Shaper for main chips of radiator reworking products

A rework product and shaping machine technology, applied in the field of radiator rework product main piece shaping machine, can solve the problems of low product qualification rate, poor shaping effect of manual pliers, poor sealing effect of water chamber, etc., to increase general performance, The effect of fast shaping speed and improved sealing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

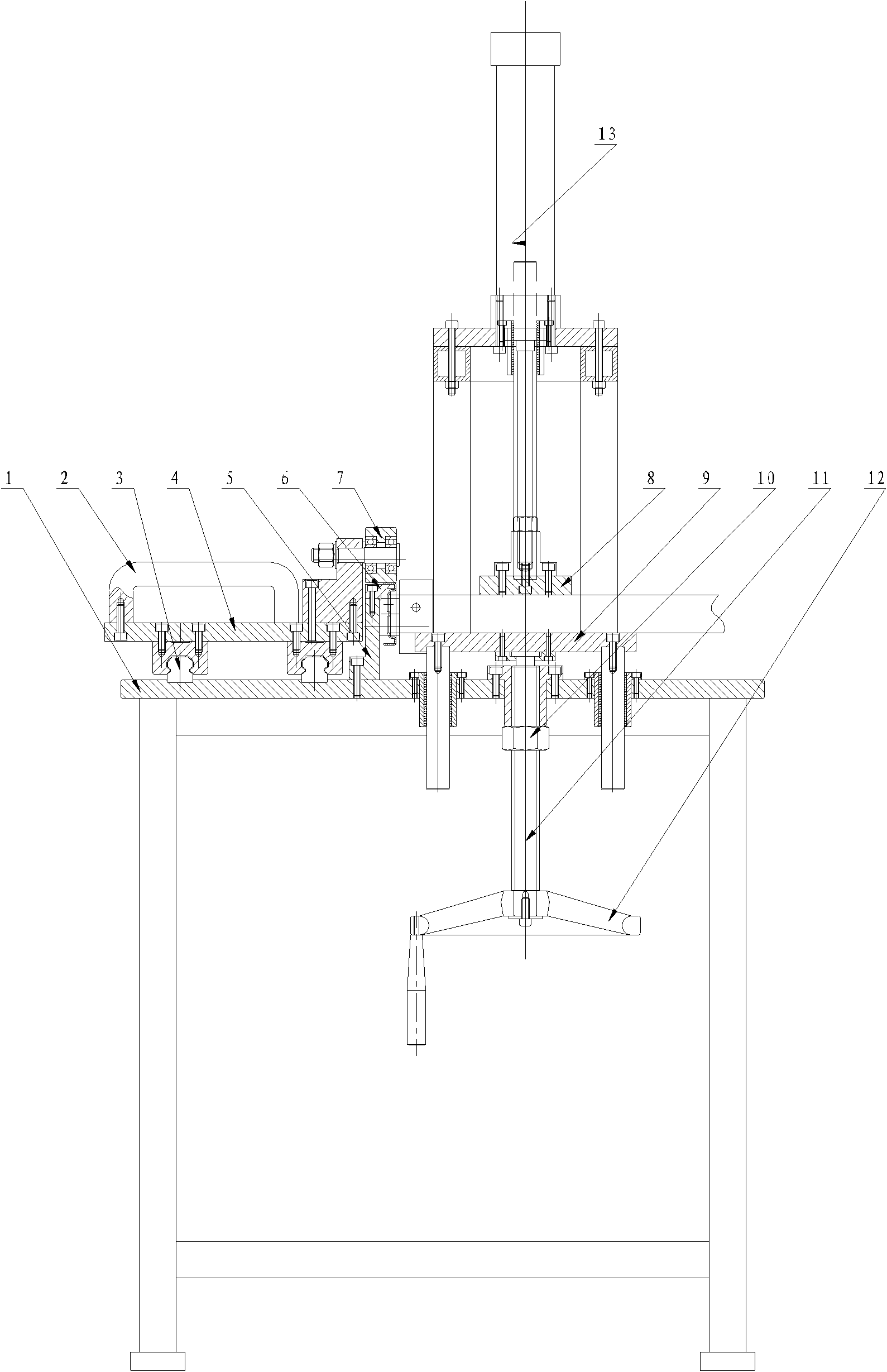

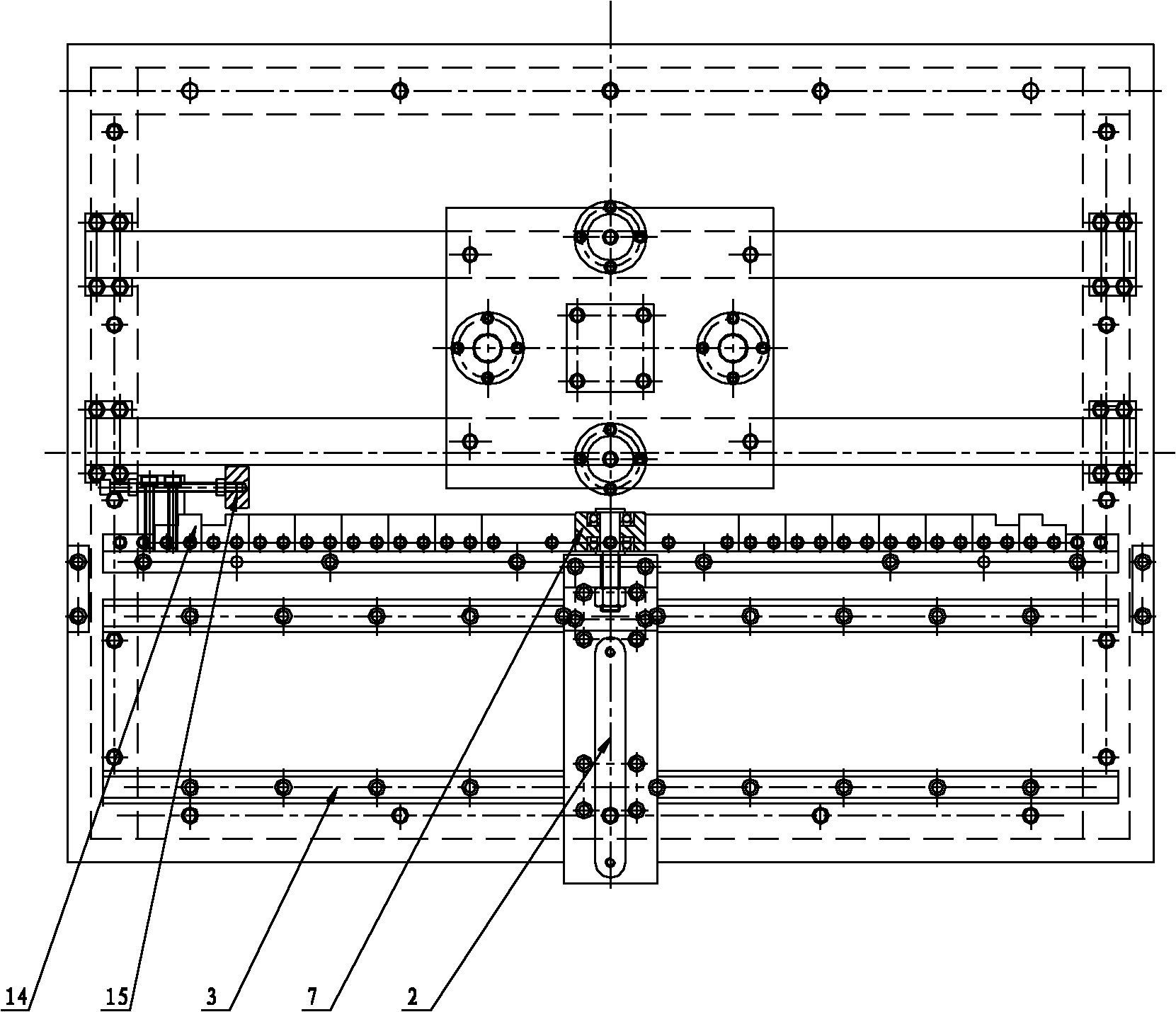

[0019] Such as Figure 1~2 As shown, a heat sink rework product main sheet shaping machine includes a base plate 1, a handle 2, a linear guide rail 3, a sliding plate 4, a support 5, a shaping pad 6, a rolling head 7, a workpiece pressure plate 8, and a workpiece support Plate 9, lock nut 10, height adjustment screw rod 11, hand wheel 12, compression cylinder 13, step-off block 14, top 15, described base plate 1 is provided with linear guide rail 3, and linear guide rail 3 is provided with two, described The sliding plate 4 straddles the two linear guide rails 3, the sliding plate 4 is provided with a handle 2, the support 5 is located on the sliding plate 4, and is located on the side of the handle 2, the plastic Pad block 6 is arranged on the bearing 5, and described rolling head 7 is arranged on the top of shaping pad 6, and rolling head 7 is arranged on the slide plate 4 near the side of step-off block 14, and rolling head 7 slides The plate 4 slides on the linear guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com