Packing barrel shaping and filling system

A technology for packaging barrels and filling materials, which is applied in the field of packaging barrel recycling equipment, can solve the problems of low filling efficiency, low production efficiency, high labor intensity of workers, etc., and achieves the effect of fast shaping and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

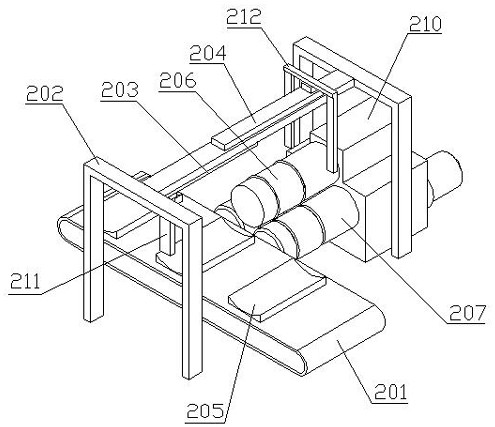

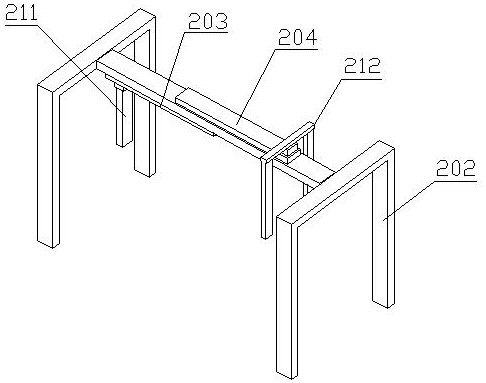

[0032] As shown in the accompanying drawings, the present invention includes a shaping device and a filling device,

[0033] The shaping device includes a conveyor 201, a three-axis rounding machine, a slide bracket 202, a feed slide 203 and a discharge slide 204,

[0034] On the conveyor belt of the conveyor 201, a group of packaging bucket trays 205 are arranged in an equidistant order, and the top of the packaging bucket tray 205 is provided with an arc-shaped limiting groove.

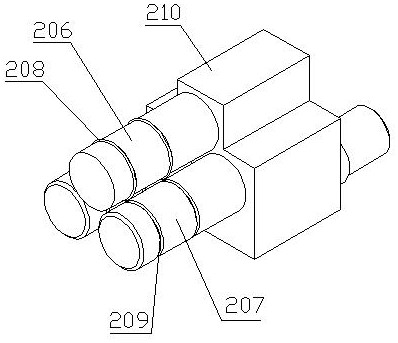

[0035] The three-axis spheronizing machine includes an upper roller 206, a pair of lower rollers 207 and a spheronizer body 210, a pair of reinforcing rib shaping protrusions 208 are arranged on the outer wall of the upper roller 206, and a pair of reinforcing ribs are formed on the lower roller 207. The rib shaping groove 209 used in conjunction with the shaping protrusion 208, one end of the upper roller 206 and a pair of lower rollers 207 are respectively movably installed on the spheronizer body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com