Camshaft flame quenching automatic heat treatment machine tool and technology

A flame quenching and camshaft technology, applied in the field of heat treatment, to achieve the effects of automatic and precise operation, strong applicability, quality assurance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

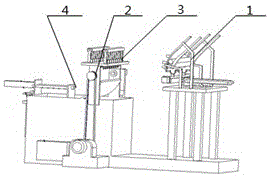

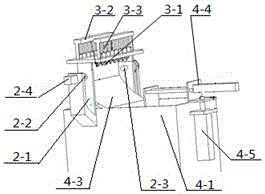

[0033] The camshaft flame quenching automatic heat treatment machine tool of the present invention includes a feeding mechanism 1, a rotating mechanism 2, a heating mechanism 3, a cooling mechanism 4 and a control mechanism arranged on the machine tool in sequence, and the control mechanism controls the coordinated operation of the various mechanisms of the machine tool. The specific structure is as figure 1 , figure 2 , image 3 , Figure 4 shown.

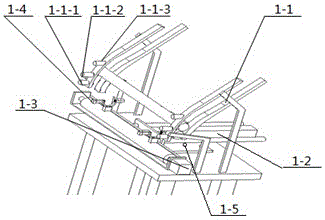

[0034]The feeding mechanism 1 of the present invention includes a sliding chute 1-1 and a feeding receiver 1-4. The function of the feeding mechanism 1 is to make the camshaft enter the rotating mechanism 2 according to the required time and order. The sliding material trough 1-1 is arranged on the machine frame body, the sliding material chute 1-1 is an upper arc structure or a straight structure, and the slid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com