Automatic calibration assembly line for measuring instruments

A technology for automatic verification and measuring instruments, which is applied in the direction of instruments, measuring devices, and measuring electrical variables. It can solve the problems of reducing the verification efficiency of the verification assembly line and uneven busyness, so as to facilitate daily maintenance and regular testing, and reduce uneven busyness. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

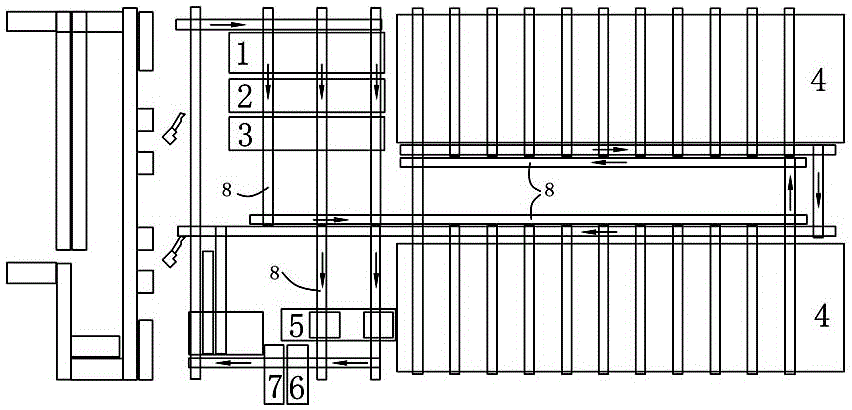

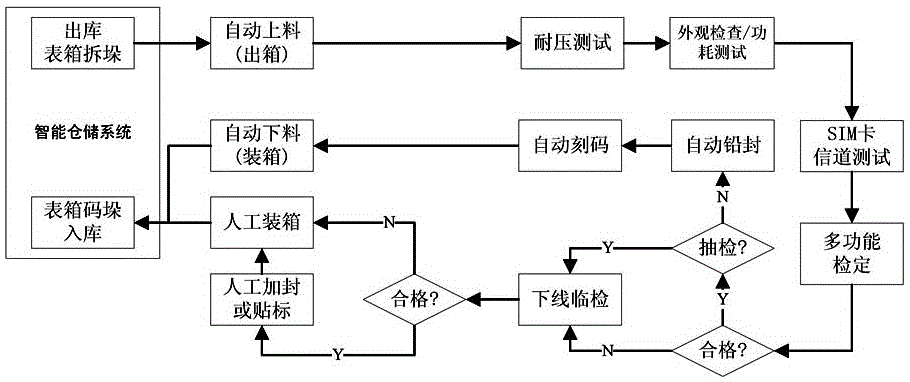

[0019] like figure 1 As shown, the automatic verification assembly line for measuring instruments in this embodiment is mainly aimed at the automatic verification of electric energy meters, including the transport track 8 and the withstand voltage test station 1 installed on the transport track 8, the appearance test station 2, and the power consumption test station. Station 3, multi-function verification station 4, automatic lead sealing station 5, automatic code engraving station 6 and automatic labeling station 7, automatic lead sealing station 5, automatic code engraving station 6 and automatic labeling station 7 are arranged in sequence along the conveying direction of the conveying track 8, the withstand voltage test station 1, the appearance inspection station 2, the power consumption test station 3 and the multi-function verification st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com