Coating method and coating device

A coating and loading technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of time-consuming processing, low practicability, lack of stability, etc., and achieve the effect of shortening the cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

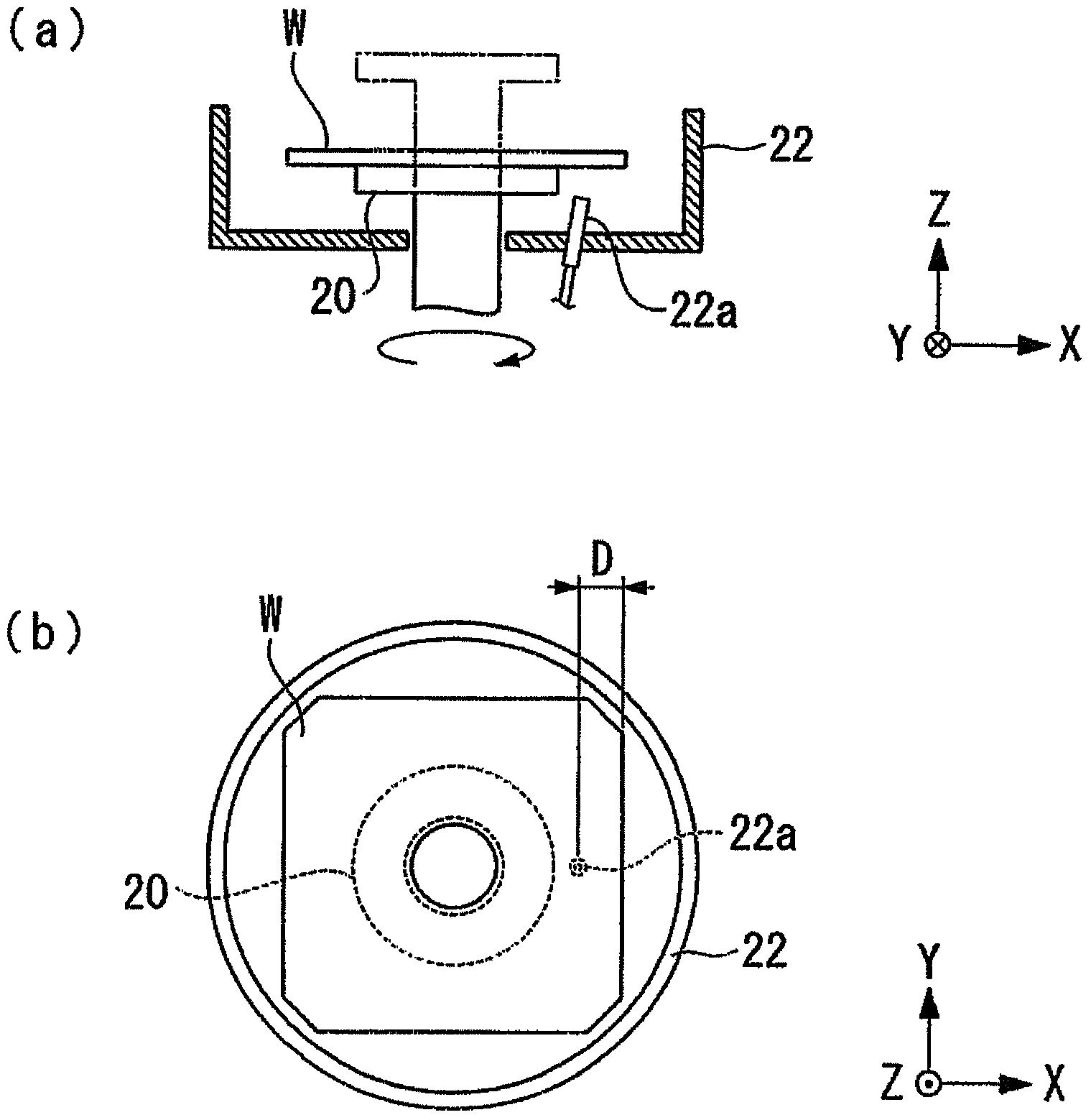

[0061] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

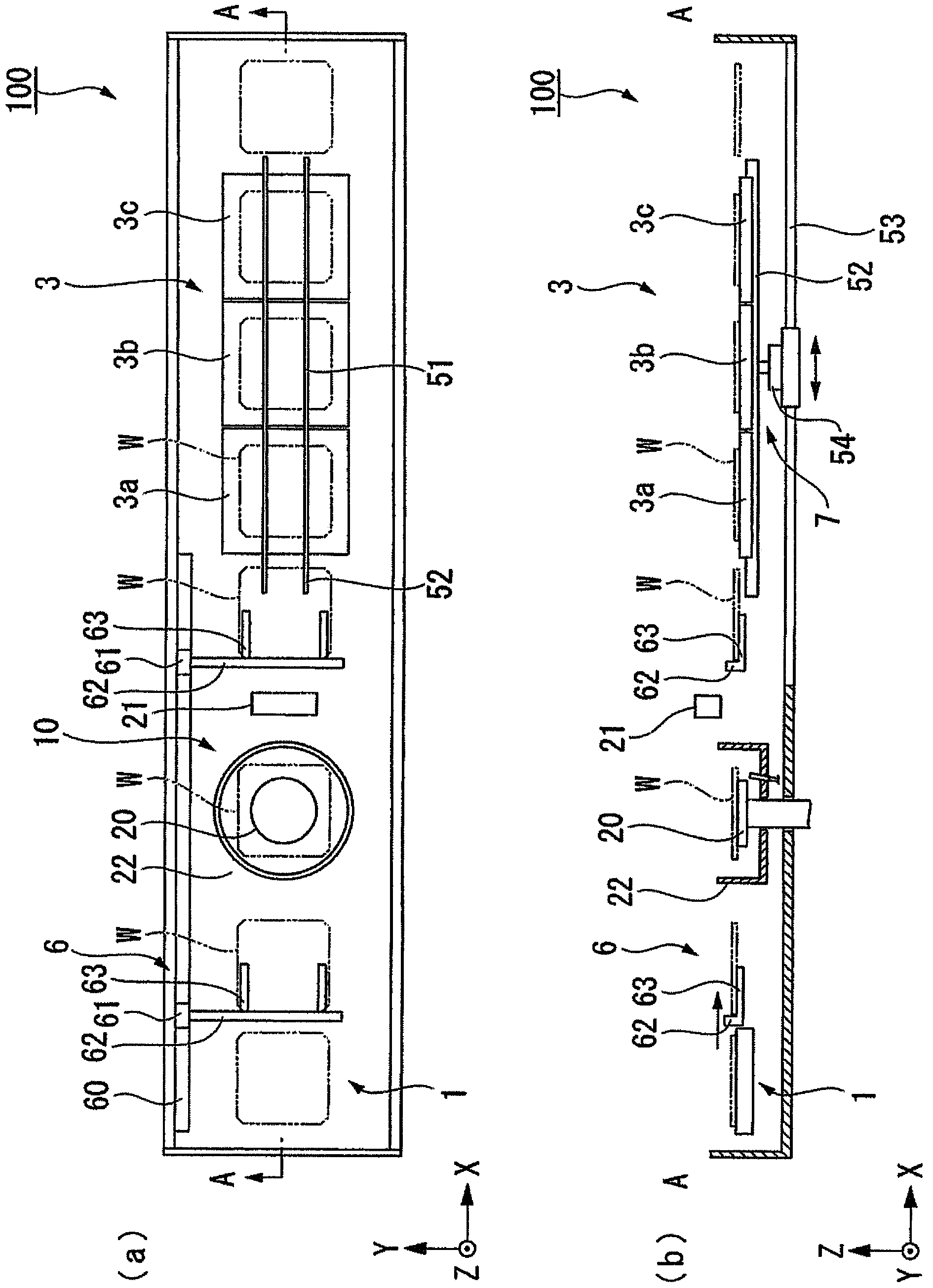

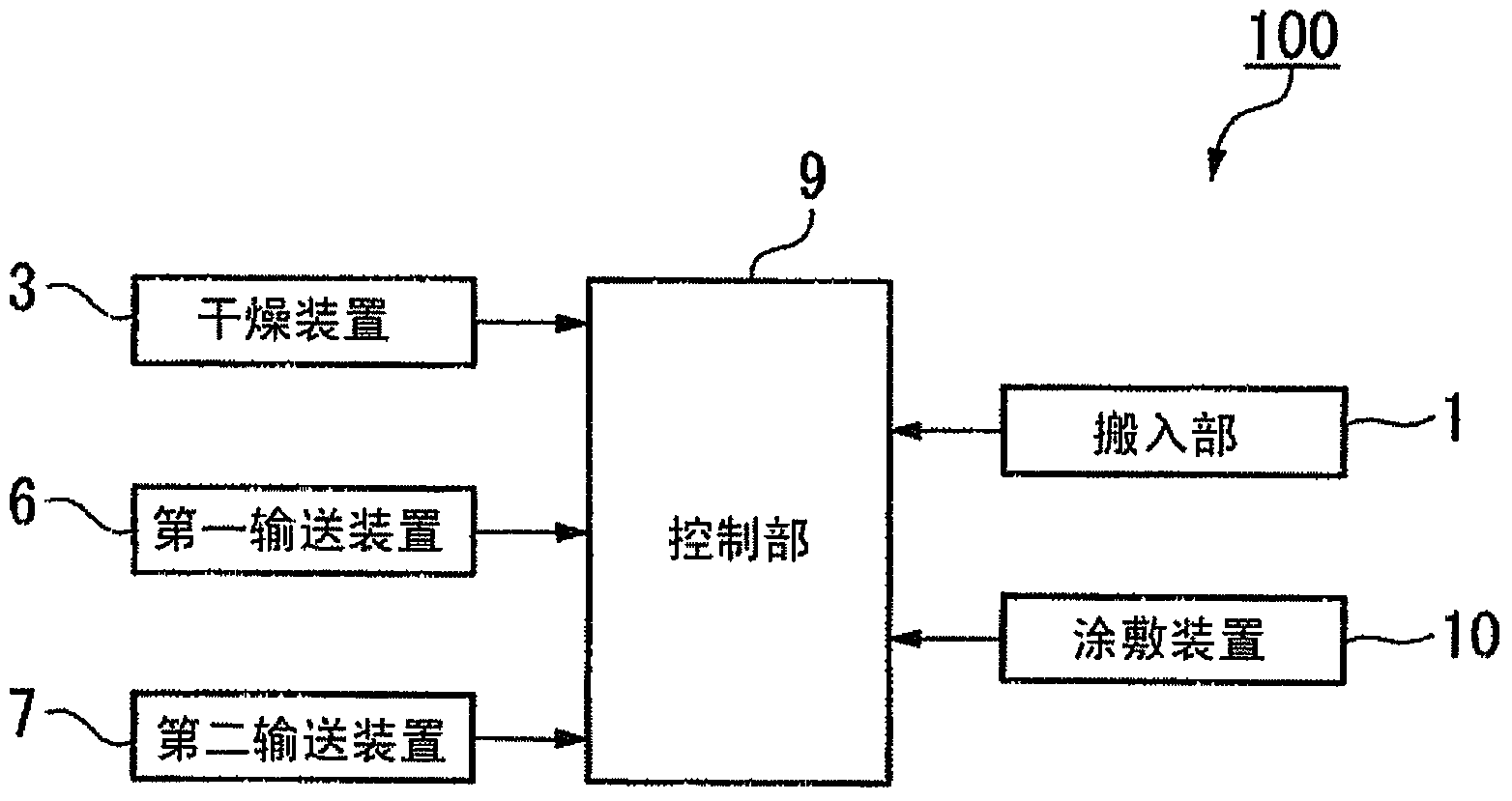

[0062] figure 1 (a) is a top view of a substrate processing apparatus including a coating apparatus of the present invention, figure 1 (b) is figure 1 (a) A cross-sectional view taken along line A-A. figure 2 It is a block diagram showing the electrical configuration of the substrate processing apparatus 100 . The substrate processing apparatus of the present embodiment is an apparatus for applying and drying a diffusion material for diffusing impurities on a solar cell substrate constituting a solar cell. Substrate) coated with diffusion material and used.

[0063] Hereinafter, when describing the structure of the substrate processing apparatus 100 , for the sake of simplicity of description, the directions in the drawings will be described using the XYZ coordinate system. The longitudinal direction of the substrate processing apparatus 100 , that is, the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com