Patents

Literature

57results about How to "Adapt to use needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

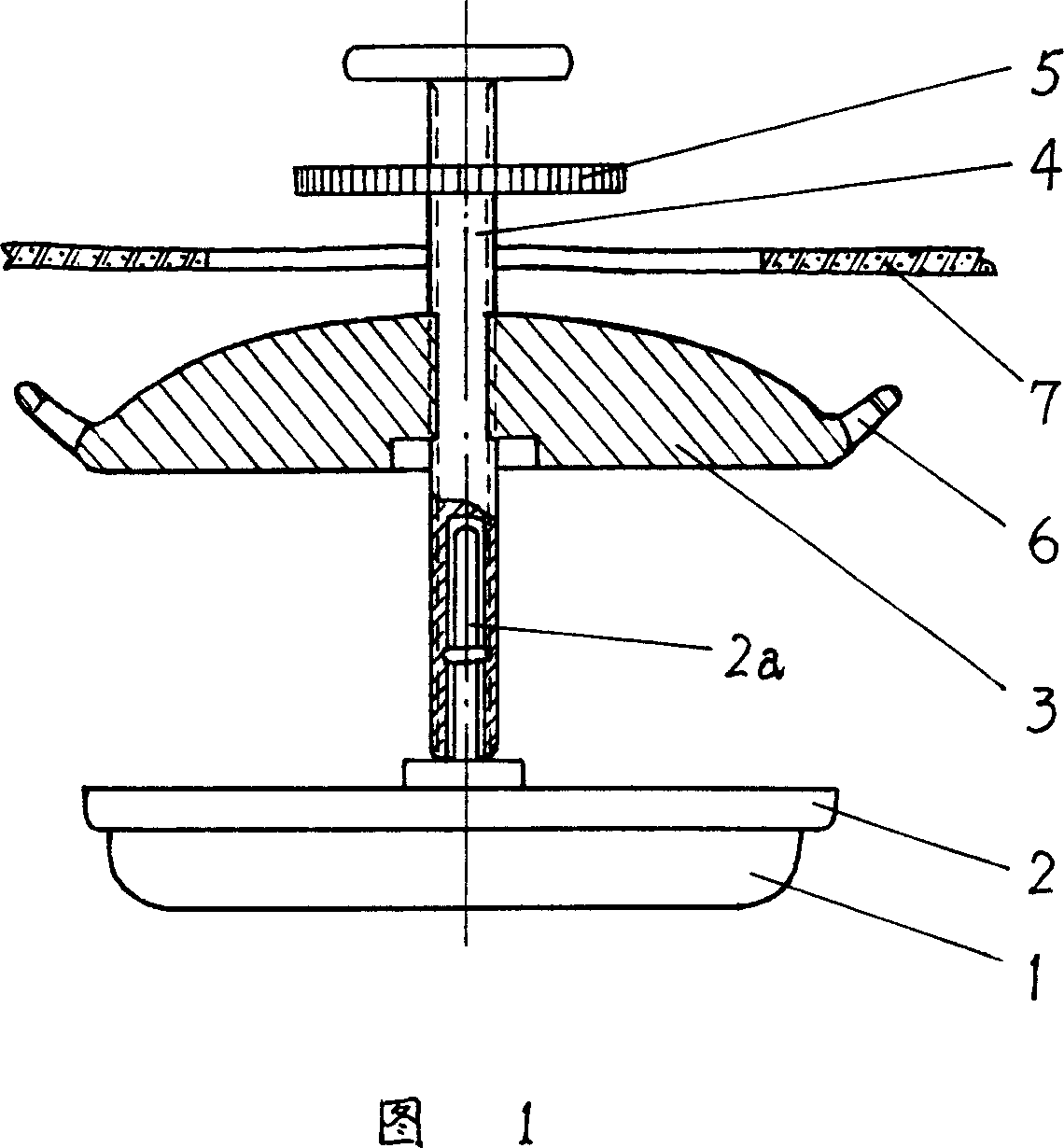

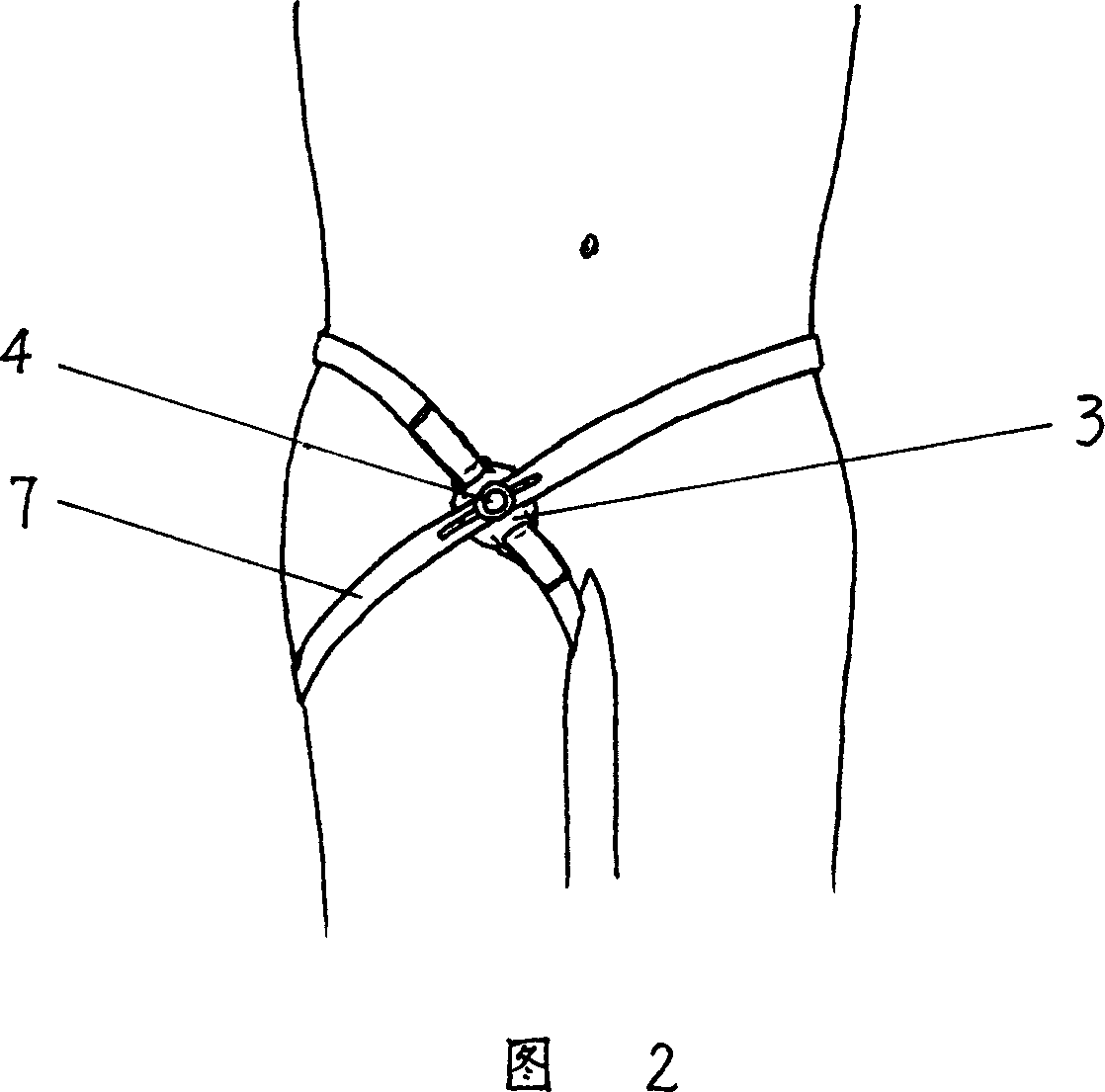

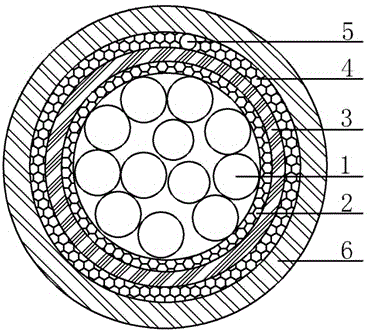

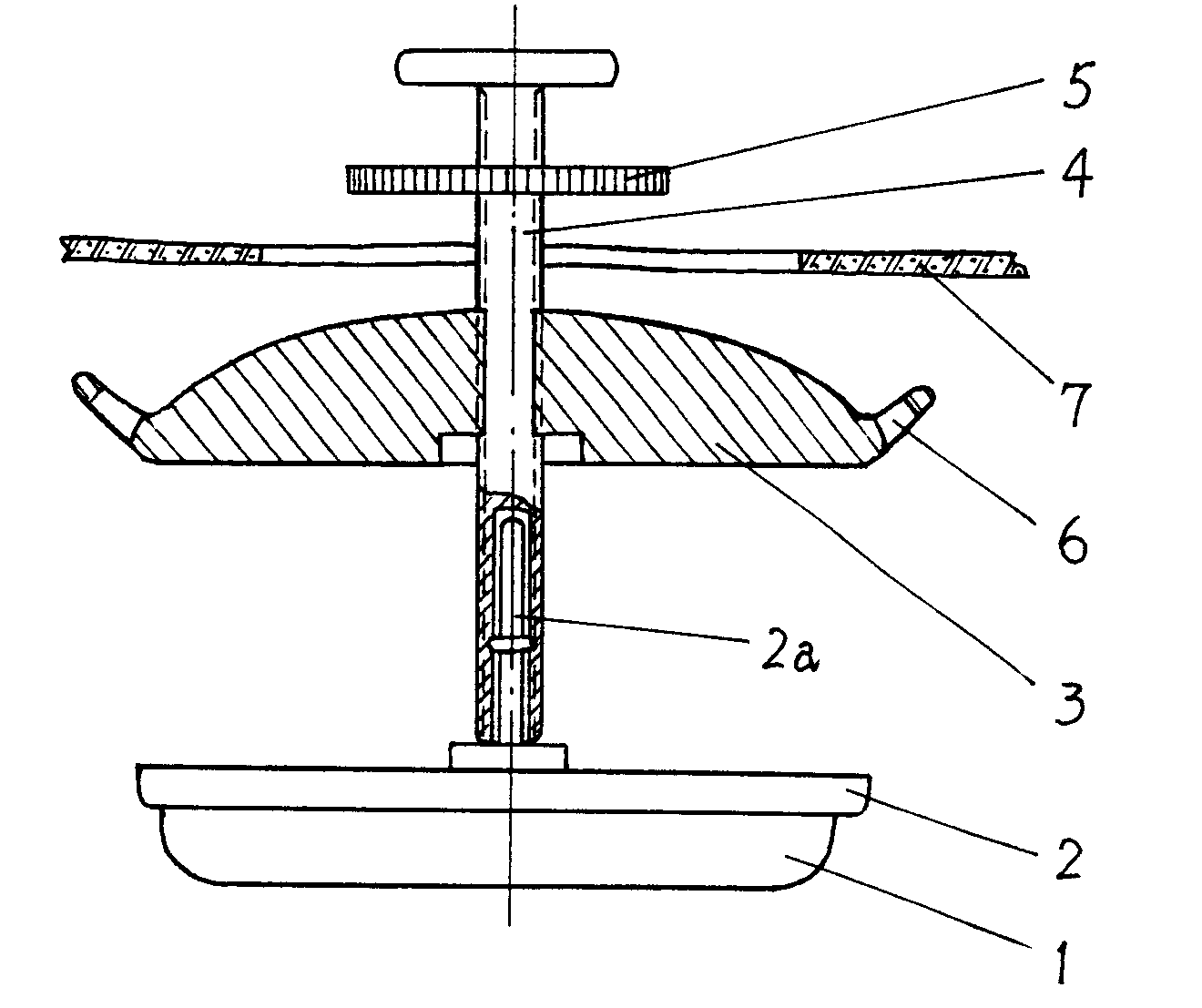

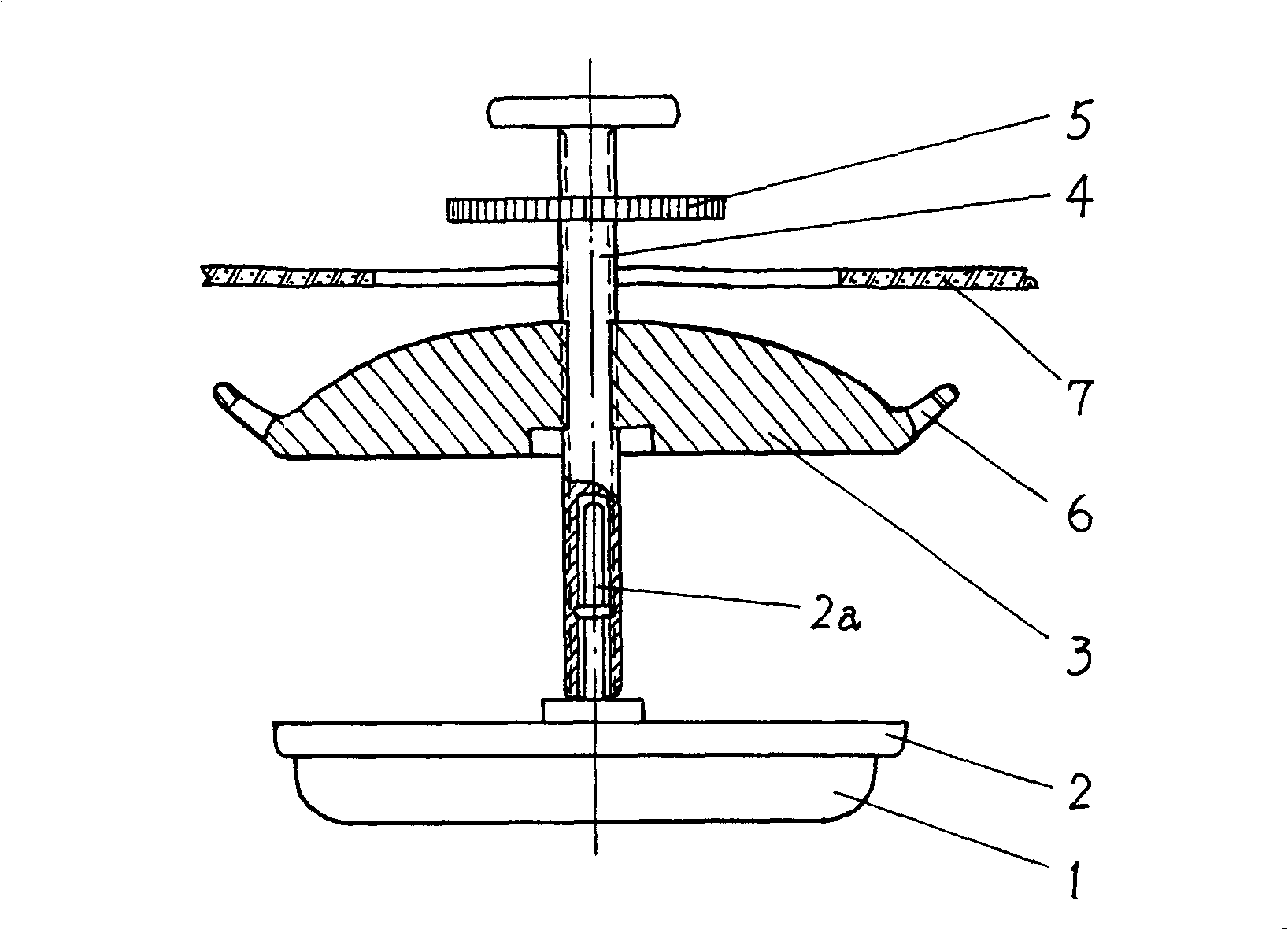

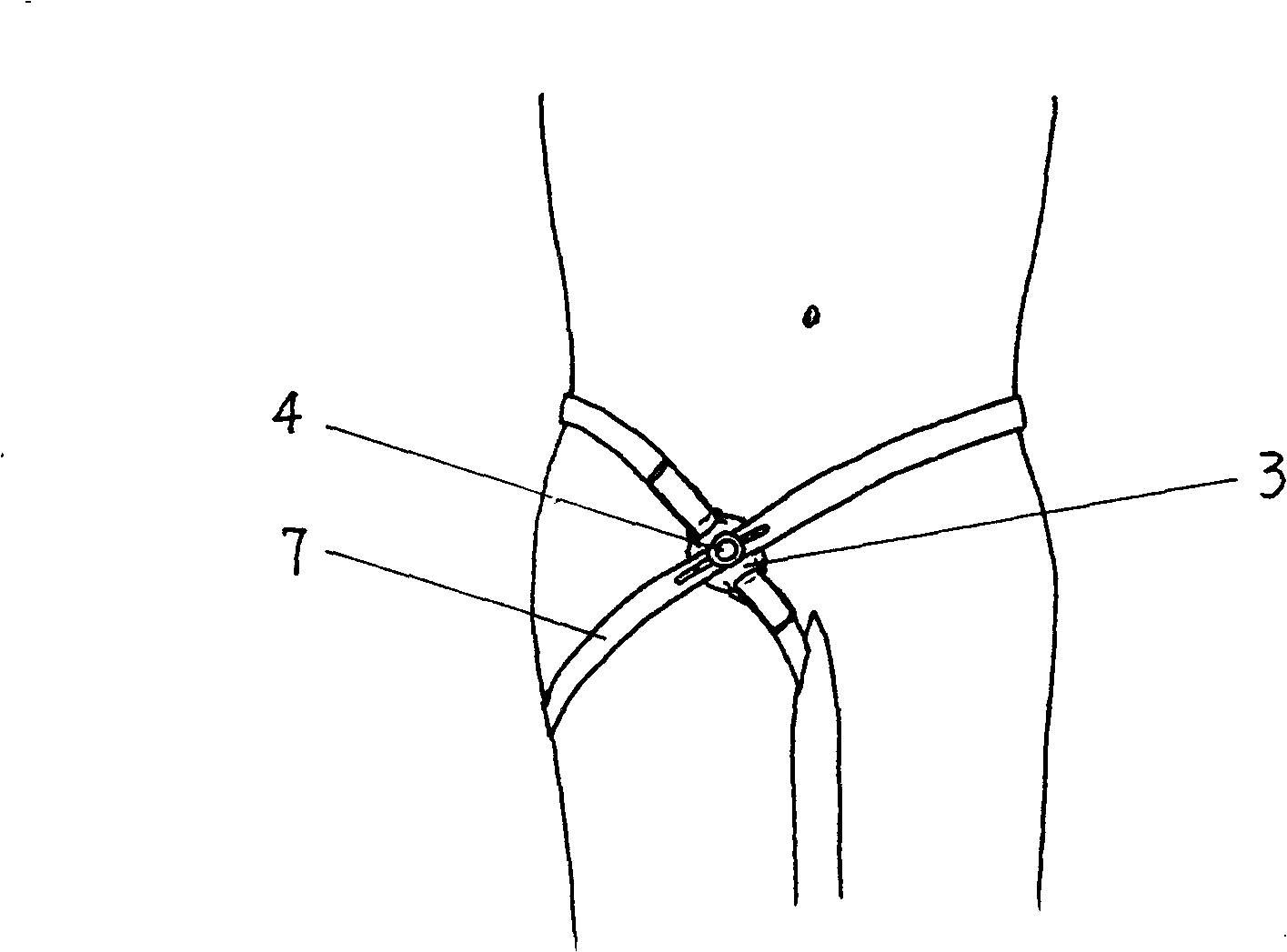

Disposable arteria femoralis compression hemostat

The invention is concerned with the one-off femoral artery oppress hemostat and it includes: the pressure adjusting compasses, the center screw hole with adjustment screw that connects the compression compasses, the two opposite lead back fastener on the adjusting compasses, and the fixation band for the adjustment screw. It improves the quality and efficiency of henostasis dressing and reduces mistakes.

