Patents

Literature

31results about How to "Shaping speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

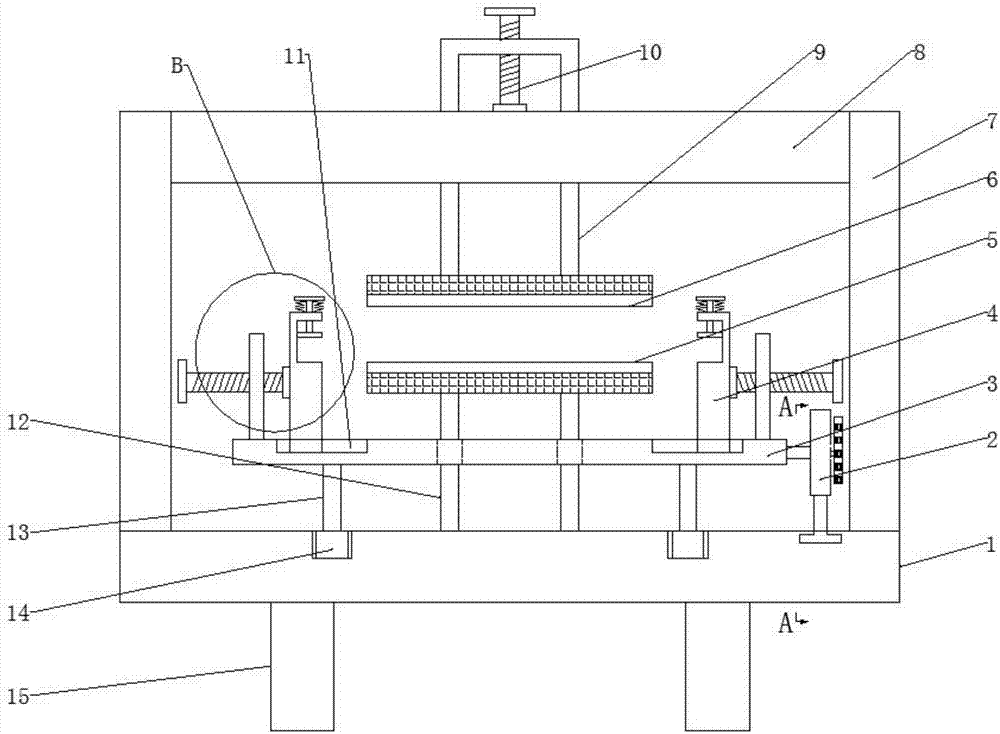

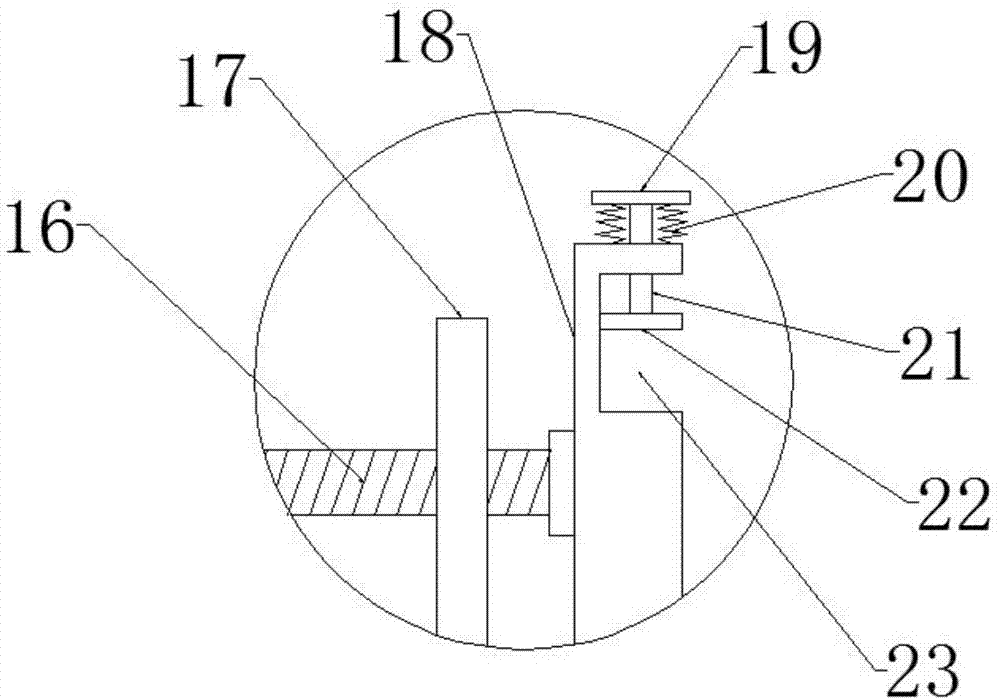

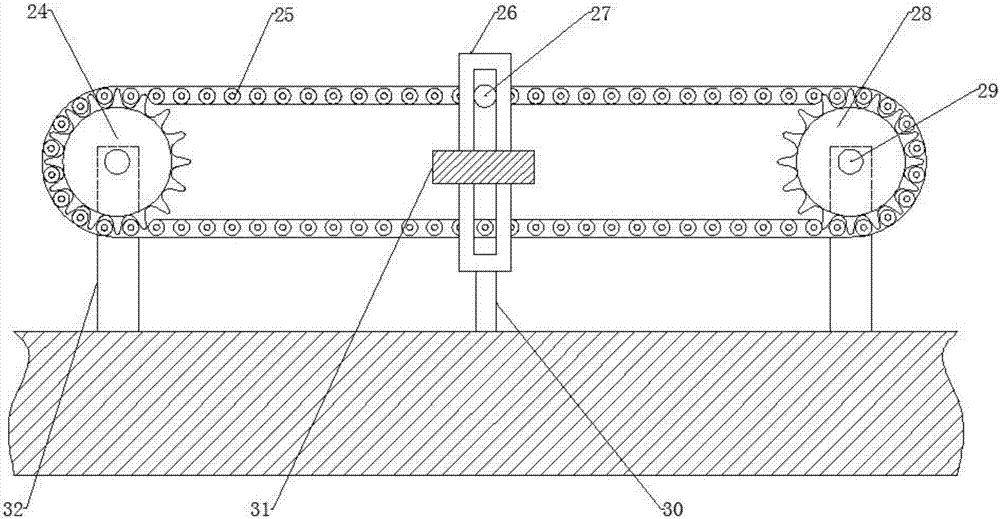

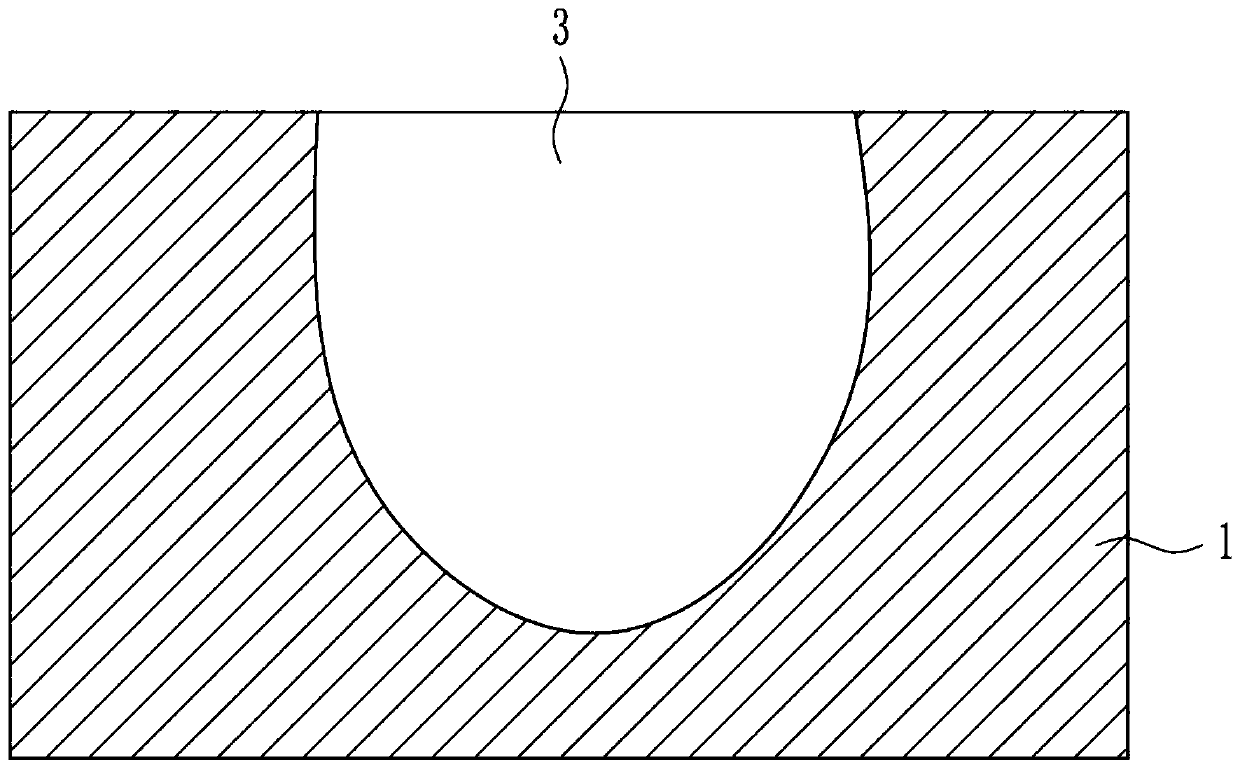

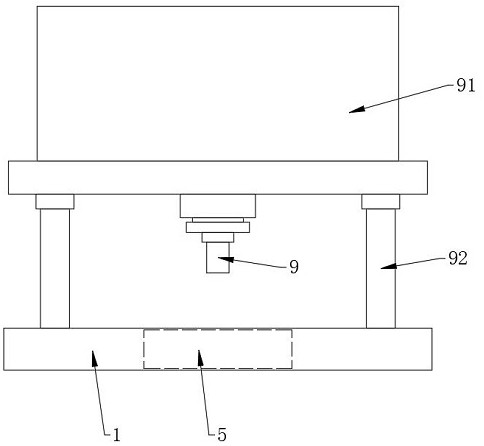

Double-faced efficient reshaping device for building decorative board

The invention discloses a double-sided high-efficiency shaping device for building decorative boards, which includes a base, a top plate, a pressing device and a movement mechanism. A working table is arranged above the base, and pressing devices are arranged on both sides of the upper part of the working table. There is a lower shaping knife between the pressing devices on both sides of the workbench, a second threaded rod is arranged in the middle of the upper part of the top plate, and an inverted U-shaped plate is spirally connected to the outside of the second threaded rod. The shaping knife is fixedly connected, and the right side of the workbench is equipped with a movement mechanism. The present invention is equipped with a pressing device to press the decorative plate, and the pressing is reliable. It is provided with a second threaded rod, an inverted U-shaped plate, an upper shaping knife and a lower The shaping knife can adapt to different thicknesses of decorative panels, and can perform double-sided shaping, which improves work efficiency. It is equipped with a movement mechanism to drive the worktable to move left and right, and the upper and lower shaping knives can repeatedly shape the upper and lower surfaces of the decorative panels. , The plastic effect is better, the labor load of the workers is reduced, and the work efficiency is improved.

