Intelligent industrial robot device for recycling waste plastic bottle

A technology for industrial robots and waste plastics, applied in plastic recycling, recycling technology, chemical instruments and methods, etc., can solve problems such as the inability to separate the bottle body from the bottle cap, the lack of a trademark removal method, and the difficulty and inefficiency of the recycling process. , to achieve the effect of precisely removing the trademark function of plastic bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

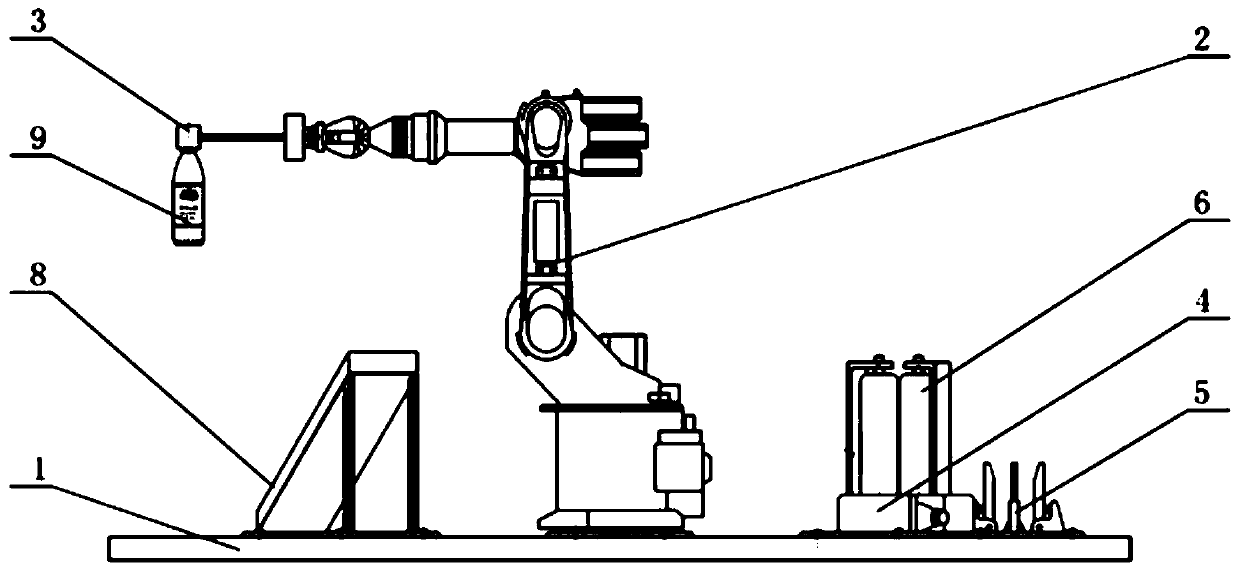

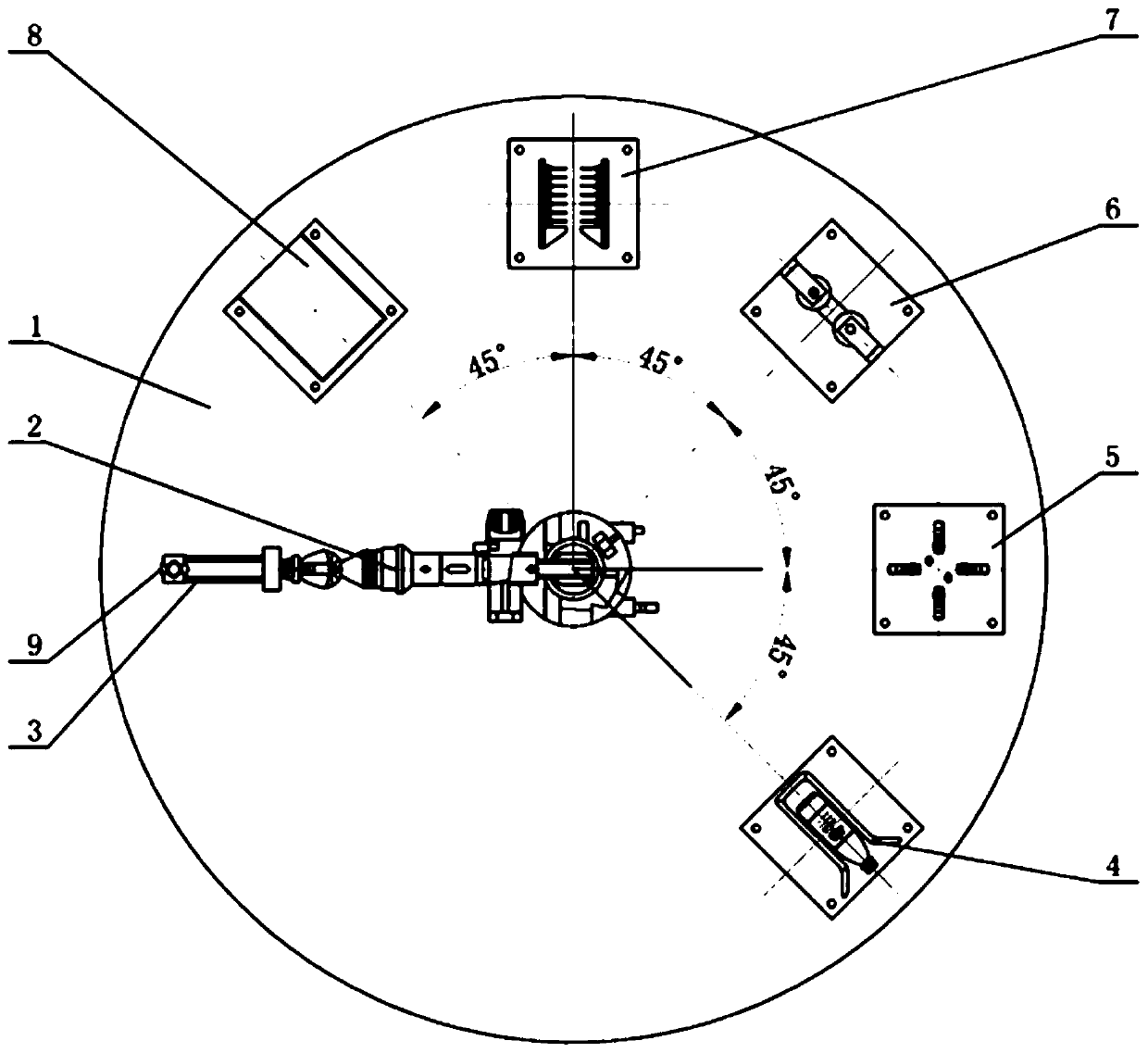

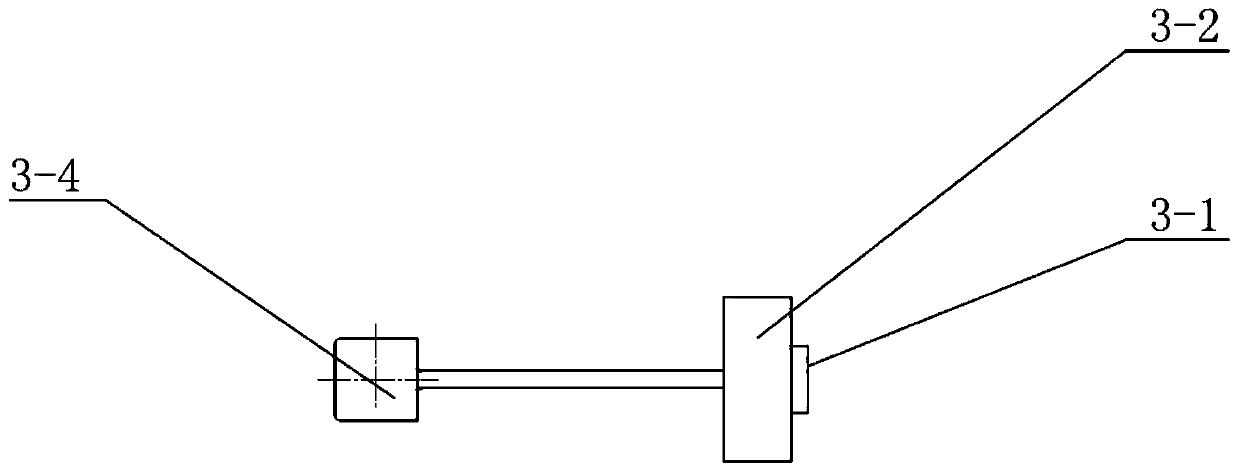

[0033] Referring to the accompanying drawings, an intelligent industrial robot device for recycling waste plastic bottles includes a base 1, a robot arm 2, a plastic bottle gripper 3, a waiting station fixture 4, a bottle cap removing station fixture 5, and a flattening station fixture 6 , remove the trademark station fixture 7, the blanking station fixture 8, the plastic bottle 9, set the machine arm 2 on the base 1 and be fixed on the base 1, set the plastic bottle gripper 3 at the front end of the machine arm 2 upper part, A plastic bottle 9 is set between the two jaws of the plastic bottle jaw 3, a waiting station fixture 4 is set on the right part of the base 1, a bottle cap removal fixture 5 is set on the right part of the base 1, and a bottle cap removal fixture 5 is set on the right part of the base 1. The flattening station fixture 6 is set on the upper right part, the trademark removal station fixture 7 is set on the upper part of the base 1, and the blanking station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com