Glass deep processing method and equipment

A technology of processing equipment and processing methods, which is applied in the direction of metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as inability to achieve polishing, achieve the effects of improving processing quality and processing efficiency, and reliable clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

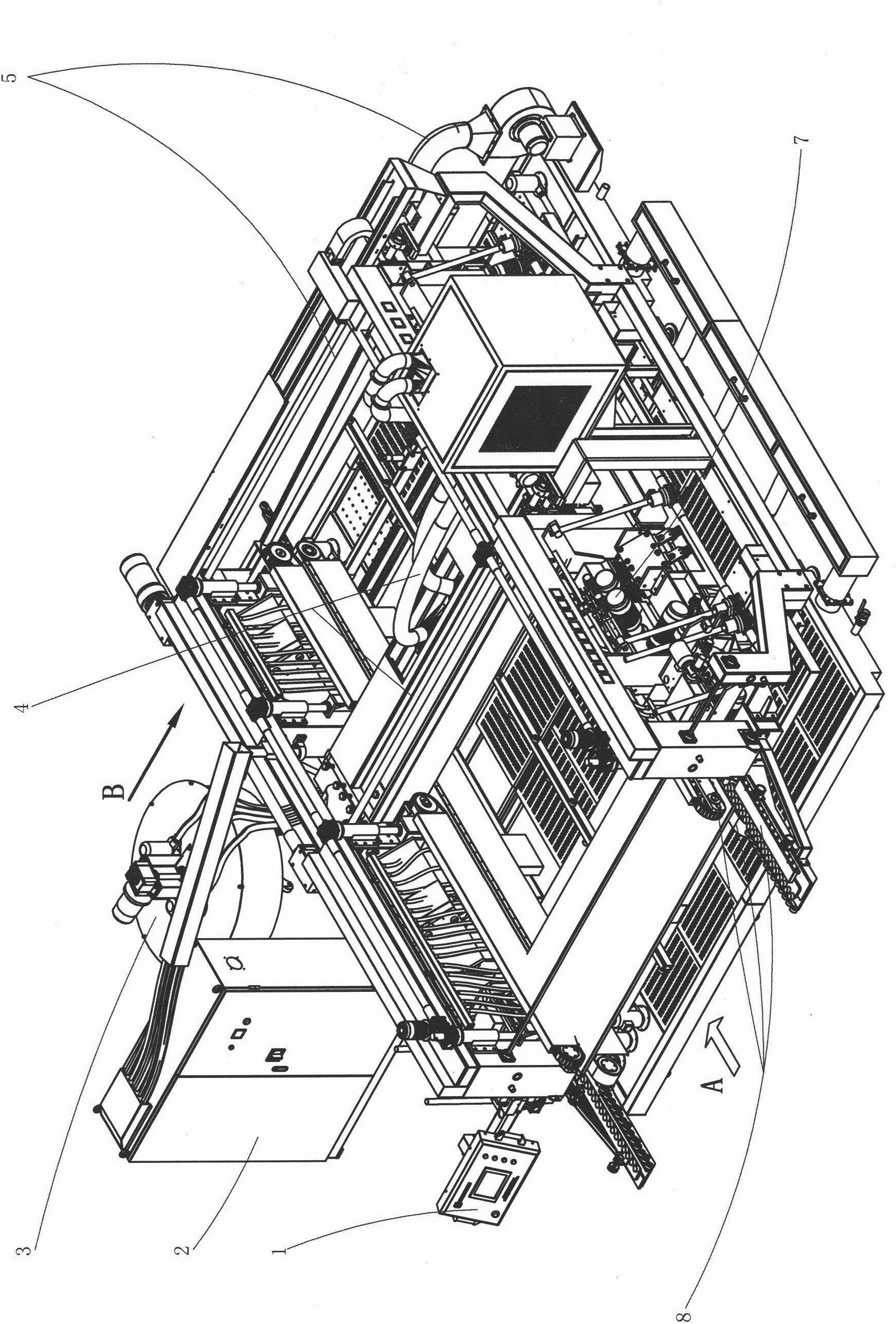

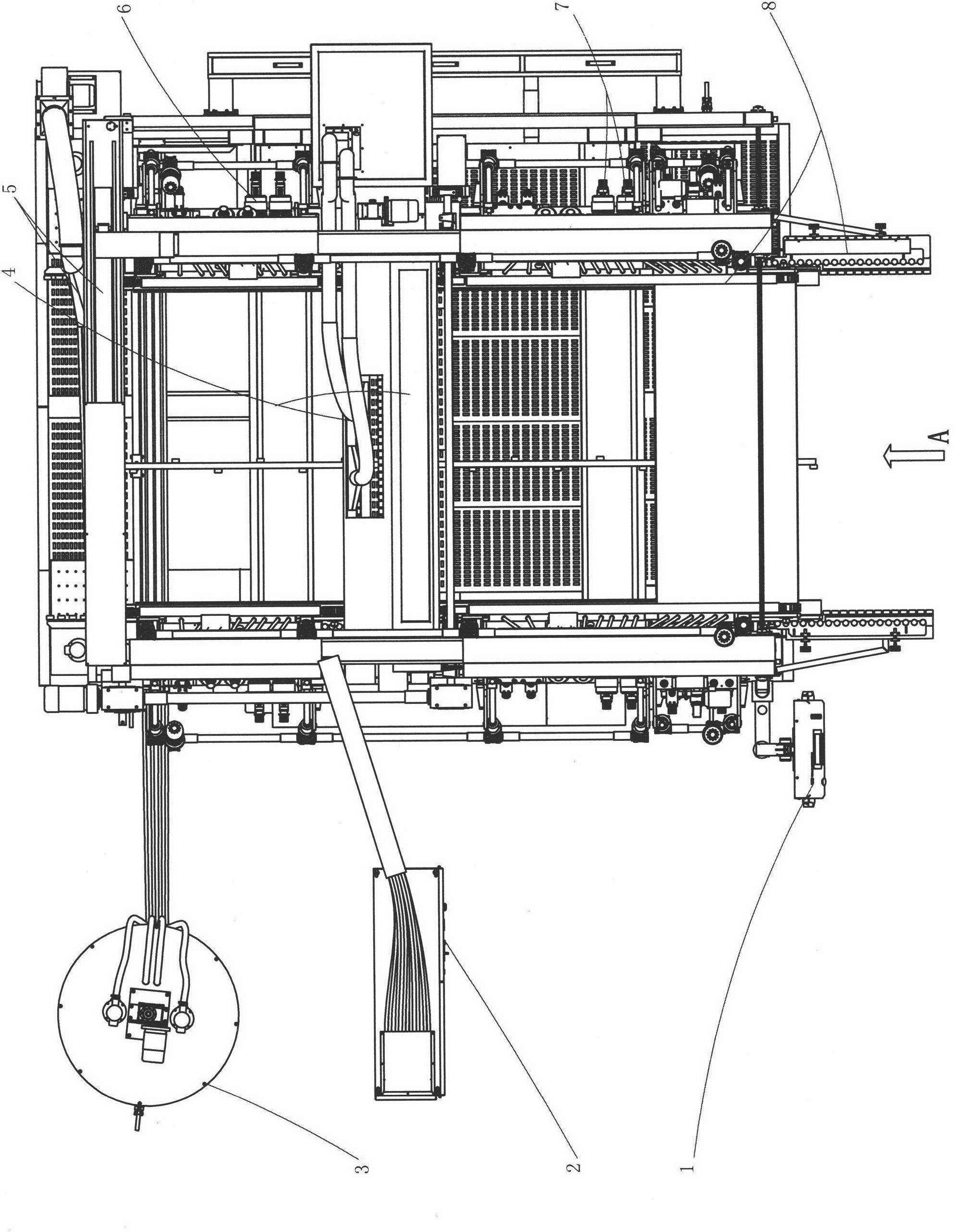

