Cup body cleaning machine

A technology for cleaning machines and cup bodies, which is applied to cleaning equipment, household cleaning devices, dishwashers/washing machines for tableware, etc. High, clean and shape fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

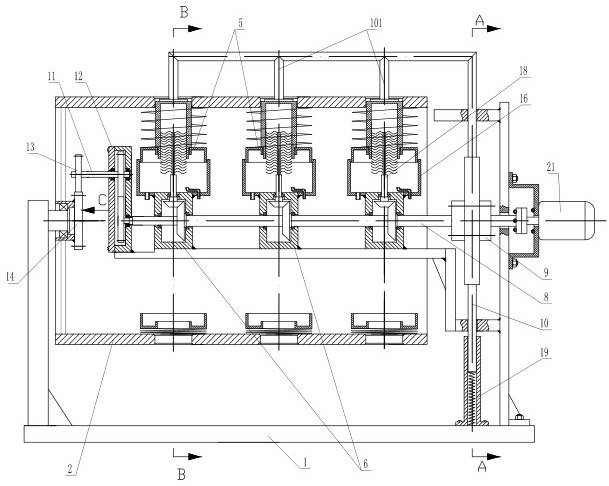

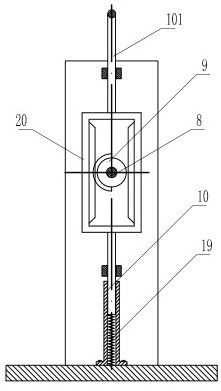

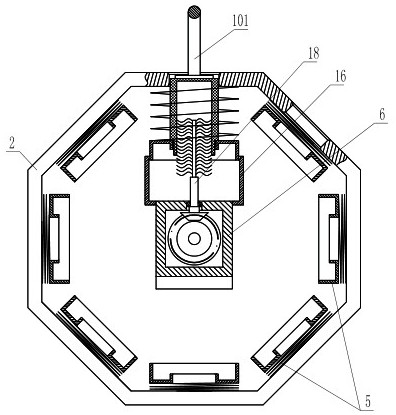

[0021] refer to figure 1 , figure 2 with image 3 , the present invention provides a kind of cup cleaning machine, and it comprises frame 1, and the structure of frame 1 can refer to figure 1 The structure shown in , of course, can also be designed into other shapes according to needs, the purpose of which is to support and fix the various components on the rack, and is not limited to the structure shown in the figure. The frame 1 is rotatably connected with a support roller 2, and the upper ring of the support roller 2 is provided with a plurality of clamping cylinders 5 for clamping the bushing and can slide up and down. Shaping gearbox 6 in the cavity. In this embodiment, the clamping cylinder 5 includes a clamping cylinder connected to the support drum 2 through a clamping spring. The clamped sleeve, that is, as shown in the figure, the sleeve is located on the support roller 2 and protrudes inwards. After the bushing is clamped in the sleeve, when there is power to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com