Owner:杭州艾力康医药科技有限公司

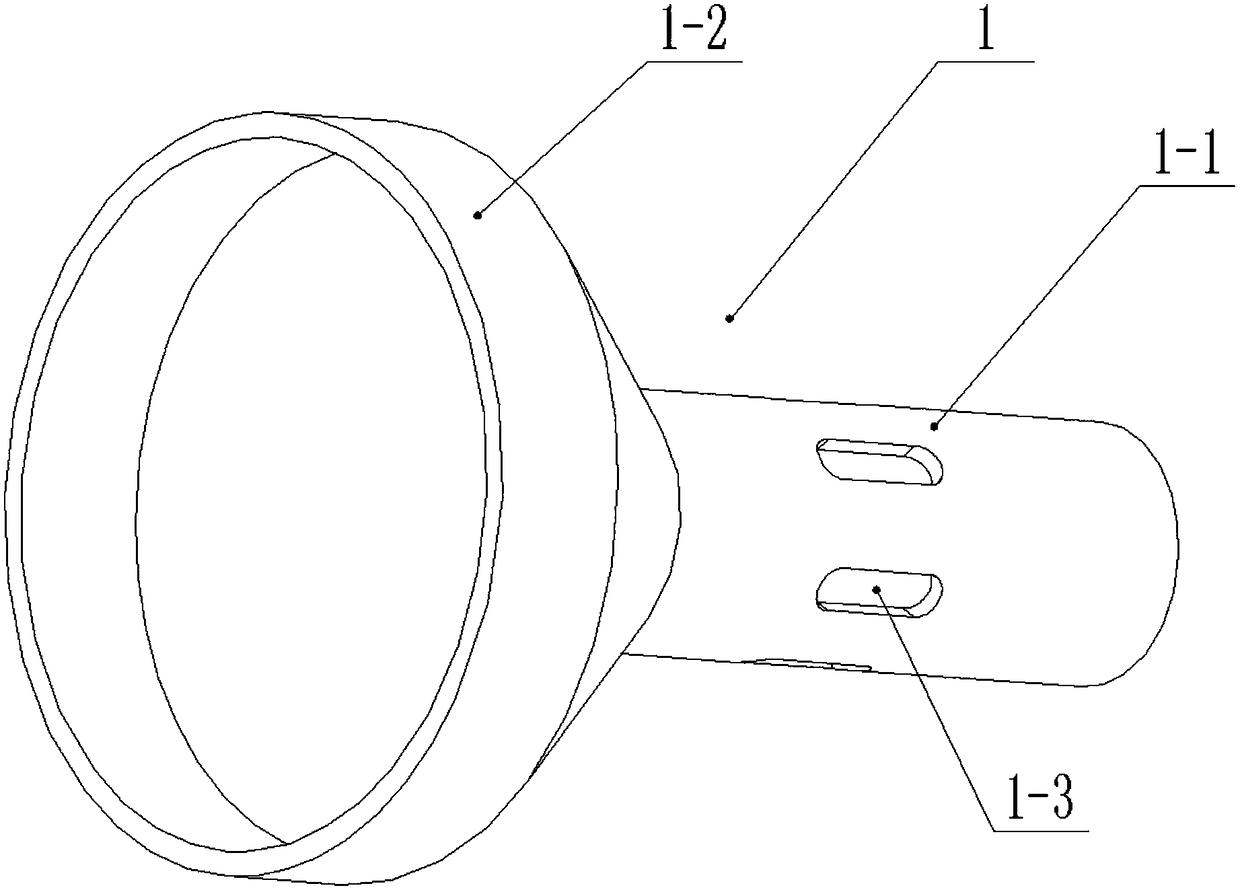

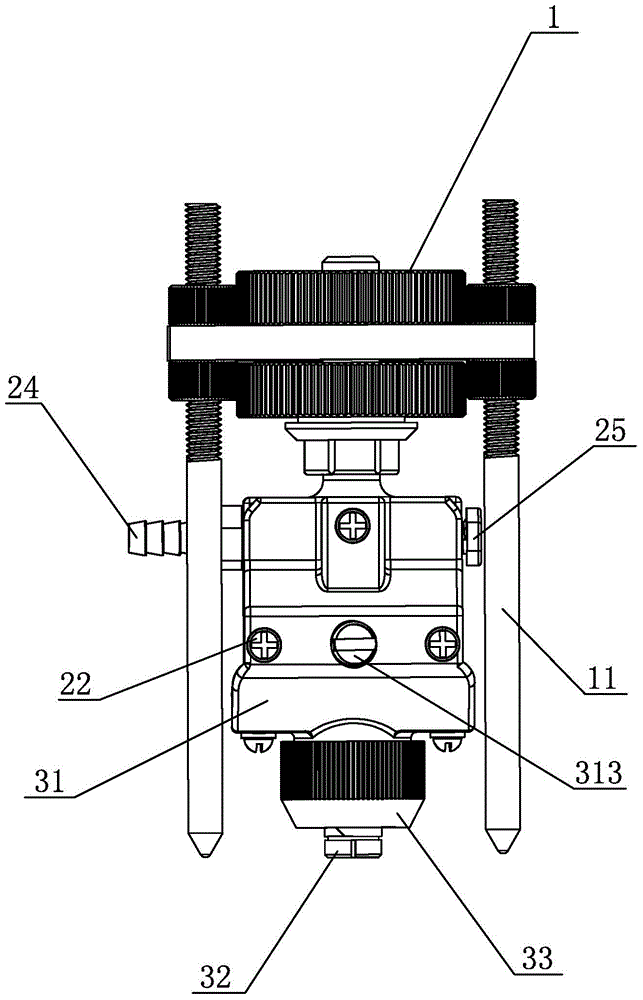

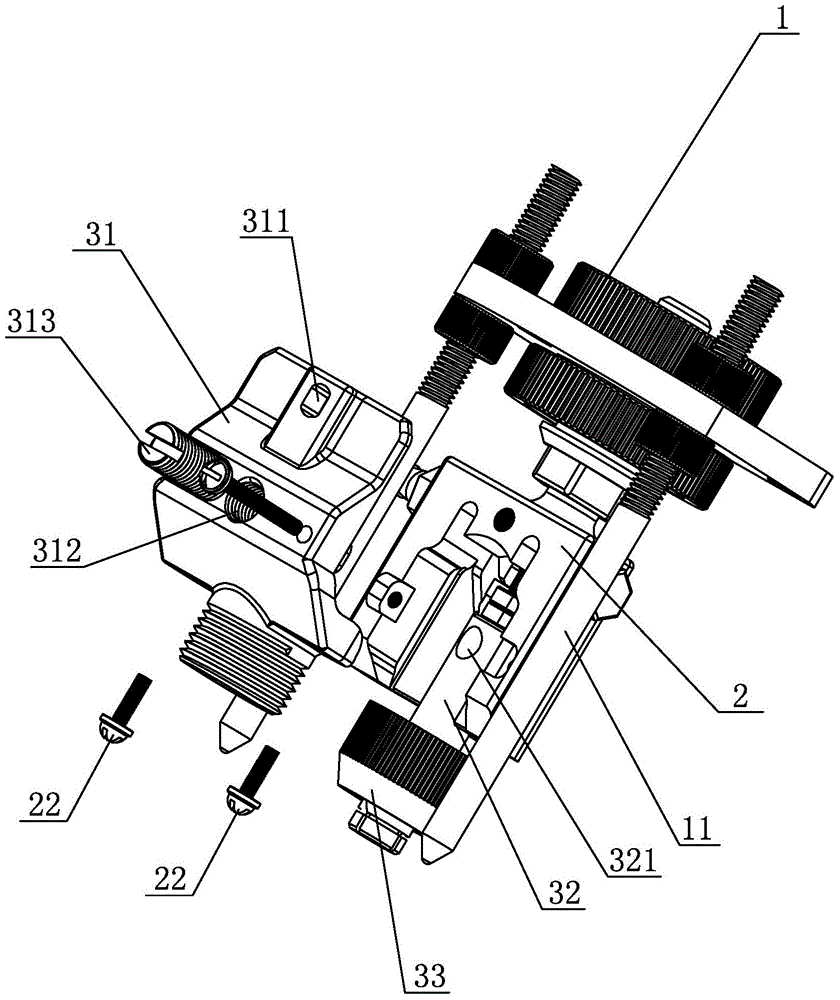

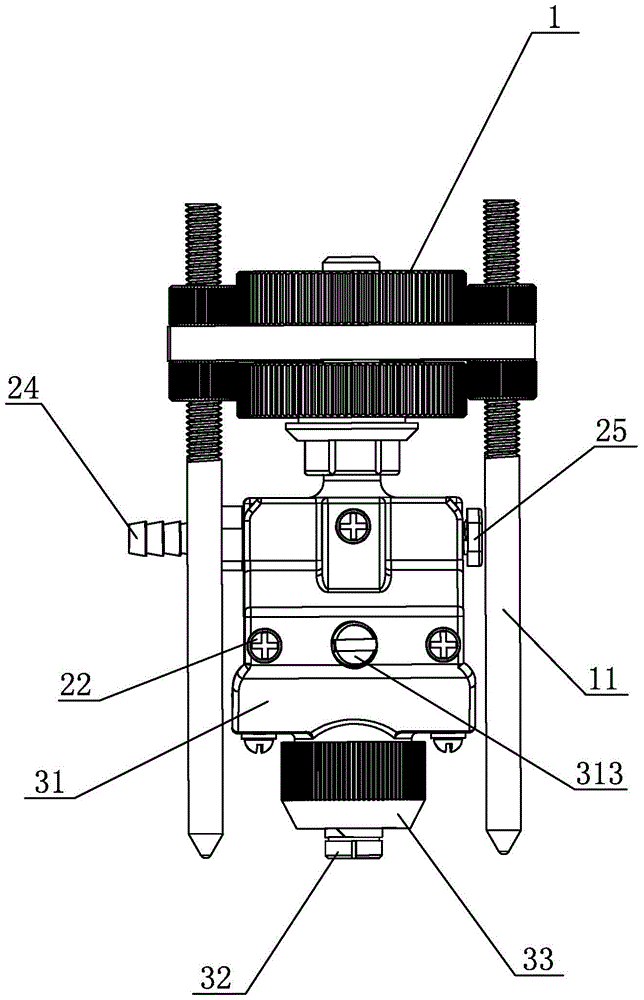

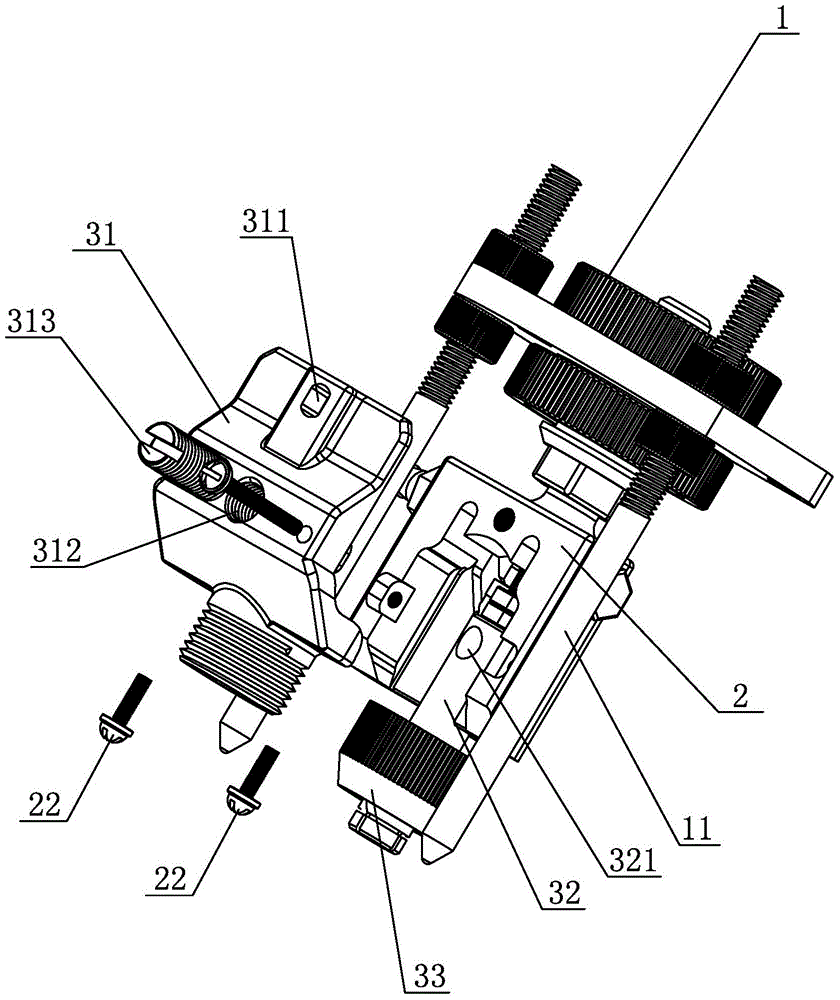

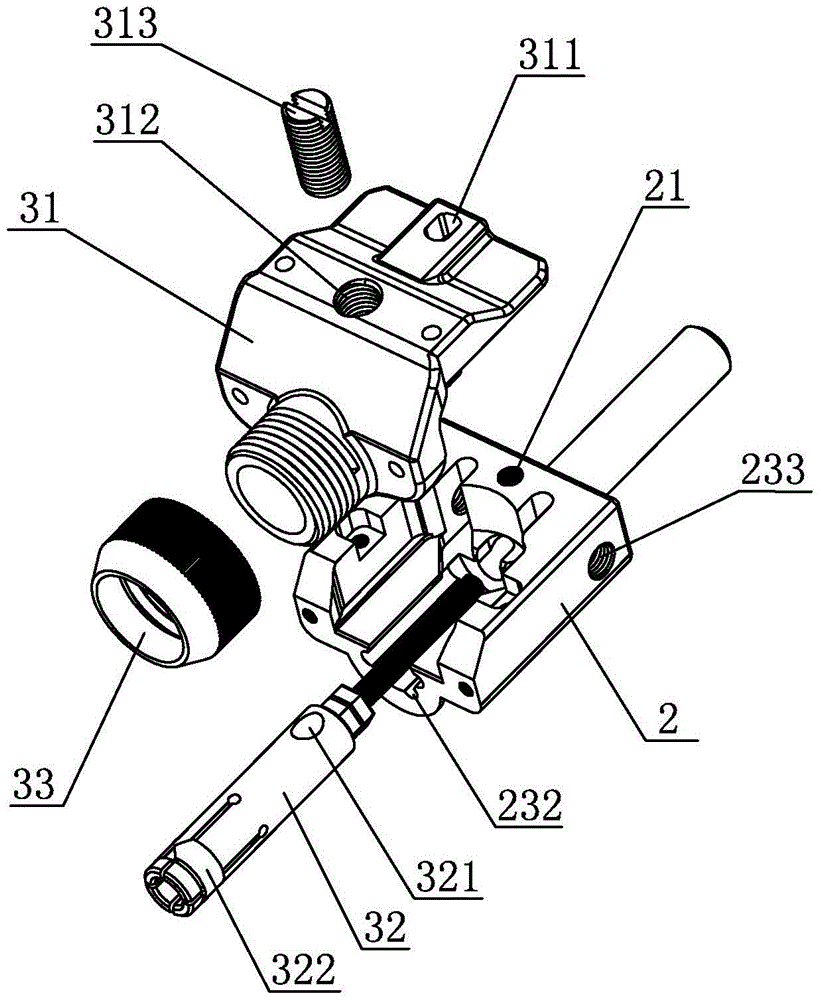

Water gun nozzle for fire fighting

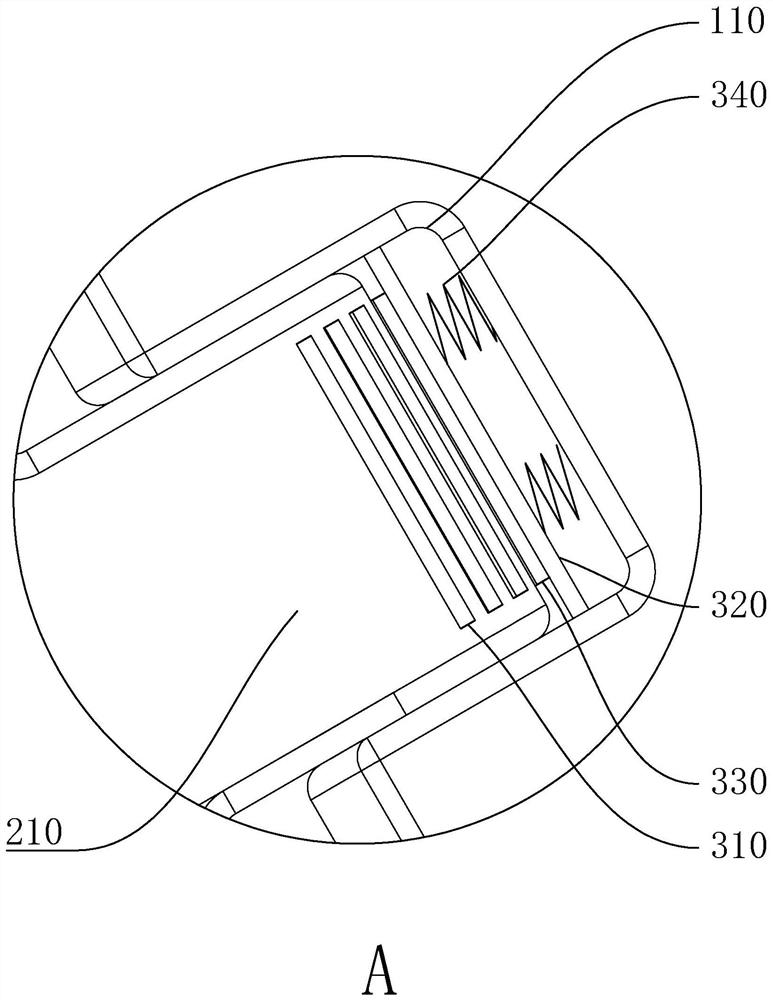

InactiveCN108339216ASolve the problem that the orientation is not suitable for adjustmentAdapt to use needsFire rescueSpray nozzleEngineering

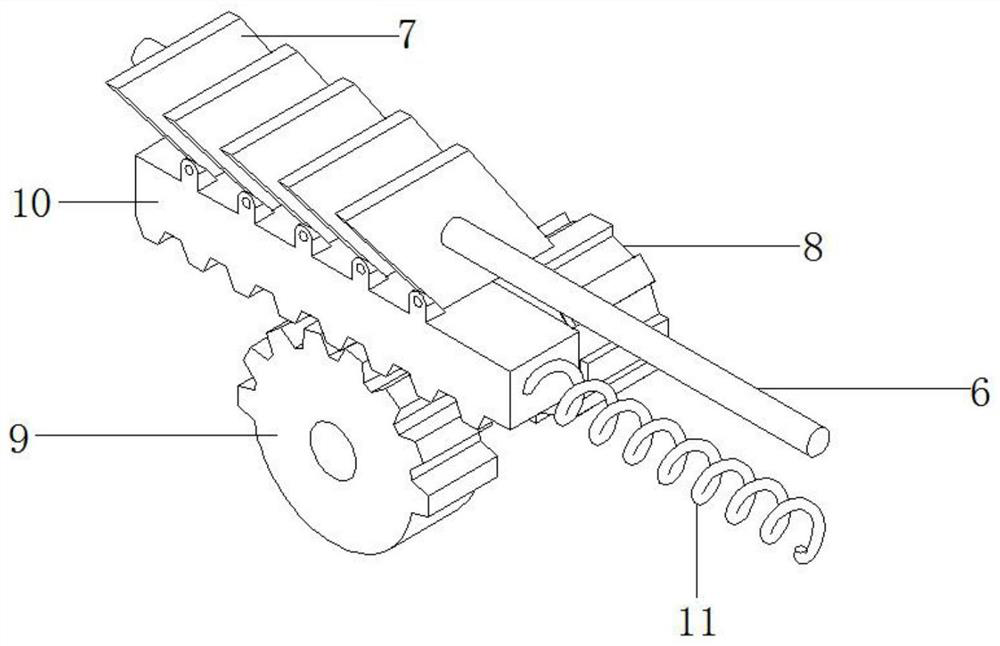

The invention relates to a water gun nozzle, in particular to a water gun nozzle for fire fighting. The water gun nozzle comprises a nozzle water pipe, a valve core, a jet nozzle, a nozzle plug cover,a valve core plug and spring assemblies, wherein the valve core is slidably connected in the nozzle water pipe, the interior of the valve core is connected with a valve core plug in a sliding mode, the jet nozzle is fixedly connected to the nozzle water pipe, the spray head plug cover is connected between the spray head water pipe