Sand core and core shooting universal mold for cold box and manufacturing method thereof

A general-purpose mold and cold box technology, applied in the direction of manufacturing tools, cores, molding machines, etc., can solve problems such as high dimensional accuracy limitations, shorten the cycle time, and solve the efficiency of mass production and assembly line production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

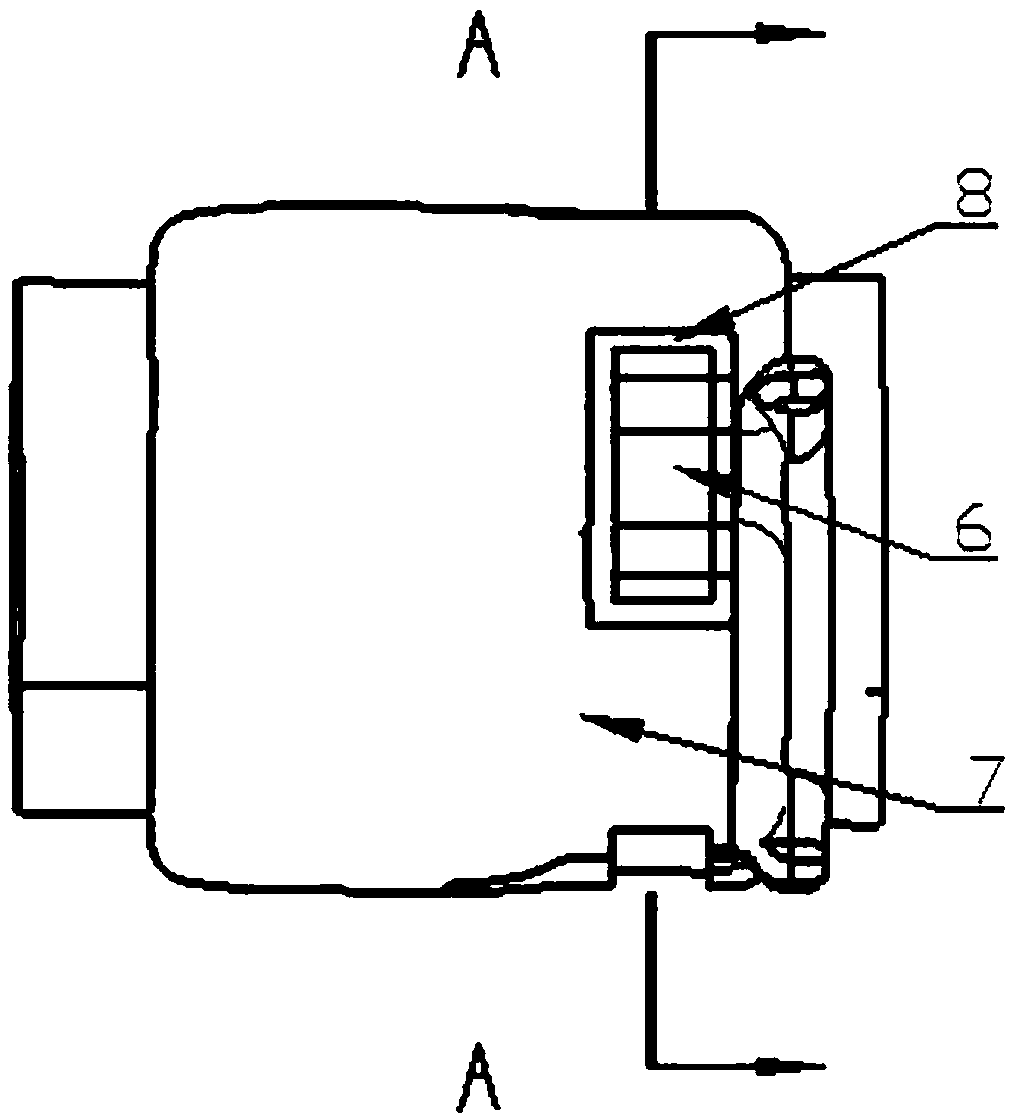

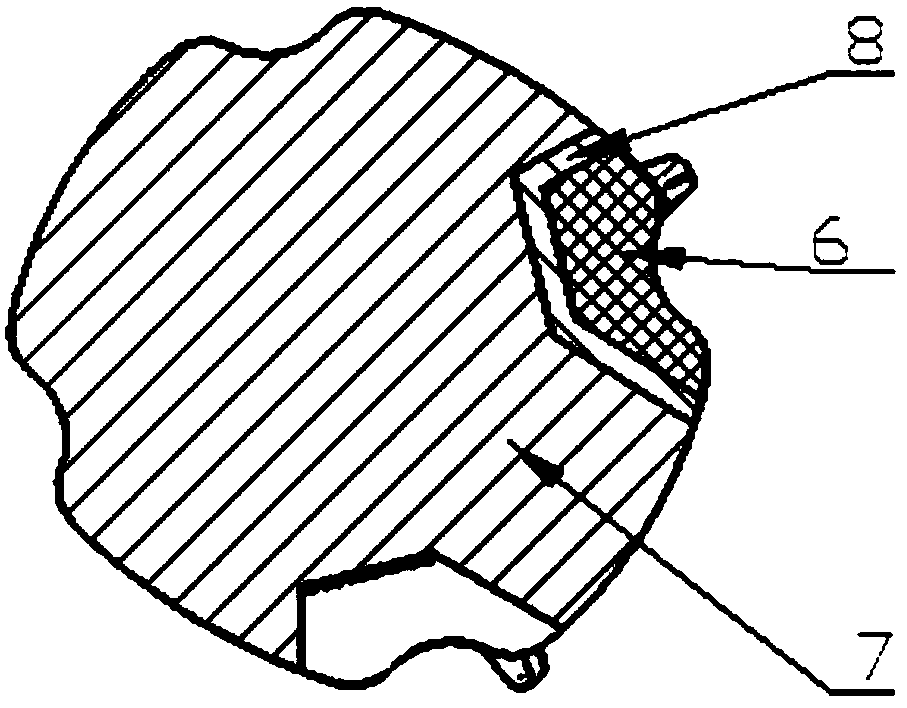

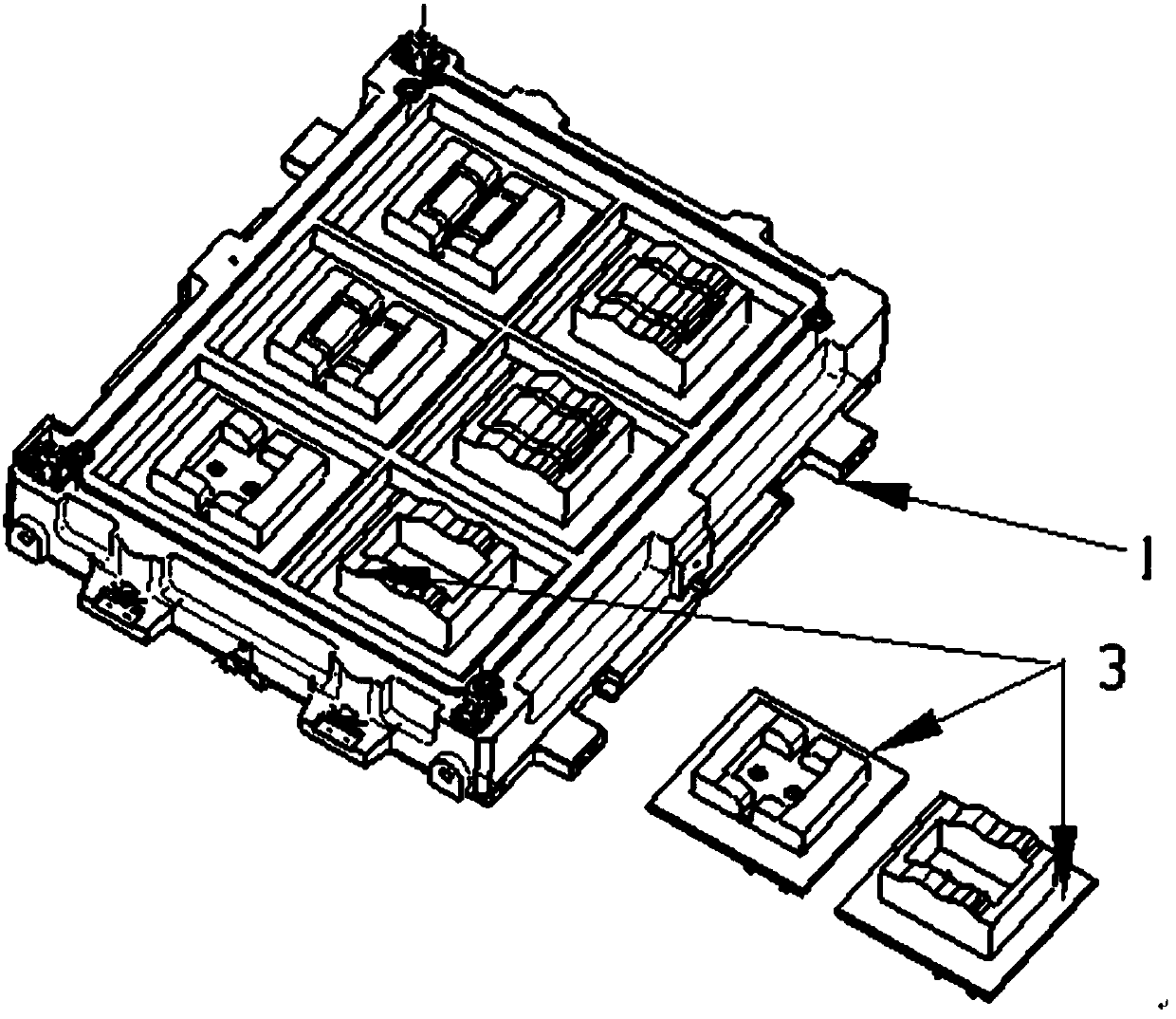

[0036] like figure 1 , figure 2 As shown, the present invention provides a sand core, including a sand core body and a chill iron 6 fixed on the sand core body, the sand core body includes a parent sand core 7 and a sub-sand core 8, and the sub-sand core 8 is embedded in on the parent sand core 7; the cold iron 6 is fixed on the sub-sand core 7.

[0037] The parent sand core can be made by cold box core shooting or 3D printing.

[0038] When using the cold box core shooting method to make the parent sand core, the secondary sand core is a sand body with a thickness of 5-30mm on the sand core body and in contact with the surrounding cold iron. The cold iron can be designed according to the conventional casting process plan. According to the structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com