Bushing inner diameter rounding machine

A spheronizing machine and bushing technology, applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve problems such as unevenness, wear of pipe wall thickness, large deformation, etc., and achieve high quality, high labor efficiency, and shaping speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

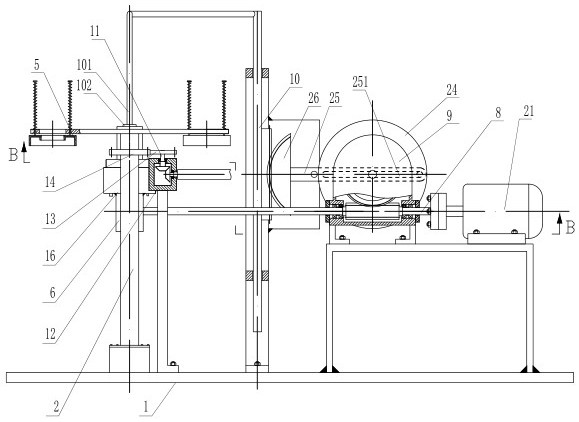

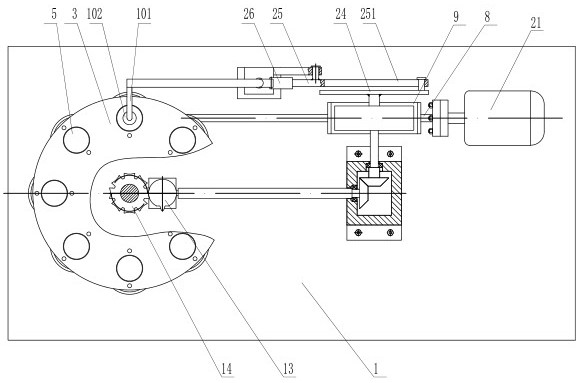

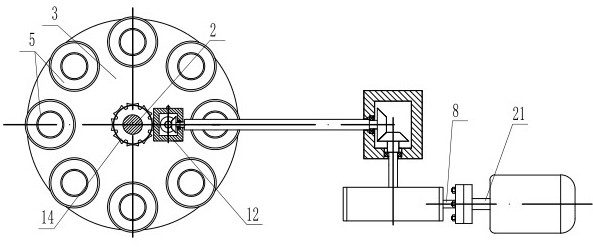

[0019] refer to figure 1 , figure 2 and image 3 , the present invention provides a bush inner diameter rounding machine, which includes a frame 1, the structure of the frame 1 can refer to figure 1 The structure shown in , of course, can also be designed into other shapes according to needs, the purpose of which is to support and fix the various components on the rack, and is not limited to the structure shown in the figure. The frame 1 is rotatably connected with a vertically arranged active power shaft 2, and the top of the main power shaft 2 is equipped with a rotating bearing plate 3 that rotates with it. A clamping cylinder 5 that can slide up and down. In this embodiment, the clamping cylinder 5 includes a clamping rod 51 connected to the rotating carrier plate 3 through a clamping spring 53. The clamping rod 51 is provided with a The outer wall of the bush to be processed clamps the clamped sleeve 52, that is, as shown in the figure, the clamping rod 51 vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com