and the jet nozzle in a threaded fit mode, the spring assemblies comprises springs I and springs II, the springs I are located in the springs II, and the springs I are located between the valve core plug and the jet nozzle, the springs II are located between the valve core and the jet nozzle, a low-pressure water cavity is formed among the nozzle water pipe, the jet nozzle and the nozzle plug cover, and a high-pressure water cavity is formed in the middle end ofthe nozzle water pipe and the jet nozzle. According to the water gun nozzle, the working water pressure can be selected according to needs, so that the working state is changed, and the use requirements of the fire-fighting operation can be well met; and the fire can be more effectively jetted according to the water pressure conversion spraying mode.

Owner:郝家平

Novel hand-held electric shears with adjustable shearing force

InactiveCN101844248AChange the shear forceReduce labor intensityLeather clicking/perforating/clickingGearingClosed loopHand held

The invention discloses a pair of novel hand-held electric shears with adjustable shearing force. A cavity is formed between two shear bodies; a motor is arranged and fixed in the cavity between the two shear bodies; an output shaft of the motor is provided with a first-stage gear; the first-stage gear and a second-stage gear form a meshing relation; the second-stage gear and a third-stage gear are fixedly arranged on the shears coaxially; a fourth-stage gear and an eccentric shaft are simultaneously arranged and fixed on a fourth-stage gear rotating shaft; and the third-stage gear and the fourth-stage gear form a meshing relation. In order to control the electric shears conveniently, proper positions on the upper parts of the shear bodies are provided with button switches, a conducting wire is fixed on the shear bodies through rubber joints, and the conducting wire is connected with two contacts of the switches to form a closed loop. In order to move the hand-held electric shears conveniently, proper positions at the bottoms of the shear bodies are provided with a proper amount of rollers.