Owner:吴秀女

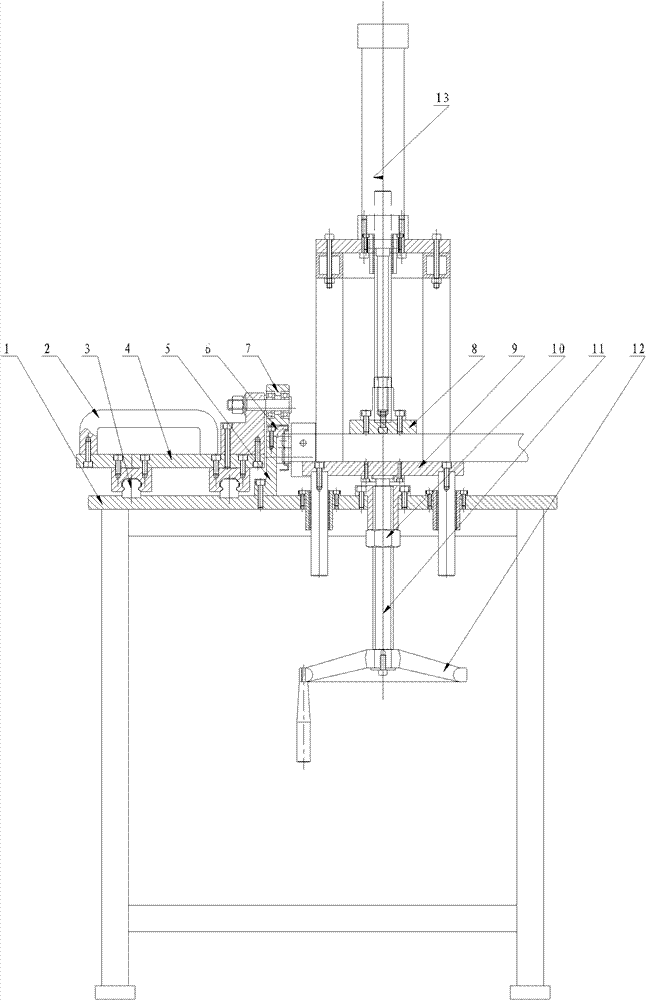

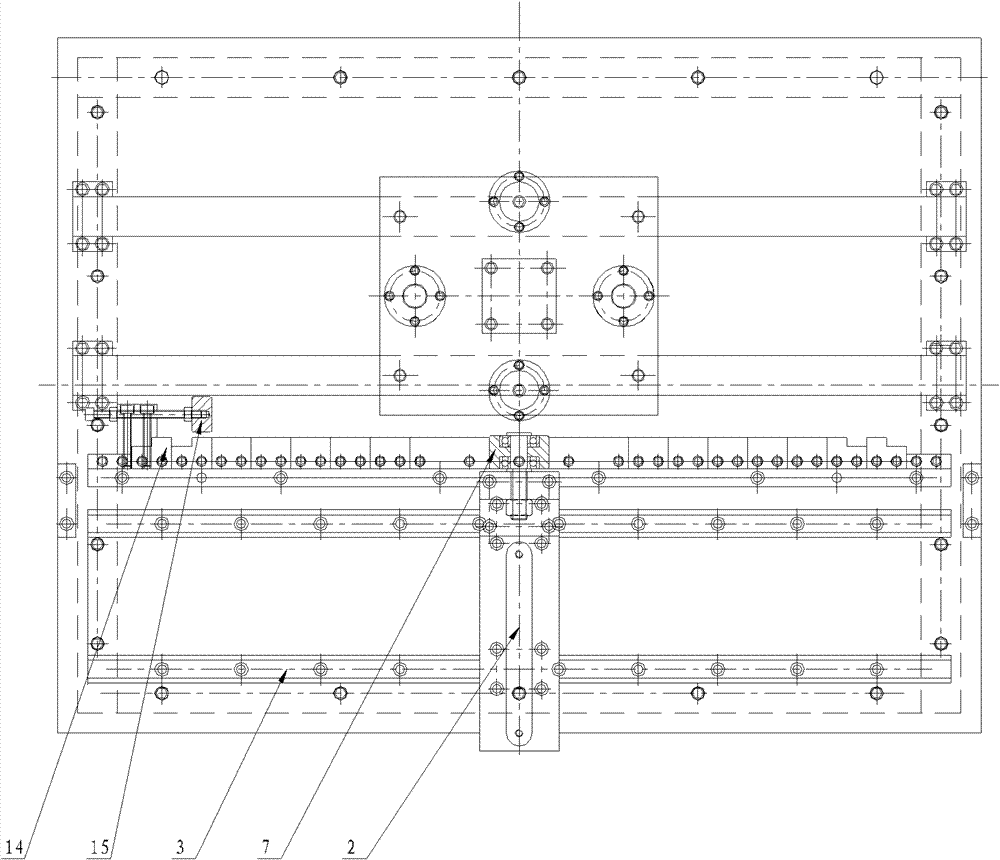

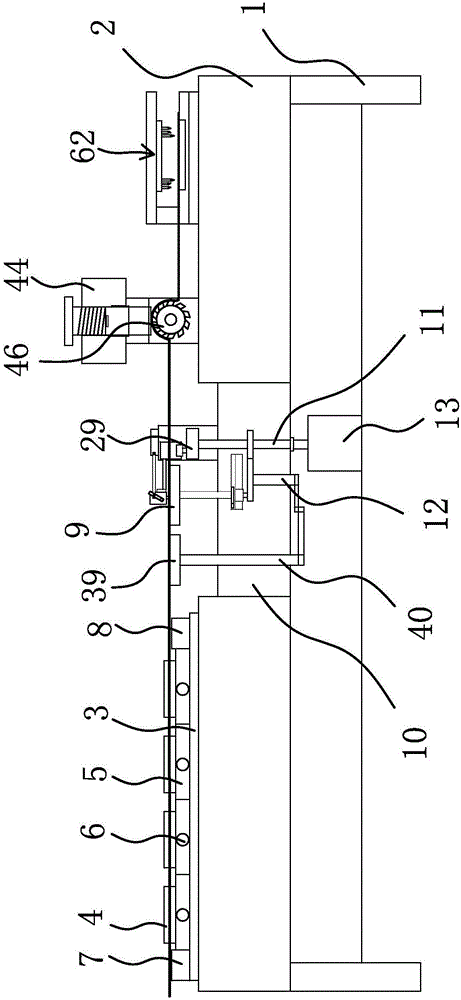

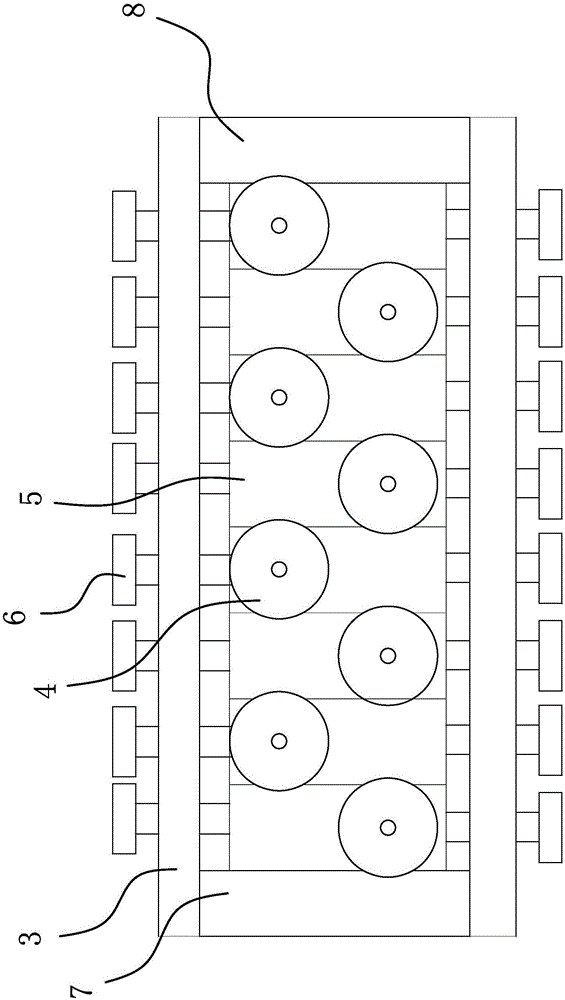

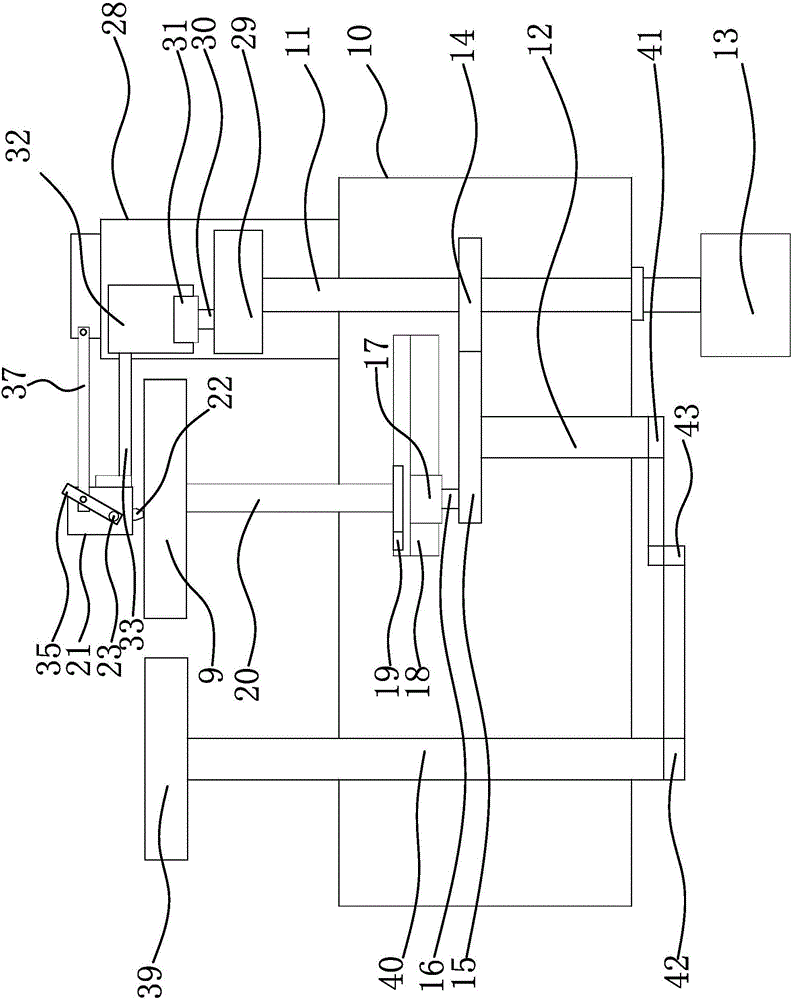

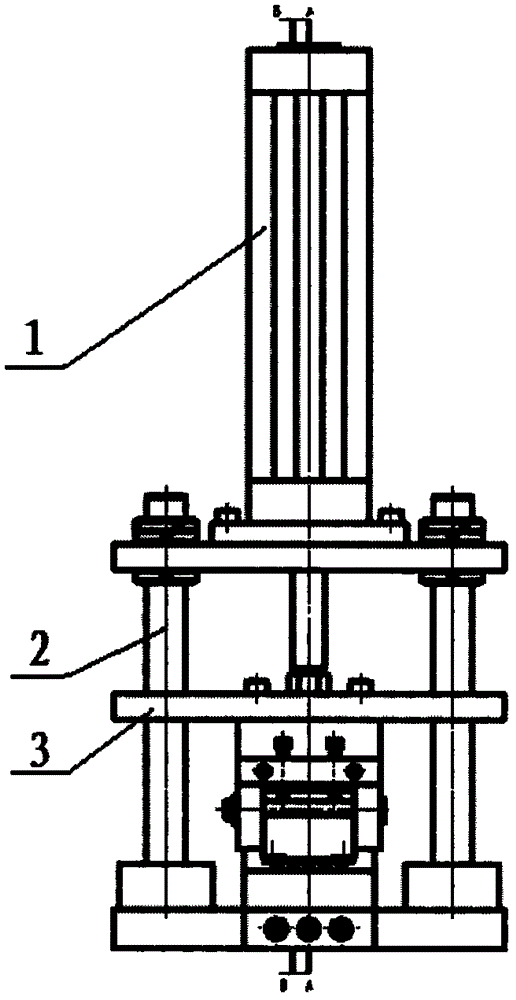

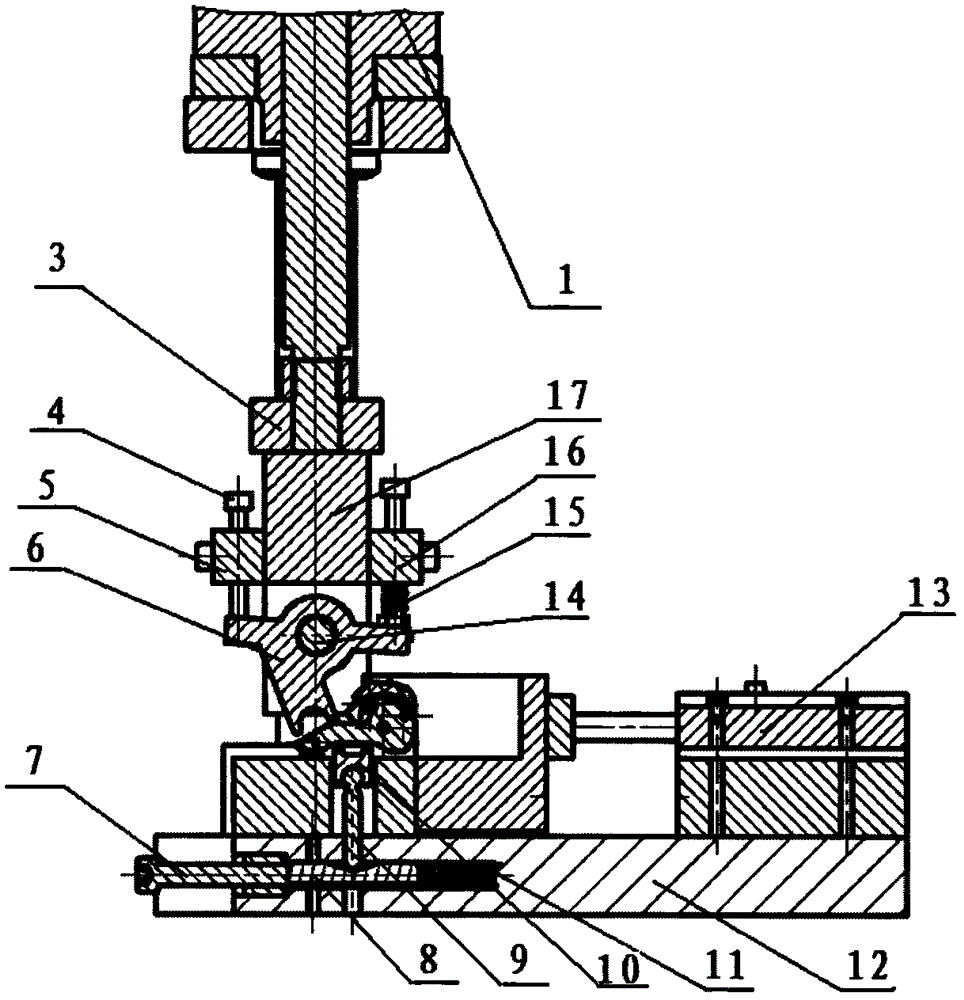

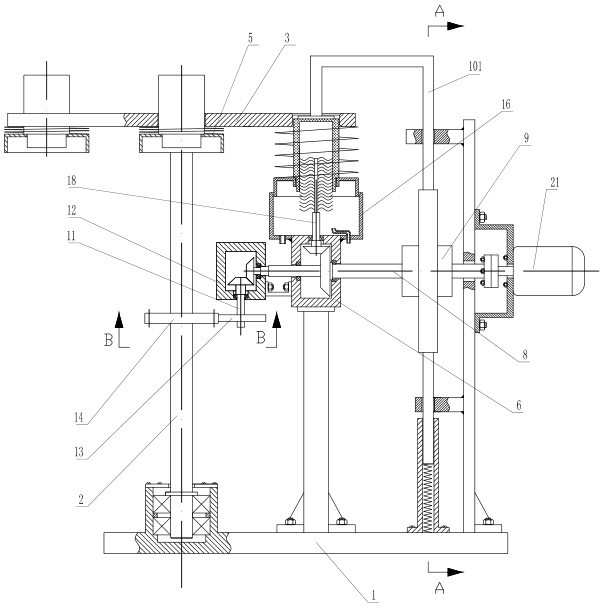

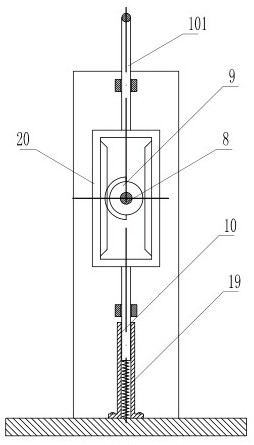

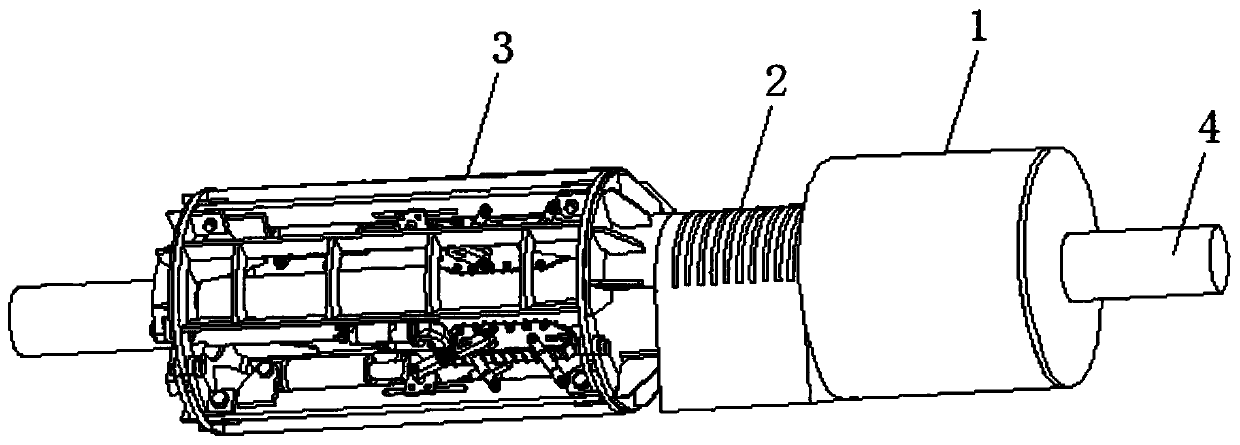

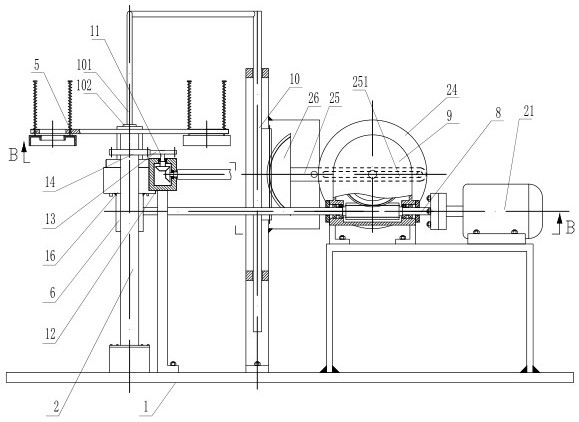

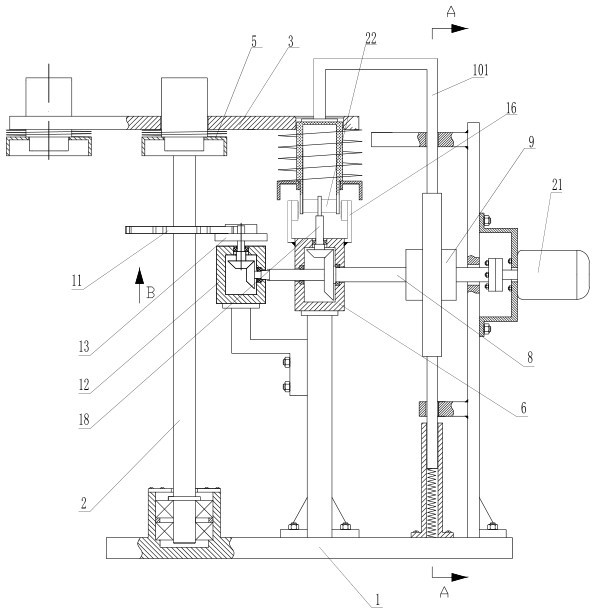

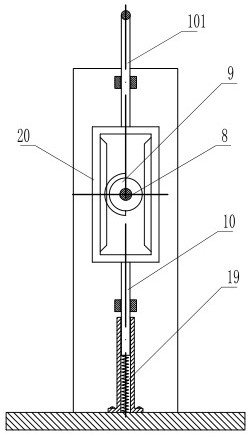

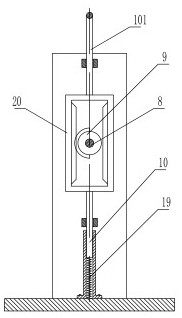

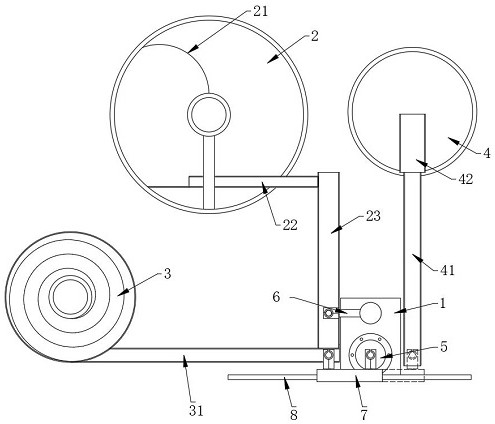

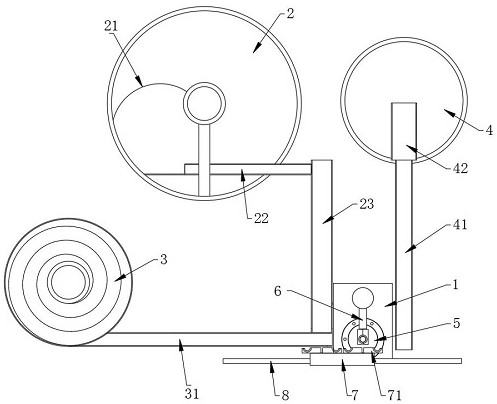

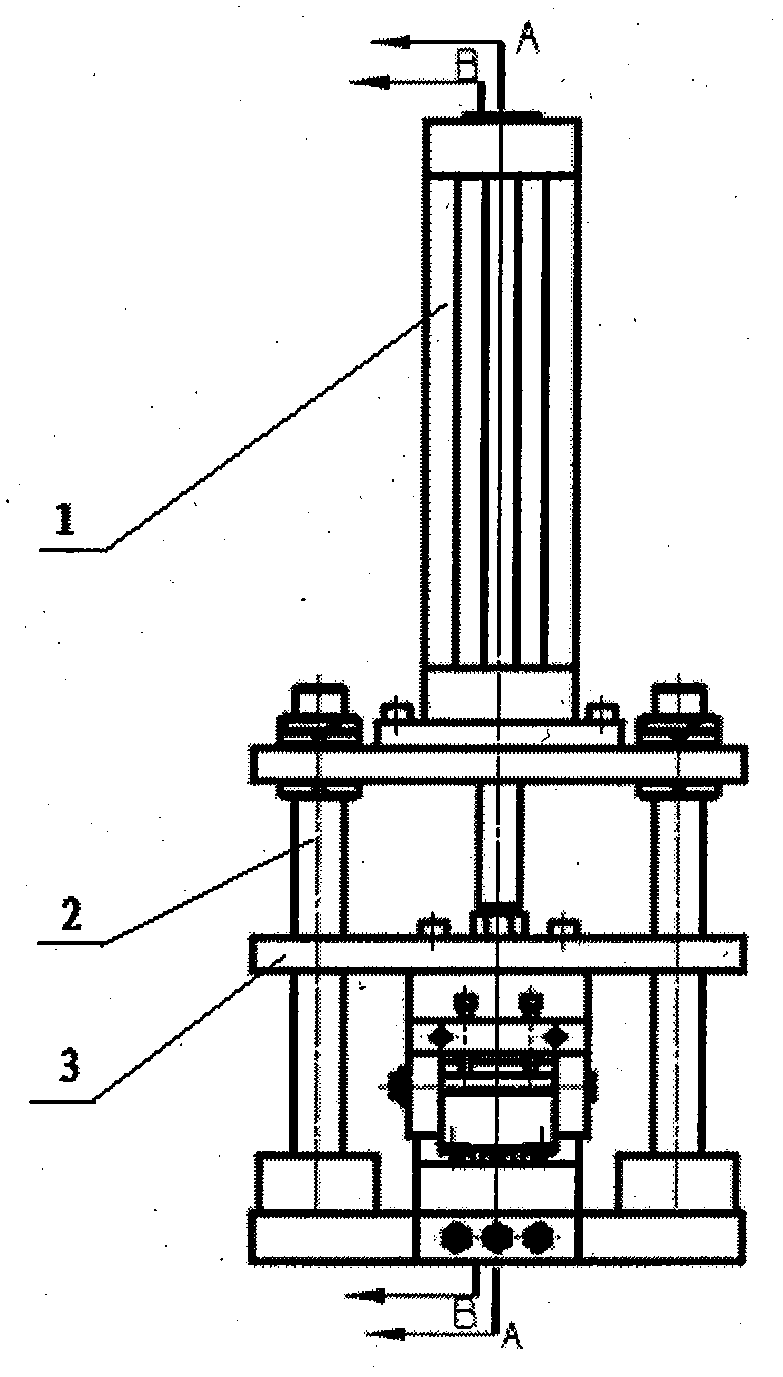

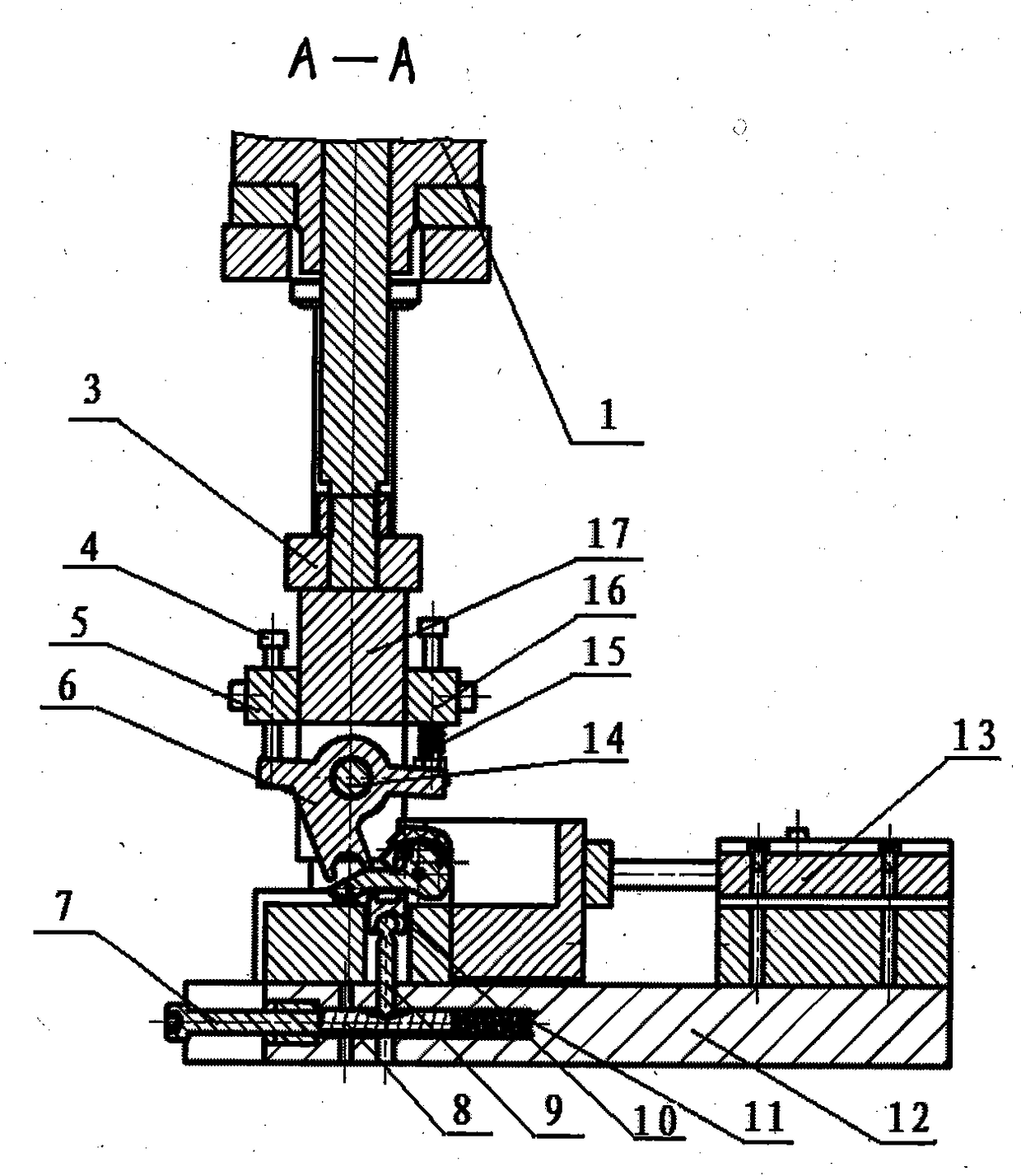

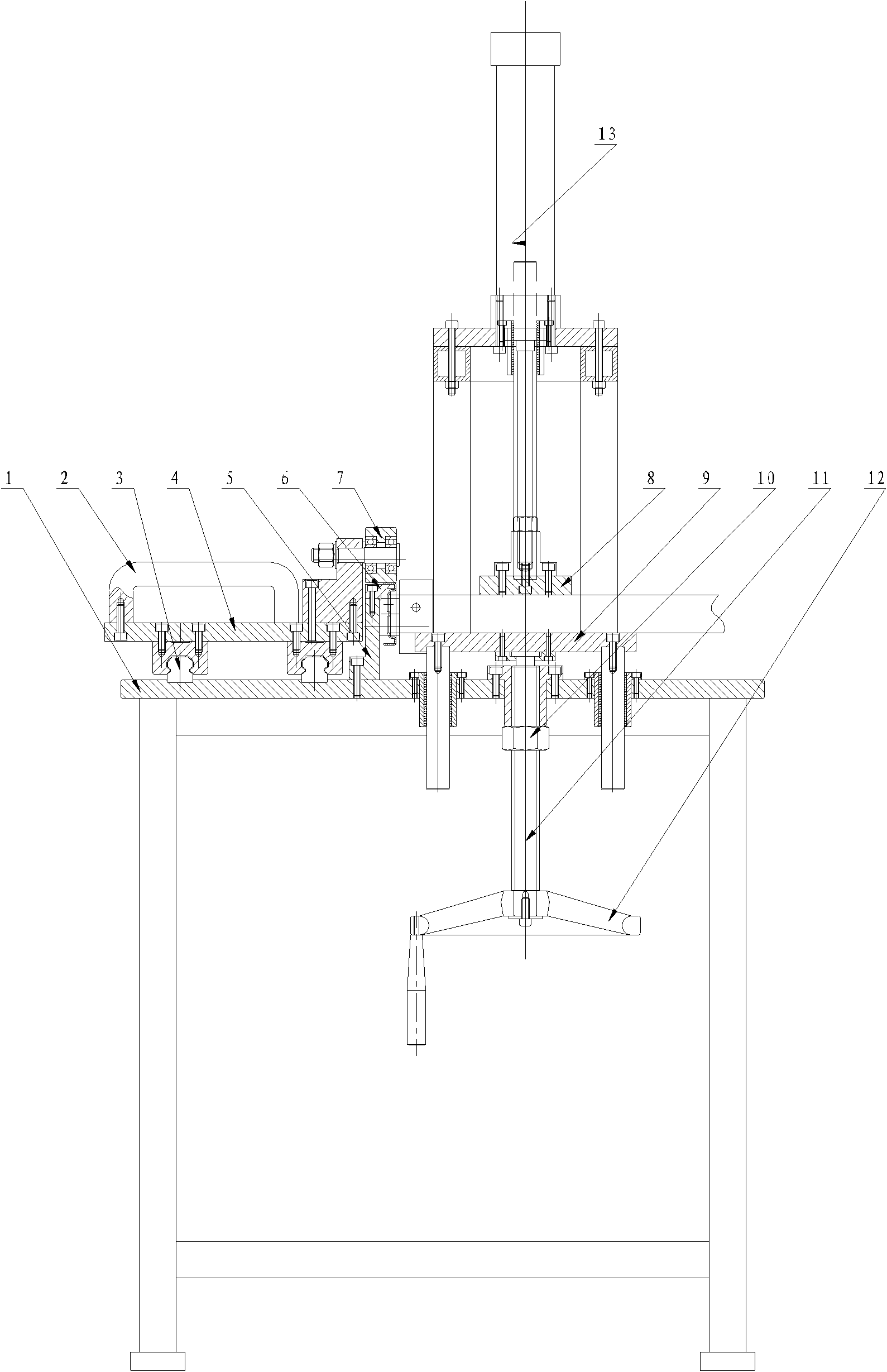

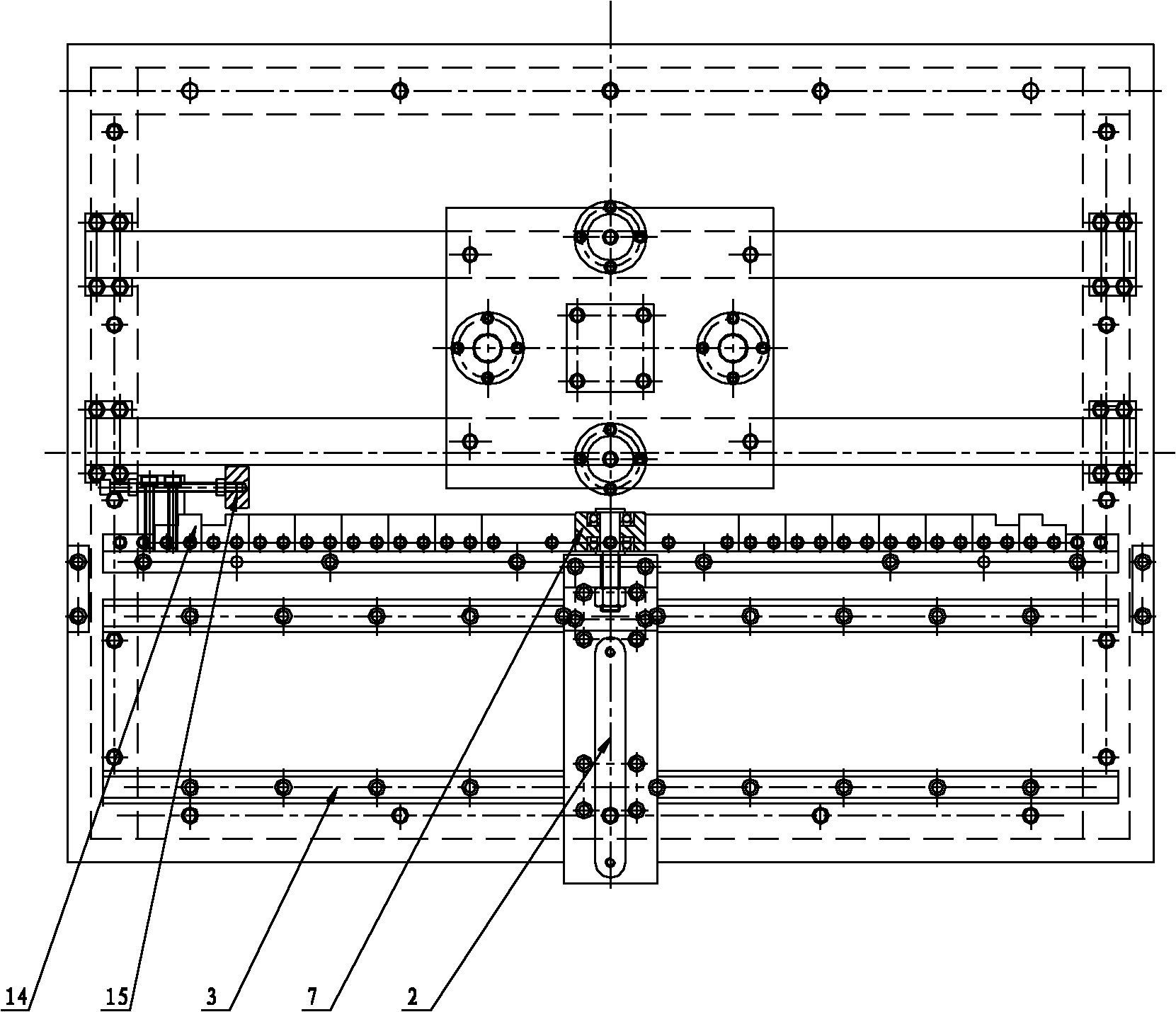

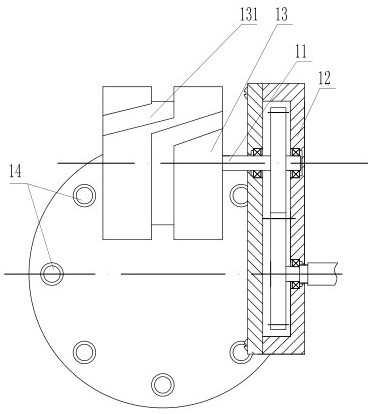

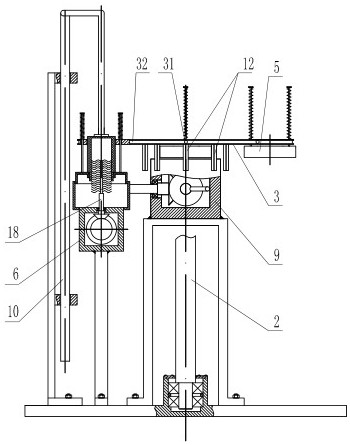

Shaper for main chips of radiator reworking products

The invention relates to a shaper for main chips of radiator reworking products. The shaper comprises a base plate (1), a handle (2), a linear guide (3), a sliding plate (4), a support (5), a reshaping cushion block (6), a rolling head (7), a workpiece press plate (8), a workpiece support plate (9), a lock nut (10), a height adjustment screw (11), a hand rocking wheel (11), a press air cylinder (13), an abdication block (14) and a protruding head (15). Compared with the prior art, the shaper can reshape core main chips of any length and width, cores of any thickness can be mounted and positioned, and the shaper has the advantages of being high in reshaping efficiency, capable of fully guaranteeing the product quality, convenient to operate, and high in generality.

