Laboratory test machine

A testing machine and laboratory technology, applied in the direction of optical testing flaws/defects, measuring devices, material analysis through optical means, etc., can solve the problem of inability to meet the imaging and lighting requirements of different products, and the camera angle and height cannot be adjusted , Dimensions cannot be measured, etc., to achieve the effect of simple structure, low maintenance cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

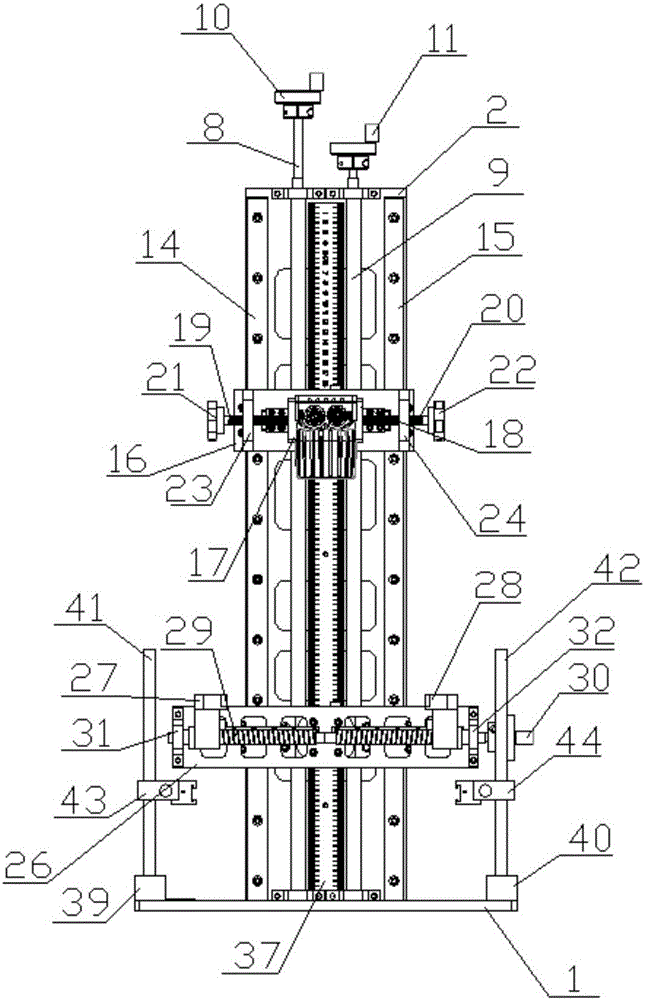

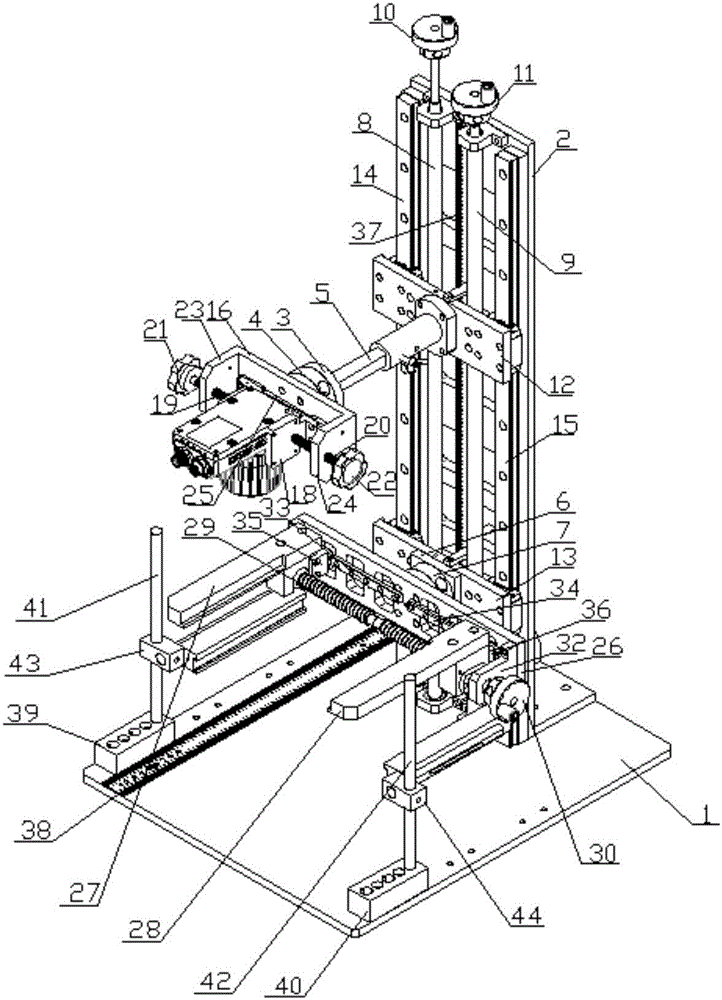

[0025] see figure 1 and 2 Shown, a kind of laboratory test machine platform, it comprises horizontal test platform 1, is located at the support 2 on the horizontal test platform, is located at the camera fixing assembly and the light source fixing assembly with vertical direction freedom degree on the support, described camera The fixing component is arranged above the light source fixing component,

[0026] The camera fixing assembly includes a first rotating mechanism and a first clamping mechanism, and the first rotating mechanism includes a first fixing part 3 and a first rotating part 4 rotationally connected with the first fixing part, and the first fixing part The part is connected to the bracket through the telescopic sleeve 5 arranged horizontally, and the first clamping mechanism is fixed on the first rotating part,

[0027] The light source fixing assembly includes a second rotating mechanism and a second clamping mechanism, the second rotating mechanism includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com