A plastic case circuit breaker moving contact synchronous shaping fixture

A molded case circuit breaker and moving contact technology, which is applied in the direction of circuit breaker contacts, circuit breaker components, circuits, etc., can solve the problems of synchronization of moving contact pieces of each phase, parts manufacturing and assembly errors, It is difficult to meet the synchronization requirements and other problems, and achieve the effect of good synchronization, reasonable structure and fast shaping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

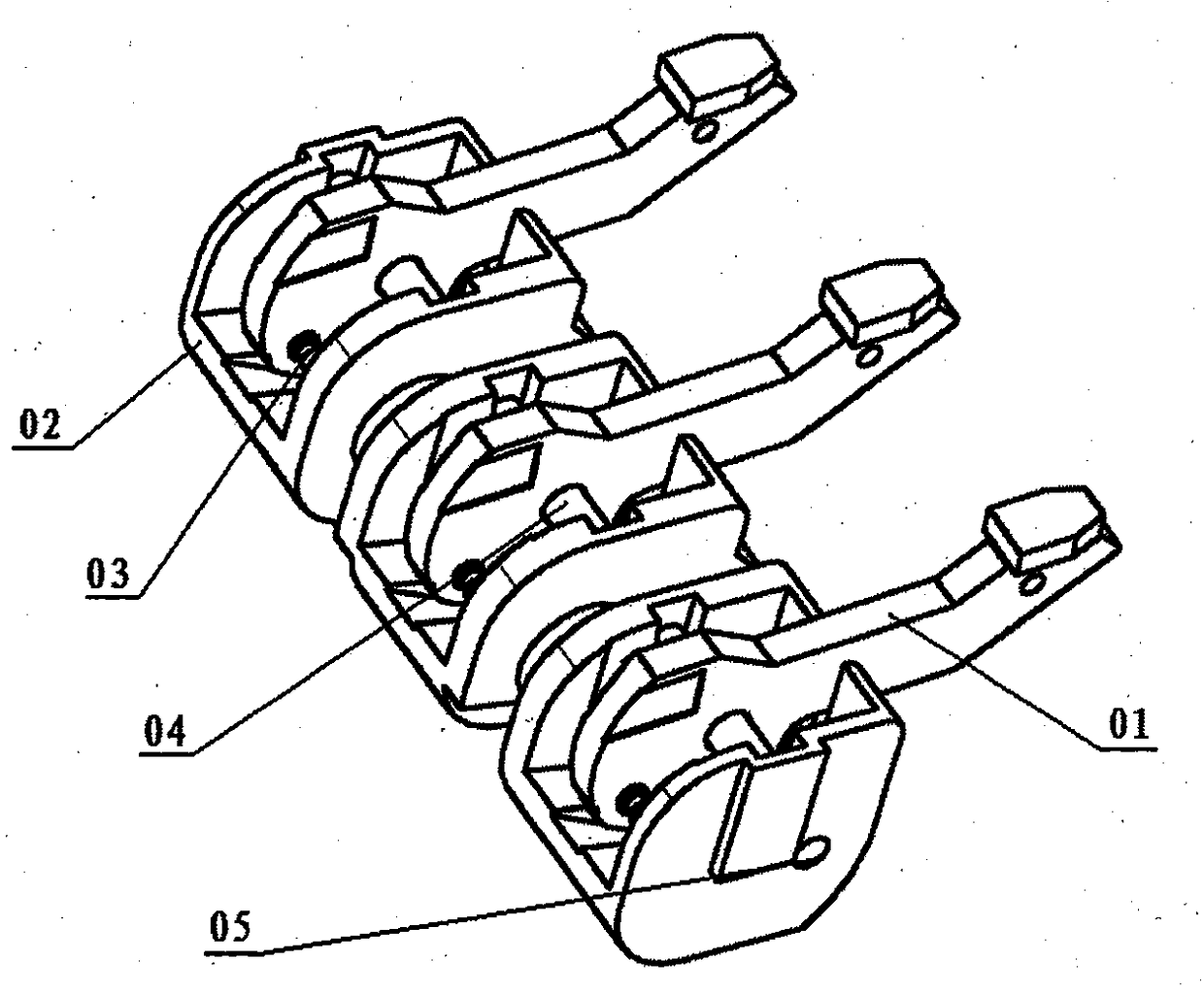

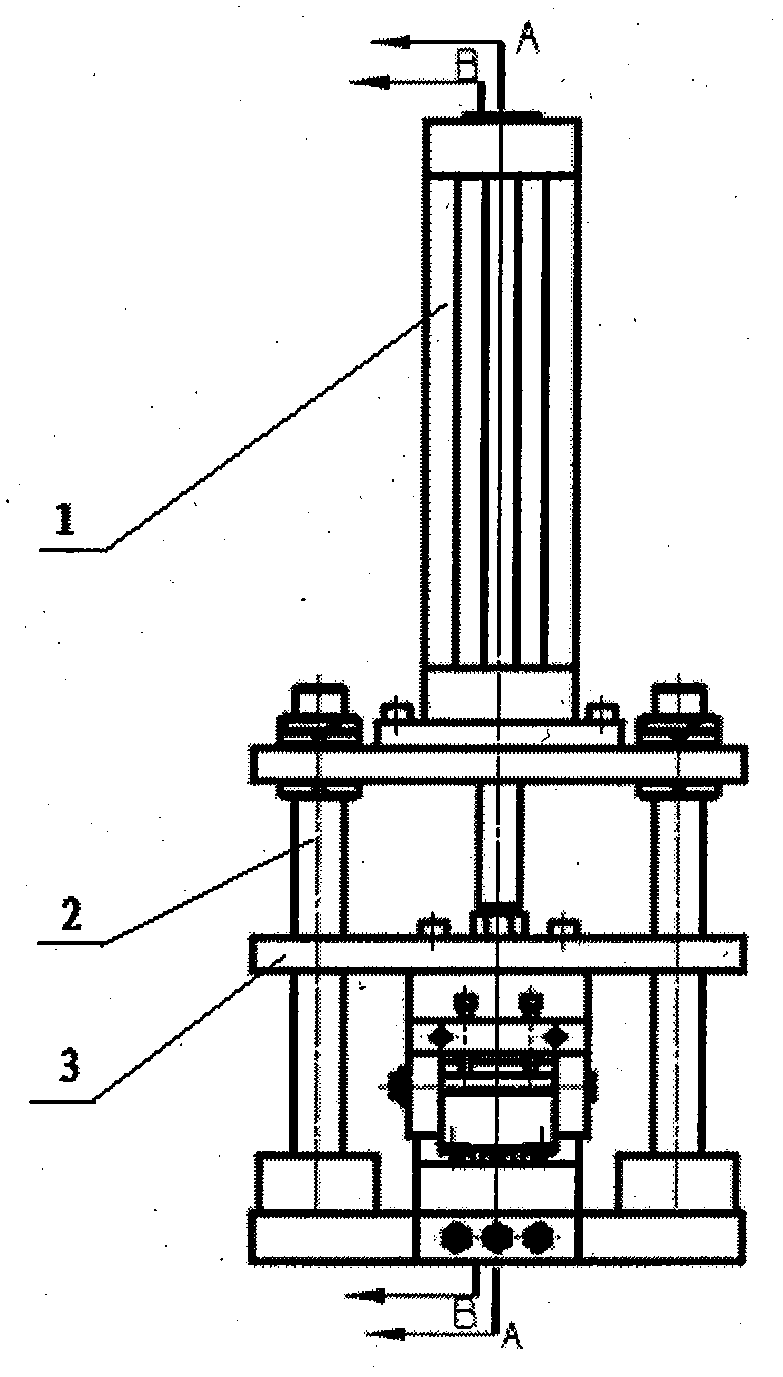

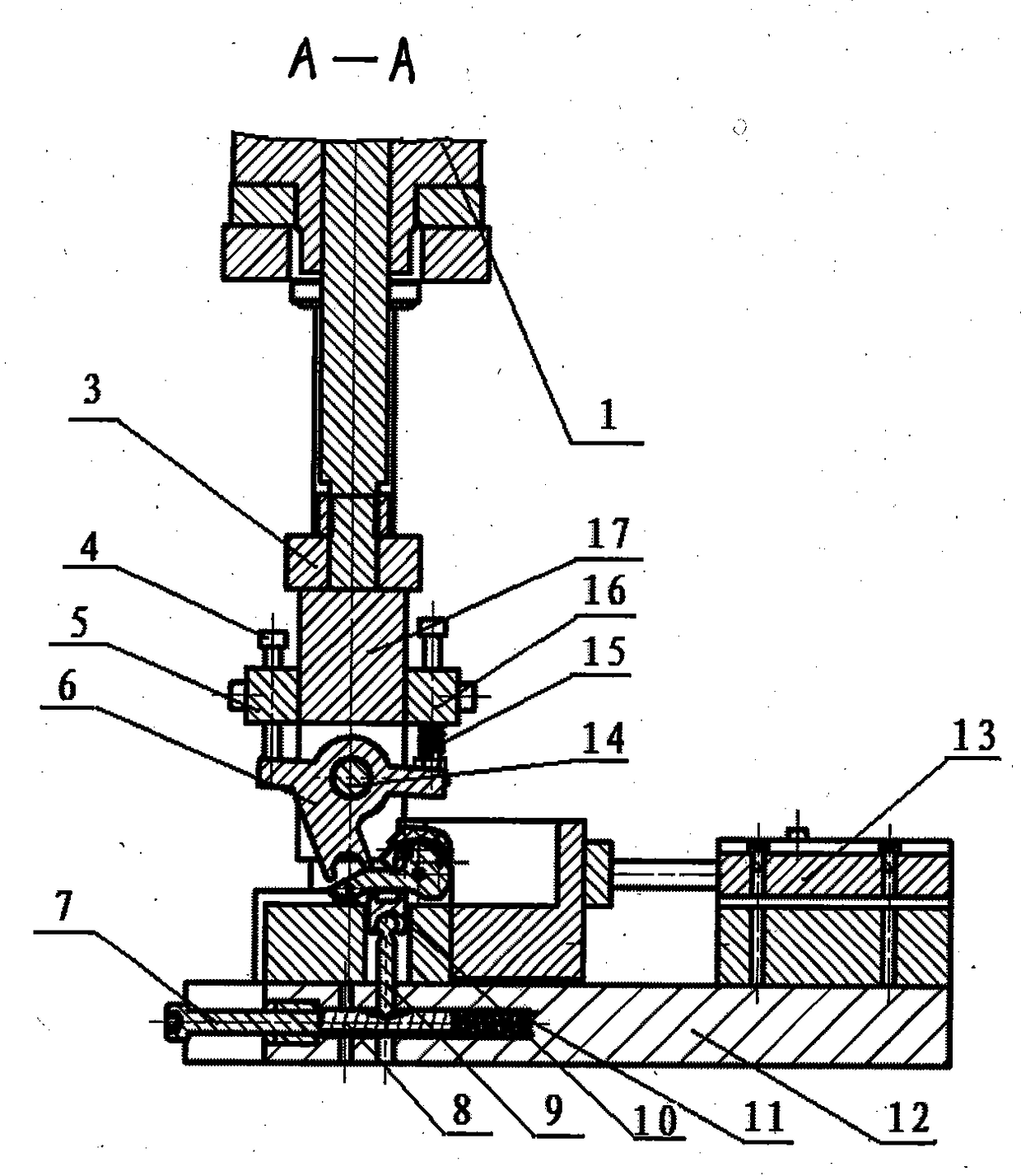

[0015] A molded case circuit breaker moving contact synchronous shaping fixture according to the present invention is composed of a pillar 2, a slide plate 3, an adjustment support 4, support blocks 5, 16, a rotating pressure block 6, a rotating support 10, a push rod 15, and a base 12 , Slide block 19 is formed. The orthopedic fixture is a double-pillar slide structure. At the top of the fixture, there is a vertical cylinder 1. The cylinder is fixed on the top plate. The slide 3 is fixedly connected to the end of the piston rod of cylinder 1. The slide 3 can follow the piston rod of cylinder 1 along the pillar 2. Slide up and down; the fixed plate 17 is fixed on the lower part of the slide plate 3, and the support blocks 5 and 16 are fixed on both sides of the fixed plate 17 by screws; the fixed plate 17 is an inverted U-shaped bracket, and the rotating pressure block 6 is placed in the gap at the lower part inside, and can rotate around the pin shaft 14 on the fixed plate 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com