Owner:SHANGHAI DELANG AUTO PARTS MFG

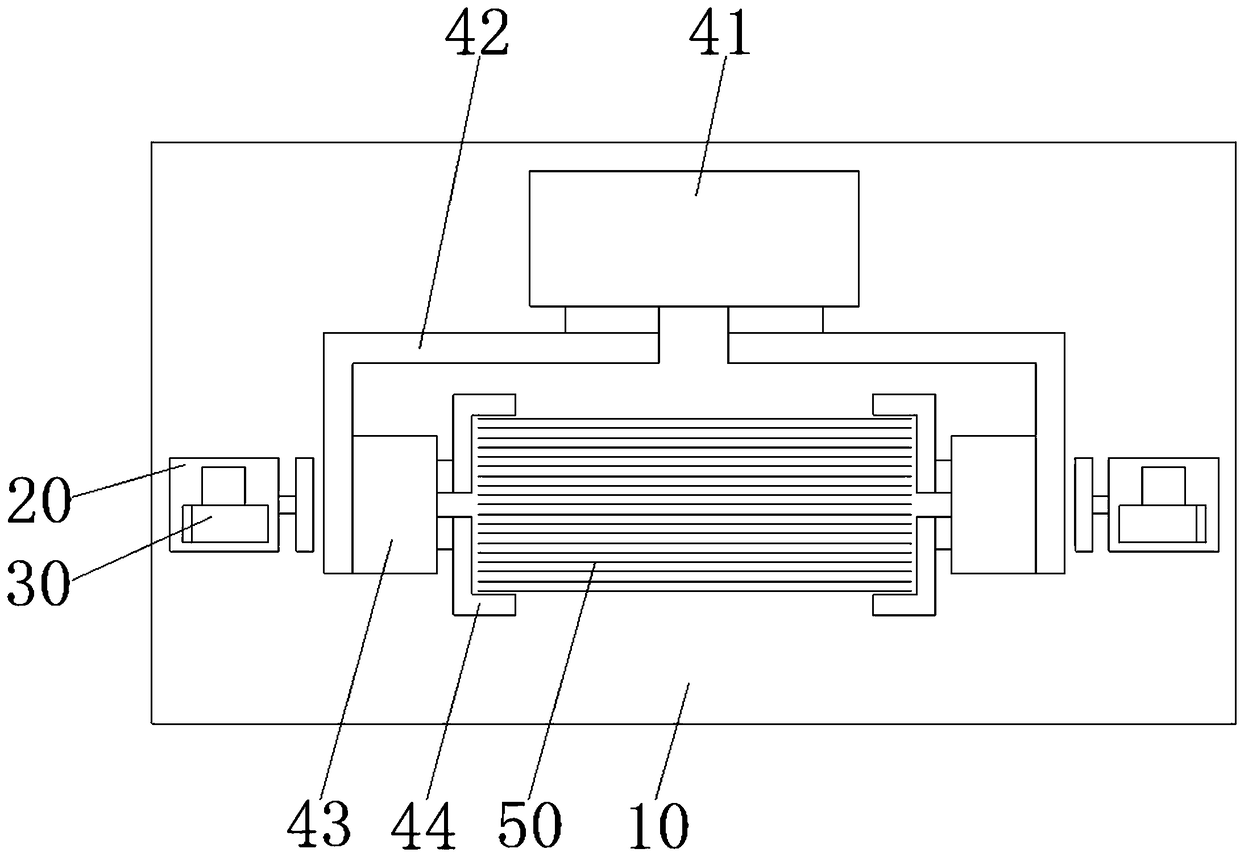

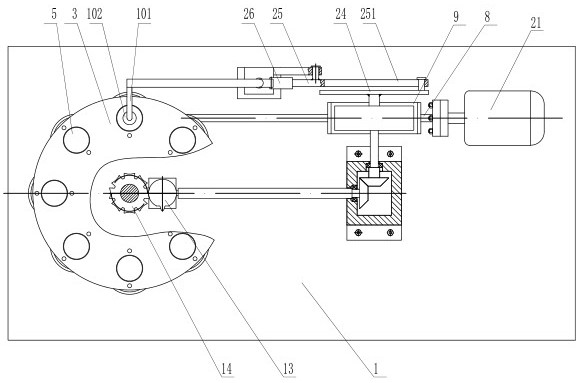

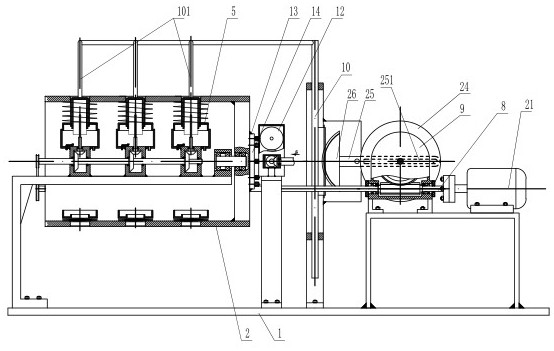

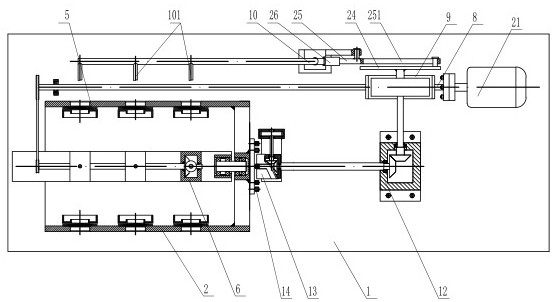

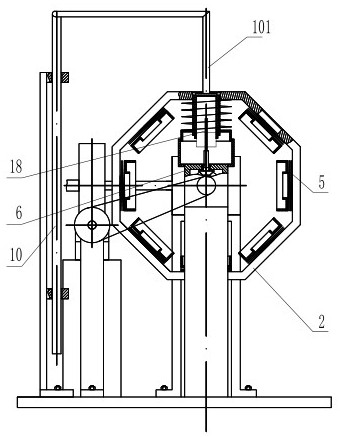

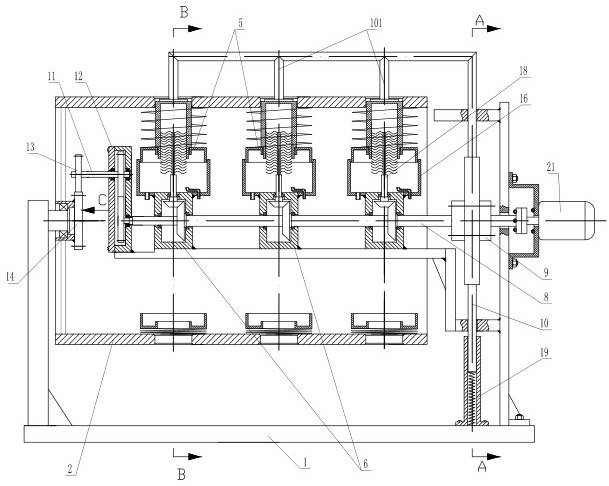

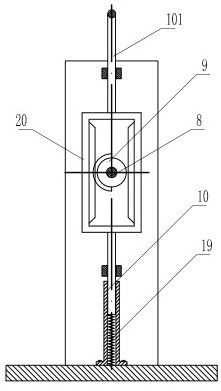

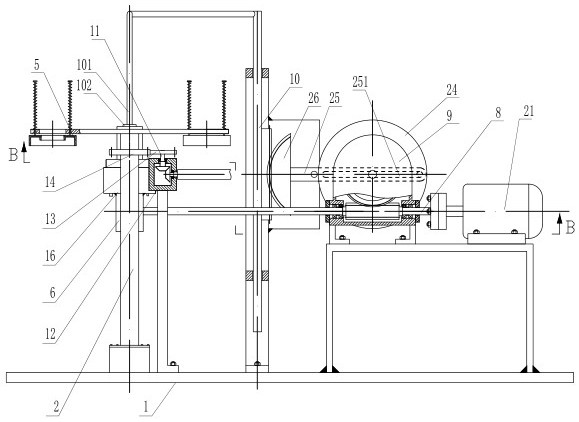

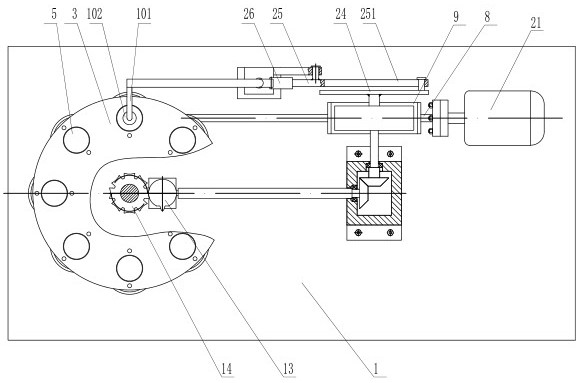

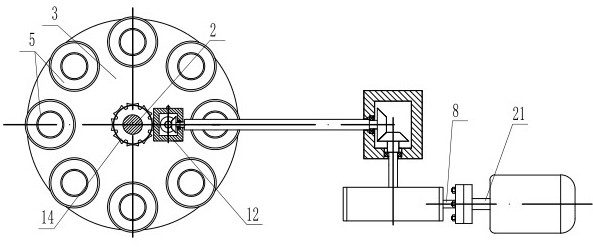

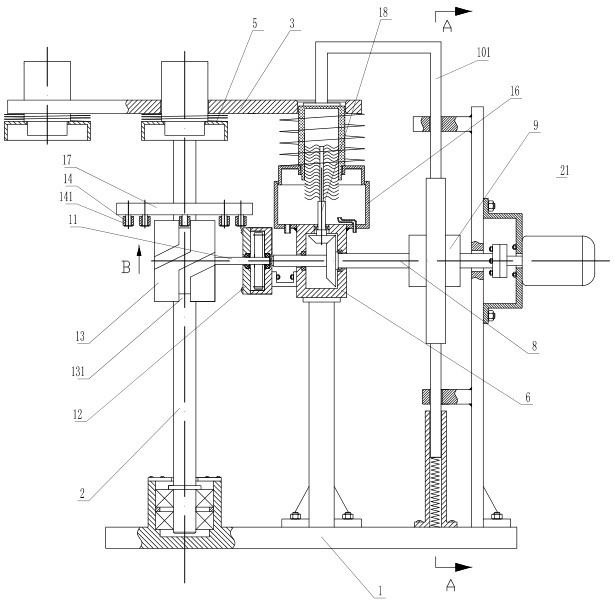

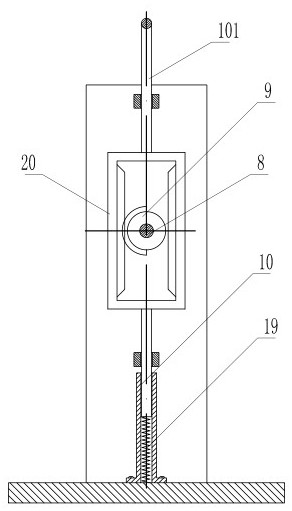

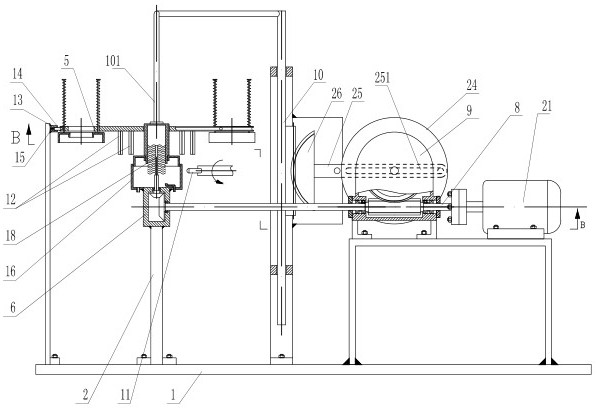

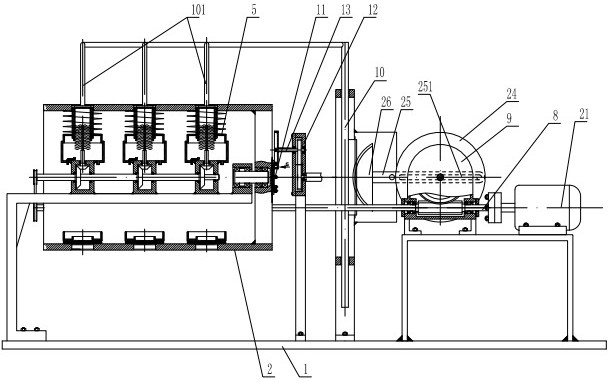

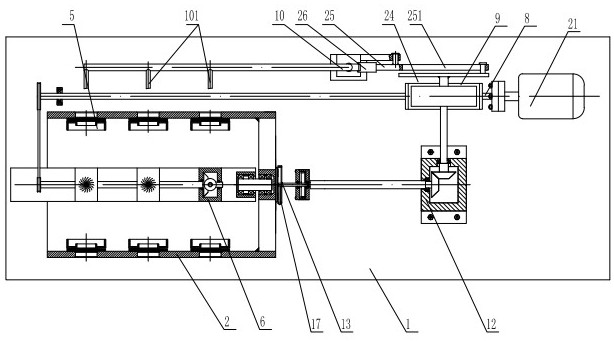

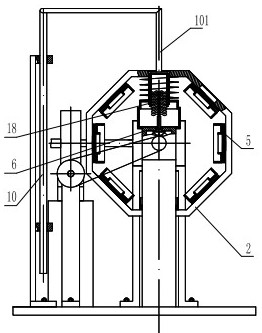

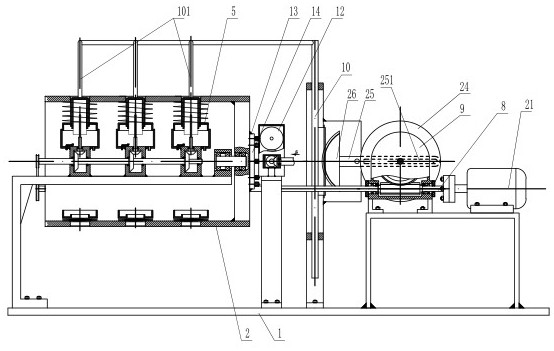

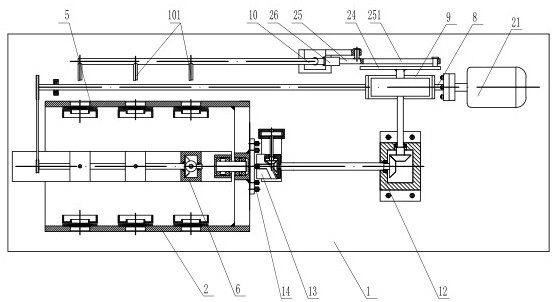

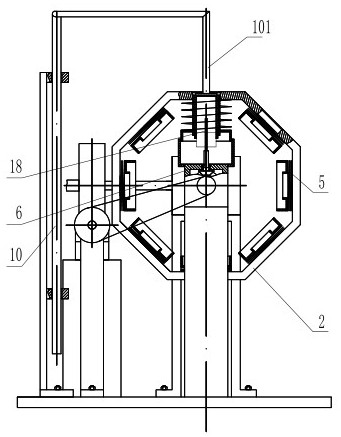

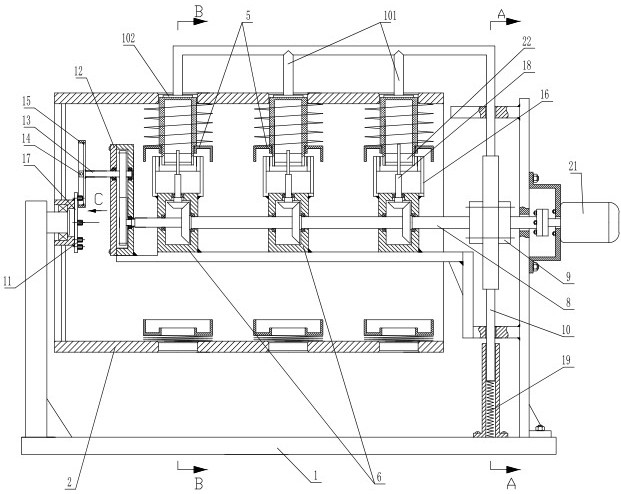

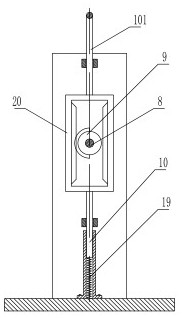

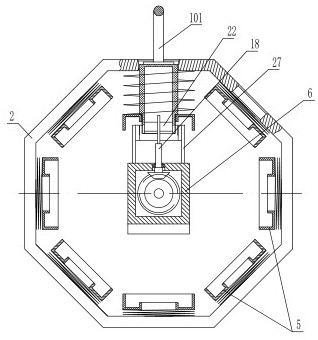

S-spring shaping device

ActiveCN106583605AIncrease productivityShaping speed is fastWire springsEngineeringMechanical engineering

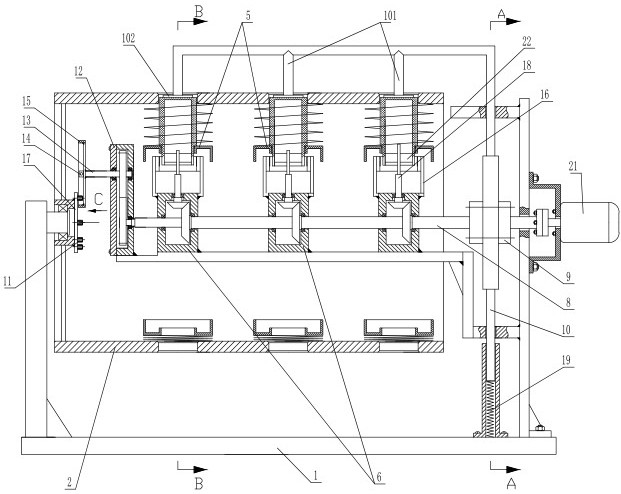

The invention provides an S-spring shaping device, belongs to the technical field of machinery and solves the problem of poor shaping effect in the prior art. The S-spring shaping device comprises a rack and a worktable arranged in the rack, wherein a base with a conveying channel is fixed on the worktable; a rotating shaft is arranged in the conveying channel in a circumferential rotating and axial fixing manner; a mounting pillar is fixed on the rotating shaft; a plurality of driving teeth capable of adjusting the pitch of an S-spring are uniformly fixed on the mounting pillar in the circumferential direction; a limit disc I and a limit disc II which can limit the width of the S-spring are arranged at the two ends of the mounting pillar; a hold-down mechanism which can always press the S-spring on the rotating shaft is arranged on the base; and a driving structure which can drive the rotating shaft to rotate is arranged at one end of the rotating shaft. The S-spring shaping device has the advantage of excellent shaping effect.

