Valve rod automatic checkout device

An automatic detection device and valve stem technology, which is applied in the direction of measuring devices, instruments, sorting, etc., can solve the problems of high cleanliness requirements on the workpiece surface, deviation of the center line of the valve stem, inaccurate measurement data, etc., and achieve omission of cleaning process, improve efficiency, and improve the effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

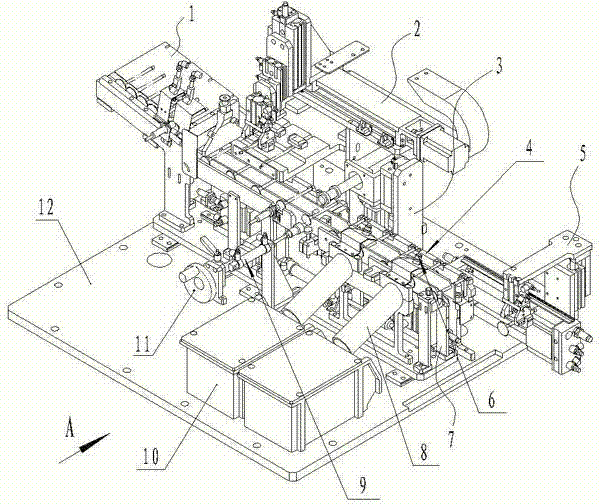

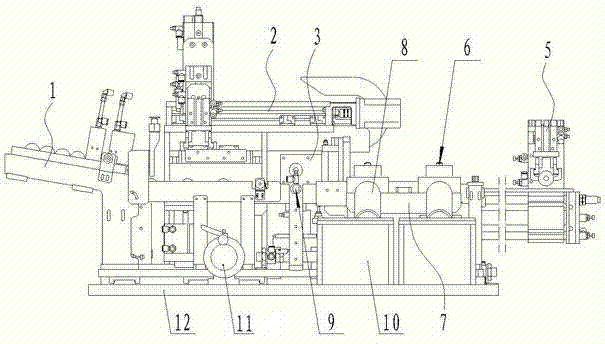

[0045] There are feeding mechanism 1, feeding mechanism 7, measuring mechanism 3 and positioning mechanism on the machine platform 12 (see Figure 1~2 ),in:

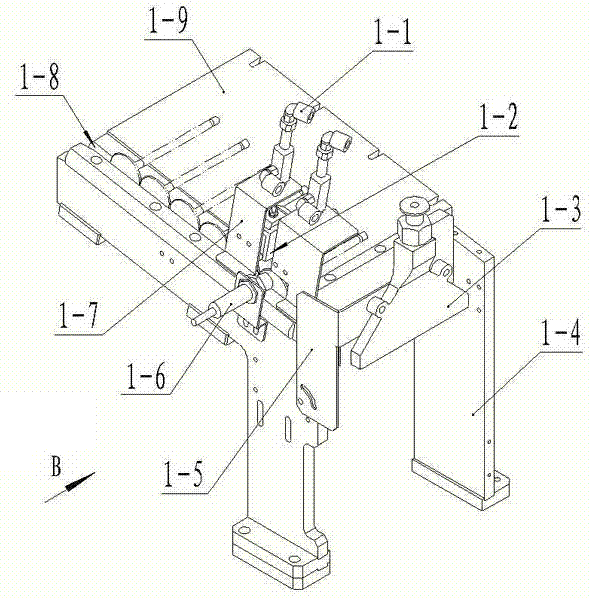

[0046] The specific structure of feeding mechanism 1 is as Figure 2-5As shown: it consists of a support plate 1-9 fixed obliquely on the machine platform 12 through the first bracket 1-4, and two distribution cylinders 1-1 fixed on the support plate through the fixing frame 1-7 respectively. 1. The material retaining ram 1-2 fixed on the piston rod of each distribution cylinder 1-1 respectively, and the proximity switch 1-6 fixed on the first bracket 1-4 are formed, and the surface of the supporting plate 1-9 is guided Slots 1-8.

[0047] Feeding mechanism 7 is positioned at the right side of material supporting plate 1-9, and its specific structure is as follows: Figures 15-18 Shown: it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com