Method for automatically correcting difference of meter calibration machines by means of comparison

A technology of automatic comparison and meter calibration machine, applied in the field of meter calibration, can solve the problems of low efficiency, time-consuming and laborious, errors in calibration results, etc., and achieve the effect of high efficiency and accurate calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

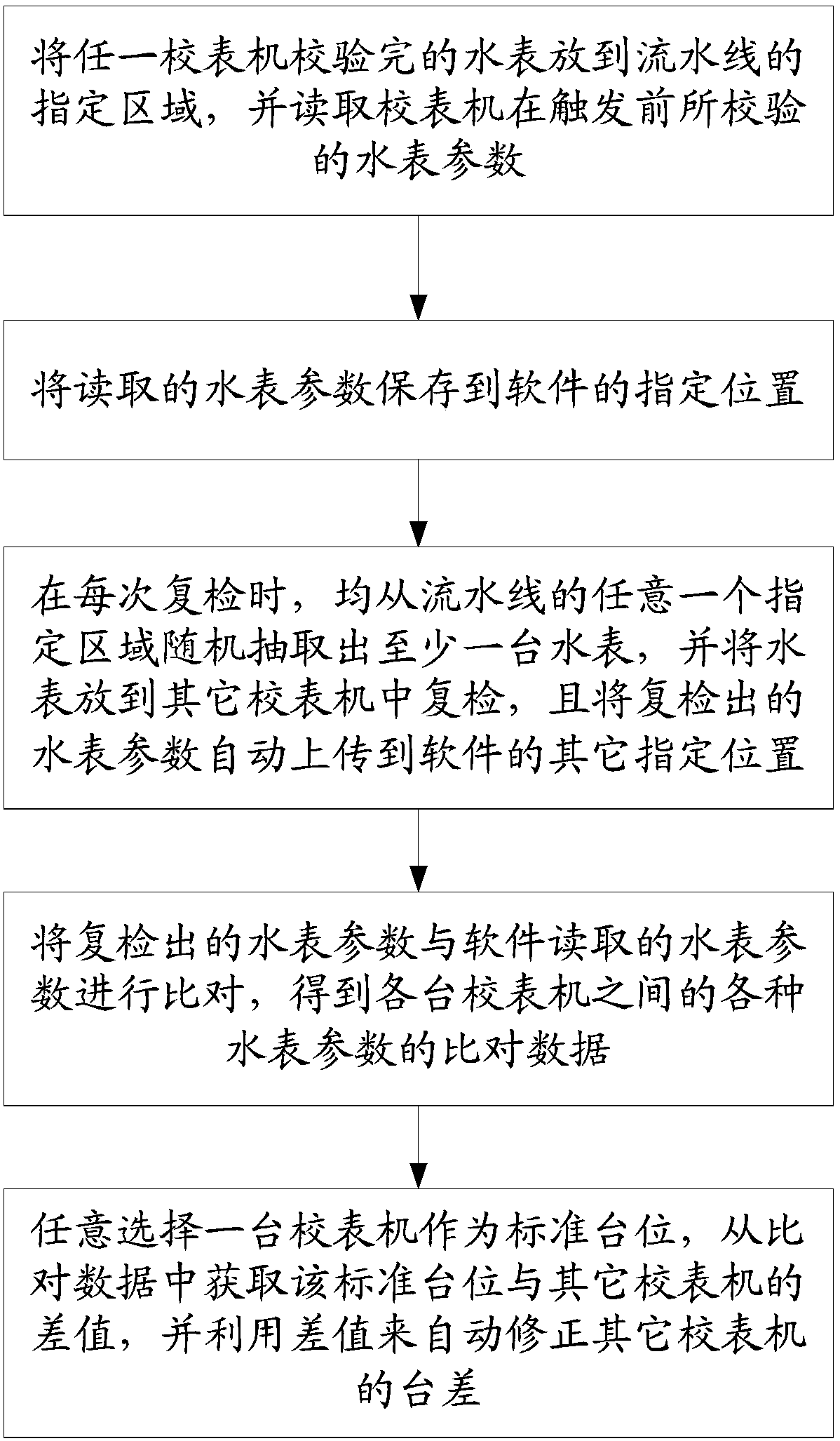

[0016] Please refer to figure 1 As shown, a preferred embodiment of the method for automatically comparing and correcting the table error of a meter calibration machine in the present invention, the method includes the following steps:

[0017] Step S1. After any meter calibrating machine has calibrated a string of water meters, place the string of water meters in a designated area on the assembly line, and trigger the software to read the water meter parameters calibrated by the meter calibrating machine before triggering;

[0018] In the step S1, the trigger software reads the water meter parameters verified by the meter calibration machine before triggering, specifically: the trigger software reads the water meter parameters verified by the meter calibration machine within 8 to 10 minutes before triggering . Since it takes about 6 to 8 minutes for the meter calibrator to complete a string of water meters, the present invention sets the reading time to 8 to 8 minutes before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com