Owner:浙江心梦享家居有限公司

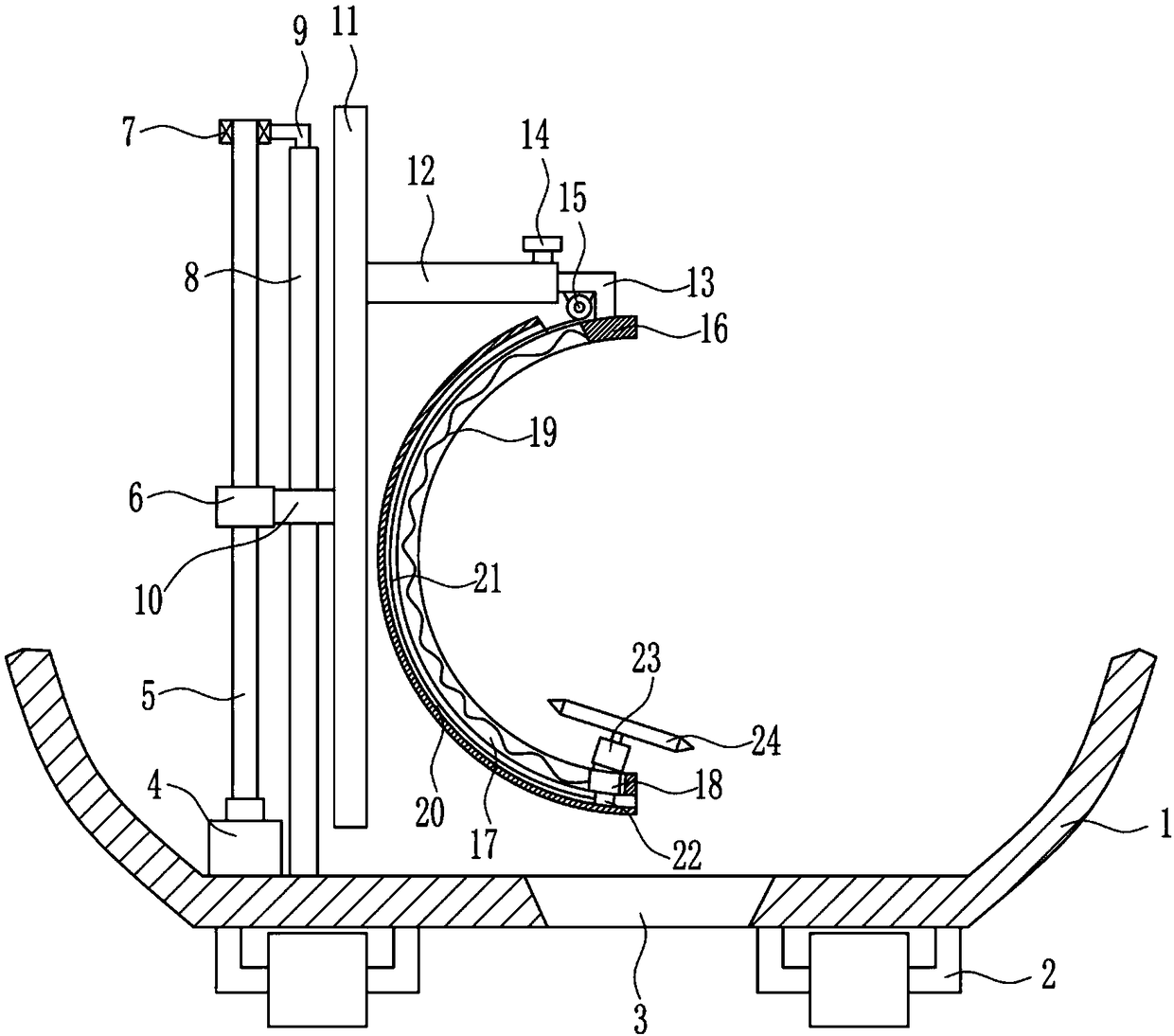

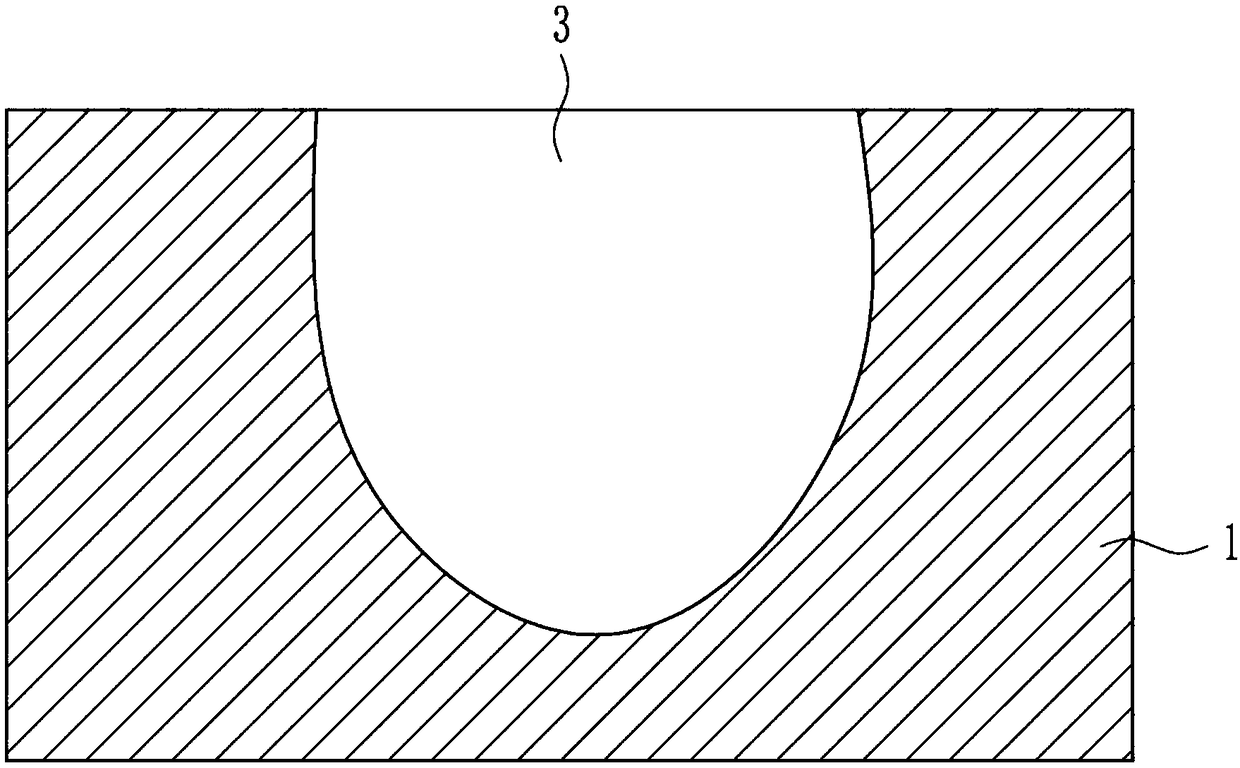

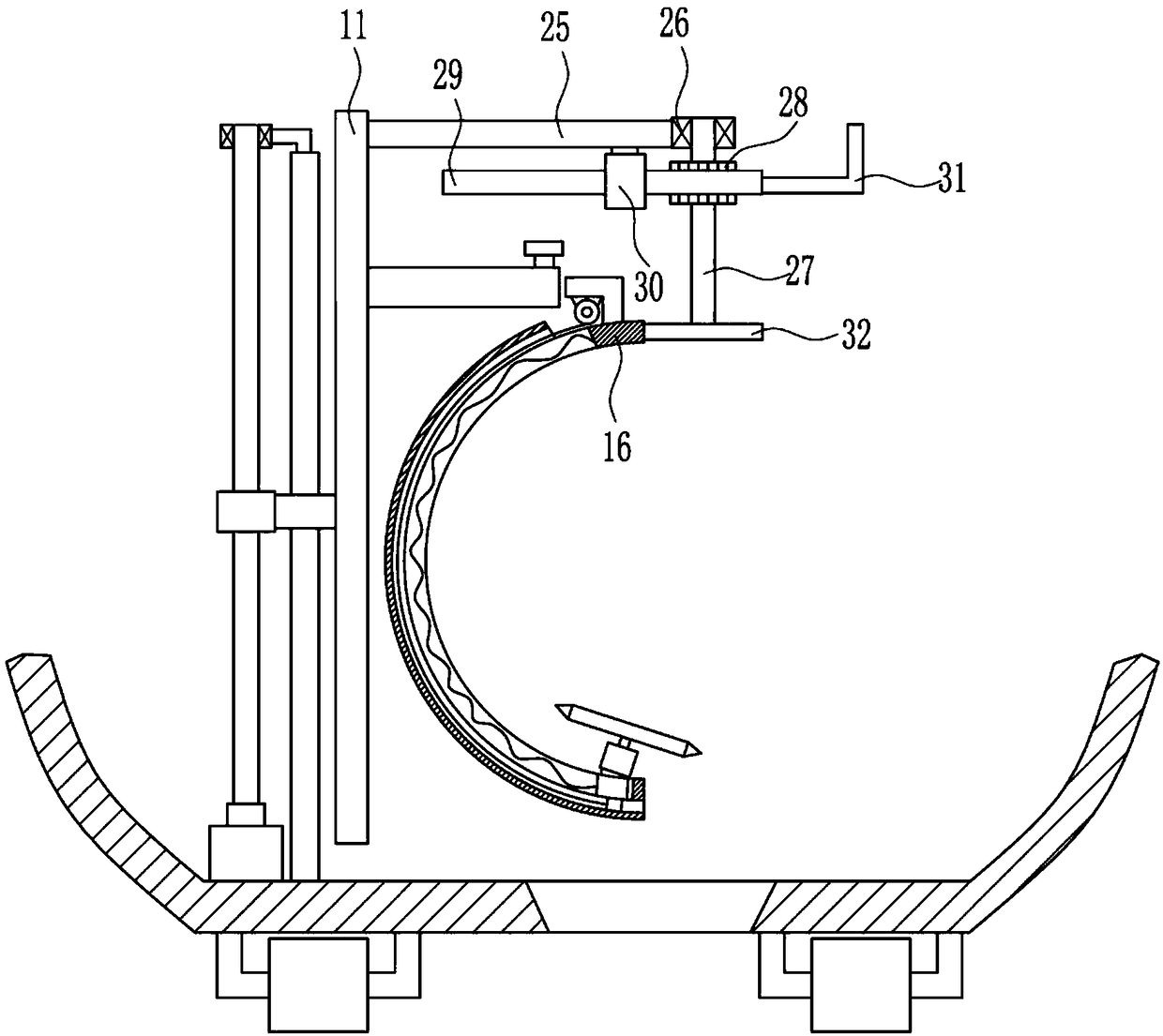

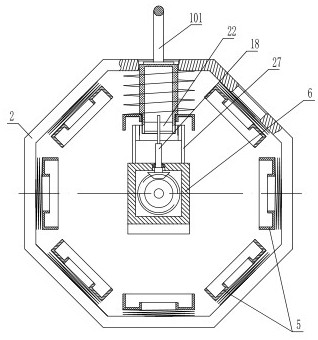

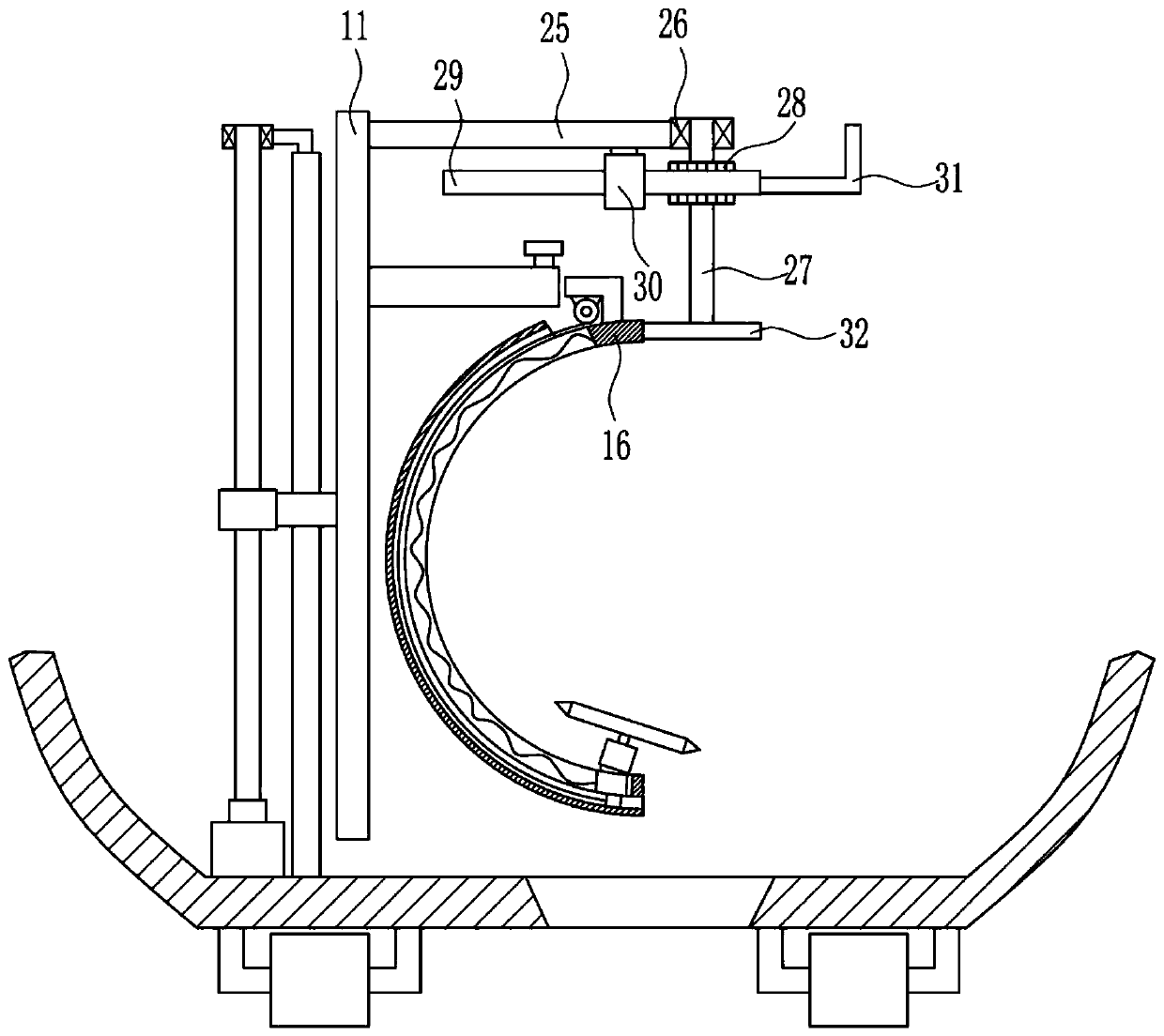

Round seedling shaping equipment

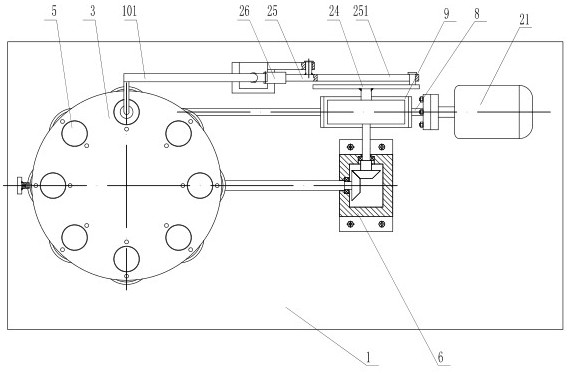

ActiveCN108811860AShaping speed is fastPrevents affecting pruning efficiencyCuttersCutting implementsEngineeringConductor Coil

The invention relates to seedling shaping equipment, in particular to round seedling shaping equipment. The technical purpose of the invention is to provide the round seedling shaping equipment capable of improving the shaping speed and saving time and labor. According to the technical scheme, the round seedling shaping equipment comprises a base, universal wheels, a first motor, a lead screw, a first nut, a first bearing seat, a sliding rod, a 7-shaped rod, a sliding sleeve, a connecting rod, a sleeve tube, a L-shaped plate and the like; a U-shaped opening is formed in the rear side surface of the base, the bottom of the base is symmetrically provided with the universal wheels, the top left side of the base is connected with the sliding rod, the sliding rod is connected with the sliding sleeve, the upper end of the sliding rod is connected with the 7-shaped rod, and the left side surface of the 7-shaped rod is connected with the first bearing seat. The equipment cooperates the lead screw with the first nut through the first motor to adjust the height of a curved shell so that high or short circular seedlings can be trimmed, and an electric winding wheel tightens or releases a pulling wire so that a cutter can move up and down to trim the circular seedlings while rotating.

Owner:叶小梅

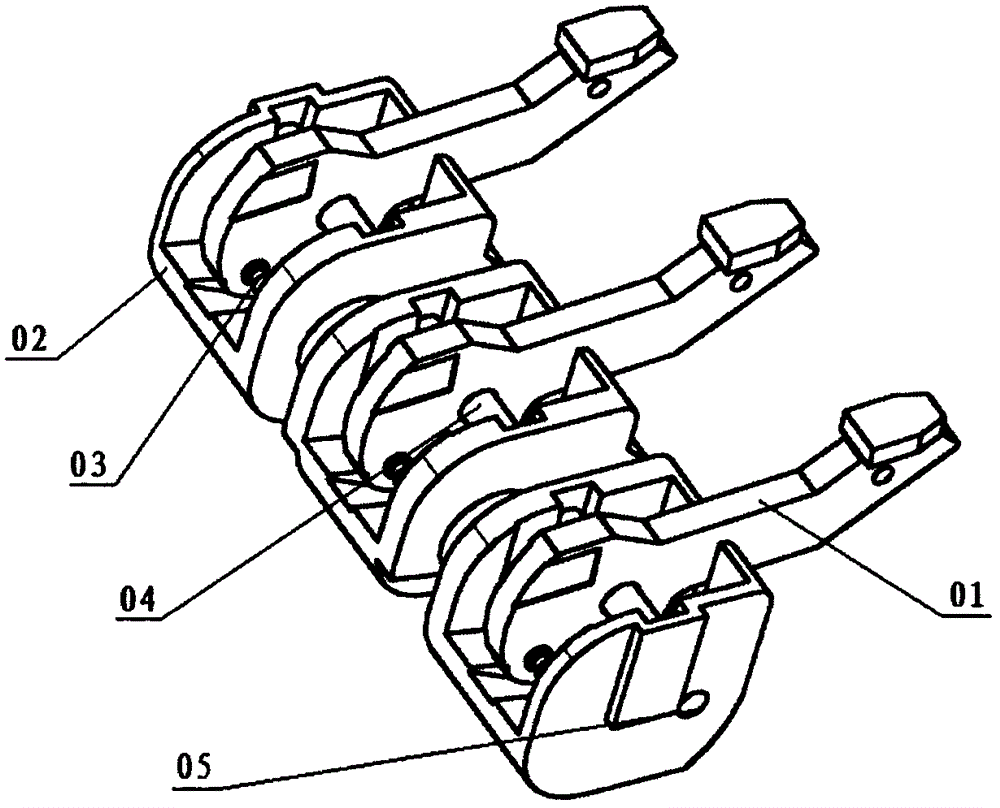

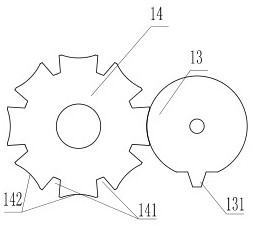

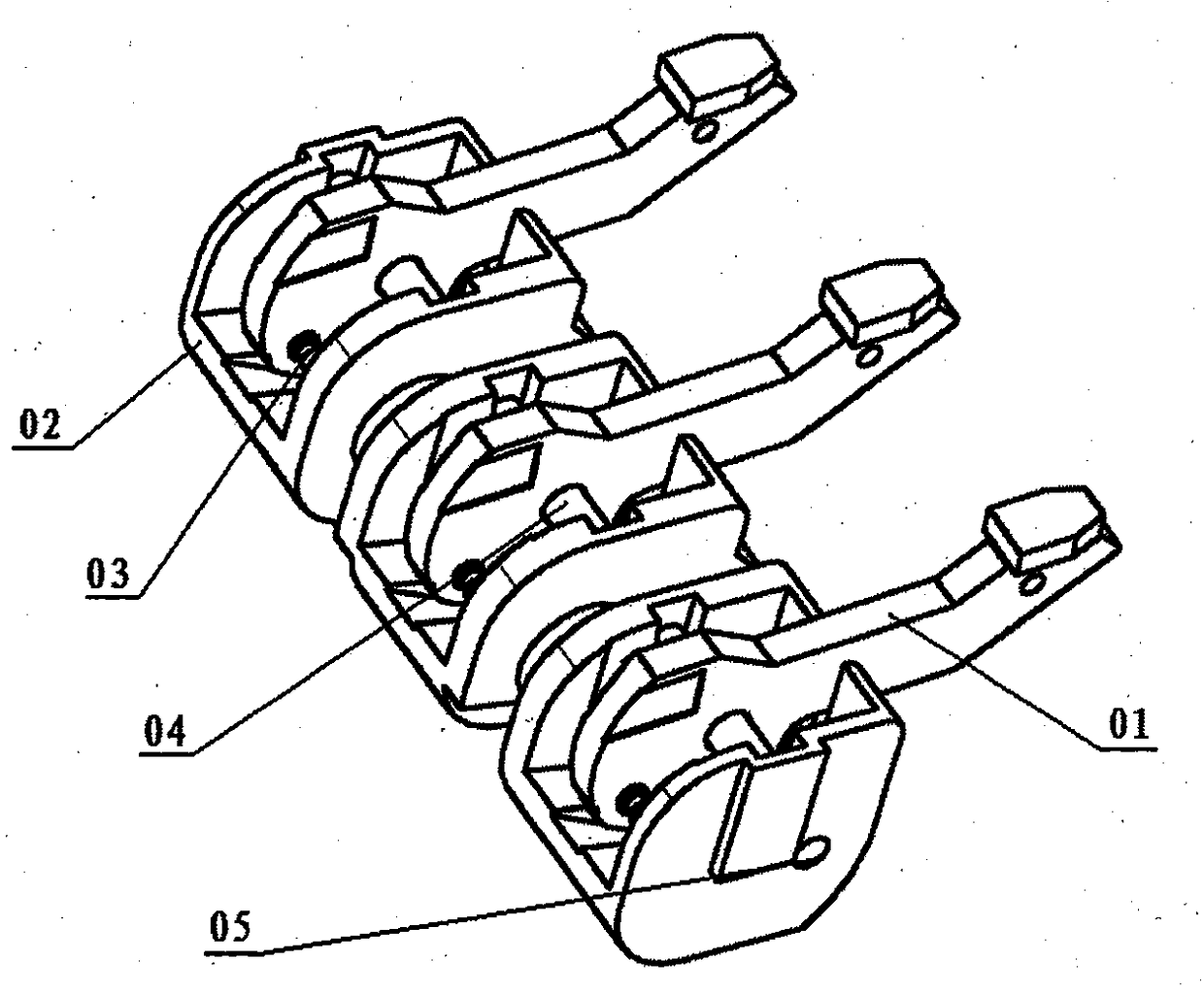

Molded case circuit breaker moving contact synchronization shaping fixture

ActiveCN105788972AGood synchronizationImprove workabilityEmergency protective device manufactureCircuit-breaking switch contactsWork performanceSlide plate

The invention discloses a molded case circuit breaker moving contact synchronization shaping fixture. The molded case circuit breaker moving contact synchronization shaping fixture comprises supporting columns, a sliding plate, adjusting bearings, bearing blocks, a rotary pressing block, a rotary bearing, pushing rods, a base, a sliding block and so on. The molded case circuit breaker moving contact synchronization shaping fixture is characterized in that the shaping fixture is of a double-column sliding plate structure. A vertical air cylinder and a horizontal air cylinder are adopted as driving power. The molded case circuit breaker moving contact synchronization shaping fixture has the advantages of reasonable structure, operation convenient and high shaping speed. With the molded case circuit breaker moving contact synchronization shaping fixture adopted, a shaped moving contact has excellent synchronization performance, and excellent working performance of a molded case circuit breaker can be ensured.

Owner:HANGZHOU ZHIJIANG SWITCHGERA

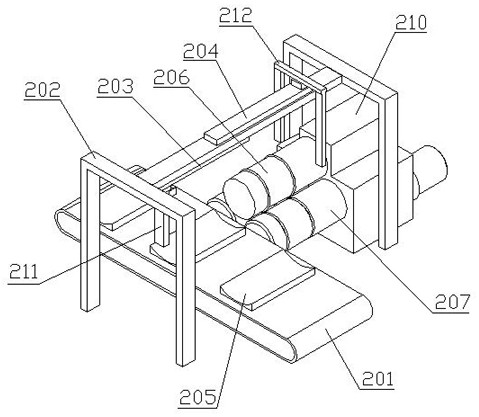

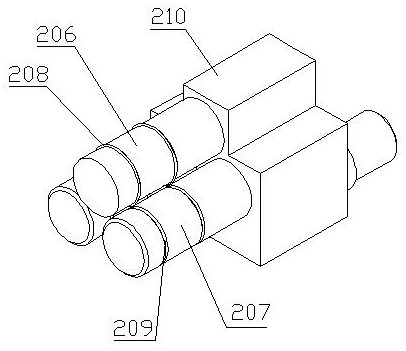

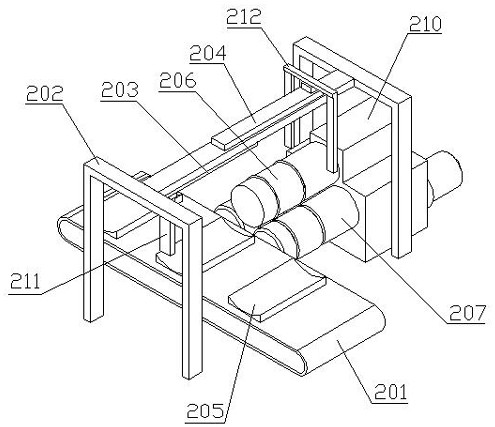

Packaging barrel shaping device

PendingCN112093457AReduce labor intensityShaping speed is fastConveyorsSolid waste disposalBarrel ShapedEngineering

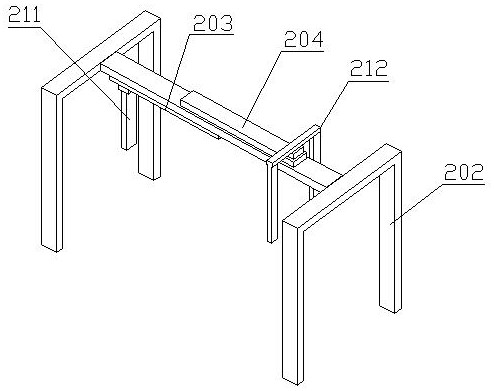

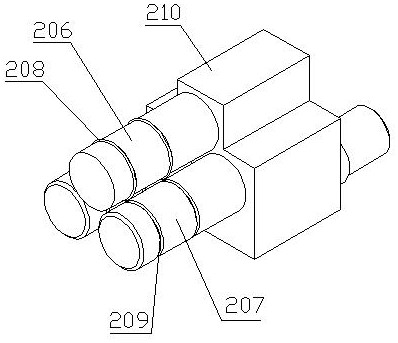

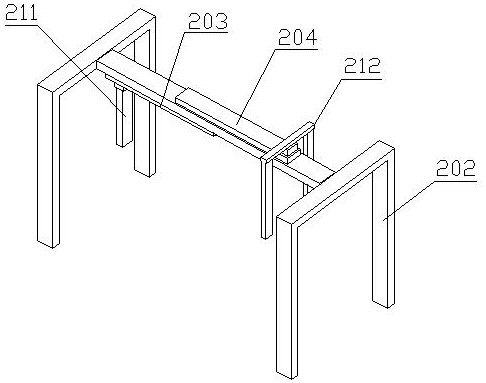

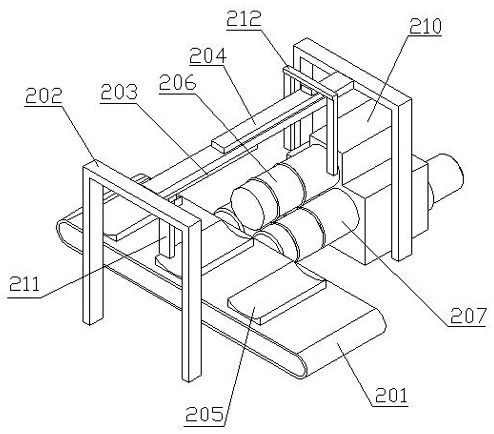

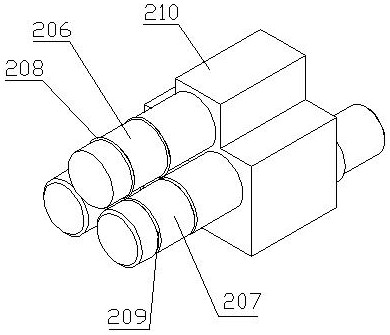

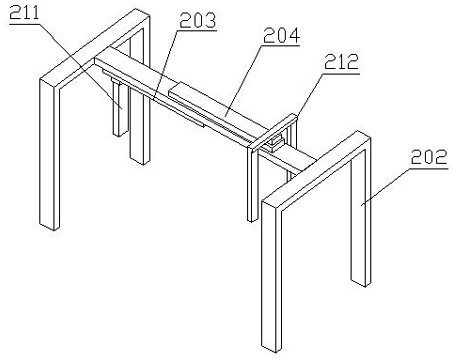

The invention discloses a packing barrel shaping device. The packing barrel shaping device comprises a conveyor (201), a three-axis rounding machine, a sliding table support (202), a feeding sliding table (203) and a discharging sliding table (204), wherein a set of packing barrel supporting plates (205) are sequentially arranged on a conveying belt of the conveyor (201) at equal intervals, and arc-shaped limiting grooves are formed in the tops of the packing barrel supporting plates (205); and the three-axis rounding machine comprises an upper roller (206), a pair of lower rollers (207) and arounding machine body (210), a pair of reinforcing rib shaping protrusions (208) is arranged on the outer wall of the upper roller (206), and a pair of reinforcing rib shaping grooves (209) used in cooperation with the reinforcing rib shaping protrusions (208) is formed in each lower roller (207). The packing barrel shaping device has the advantages that a packaging barrel is automatically shifted to the rounding machine to be shaped, the shaping speed is high, and the labor intensity of workers is relieved.

