Full-automatic detection device of performance of electric control valve

A technology of detection equipment and electric control valve, applied in sorting and other directions, to achieve the effect of improving detection efficiency, avoiding downtime and waiting, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

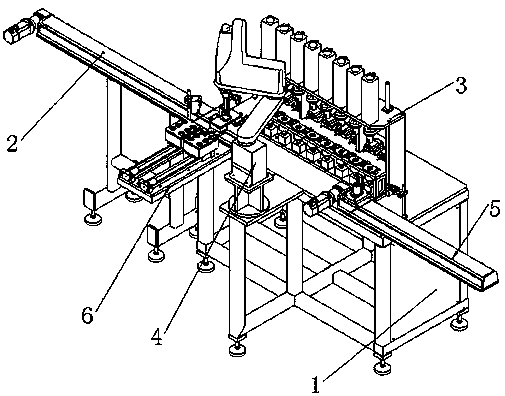

[0035] Such as figure 1 As shown, a fully automatic testing device for the performance of an electric control valve, its structure includes an equipment bracket 1, a feeding module 2, a testing module 3, a robot module 4, a blanking module 5 and a non-conforming product blanking module 6; wherein the loading module 2 is installed on the left end of the top upper surface of the equipment support 1, the unloading module 5 is installed on the right end of the top upper surface of the equipment support 1, and the detection module 3 is installed on the loading module 2 And between the blanking module 5, the robot module 4 is installed on the protruding part of the front side of the equipment support 1, and the unqualified product blanking module 6 is located on the side of the top edge of the equipment support 1 near the loading module 2.

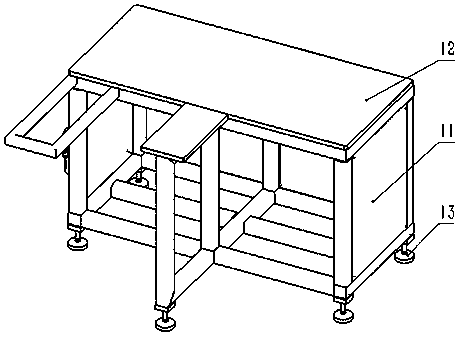

[0036] Such as figure 2As shown, the equipment bracket 1 includes a welding bracket 11, a large mounting plate 12 and a bracket foot 13, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com