Preparation method of graphene thin film

A graphene film and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as poor performance, time-consuming high-temperature reduction, high energy consumption, etc., and achieve excellent performance and avoid cooling opportunities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, graphene oxide powder and reduced graphene oxide powder are prepared. 30 grams of graphite mixed with 15 grams of sodium nitrate and 750 milliliters of concentrated sulfuric acid. The mixture was cooled to 0°C in an ice bath, and after stirring for 2 h, 90 g of potassium permanganate was slowly added, keeping the temperature of the mixture below 5°C during the mixing process. The mixture was stirred for another hour and allowed to warm to room temperature by removing the ice bath. Add 1 liter of distilled water to the mixture and increase the temperature in the oil bath to 90°C. Another 300 ml of water were added and stirred for another hour and a half. The color of the mixture turned brown. The mixture was then treated and diluted with 30% hydrogen peroxide in 300 ml and 30 liters of hot water. The mixture was further washed with excess water until the pH of the filtrate was almost neutral to obtain graphene oxide. Then graphene oxide was dispersed in water...

Embodiment 2

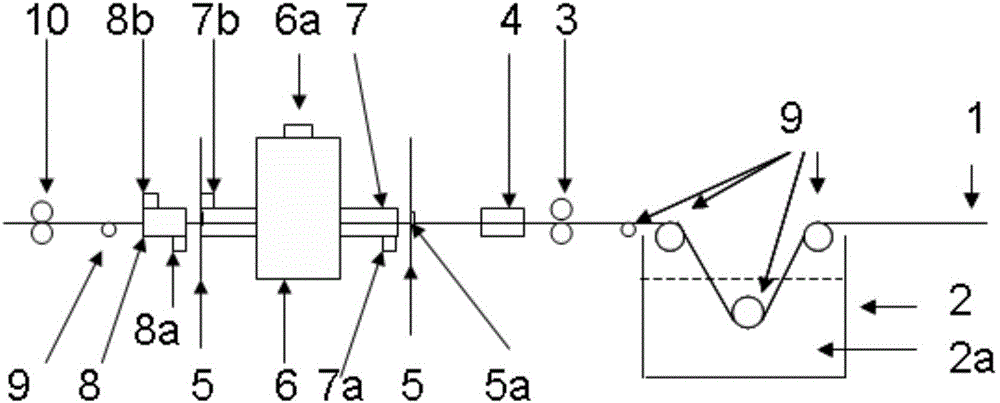

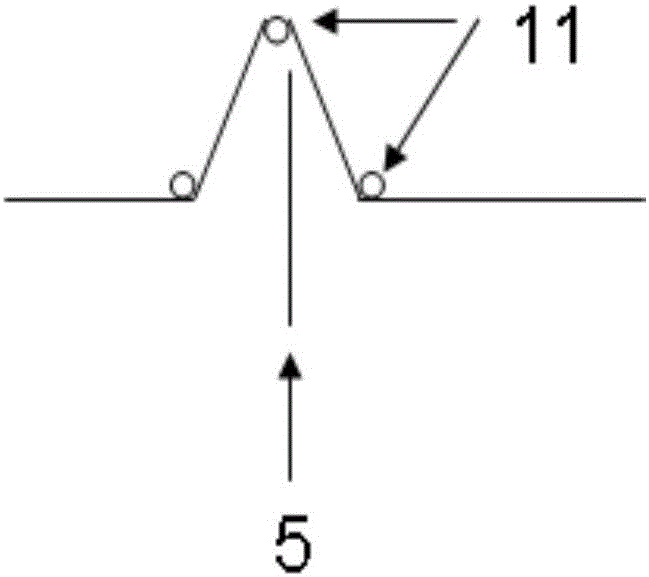

[0030] First obtain dust-free asbestos paper with a thickness of 1 mm, a length of 1 meter, and a width of 0.5 meters. Then soak the dust-free asbestos paper in a 10 mg / ml graphene oxide aqueous solution for 5 minutes, then take it out and dry it in the air to obtain a composite asbestos paper coated with a graphene oxide layer on the surface. The composite asbestos paper was treated in hydrazine hydrate vapor at 95 degrees Celsius for 24 hours to reduce the graphene oxide layer to obtain the composite asbestos paper coated with the reduced graphene oxide layer. Then, under the protection of nitrogen at room temperature, the composite asbestos paper is driven by a high-temperature conveyor belt at a speed of 0.05 m / s to pass through a heating zone with a width of 0.5 meters and a length of 0.1 meters constructed by five microwave ovens with a power of 1000W for about 2 seconds. The composite asbestos paper enters the room temperature area for cooling, repeats the microwave hea...

Embodiment 3

[0032] First, obtain an alkali-free glass fiber cloth with a thickness of 0.1 mm and a width of 10 cm with a warp and latitude of 47.4*27.5. Then the non-alkali glass fiber cloth is passed through a 30 cm long 1 mg / ml reduced graphene oxide aqueous solution at a speed of 0.01 m / s, and after drying, a composite non-alkali glass fiber cloth coated with a reduced graphene oxide layer is obtained. Under the protection of helium, the composite non-alkali glass fiber cloth is heated at a speed of 0.05 m / s at room temperature by a microwave oven with a power of 1000W and a heating area with a diameter of 10 cm for about 2 seconds, then enters the room temperature area again for cooling, and repeats The above microwave heating-cooling process was performed 5 times, and then the composite non-alkali glass fiber cloth was extruded through extrusion rollers with a line pressure of 1300 N / cm to obtain a carbon content greater than 90% and an electrical conductivity greater than 5000Sm -1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com