Owner:湖北爱国环保技术开发有限公司

Cup body inner wall cleaning machine

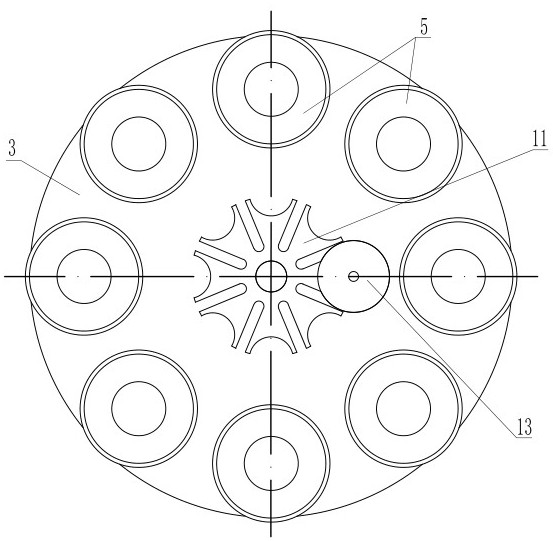

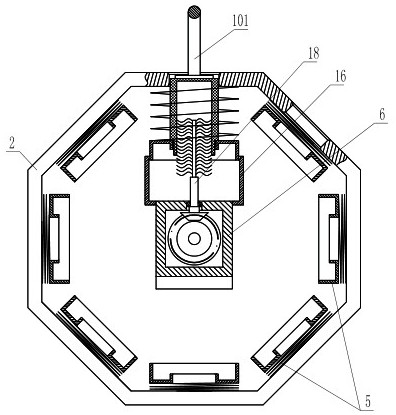

InactiveCN112661396AFast cleaning and shapingQuality improvementHollow article cleaningGlass reforming apparatusEngineeringDrive wheel

The invention discloses a cup body inner wall cleaning machine which comprises a machine frame, a main power shaft is rotatably connected to the machine frame, a rotary bearing disc is installed at the top of the main power shaft, clamping cylinders are annularly distributed on the bearing disc, a cleaning and shaping gearbox is installed on the machine frame, and a cleaning and shaping device is installed on the cleaning and shaping gearbox. A driving shaft in power connection with a power machine is installed on the machine frame, a driving half gear is connected to the driving shaft, a driving column is installed on the machine frame, a rack is connected to the driving column, a driving arm is installed on the driving column, a driving head is installed on the driving arm, a stirring driving shaft is in power connection with the rotating driving box, and a power wheel disc is connected to the stirring driving shaft. A driving wheel disc is installed on the main power shaft, a plurality of driving sliding grooves are annularly distributed in the driving wheel disc, the outer circumferential face, between every two adjacent driving sliding grooves, of the driving wheel disc is a wheel disc retaining face, and driving protruding teeth for driving the rotary bearing disc to rotate are installed on the power wheel disc. The cleaning machine has the advantages of being high in cleaning and shaping speed, high in quality and high in labor efficiency.

Owner:马行坤

Cup rim cleaning and shaping machine

PendingCN112499947AFast cleaning and shapingQuality improvementGlass reforming apparatusCrankComputer hardware

The invention discloses a cup rim cleaning and shaping machine. The machine comprises a machine frame, a main power shaft is rotatably connected to the machine frame, a rotary bearing disc is installed at the top of the main power shaft, clamping cylinders are annularly distributed on the rotary bearing disc, a cleaning and shaping gearbox is installed on the machine frame, a cleaning and shapingdevice is installed on the cleaning and shaping gearbox, and a driving shaft is installed on the machine frame; a first crank is in power connection with the driving shaft, a driving swing rod is hinged to the rack, an arc-shaped gear is fixedly connected to one end of the driving swing rod, a long sliding groove is formed in the other end of the driving swing rod, a driving column is installed onthe rack, a rack is connected to the driving column, a driving arm is installed on the driving column, a driving head is installed on the driving arm, and a rotating driving box is installed on the rack; a driving disc is further installed on the rotary bearing disc, driving sliding grooves are annularly distributed in the driving disc, a power disc is installed on the rotary driving box, a driving column is installed on the power disc, and the driving column can extend into the driving sliding grooves so as to drive the rotary bearing disc to rotate. The device has the advantages of being high in cleaning and shaping speed, high in quality and high in labor efficiency.

Owner:马海洋

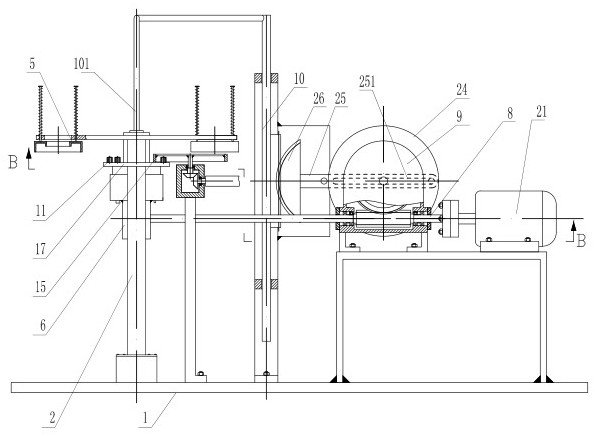

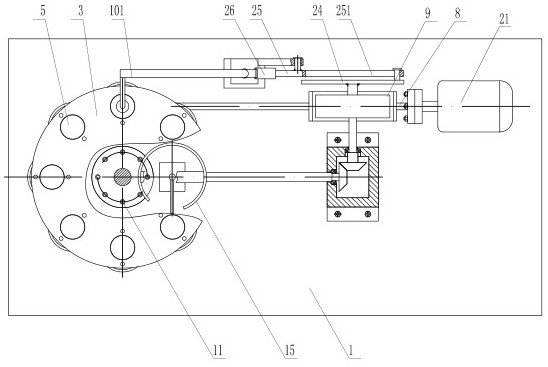

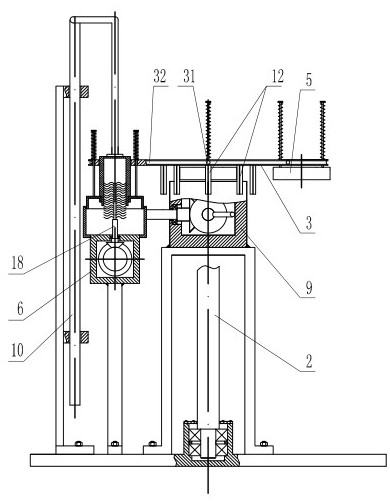

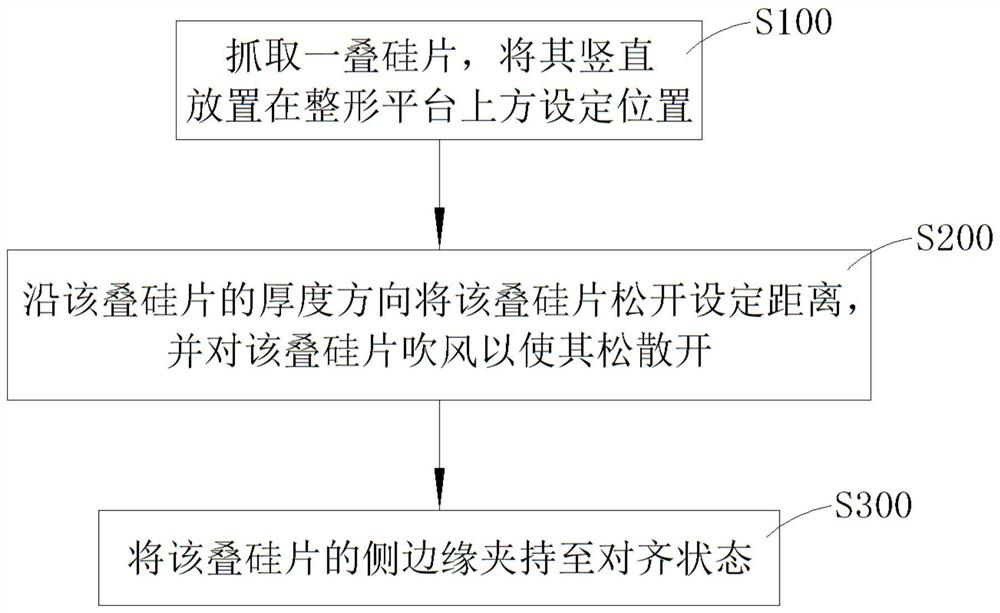

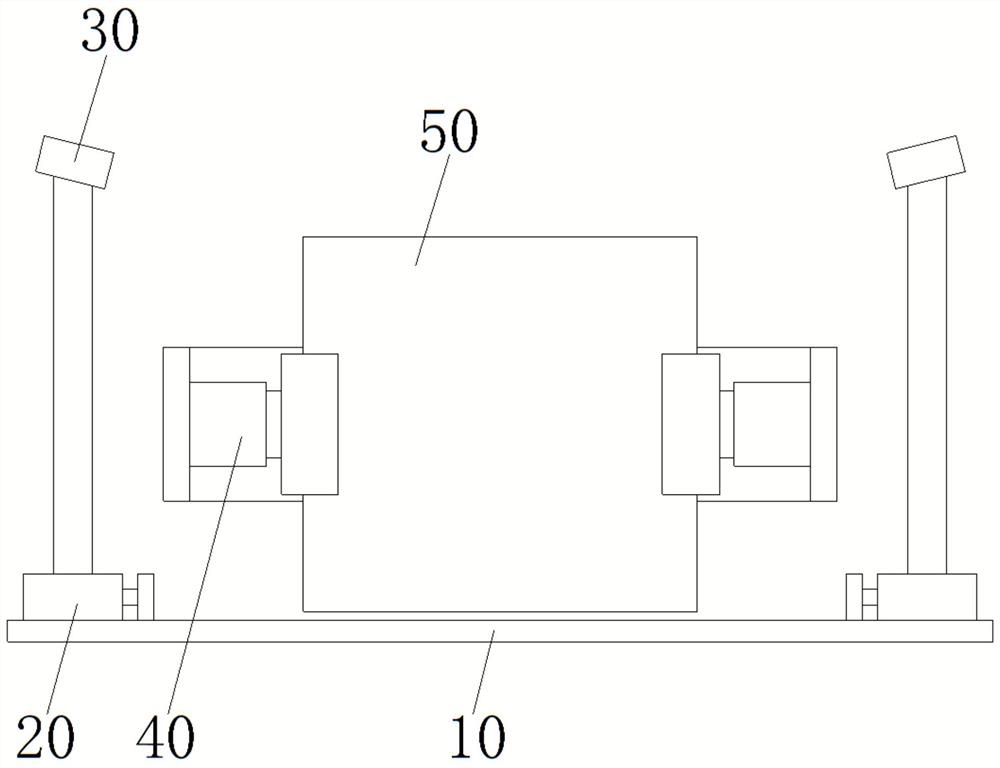

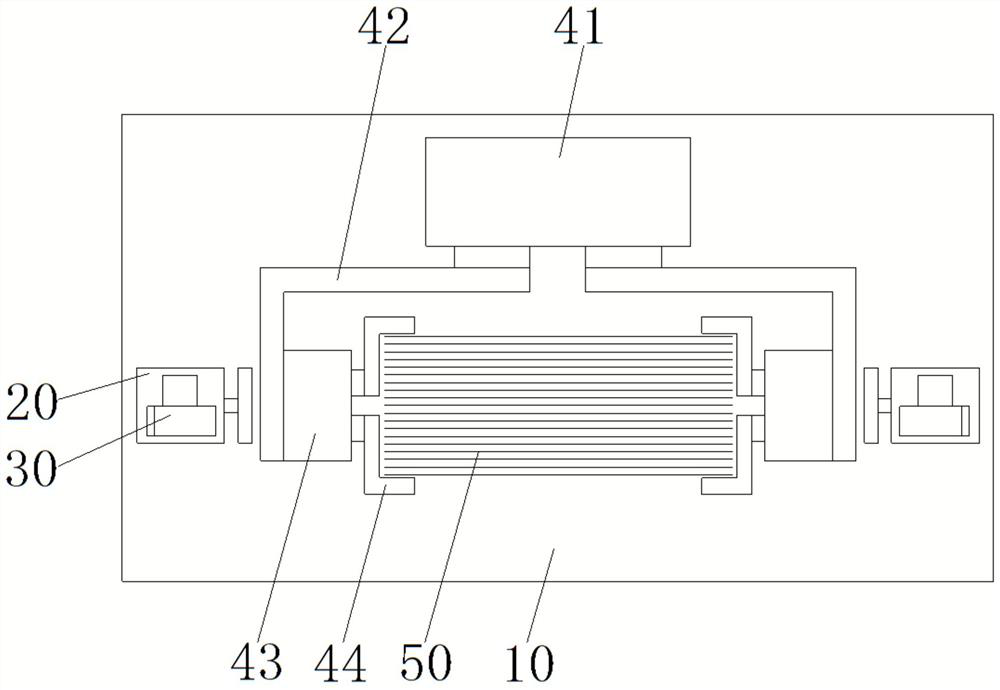

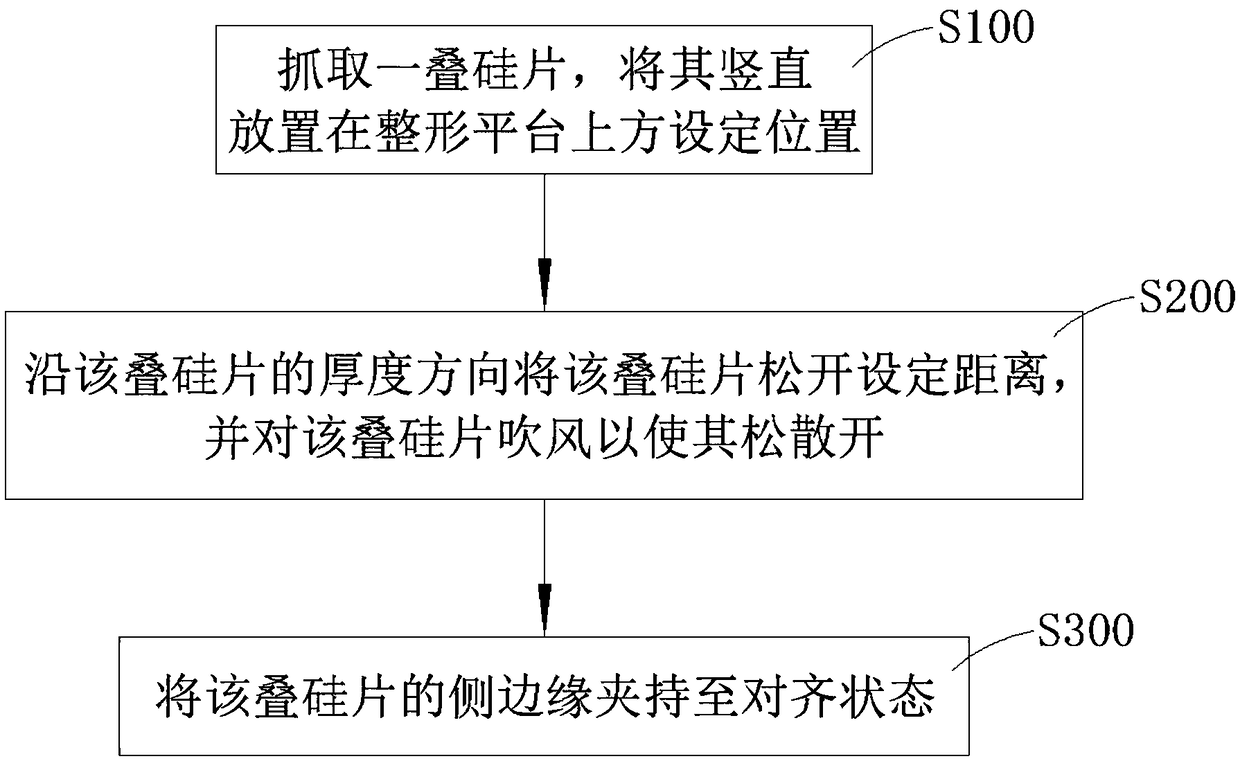

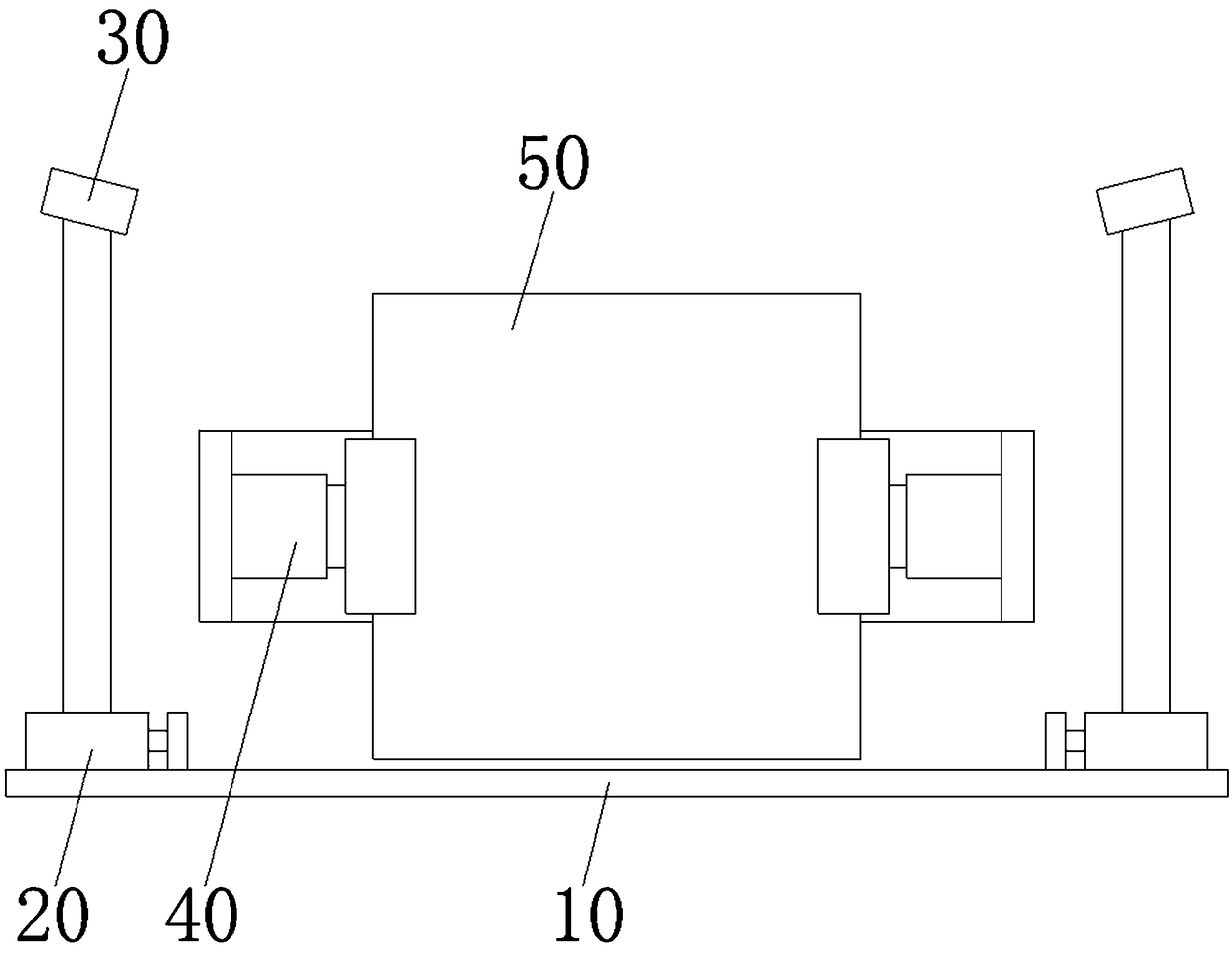

Silicon wafer shaping method and device

The invention discloses a silicon chip shaping method and device, wherein the shaping method includes: grabbing a stack of silicon chips, placing it vertically on a set position above a shaping platform; The wafers are loosened by a set distance, and the stack of silicon wafers is blown to loosen; the side edges of the stack of silicon wafers are clamped to an aligned state. The invention can automatically realize the shaping of silicon wafers, arrange and align the surrounding edges of a stack of silicon wafers, and facilitate subsequent plastic sealing and packaging of silicon wafers, thus avoiding protruding corners of silicon wafers caused by misalignment of silicon wafers Fragmentation or hidden cracking also avoids the silicon wafer size after plastic sealing being too large and difficult to fit into the foam box due to misalignment of the silicon wafers; the shaping method is simple and convenient, the shaping speed is fast, the efficiency is high, and the shaping effect is good.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Silicon wafer shaping method and device

