Intelligent flexible automatic assembly system for drill bit assembly

A flexible and automatic assembly technology, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency and narrow applicability of parts assembly, so as to improve production efficiency, quality, and precise assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

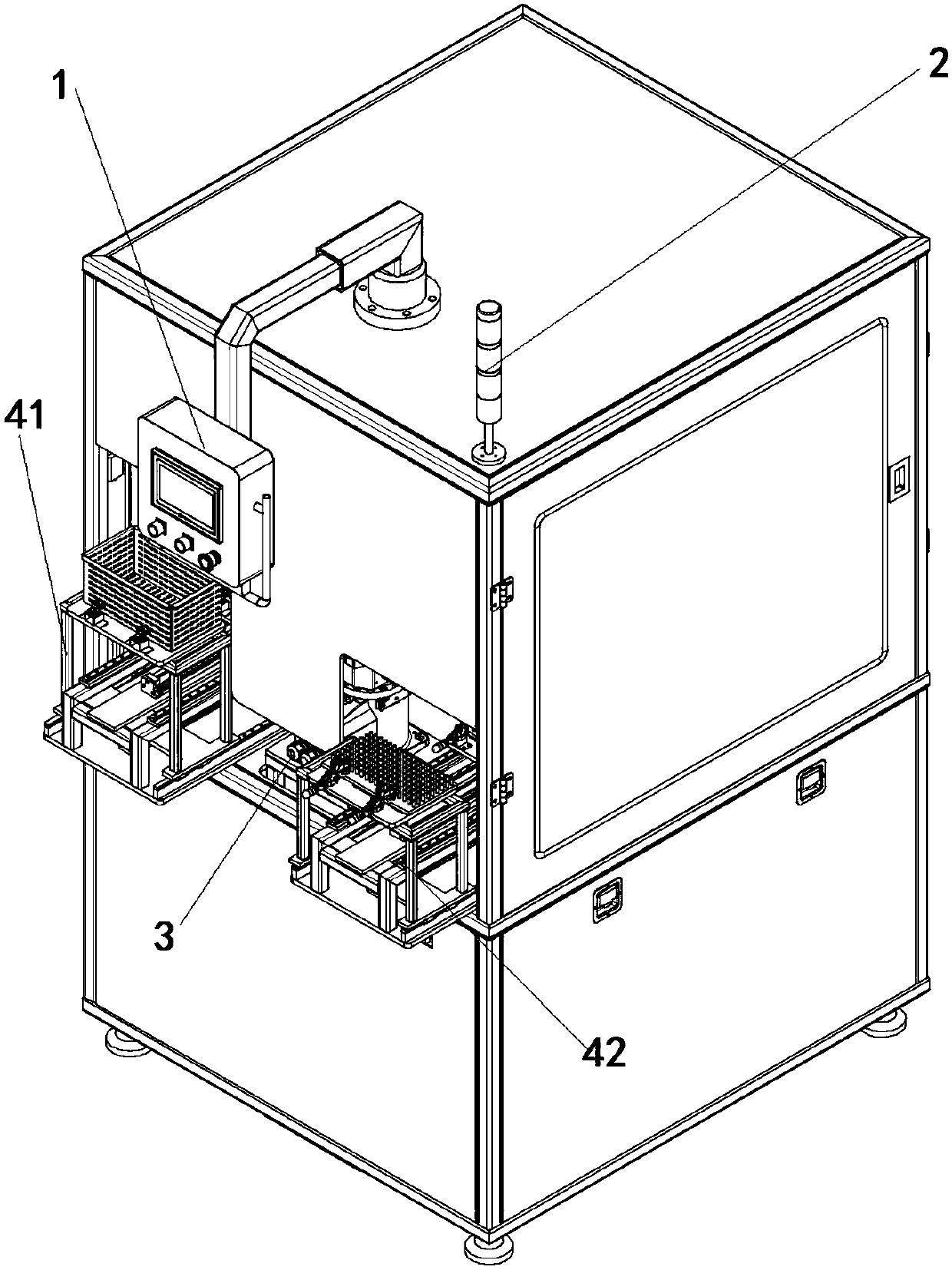

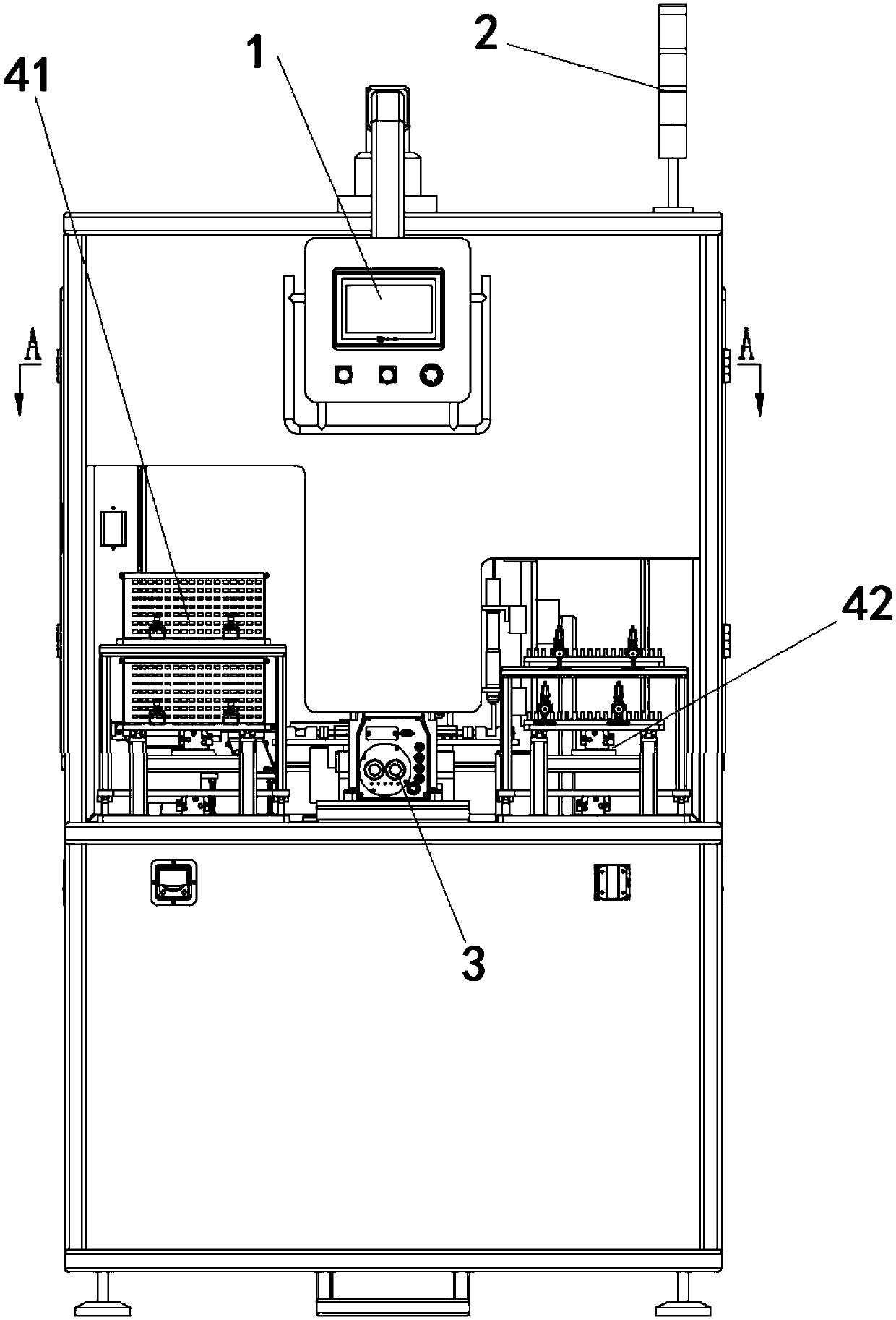

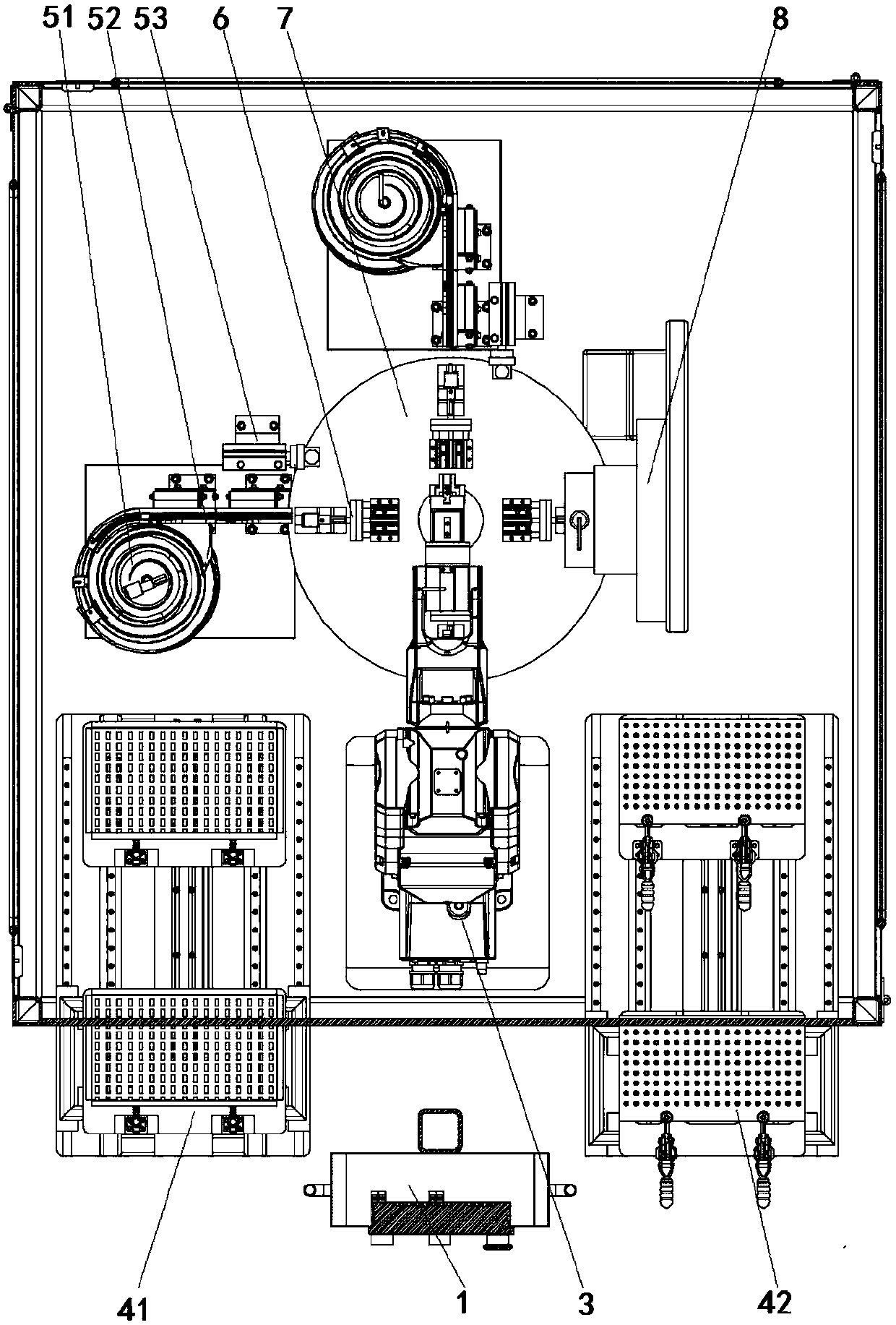

[0039] Such as Figure 1 to Figure 3 As shown, in this embodiment, the predetermined angle is set to 90°. The rotary disk mechanism 7 needs four rotation actions during a complete technological process, that is, four pauses, so as to complete four process assembly actions. The first discharge assembly, the second discharge assembly, an automatic screw-tightening mechanism 8, and a robot system 3 are arranged in turn clockwise (in other embodiments, it can also be counterclockwise) near the rotating disk. Circumferential position of mechanism 7 . Four jig assemblies 6 are arranged on the rotating disk mechanism 7 .

[0040] The first part of the assembly comes out through the discharge channel 52 of the first discharge assembly, and is grabbed by the first transfer mechanism and put into the jig 12 on the rotating disk mechanism 7 . Then, the rotary disk mechanism 7 is rotated by 90°, so that the jig 12 reaches the second discharge assembly. The second part of the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com