Packaging barrel feeding rounding system

A packaging barrel and material feeding technology, which is applied in the direction of transportation and packaging, solid waste removal, conveyors, etc., can solve the problems of low production efficiency and high labor intensity of workers, and achieve the effect of fast shaping speed and lightening labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Embodiment: when the waste oil barrel enters the first conveyor belt 101 and is in the waste oil barrel placement area 131 for placing the waste oil barrel, the back waste oil barrel is blocked by one of the rollers 132 and is waiting to enter the back waste oil barrel In the placement area 131, the waste oil barrels entering the waste oil barrel placement area 131 are lowered by the cooperation of the roller 132 and the second roller conveyor belt 102 and move along the direction of the second roller conveyor belt 102 until it is pushed out of the second roller conveyor belt. The two-roller conveyor belt 102 can enter the next station.

[0047] The photoelectric sensor mainly detects the position to be entered into the waste oil drum placement area 131, and when there is a waste oil drum at this position, the motor starts to drive the transfer block 103 to start rotating.

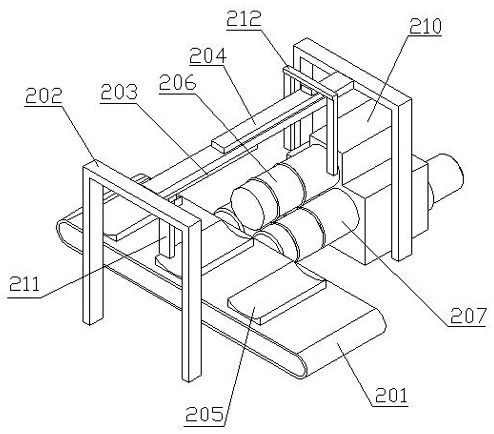

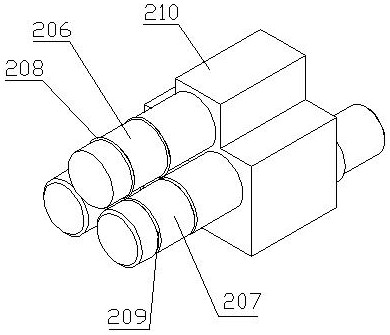

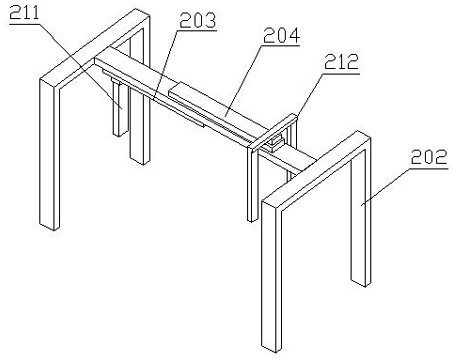

[0048] Working method and principle: put the packaging drum 220 on the packaging drum tray 205 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com