Special tooling for turning high-precision thin-wall cylinder liner bores

A high-precision, thin-walled technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in ensuring the design and process requirements of thin-walled cylinder liners, reduced machining accuracy of cylinder liners, and easy production of substandard products. , to achieve the effect of meeting precision requirements, reducing deformation, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

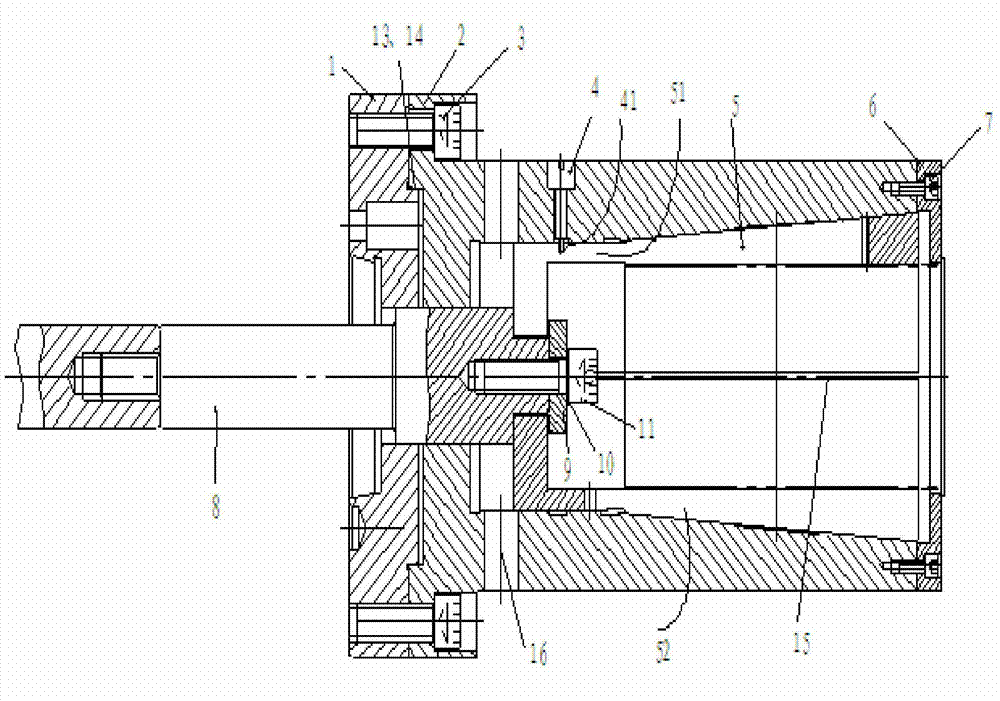

[0014] Such as figure 1 As shown, a special tool for turning the inner hole of a thin-walled cylinder liner with high precision, including an inner taper sleeve 2, an elastic clip 5, and an axial positioning plate 6, and the left end of the inner taper sleeve 2 is fastened to the spindle connecting plate 1 of a CNC lathe. The screw 3 is connected, and the right end of the inner tapered sleeve 2 is connected with the axial positioning disc 6 through the screw 7. The right side of the inner tapered sleeve 2 is provided with a tapered hole, and the tapered hole is connected with the cylindrical hole on the left side. The side wall of the guide hole is provided with a guide hole, the guide hole is provided with a guide screw 4, the lower end of the guide screw 4 is provided with a guide pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com