Cylinder cover positioning and clamping device in the process of finish-milling top surface of cylinder cover

A technology for positioning clamping and cylinder head, which is applied in the direction of positioning device, clamping, milling machine equipment, etc., can solve the problem of the change of the positioning point of the boss, and achieve the effects of small change and deformation, reliable clamping, convenient and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

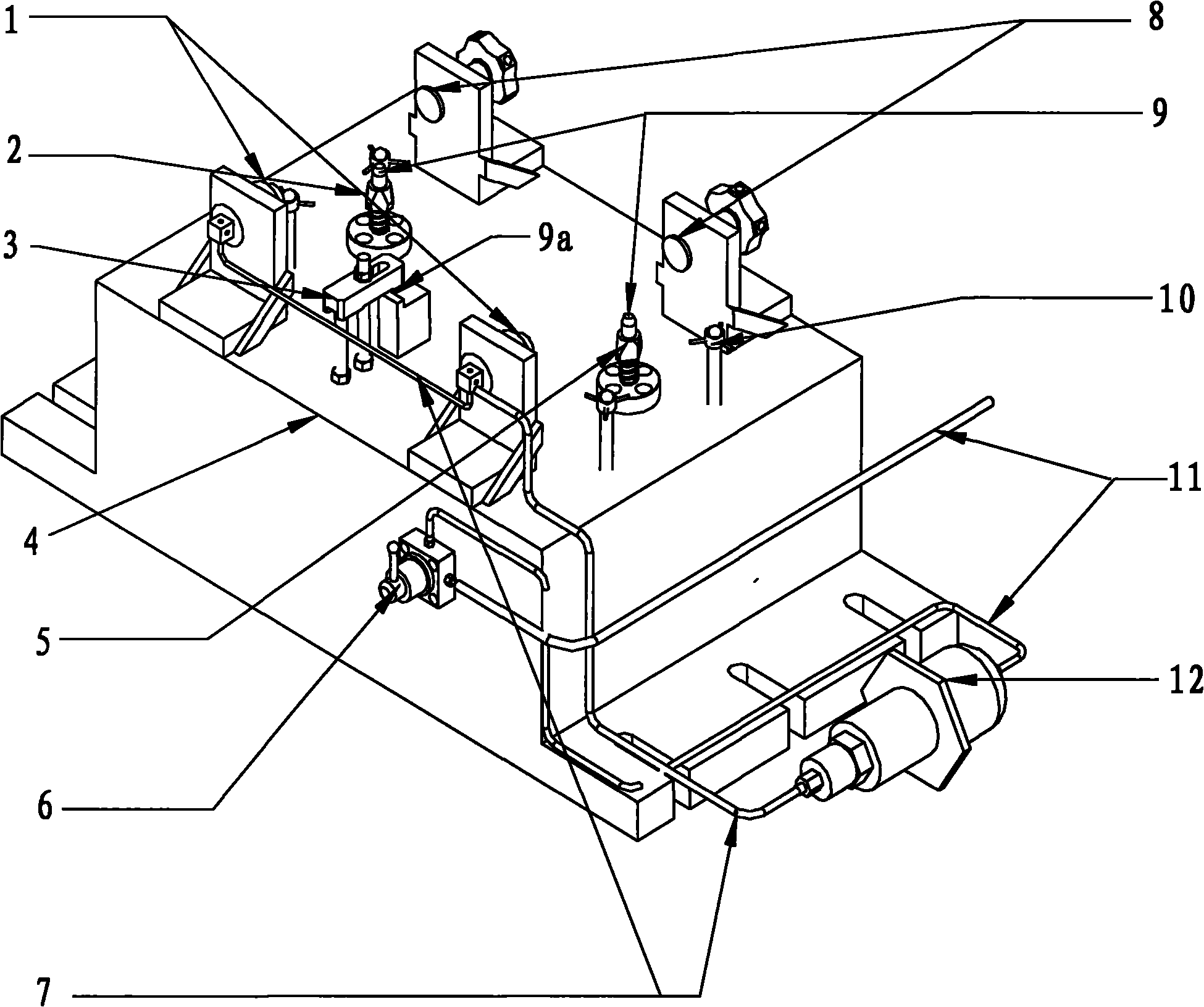

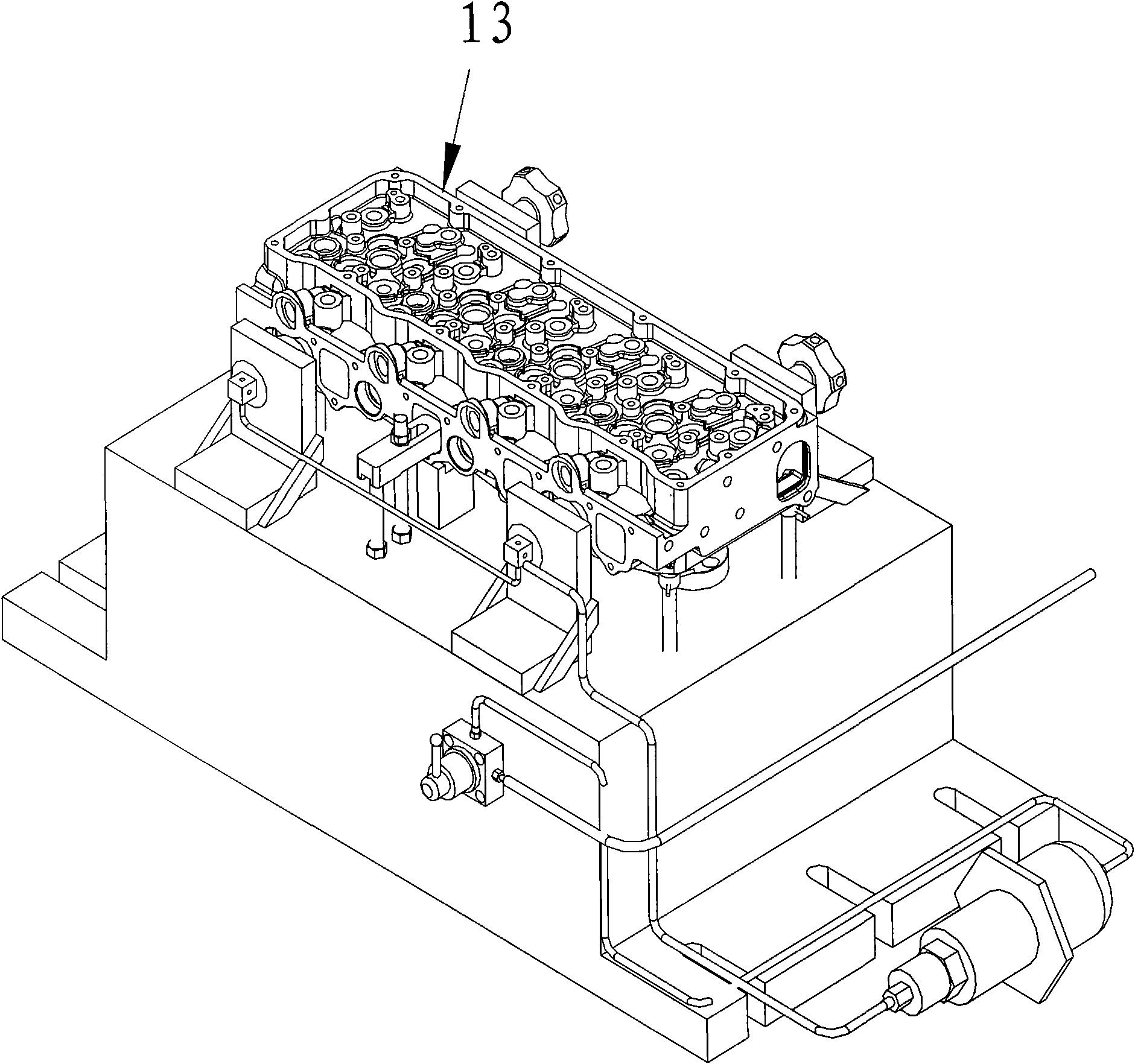

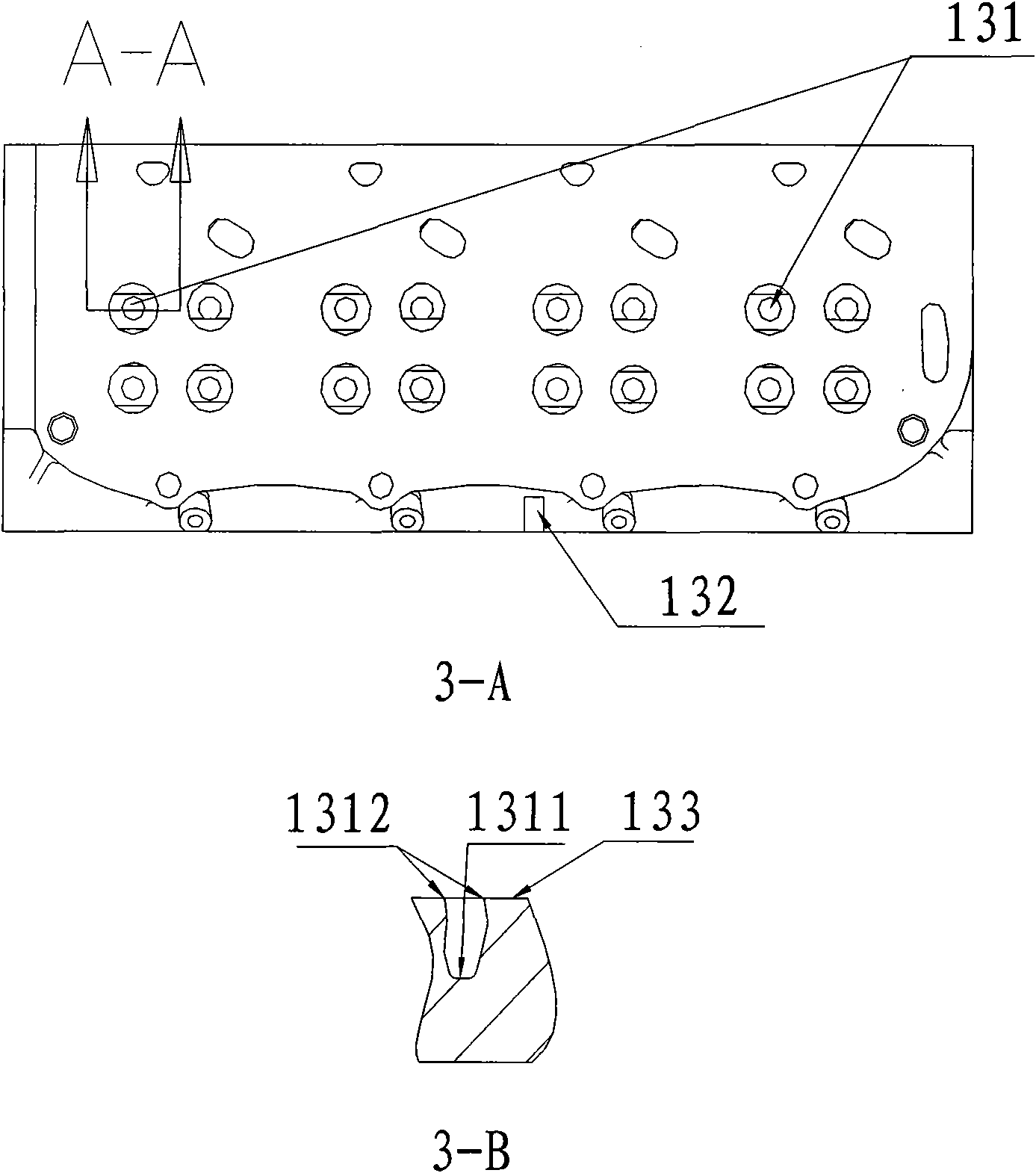

[0014] Such as figure 1 As shown, the cylinder head positioning and clamping device for finishing the top surface of the cylinder head of the present invention includes a clamp base 4 on which is provided a three-point positioning support mechanism for positioning the bottom surface of the cylinder head to be processed. The mechanism includes two front and rear cylinder head intake boss support points 9 (as an auxiliary centering device for elastic cones) and a support platform 9a in the middle. The support points 9 of the front and rear cylinder head intake bosses are respectively sleeved with set centering cone pins (one of the two centering cone pins is elastic cone pin 2 and the other is elastic diamond cone pin 5), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com