Owner:刘振光

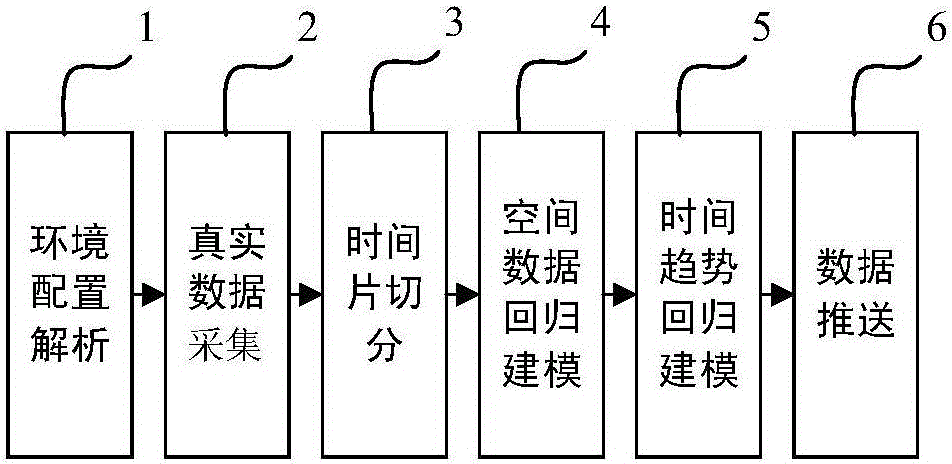

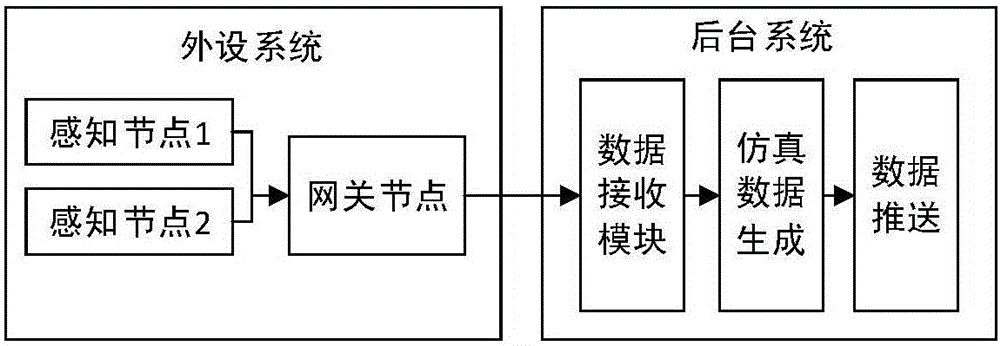

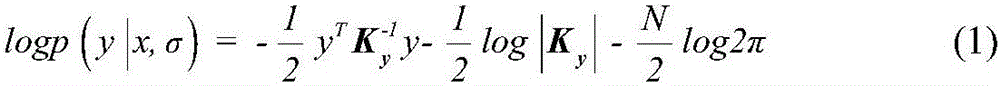

Simulation data generation method for simulating real physical environment

ActiveCN106227660AAdapt to use needsStrong configurabilitySoftware testing/debuggingAcquisition timeSimulation

The invention provides a simulation data generation method for simulating a real physical environment. The simulation data generation method includes the steps: 1) receiving a series of real environment data; 2) dividing an acquisition time slot of the real environment data into a plurality of time intervals; 3) fitting space distribution of physical environment parameters based on a Gaussian process model according to data values of a plurality of different positions at the same time for each time interval to obtain the value of the physical environment parameter at an optional designated position at the time corresponding to the time interval; 4) modeling time trend according to the obtained data values at each position at different time to obtain a time trend function at the position; 5) generating simulation data of the physical environment parameters according to the designated time and position. Data points at different positions at each time interval are regarded as data points acquired at the same time. Massive simulation environment data can be generated at small overhead, and the simulation data generation method is high in configurability and universality.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