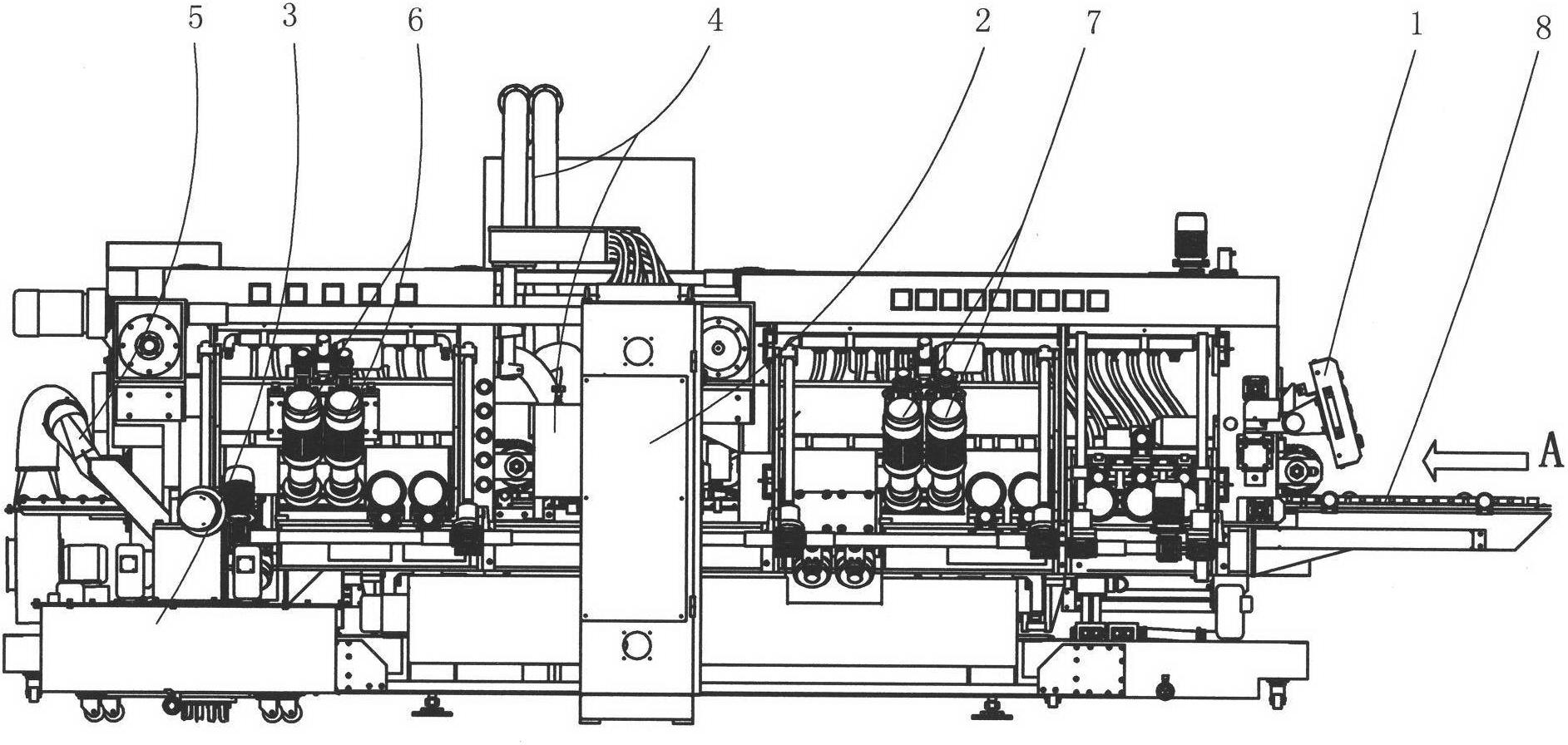

[0022] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 5 . The processing equipment includes glass positioning, transmission and clamping device 8, rough and fine grinding device 7, first cleaning and air-drying device 4, second cleaning and air-drying device 5, operation box 1 and electric control box 3, and also includes polishing device 6 and polishing liquid Supply processing device 3. The glass sheet to be processed is sent into the processing equipment along the direction A in the glass positioning transmission clamping device 8. The glass positioning transmission clamping device 8 adopts rubber roller and timing belt transmission and clamping to maintain the synchronous transmission of the glass sheet in each device. speed; first, the glass sheet is ground bilaterally by the coarse and fine grinding device 7, and processed according to the required shape and angle; Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com