Manual folding method and folding device for air bag

A folding device and folding method technology, which are applied in the directions of transportation and packaging, pedestrian/occupant safety arrangement, vehicle safety arrangement, etc., can solve the problems of expensive equipment, cumbersome folding method, large floor space, etc., and save time and weight. Light, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

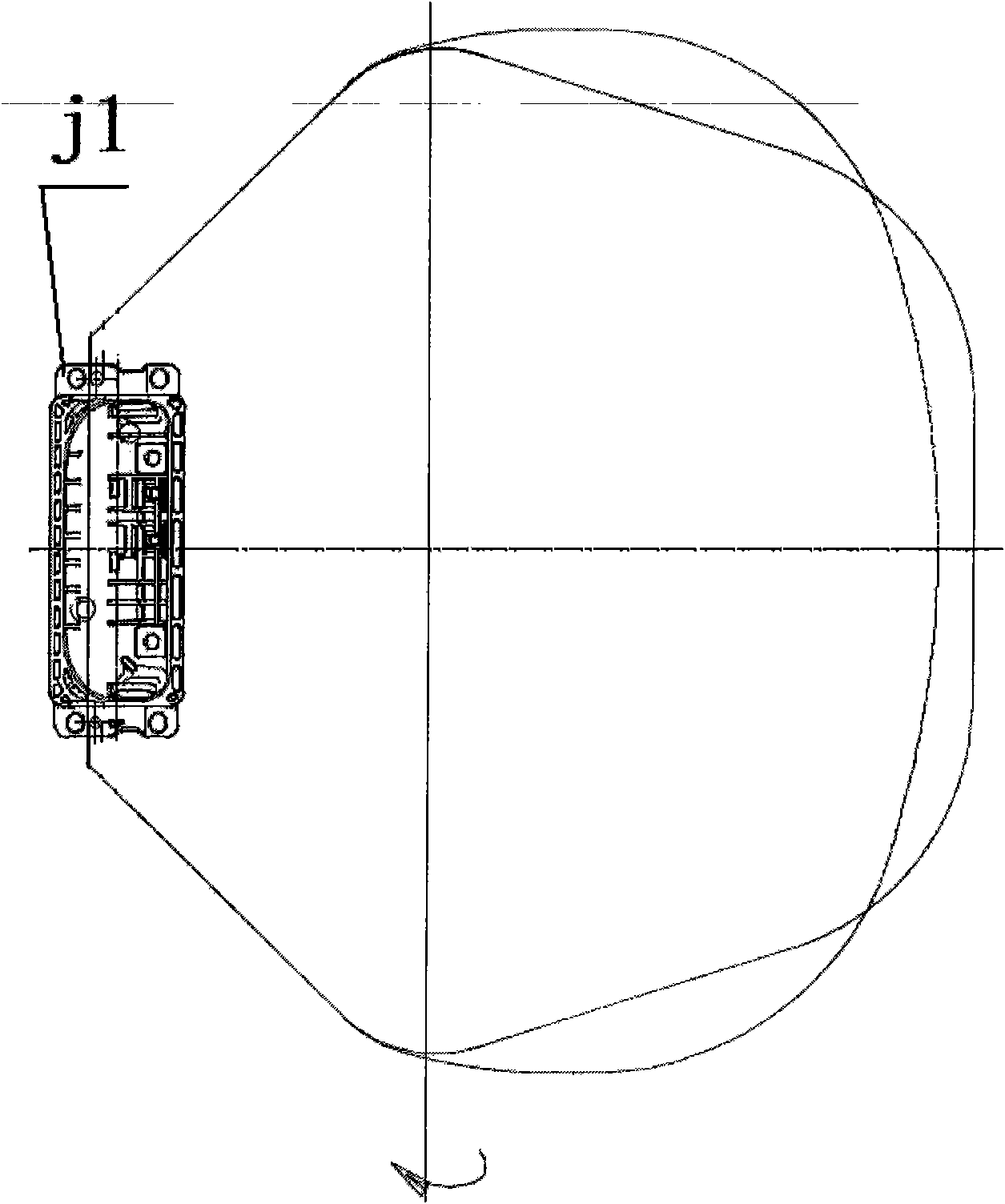

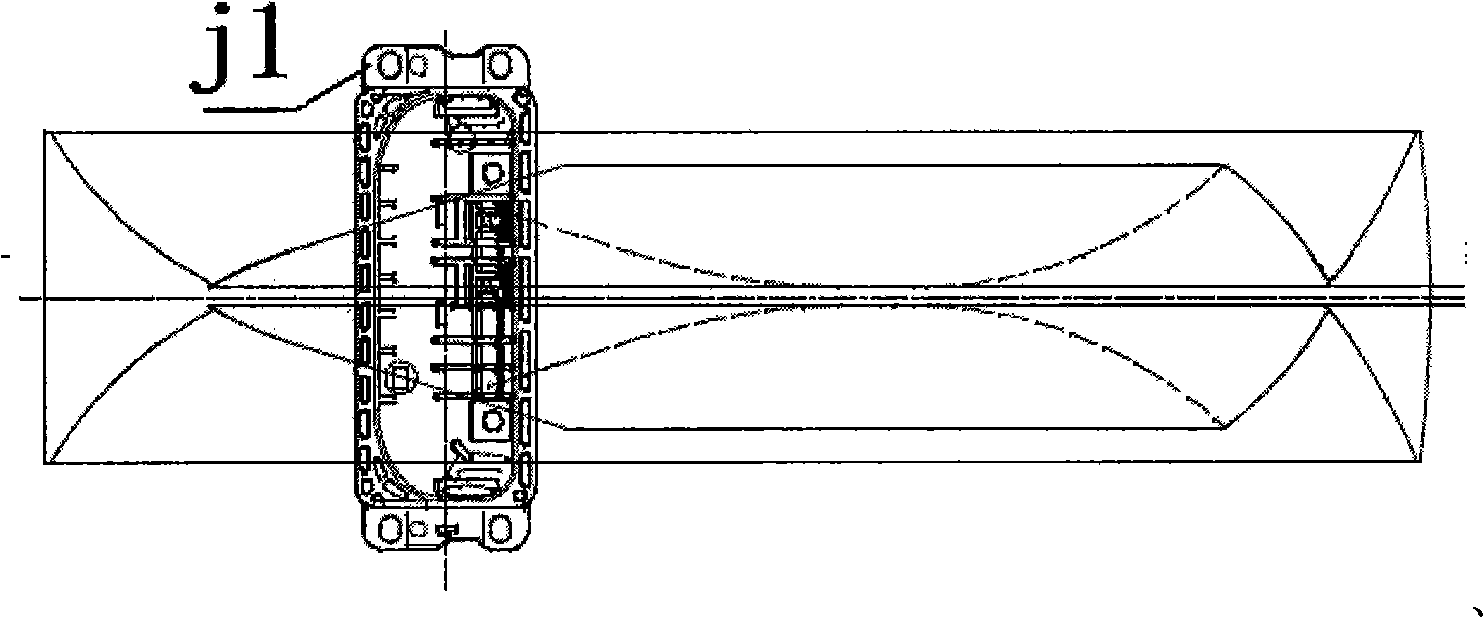

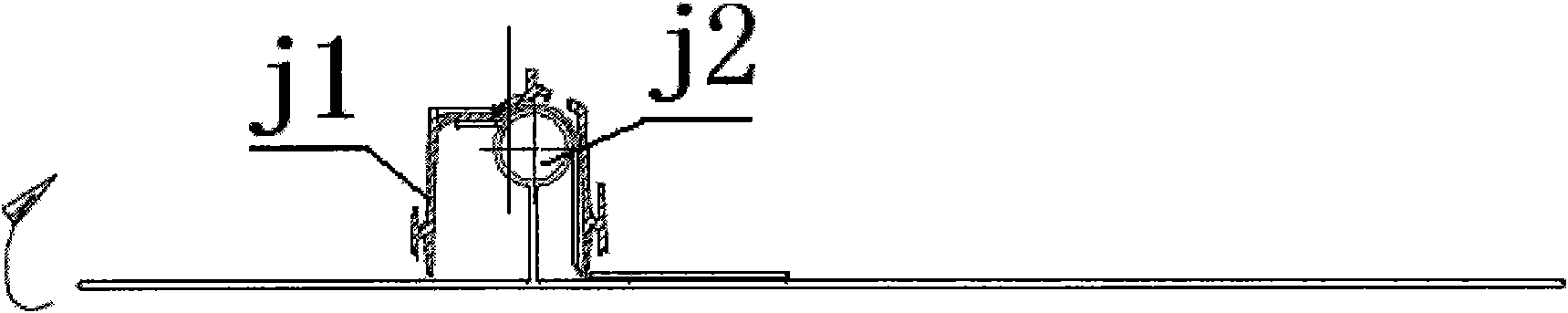

[0050] Airbag manual folding method of the present invention, as figure 1 As shown: Step 1, fold the horizontally spread air bag longitudinally once, adjust the position of the air bag on the workbench, and make the left and right pieces of the airbag symmetrical along the center line of the workbench; figure 2 Shown: In the second step, along the center line, stack the left air bag twice and fold the right air bag twice to reduce its transverse width. After this step, the air bag is folded into a rectangle; The second step is folded into a rectangular airbag, and the folded rectangular airbag is divided into an upper piece and a lower piece in the longitudinal direction, and the longitudinal length of the upper piece is greater than the longitudinal length of the lower piece; as image 3 Shown: the third step is to start folding from the longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com