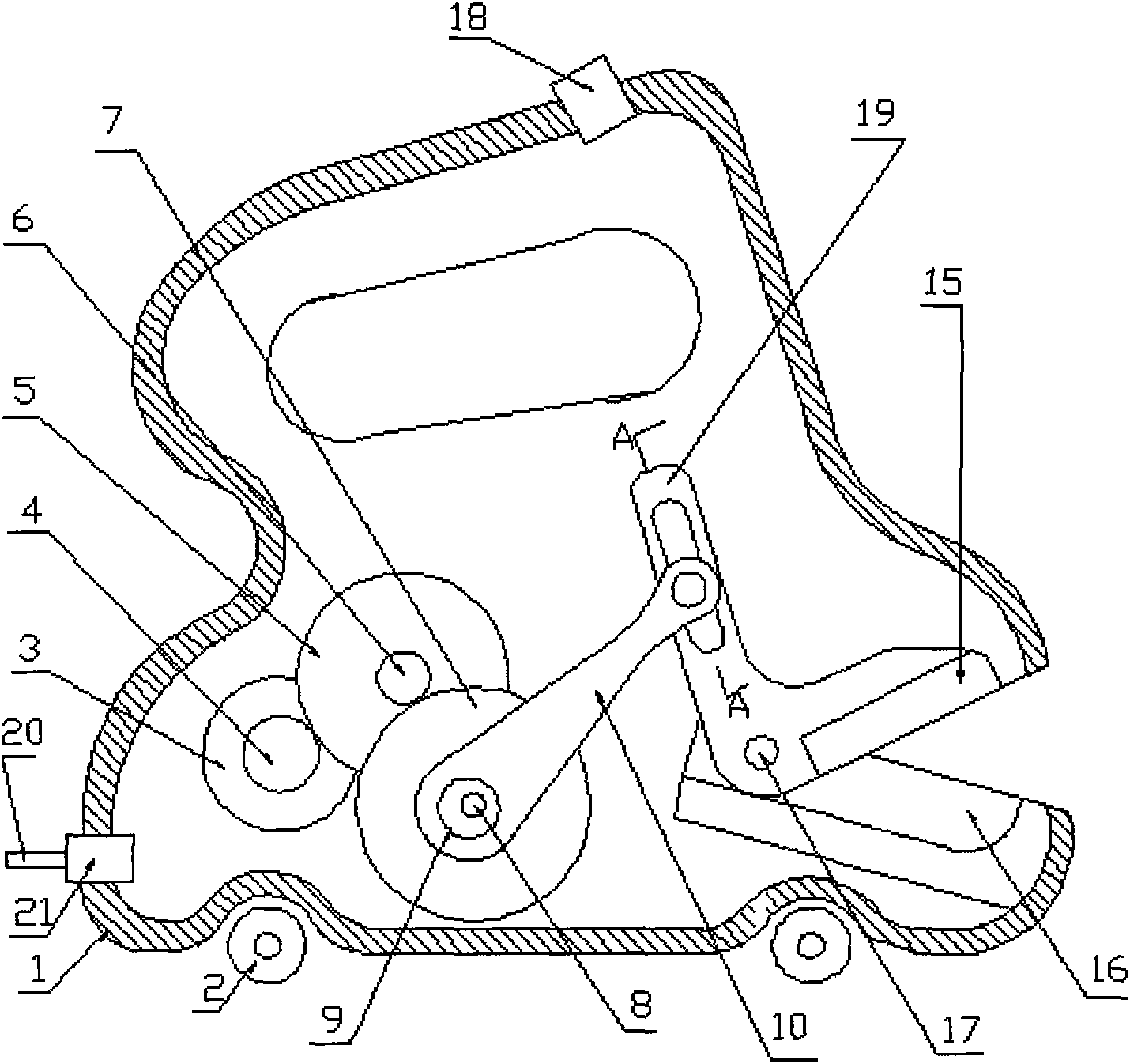

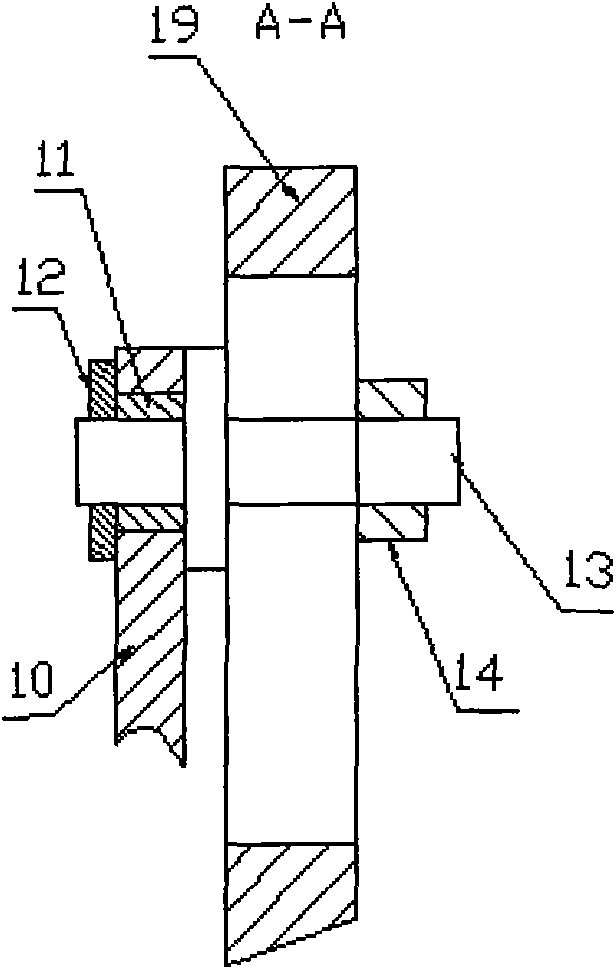

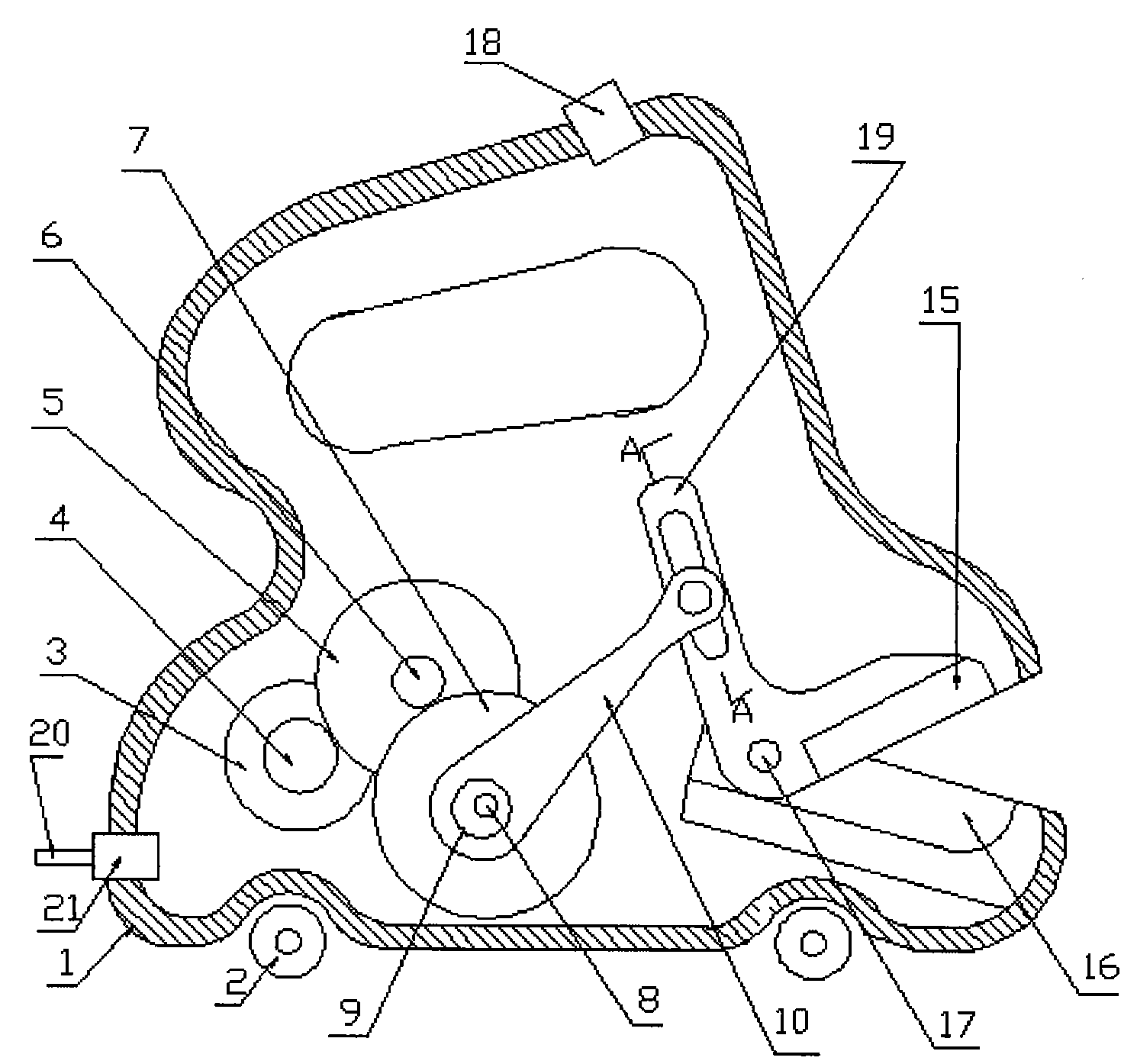

