Intake manifold milling plane clamp device

A technology of intake manifold and fixture device, which is applied in the direction of positioning device, clamping, manufacturing tools, etc., can solve the problems of unstable processing quality, high labor intensity of workers, and low positioning accuracy of workpieces, so as to improve stability and positioning Precise clamping and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

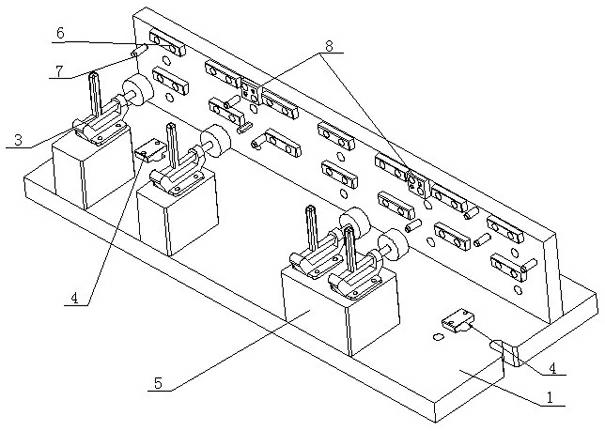

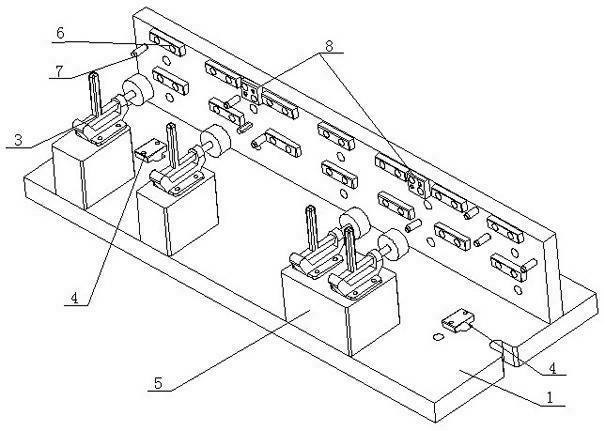

[0008] See figure 1 , the present invention includes a base plate 1, a workpiece positioning plate 2, a vigorous clamping hand 3 and a machine tool positioning block 4, the workpiece positioning plate 2 is vertically installed on the base plate 1, and the vigorous clamping hand 3 is fixed on the base plate 1 through a pad 5, and faces the workpiece On the positioning surface of the positioning plate 2, the positioning block 4 of the machine tool passes through the base plate 1 and is fixed to the base plate 1 by bolts. A workpiece support plate 6 and a workpiece positioning pin 7 are installed on the positioning surface of the workpiece positioning plate 2; the workpiece supporting plate 6 is provided with upper and lower rows; the position of the workpiece positioning pin 7 is set according to the positioning reference of the workpiece to be processed; the workpiece positioning The upper edge of the positioning surface of the plate 2 is also provided with a tool setting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com