The invention discloses a silicon wafer shaping method and device. The shaping method comprises that a stack of silicon wafers is grabbed and vertically placed at the setting position on a shaping platform, the stack of silicon wafers is loosened at a set distance in the thickness direction of the stack of silicon wafers, the stack of silicon wafers is blown so as to make stack of silicon wafers loose, and the side edge of the stack of silicon wafers is clamped to an alignment state. By means of the shaping method, the silicon wafers can be automatically shaped, the surrounding edges of the stack of silicon wafers is arranged and aligned so as to facilitate the follow-up plastic sealing and packaging of the silicon wafers, the fragmentation or cleavage of the corners of the protruding silicon wafers due to the misalignment of the silicon wafers is avoided accordingly, the fact that the plastic-sealed silicon wafers of the excessive size are hard to be loaded in a foam box due to the misalignment of the silicon wafers is also avoided, the shaping method is simple and convenient, high in shaping speed, high in efficiency, and high in shaping effect.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

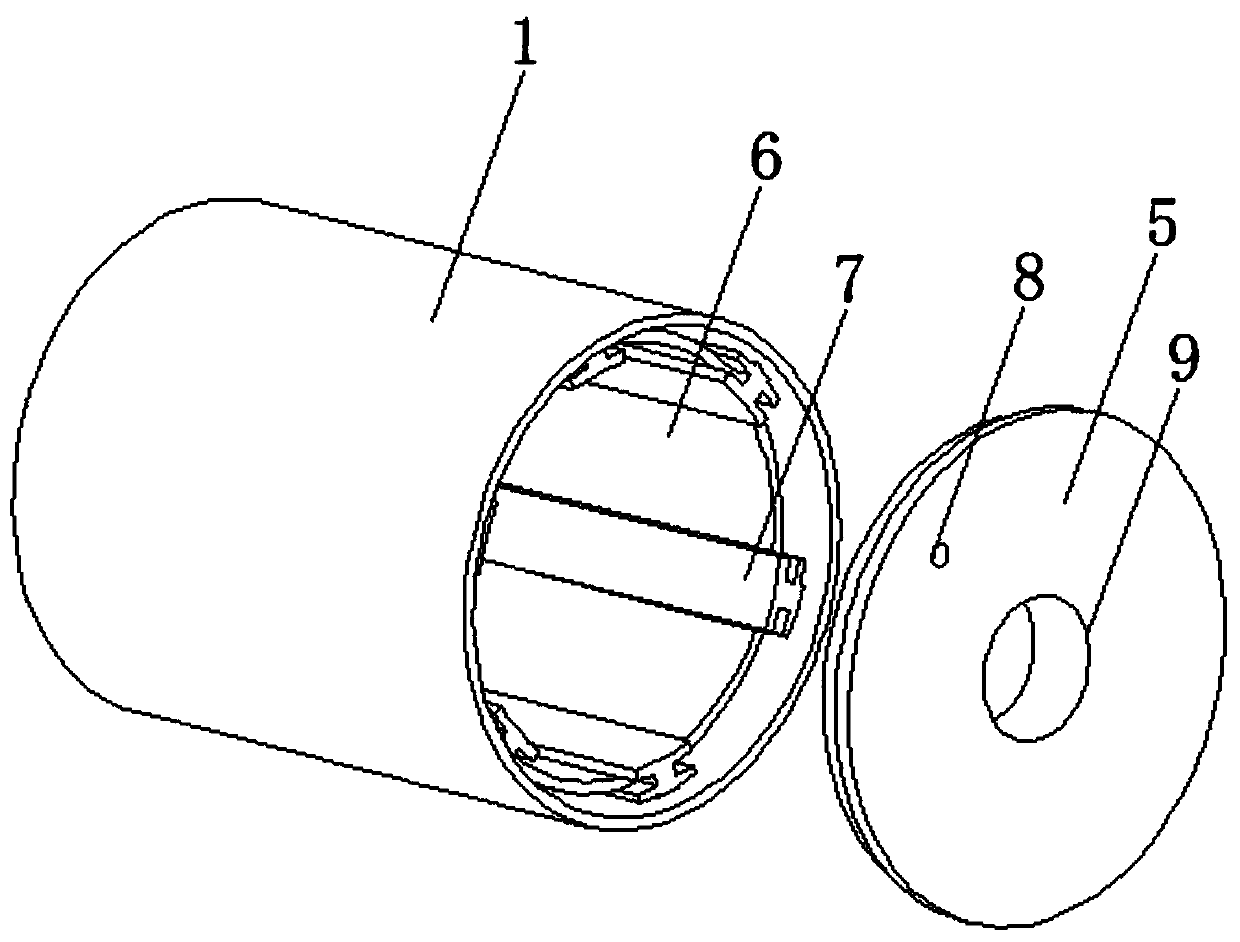

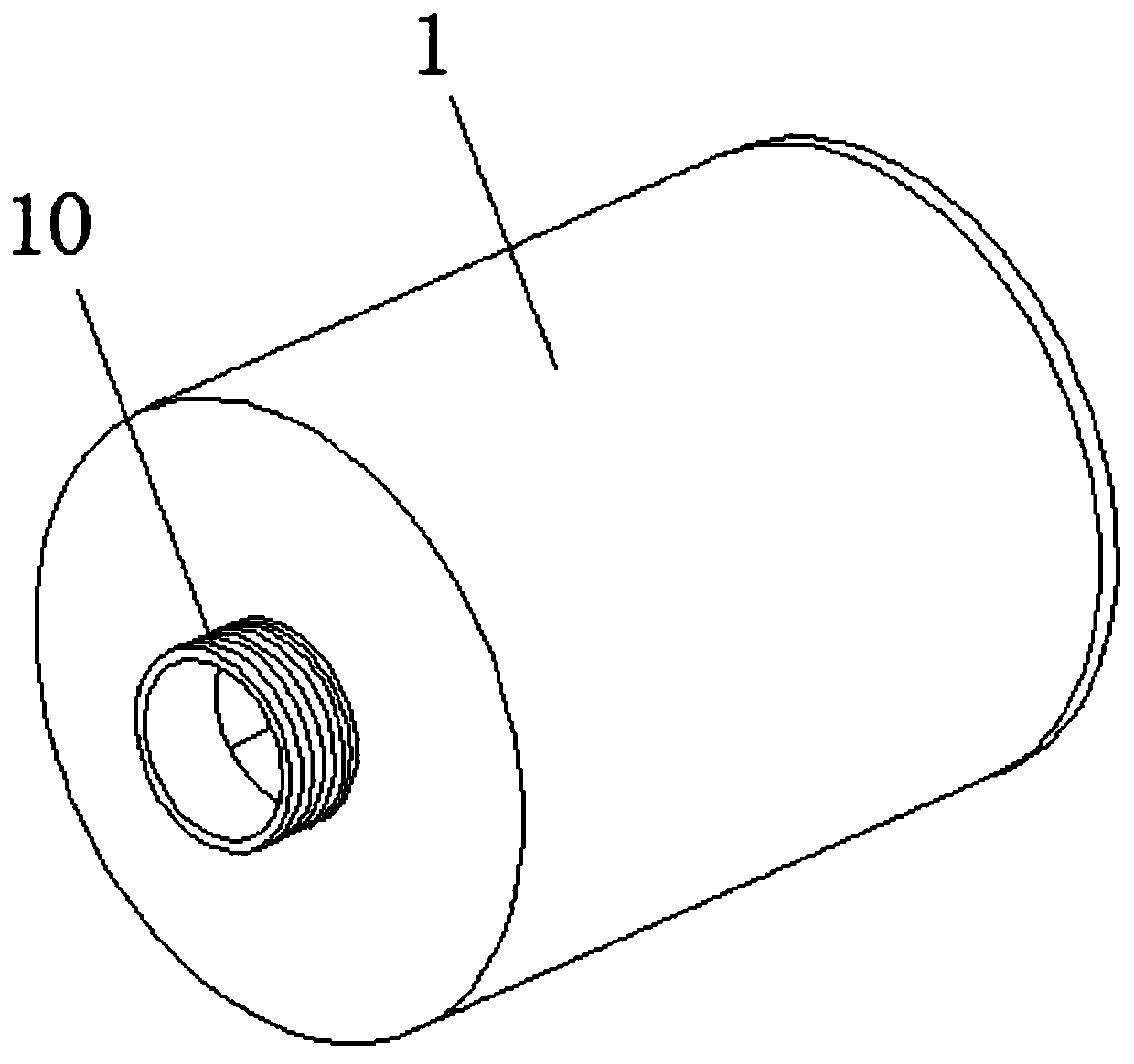

Heater for shaping of polyester rope and operation method of heater

InactiveCN110552099AShaping speed is fastEasy to controlTextiles and paperElectric machineryPolyester

The invention discloses a heater for shaping of a polyester rope and an operation method of the heater. The heater comprises a heating cylinder, six clamping plates are welded to the inner circumference face of the heating cylinder, and an arc heating plate is installed between every two clamping plates; a cooling box is connected to one end of the heating cylinder, a second motor is installed atthe bottom of the cooling box, a heat dissipation fan is installed at the output shaft end of the second motor, and a conveying mechanism is connected to the end, away from the heating cylinder, of the cooling box. According to the heater, the distances between the inner side faces of all the heating plates and the surface of the polyester rope are identical, so that the surface of the polyester rope is evenly heated; through the heat dissipation fan, the polyester rope shaped just now is cooled, softening of the polyester rope is eliminated accordingly, the situation that during operation ofthe conveying mechanism, due to too large pull force of the polyester rope, the polyester rope deforms is avoided, and the effect of shaping the polyester rope is guaranteed; through the conveying mechanism, it can be effectively guaranteed that the polyester rope passes through the heating cylinder at the constant speed, and accordingly the time of heating all the parts of the polyester rope is identical.

Owner:安徽嘉明新材料科技有限公司

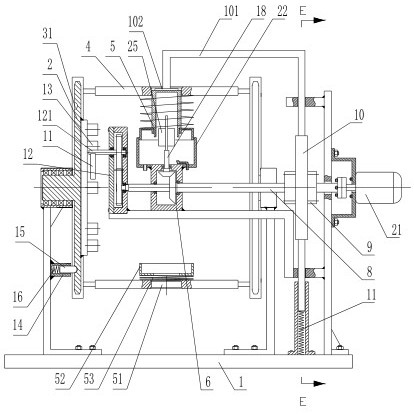

Bushing liner rolling machine

ActiveCN112387814ASave powerShaping speed is fastMetal-working feeding devicesPositioning devicesDrive wheelCrank

The invention discloses a bushing liner rolling machine which comprises a rack. A main power shaft is rotatably connected to the rack, a rotary bearing disc is mounted on the main power shaft, clamping barrels are distributed annularly on the rotary bearing disc, a shaping transmission is mounted on the rack, a cleaning shaping device is mounted on the shaping transmission, a driving shaft is mounted on the rack, a first crank is in power connection to the driving shaft, a driving swing bar is hinged to the rack, an arc-shaped gear is fixedly connected to one end of the driving swing bar and along chute is formed in the other end of the driving swing bar, a driving column is mounted on the rack, a rack is connected to the driving column, a driving arm is mounted on the driving column, a driving head is mounted on the driving arm, a stirring driving shaft is in power connection to the rotary driving box, a power wheel disc is connected to the stirring driving shaft, a driving wheel disc is mounted on the main power shaft, a plurality of driving chutes are distributed annularly on the driving wheel disc, and a driving protruding tooth capable of stretching into the driving chute anddriving the rotary bearing disc to rotate is mounted on the power wheel disc. The bushing liner rolling machine has the advantages of high shaping speed, good quality and high labor efficiency.

Owner:新松智能制造公共服务平台(青州)有限公司

Packing barrel shaping and filling system

PendingCN112093456AShaping speed is fastReduce labor intensityConveyorsBarrels/casks fillingPhysicsEngineering

The invention discloses a packing barrel shaping and filling system. The packing barrel shaping and filling system involves a shaping device and a filling device; the shaping device comprises a conveyor (201), a three-axis rounding machine, a sliding table support (202), a feeding sliding table (203) and a discharging sliding table (204), a set of packing barrel supporting plates (205) are sequentially arranged on a conveying belt of the conveyor (201) at equal intervals, and arc-shaped limiting grooves are formed in the tops of the packing barrel supporting plates (205); and the three-axis rounding machine comprises an upper roller (206), a pair of lower rollers (207) and a rounding machine body (210), a pair of reinforcing rib shaping protrusions (208) is arranged on the outer wall of the upper roller (206), and a pair of reinforcing rib shaping grooves (209) used in cooperation with the reinforcing rib shaping protrusions (208) is formed in each lower roller (207). The packing barrel shaping and filling system has the advantages that a packaging barrel is automatically shifted to the rounding machine to be shaped, the shaping speed is high, and the labor intensity of workers isrelieved.

Owner:湖北爱国环保技术开发有限公司

Metal pipe body port shaping machine

InactiveCN112427496AShaping speed is fastQuality improvementElectrical and Electronics engineeringRack and pinion

The invention discloses a metal pipe body port shaping machine which comprises a machine frame. A main power shaft is rotatably connected to the machine frame, a rotating bearing disc is installed atthe top of the main power shaft, clamping cylinders are annularly distributed on the rotating bearing disc, a shaping gearbox is installed on the machine frame, a shaping device is installed on the shaping gearbox, a driving shaft is installed on the machine frame, the shaping gearbox is in power connection with the driving shaft, a driving half gear is connected to the driving shaft, a driving column is installed on the machine frame, racks capable of being engaged with the driving half gear are connected to the driving column, a driving arm is installed on the driving column, a driving headis installed on the driving arm, a rotating driving box is installed on the machine frame, a driving disc is further installed on the rotating bearing disc, driving sliding grooves are annularly distributed in the driving disc, a power disc is installed on the rotating driving box, the driving column is installed on the power disc, and the driving column can extend into the driving sliding grooveswhen rotating along with the power disc so as to drive the rotating bearing disc to rotate. The metal pipe body port shaping machine has the advantages of being high in shaping speed, high in qualityand high in labor efficiency.

Owner:山东德日机械科技有限公司

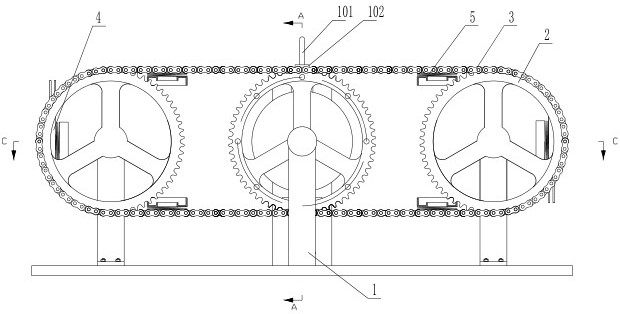

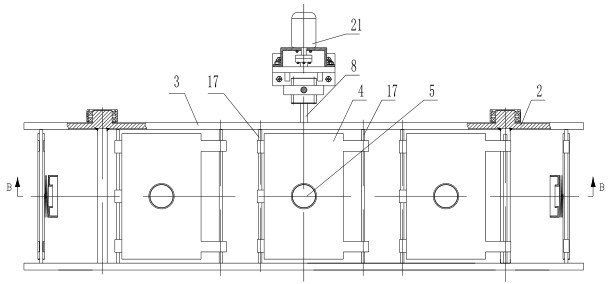

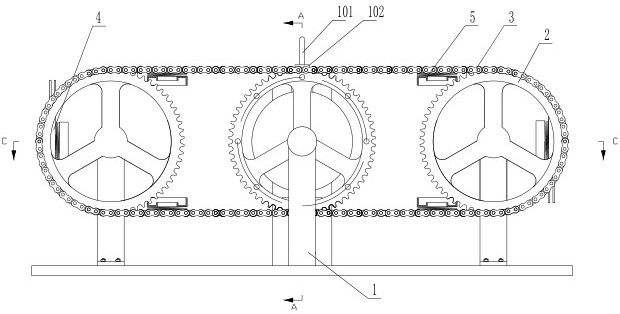

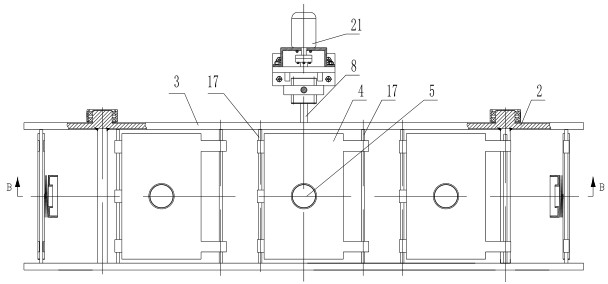

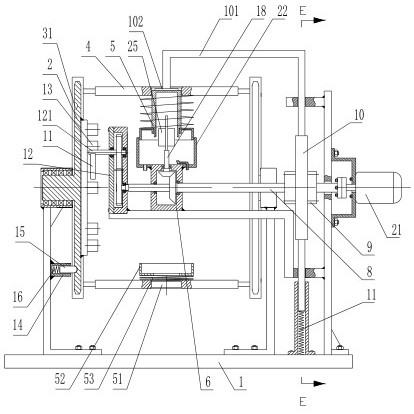

Pipe orifice rolling shaping machine

The invention discloses a pipe orifice rolling shaping machine which comprises a rack. Two groups of transmission chains are mounted on the rack. Each transmission chain comprises a transmission wheeland a conveyor belt. A clamping supporting rack is mounted between the two conveyor belts. A clamping barrel is mounted on the clamping supporting rack. A shaping transmission is mounted on the rack.A shaping device is mounted on the shaping transmission. A driving shaft in power connection to a power machine is mounted on the rack. The shaping transmission is in power connection to the drivingshaft. A driving semi-gear is connected to the driving shaft. A driving column is mounted on the rack. A rack is connected to the driving column. A driving arm is mounted on the driving column. A driving head is mounted on the driving arm. A rotary driving box is mounted on the rack. A driving crank rod is in power connection to the rotary driving box. A plurality of stirring columns that are distributed annularly are mounted on the driving arm. An elastic positioning device capable of positioning the transmission wheel and releasing the transmission wheel is mounted on the rack. The pipe orifice rolling shaping machine is high in shaping speed and good in shaping quality and improves the labor efficiency greatly.

