Full-automatic welding equipment for battery cover plate guide sheets

A fully automatic welding and battery cover technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as low welding efficiency, low assembly accuracy, and manual assembly human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

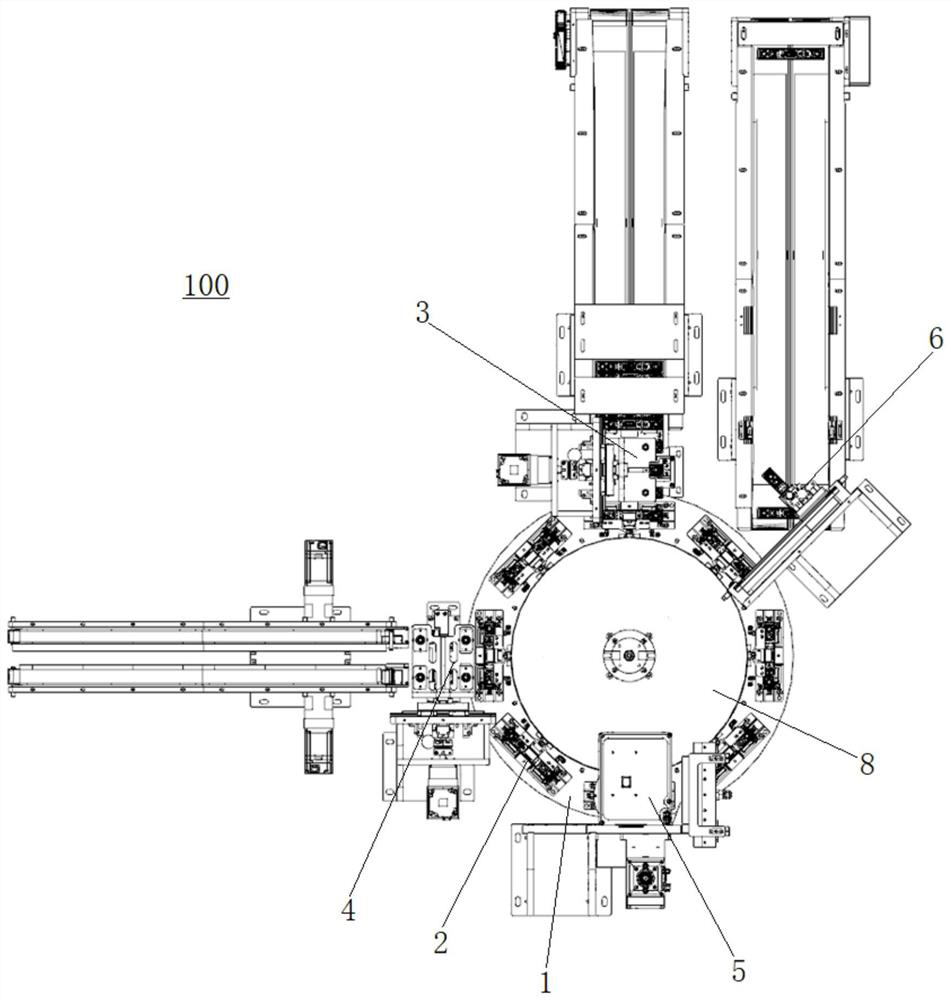

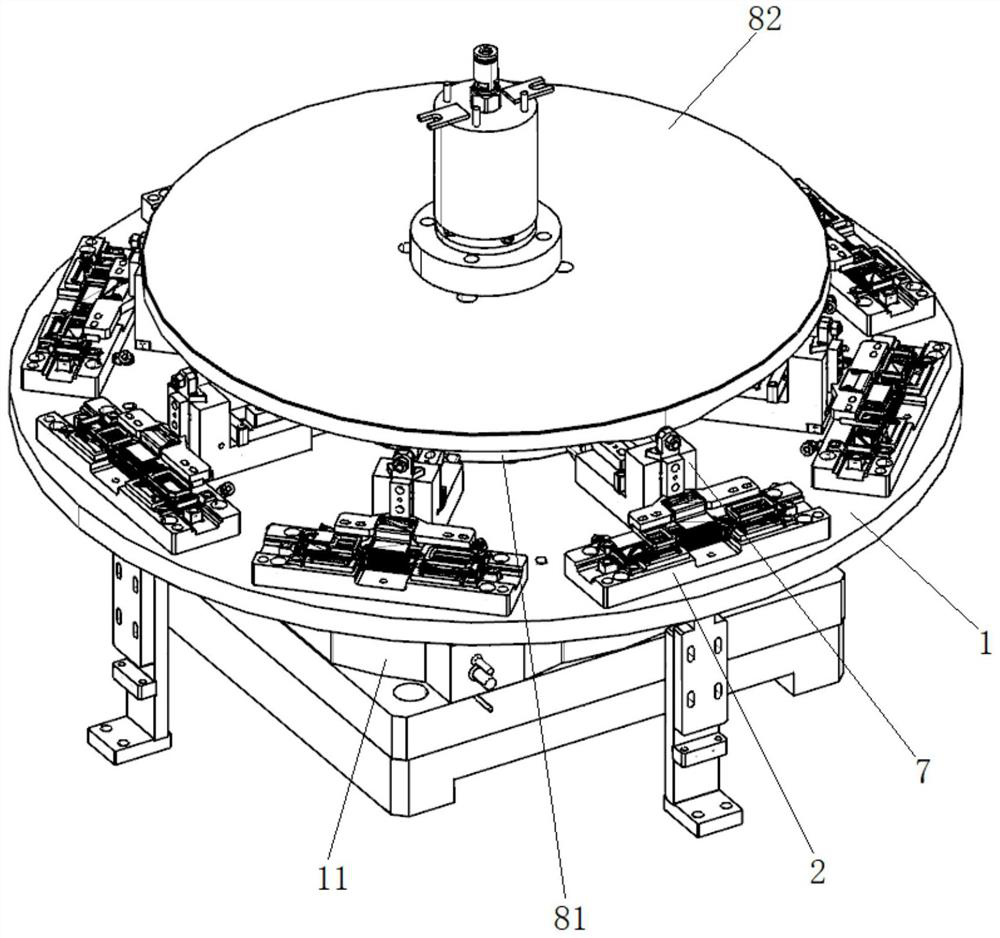

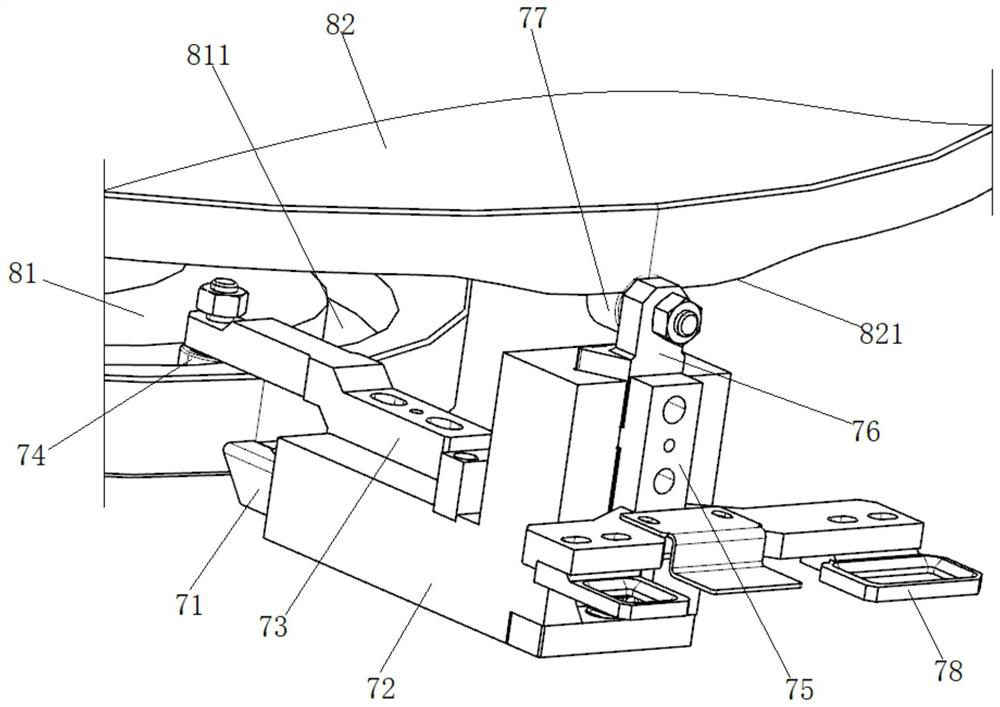

[0039] Please refer to Figure 1-Figure 10 , the present embodiment is a fully automatic welding equipment 100 for battery cover lead tabs, which includes a rotating disk 1 for rotating motion, a number of jigs 2 equiangularly distributed on the rotating disk 1, and a cover plate arranged around the rotating disk 1 Feeding and loading unit 3, positive and negative tab feeding and loading unit 4, laser welding module 5, and finished product unloading and conveying unit 6, and cover plate tabs corresponding to jigs 2 are arranged on the rotating disk 1 The pressing unit 7 is fixed above the rotating disk 1 and is fixedly provided with a cam unit 8 that drives the cover plate lead piece pressing unit 7 on the setting station to move forward and downward to compress the cover plate and the lead piece on the jig 2 .

[0040] The rotating disk 1 is rotated at an equal angle by the driving motor 11, so that the jig 2 stays at the set position.

[0041] The jig 2 includes a base 21 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com