Sample digestion processing device

A technology for processing devices and samples, applied in the field of sample digestion and processing devices, can solve the problems of inaccurate control of solvent or sample addition, human and environmental hazards, low digestion efficiency, etc., to accelerate complete dissolution and mutual reaction, and shorten the digestion process. , the effect of eliminating human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

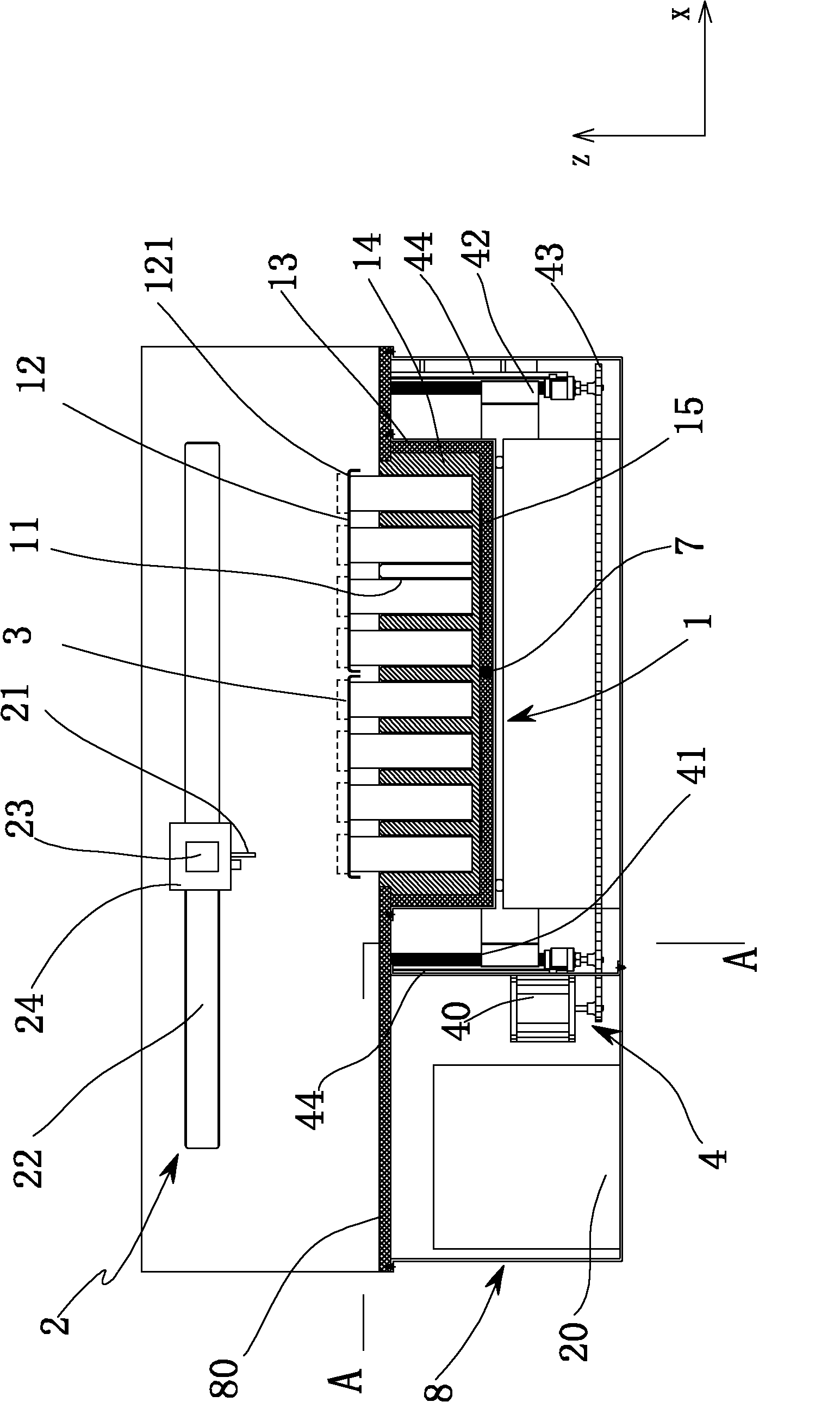

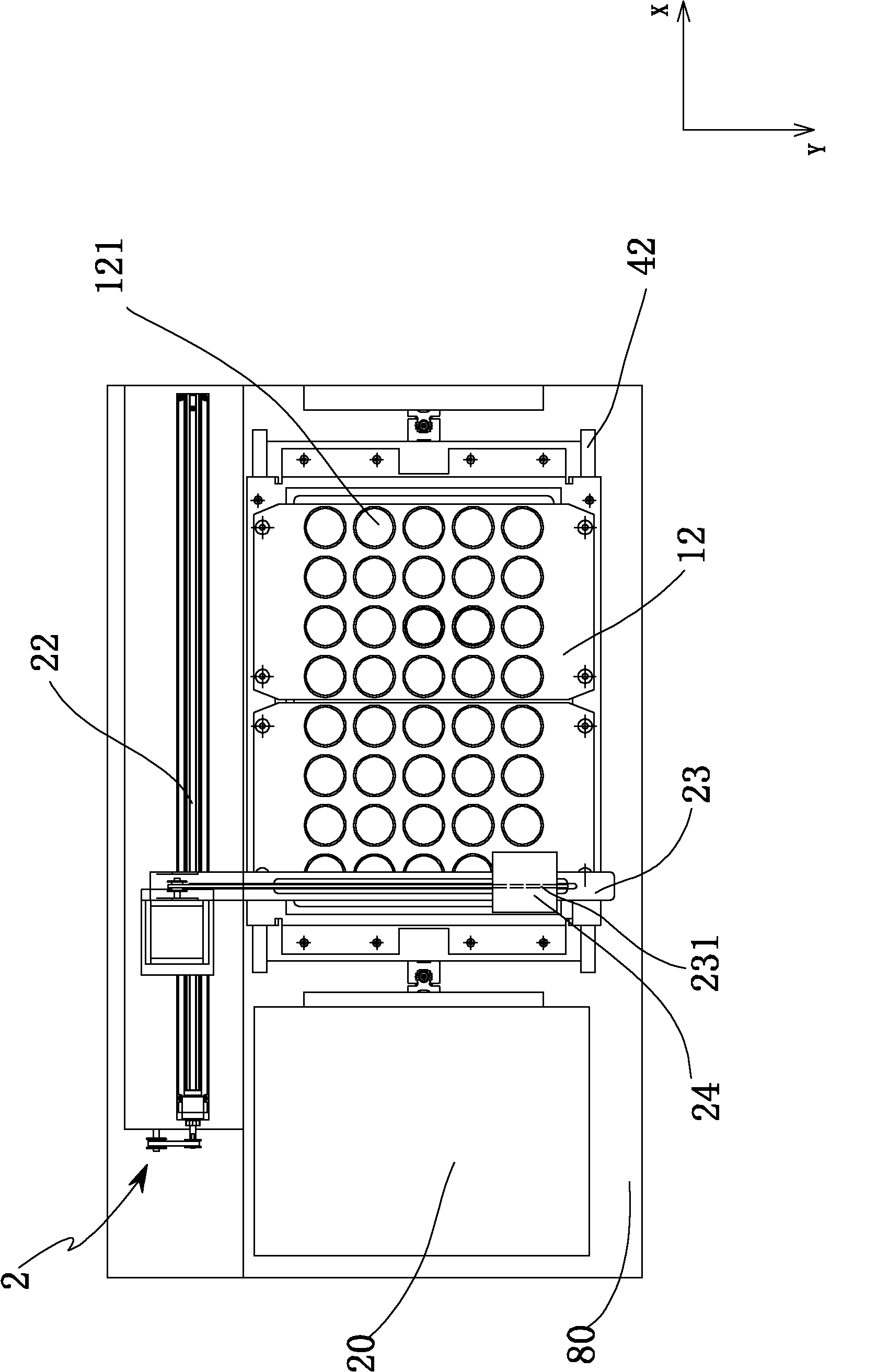

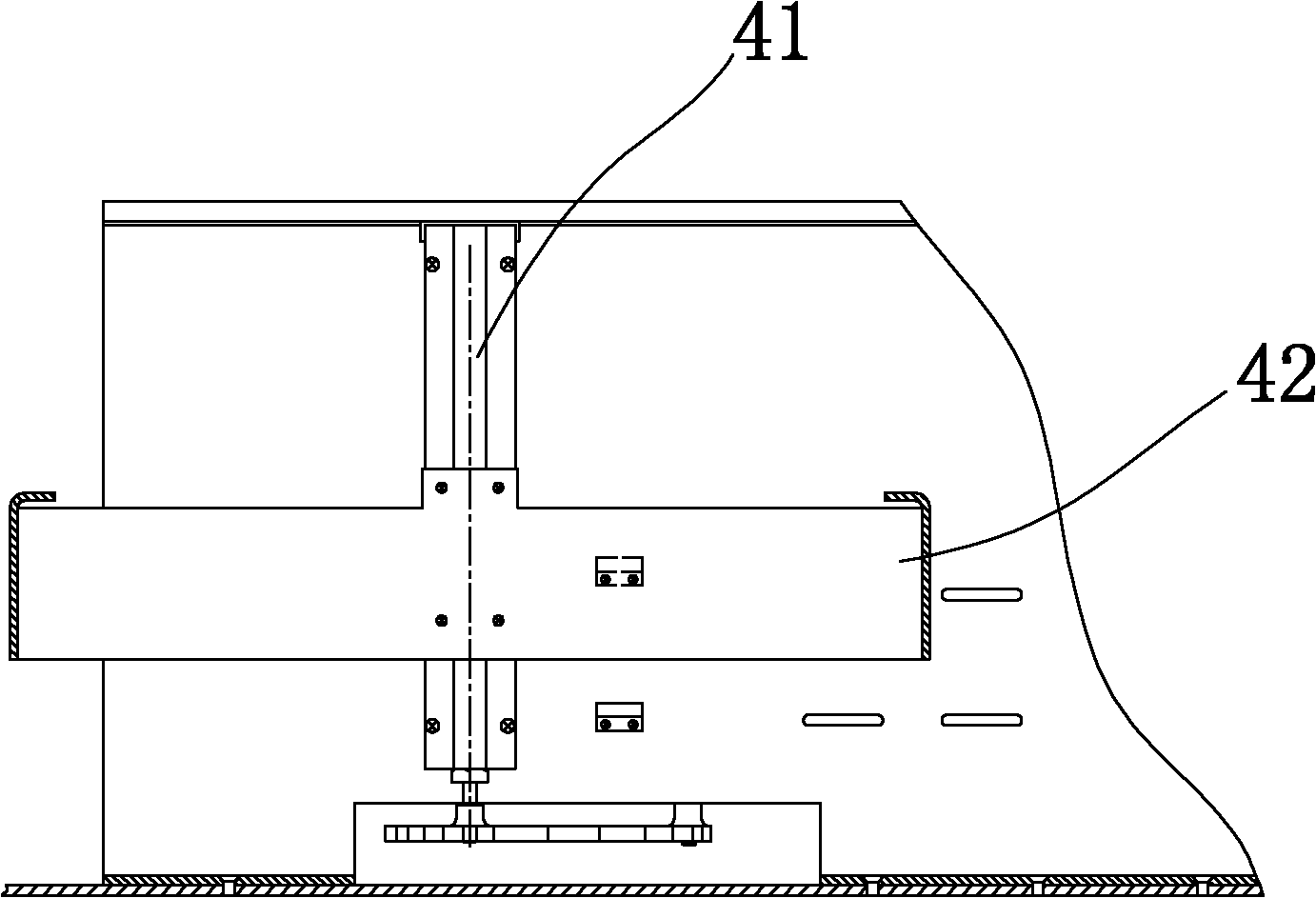

[0049] figure 1 is a schematic front view of the sample digestion device of the present invention; figure 2 is a schematic top view of the sample digestion device of the present invention; image 3 is along figure 1 A schematic cross-sectional view of line A-A in the center; Figure 4 is a schematic side view of the sample digestion device of the present invention; Figure 5 yes Figure 4 Schematic diagram in direction B; Figure 6 is along Figure 5 The schematic cross-sectional view of the C-C line in the middle, in order to clearly show the connection relationship between the test tube rack and the oscillation mechanism, in Figure 6 Other parts are not indicated in Figure 7 It is a structural schematic diagram of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com