Owner:新松智能制造公共服务平台(青州)有限公司

Bushing rolling shaping machine

Owner:新松智能制造公共服务平台(青州)有限公司

A kind of circular seedling shaping equipment

ActiveCN108811860BShaping speed is fastPrevents affecting pruning efficiencyCuttersCutting implementsElectric machineAgricultural engineering

The invention relates to seedling shaping equipment, in particular to round seedling shaping equipment. The technical purpose of the invention is to provide the round seedling shaping equipment capable of improving the shaping speed and saving time and labor. According to the technical scheme, the round seedling shaping equipment comprises a base, universal wheels, a first motor, a lead screw, a first nut, a first bearing seat, a sliding rod, a 7-shaped rod, a sliding sleeve, a connecting rod, a sleeve tube, a L-shaped plate and the like; a U-shaped opening is formed in the rear side surface of the base, the bottom of the base is symmetrically provided with the universal wheels, the top left side of the base is connected with the sliding rod, the sliding rod is connected with the sliding sleeve, the upper end of the sliding rod is connected with the 7-shaped rod, and the left side surface of the 7-shaped rod is connected with the first bearing seat. The equipment cooperates the lead screw with the first nut through the first motor to adjust the height of a curved shell so that high or short circular seedlings can be trimmed, and an electric winding wheel tightens or releases a pulling wire so that a cutter can move up and down to trim the circular seedlings while rotating.

Owner:叶小梅

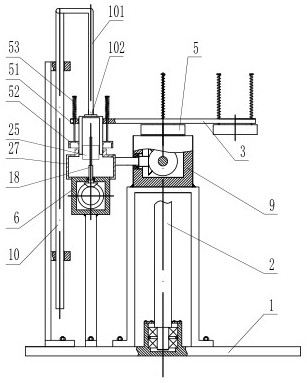

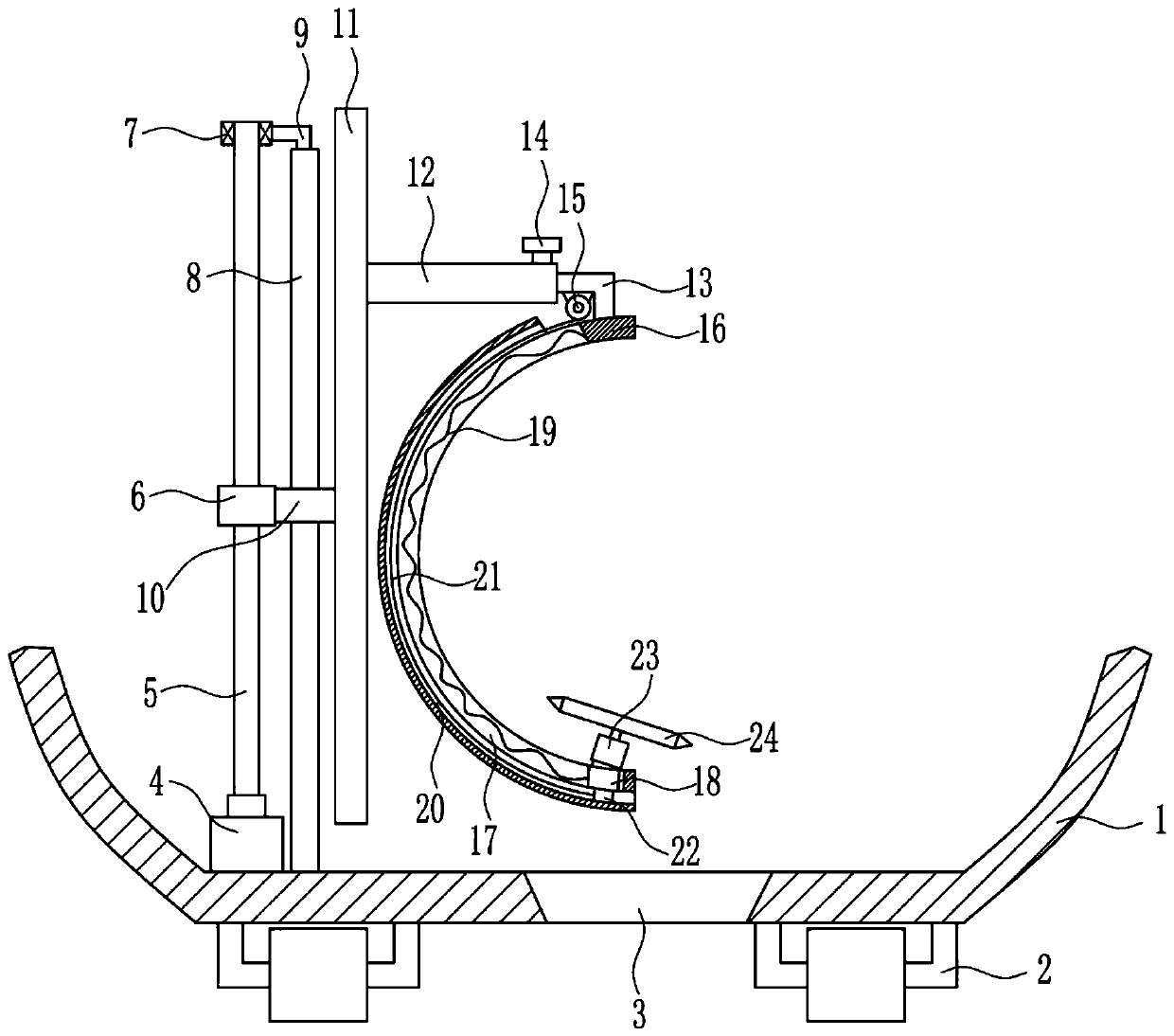

Powder metallurgy pressing sleeve shaping device

InactiveCN113263078AShaping speed is fastIncrease production rateMetal-working feeding devicesStripping-off devicesWorkbenchIndustrial engineering

The invention belongs to the technical field of pressing sleeve shaping, and particularly relates to a powder metallurgy pressing sleeve shaping device. The device comprises a workbench and a shaping mechanism arranged on the workbench and used for pressing sleeve shaping, wherein, one side of the workbench is provided with a workpiece supply disc used for supplying a first workpiece and a spiral feeder used for supplying a second workpiece, a first workpiece supply conveying belt is arranged between the workpiece supply disc and the workbench, and a second workpiece supply conveying belt is arranged between the spiral feeder and the workbench. According to the device, by arranging the workbench with the shaping mechanism and an extrusion head, a pressing sleeve insert and a pressing sleeve can be conveyed by the workpiece feeding disc and the spiral feeder respectively and conveyed into a shaping groove by a second workpiece clamping mechanism and a first workpiece clamping mechanism in sequence, the inner diameter and the outer diameter of a workpiece can be automatically detected, and under the condition that the size is qualified the two workpieces are clamped into each other, the shaping process of the workpieces is completed, and the shaping speed of the pressing sleeve is increased.

Owner:宁波新弘精密零部件有限公司

A nozzle diameter trimming machine

Owner:新松智能制造公共服务平台(青州)有限公司

Packaging barrel feeding rounding system

PendingCN112093461AReduce labor intensityShaping speed is fastConveyorsSolid waste disposalWaste oilIdler-wheel

The invention provides a packing barrel feeding rounding system. The system comprises a feeding device and a rounding device; the feeding device comprises a first conveying belt (101) which inclines downwards, a second roller conveying belt (102) which extends upwards in the arc direction and a transferring block (103); an outlet of the first conveying belt (101) is located at an inlet of the second roller conveying belt (102) which extends upwards in the arc direction; at least four waste oil barrel containing areas (131) which are used for containing waste oil barrels are arranged on the transferring block (103); a rotatable idler wheel (132) is arranged at the end part between every two waste oil barrel containing areas (131); and the edge of each idler wheel (132) is located in the corresponding waste oil barrel containing area (131). The system has the advantages that a packaging barrel is automatically shifted to a rounding machine to be shaped, the shaping speed is high, and thelabor intensity of workers is relieved.

Owner:湖北爱国环保技术开发有限公司

A plastic case circuit breaker moving contact synchronous shaping fixture

ActiveCN105788972BGood synchronizationImprove workabilityEmergency protective device manufactureCircuit-breaking switch contactsWork performanceSlide plate

The invention discloses a molded case circuit breaker moving contact synchronization shaping fixture. The molded case circuit breaker moving contact synchronization shaping fixture comprises supporting columns, a sliding plate, adjusting bearings, bearing blocks, a rotary pressing block, a rotary bearing, pushing rods, a base, a sliding block and so on. The molded case circuit breaker moving contact synchronization shaping fixture is characterized in that the shaping fixture is of a double-column sliding plate structure. A vertical air cylinder and a horizontal air cylinder are adopted as driving power. The molded case circuit breaker moving contact synchronization shaping fixture has the advantages of reasonable structure, operation convenient and high shaping speed. With the molded case circuit breaker moving contact synchronization shaping fixture adopted, a shaped moving contact has excellent synchronization performance, and excellent working performance of a molded case circuit breaker can be ensured.

Owner:HANGZHOU ZHIJIANG SWITCHGERA

Cup body cleaning machine

InactiveCN112515603AFast cleaning and shapingQuality improvementTableware washing/rinsing machine detailsDrive wheelGear wheel

The invention discloses a cup body cleaning machine which comprises a machine frame, a supporting roller is rotatably connected to the machine frame, a plurality of clamping cylinders are annularly distributed on the supporting roller, a shaping gearbox is installed on the machine frame, a shaping device is installed on the shaping gearbox, a driving shaft in power connection with a power machineis installed on the machine frame, a driving half gear is connected to the driving shaft, a driving column is installed on the machine frame, a rack capable of being meshed with the driving half gearis connected to the driving column, a driving arm is installed on the driving column, a driving head is installed on the driving arm, a stirring driving shaft is in power connection with the rotatingdriving box, a power wheel disc is connected to the stirring driving shaft, a driving wheel disc is installed on a main power shaft, a plurality of driving sliding grooves are annularly distributed inthe driving wheel disc, the outer circumferential face, between every two adjacent driving sliding grooves, of the driving wheel disc is a wheel disc keeping face, and driving protruding teeth for driving a rotary bearing disc to rotate are installed on the power wheel disc. The machine has the advantages of being high in shaping speed, high in quality and high in labor efficiency.

Owner:马海洋

Bushing inner diameter rounding machine

ActiveCN112387814BSave powerShaping speed is fastMetal-working feeding devicesPositioning devicesDrive wheelDrive shaft

The invention discloses a bushing inner diameter rounding machine, which comprises a frame, a main power shaft is rotatably connected to the frame, a rotating bearing plate is arranged on the main power shaft, a clamping cylinder is arranged on the rotating bearing plate, and the frame is equipped with Shaping gearbox, a cleaning and shaping device is installed on the shaping gearbox, a drive shaft is installed on the frame, a first crank is connected to the drive shaft for power, a drive swing rod is hinged on the frame, and one end of the drive swing rod is fixed with an arc gear , The other end is provided with a long chute, a drive column is installed on the frame, a rack is connected to the drive column, a drive arm is installed on the drive column, a drive head is installed on the drive arm, and a toggle drive shaft is connected to the power of the rotating drive box. A power wheel disc is connected to the toggle drive shaft, a drive wheel disc is installed on the main power shaft, and a plurality of drive chutes are arranged on the drive wheel disc. Rotating drive lobes. The invention has the advantages of fast shaping speed, high quality and high labor efficiency.

Owner:新松智能制造公共服务平台(青州)有限公司

Shaper for main chips of radiator reworking products

The invention relates to a shaper for main chips of radiator reworking products. The shaper comprises a base plate (1), a handle (2), a linear guide (3), a sliding plate (4), a support (5), a reshaping cushion block (6), a rolling head (7), a workpiece press plate (8), a workpiece support plate (9), a lock nut (10), a height adjustment screw (11), a hand rocking wheel (11), a press air cylinder (13), an abdication block (14) and a protruding head (15). Compared with the prior art, the shaper can reshape core main chips of any length and width, cores of any thickness can be mounted and positioned, and the shaper has the advantages of being high in reshaping efficiency, capable of fully guaranteeing the product quality, convenient to operate, and high in generality.

Owner:SHANGHAI DELANG AUTO PARTS MFG

Cup body inner wall sweeper

The invention discloses a cup body inner wall cleaning machine which comprises a machine frame, a main power shaft is rotatably connected to the machine frame, a rotary bearing disc is installed at the top of the main power shaft, clamping cylinders are annularly distributed on the bearing disc, a cleaning and shaping gearbox is installed on the machine frame, and a cleaning and shaping device is installed on the cleaning and shaping gearbox. A driving shaft in power connection with a power machine is installed on the machine frame, a driving half gear is connected to the driving shaft, a driving column is installed on the machine frame, a rack is connected to the driving column, a driving arm is installed on the driving column, a driving head is installed on the driving arm, a rotating driving box is installed on the machine frame, and a shifting driving shaft is in power connection with the rotating driving box. A power cam is connected to the shifting driving shaft, a power disc is installed on the main power shaft, a plurality of driving shifting columns are annularly distributed on the power disc, and a driving cam groove for driving the rotating bearing disc to rotate is formed in the power cam. The cleaning machine has the advantages of being high in cleaning and shaping speed, high in quality and high in labor efficiency.

Owner:马行坤

A nozzle rolling shaping machine

The invention discloses a nozzle rolling shaping machine, which comprises a frame on which two sets of transmission chains are installed, the transmission chain includes a transmission wheel and a conveyor belt, a clamping support frame is installed between the two transmission belts, and the clamping support frame There is a clamping cylinder on the top, a shaping gearbox is installed on the frame, a shaping device is installed on the shaping gearbox, a driving shaft connected to the power motor is installed on the frame, the shaping gearbox is connected to the driving shaft, and a driving shaft is connected to the driving shaft. Half gear, the frame is equipped with a driving column, the driving column is connected with a rack, the driving column is equipped with a driving arm, the driving arm is equipped with a driving head, the frame is equipped with a rotating drive box, and the driving box is connected with a driving crank rod The transmission wheel is equipped with a plurality of ring-clothed toggle columns, and the frame is equipped with an elastic positioning device that can position the transmission wheel and release the transmission wheel. The invention has fast shaping speed and high quality, and greatly improves labor efficiency.

Owner:新松智能制造公共服务平台(青州)有限公司

Cup rim inner wall cleaning machine

ActiveCN112845469ASave powerShaping speed is fastHollow article cleaningGlass reforming apparatusCrankDrive shaft

The invention discloses a cup body inner wall cleaning machine. The machine comprises a machine frame, a main power shaft is rotationally connected to the machine frame, a rotary bearing disc is installed at the top of the main power shaft, clamping cylinders are annularly distributed on the rotary bearing disc, a cleaning and shaping gearbox is installed on the machine frame, and a cleaning and shaping device is installed on the cleaning and shaping gearbox. A driving shaft in power connection with a power machine is installed on the machine frame, a first crank is in power connection with the driving shaft, a driving swing rod is hinged to the machine frame, an arc-shaped gear is fixedly connected to one end of the driving swing rod, a long sliding groove is formed at the other end of the driving swing rod, a connecting rod of the first crank extends into the long sliding groove, a driving column is installed on the machine frame, and a rack is connected to the driving column. The driving column is provided with a driving arm, the driving arm is provided with a driving head, the shaping gearbox is further in power connection with a driving crank rod, the rotary bearing disc is provided with a plurality of power rods which are annularly distributed, and the machine frame is provided with an elastic disc side positioning device. The machine has the advantages of being high in cleaning and shaping speed, high in quality and high in labor efficiency.

Owner:威海云之卫智能科技有限公司

Pipe orifice inner wall cleaning machine

InactiveCN112756341ASave powerShaping speed is fastHollow article cleaningGlass reforming apparatusDrive wheelDrive shaft

The invention discloses a pipe orifice inner wall cleaning machine. The pipe orifice inner wall cleaning machine comprises a machine frame, a supporting roller is rotationally connected to the machine frame, a plurality of clamping cylinders are annularly distributed on the supporting roller, a shaping gearbox is installed on the machine frame, a shaping device is installed on the shaping gearbox, a driving shaft in power connection with a power machine is installed on the machine frame, and a driving gear is connected to the driving shaft. A driving column is installed on the machine frame, a rack capable of being meshed with the driving gear is connected to the driving column, a driving arm is installed on the driving column, a driving head is installed on the driving arm, a power wheel disc is installed in the supporting roller, driving column bodies are installed on the power wheel disc, a driving wheel shaft is installed on a rotating driving box, and a driving shifting column is installed on the driving wheel shaft. The driving wheel shaft is provided with a semi-circular ring which can abut against the driving column bodies when the driving column bodies are not shifted by the driving shifting column so that the supporting roller is kept in a static state. The pipe orifice inner wall cleaning machine has the advantages of being high in shaping speed, high in quality and high in labor efficiency.

Owner:山东德日机械科技有限公司

Pipe orifice diameter finisher

The invention discloses a pipe orifice diameter finisher which comprises a rack. A supporting roller is rotatably connected to the rack, a plurality of clamping barrels are distributed annularly on the supporting roller, a shaping transmission is mounted on the rack, a rolling shaping device is mounted on the shaping transmission, a driving shaft in power connection to a power machine is mounted on the rack, a driving gear is connected to the driving shaft, a driving column is mounted on the rack, a rack capable of being engaged to a driving gear is connected to the driving column, a driving arm is mounted on the driving column, a driving head is mounted on the driving arm, a power disc is mounted in the supporting roller, a stirring driving shaft is in power connection to the rotary driving box, a power cam is connected to the stirring driving shaft, a plurality of driving stirring columns are distributed annularly on the power disc, and a driving cam groove which rotates therealong,stretches into the driving columns and drives the supporting roller to rotate intermittently is mounted on the power cam. The pipe orifice diameter finisher has the advantages of high shaping speed, good quality and high labor efficiency.

Owner:新松智能制造公共服务平台(青州)有限公司

Bush rolling shaper

The invention discloses a bush rolling shaper which comprises a machine frame. A supporting roller is rotatably connected onto the machine frame; a plurality of clamping cylinders are annularly distributed on the supporting roller; a shaping gearbox is installed on the machine frame; a rolling shaping device is installed on the shaping gearbox; a driving shaft in power connection with a power machine is installed on the machine frame; a driving half gear is connected onto the driving shaft; a driving column is installed on the machine frame; a rack capable of being meshed with the driving halfgear is connected onto the driving column; a driving arm is installed on the driving column; a driving head is installed on the driving arm; a rotating driving box is installed on the machine frame;a power wheel disc is installed in the supporting roller; a plurality of power swing rods are installed on the power wheel disc; a driving wheel shaft is installed on the rotating driving box; the driving wheel shaft is provided with a driving poking column enabling the supporting roller to rotate intermittently; and the driving wheel shaft is provided with a semi-circular ring enabling the supporting roller to be kept in a static state. The bush rolling shaper provided by the invention has the advantages of being high in shaping speed, high in quality and high in labor efficiency.

Owner:新松智能制造公共服务平台(青州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com