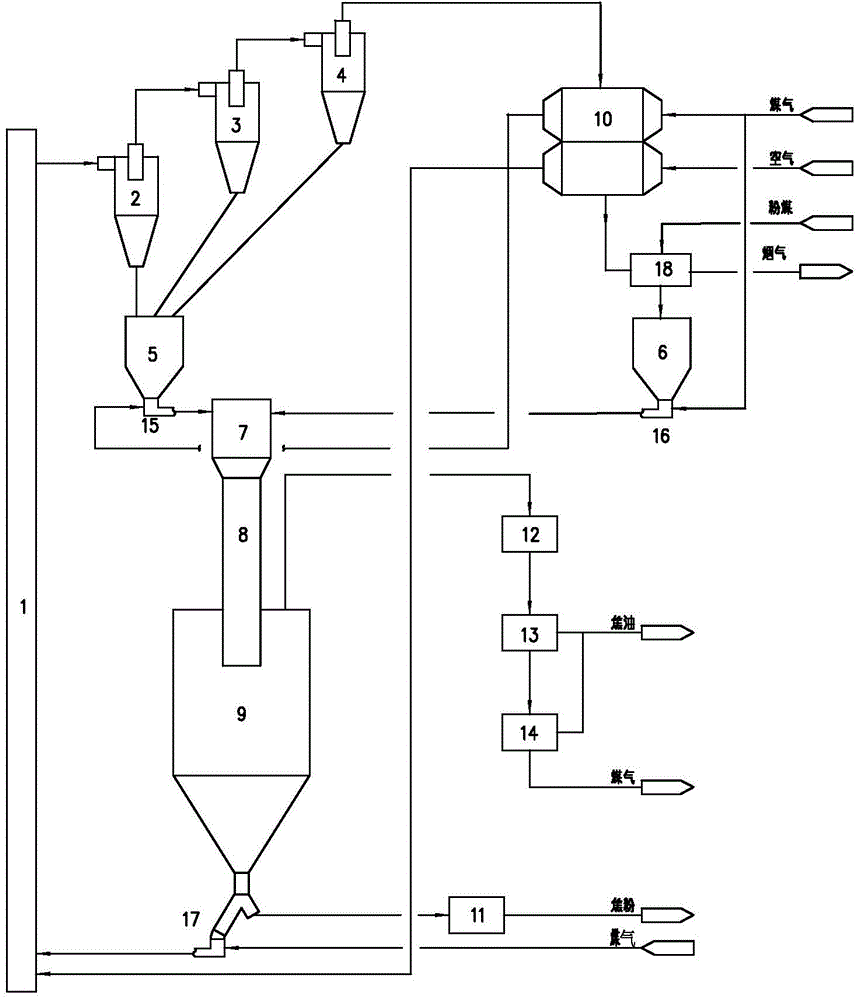

[0031] Depend on figure 1 It can be seen that the downstream gas semi-coke activated pulverized coal pyrolysis system in this embodiment is composed of an upward heating riser 1, a first-stage cyclone dust collector 2, a second-stage cyclone dust collector 3, a third-stage cyclone dust collector 4, and a high-temperature semi-coke. Coke buffer bin 5, dry coal bunker 6, cyclone mixer 7, downlink reaction pipe 8, oil and gas cyclone dust collector 9, high temperature flue gas heat exchanger 10, semi-coke cooler 11, fixed bed fine dust collector 12, oil washing device 13. Electric tar catcher 14, first L-shaped valve 15, second L-shaped valve 16, third L-shaped valve 17 and vertical mill 18 are connected.

[0032] The high-temperature flue gas heat exchanger 10 of this embodiment is an ordinary flue gas heat exchanger. The gas inlet of the high-temperature flue gas heat exchanger 10 is connected to the gas pipeline outside, the air inlet is connected to the outside atmosphere, an...

Embodiment 2

[0042] The stroke of the descending reaction tube 8 in this embodiment is 40m, and the feeding port of the descending reaction tube 8 is connected with the feeding port of the cyclone mixer 7 , and the feeding port is connected with the feeding port of the oil-gas cyclone dust collector 9 .

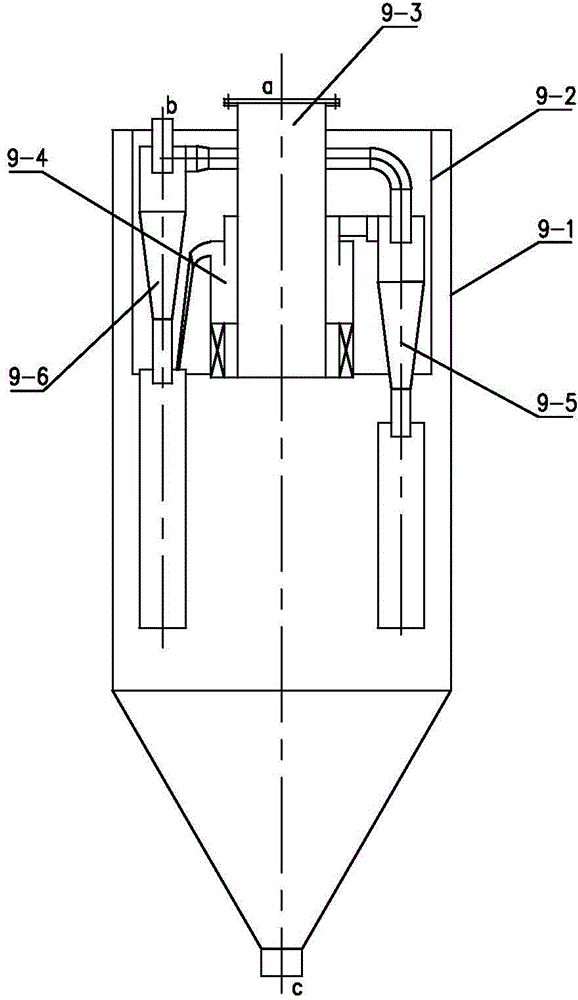

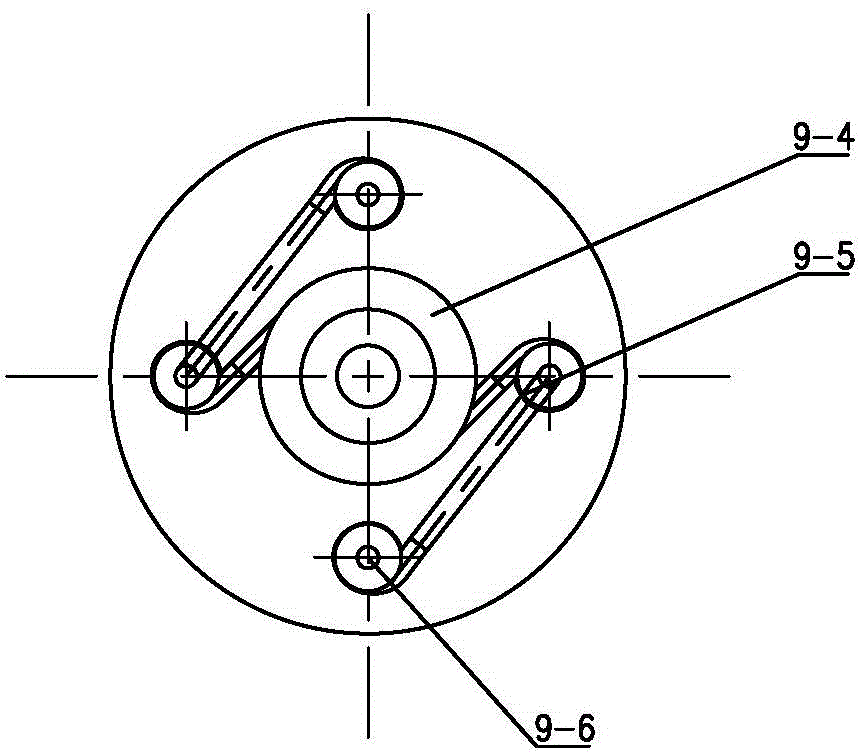

[0043]In the oil-gas cyclone dust collector 9 of the present embodiment, four guide vanes installed obliquely are arranged on the outer wall of the lower end of the vortex inner tube. The outlet angle of the guide vanes is 25°. The vortex outer tube is sealed at the top of the vortex outer tube and the vortex inner tube. Two raw gas outlets are processed on the upper side wall of the vortex outer tube. The airflow exit directions of the two raw gas outlets are symmetrical about the central axis. There are three dust collection ports on the lower side of the raw gas outlet, and each dust collection port is equipped with a feeding leg extending to the semi-coke buffer bin. Two secondary cyc...

Embodiment 3

[0047] The stroke of the descending reaction tube 8 in this embodiment is 80m. In the oil-gas cyclone dust collector 9, four guide vanes installed obliquely are arranged on the outer wall of the lower end of the vortex inner tube, and the outlet angle of the guide vanes is 25°. The structures are exactly the same, and they all adopt the commercially available Stairmand HE high-efficiency cyclone separator. The diameter of the cylinder is 860mm, and the feeding leg extends into the semi-coke buffer bin. The feeding leg of the primary vortex dust removal unit 9-4, the secondary The distance between the feeding legs of the first-level cyclone 9-5 is 600mm, and the distance between the feeding legs of the second-level cyclone 9-5 and the third-level cyclone 9-6 is 600mm, so as to ensure that they do not cross each other. gas.

[0048] Other components and their connections are the same as those in Embodiment 1.

[0049] The pulverized coal pyrolysis method of this embodiment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com