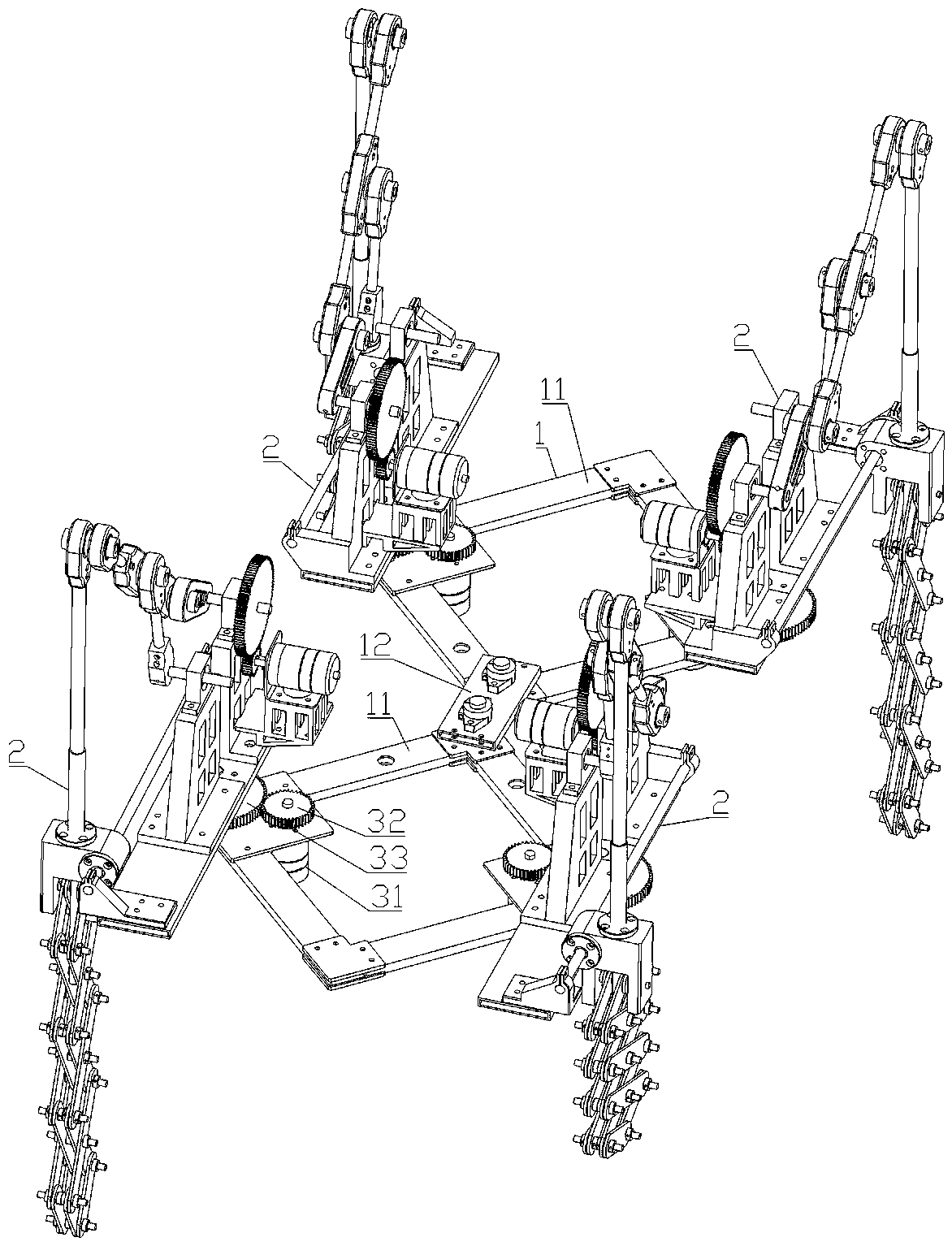

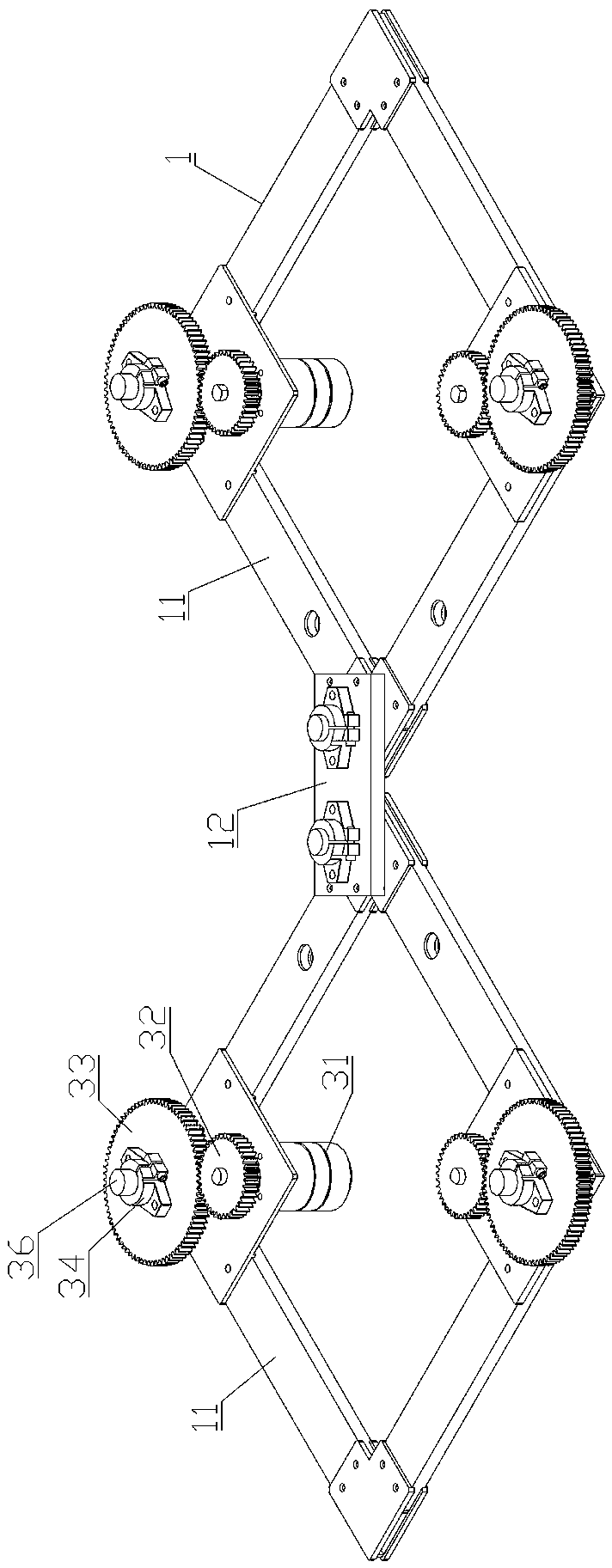

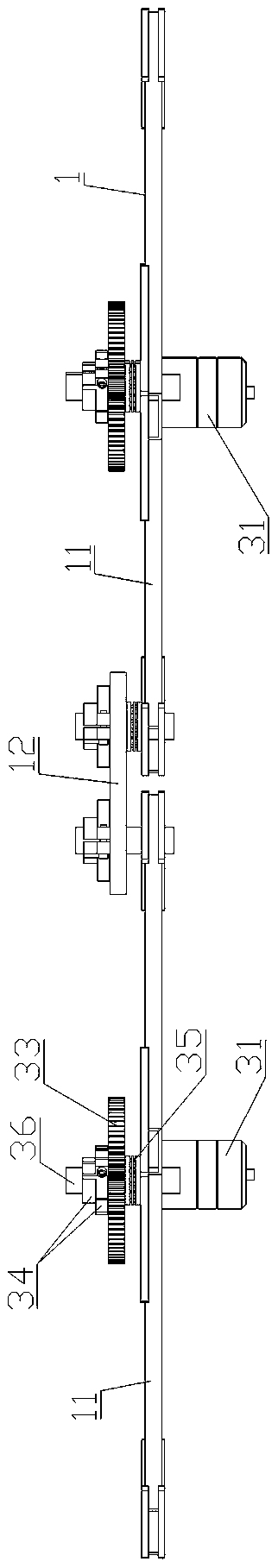

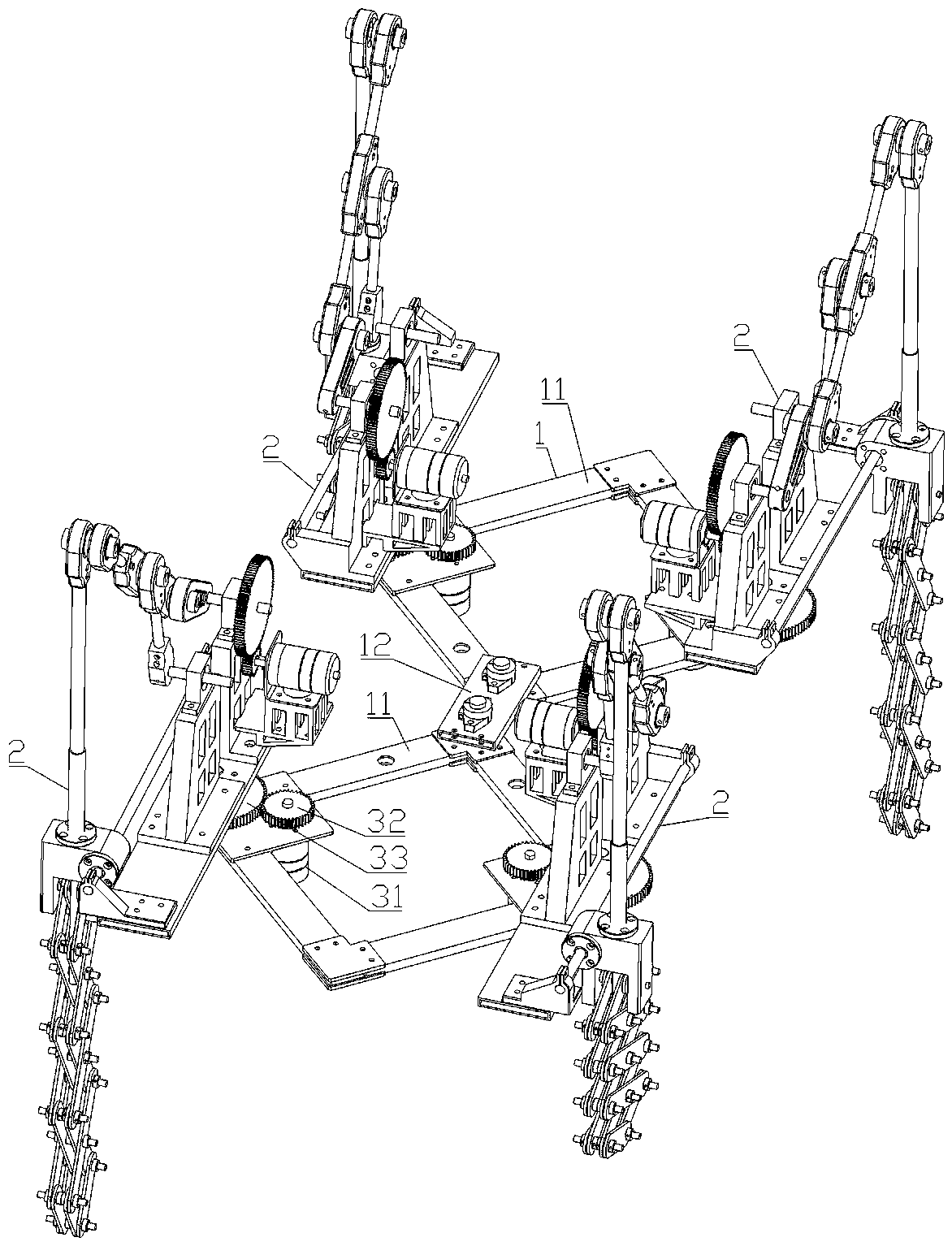

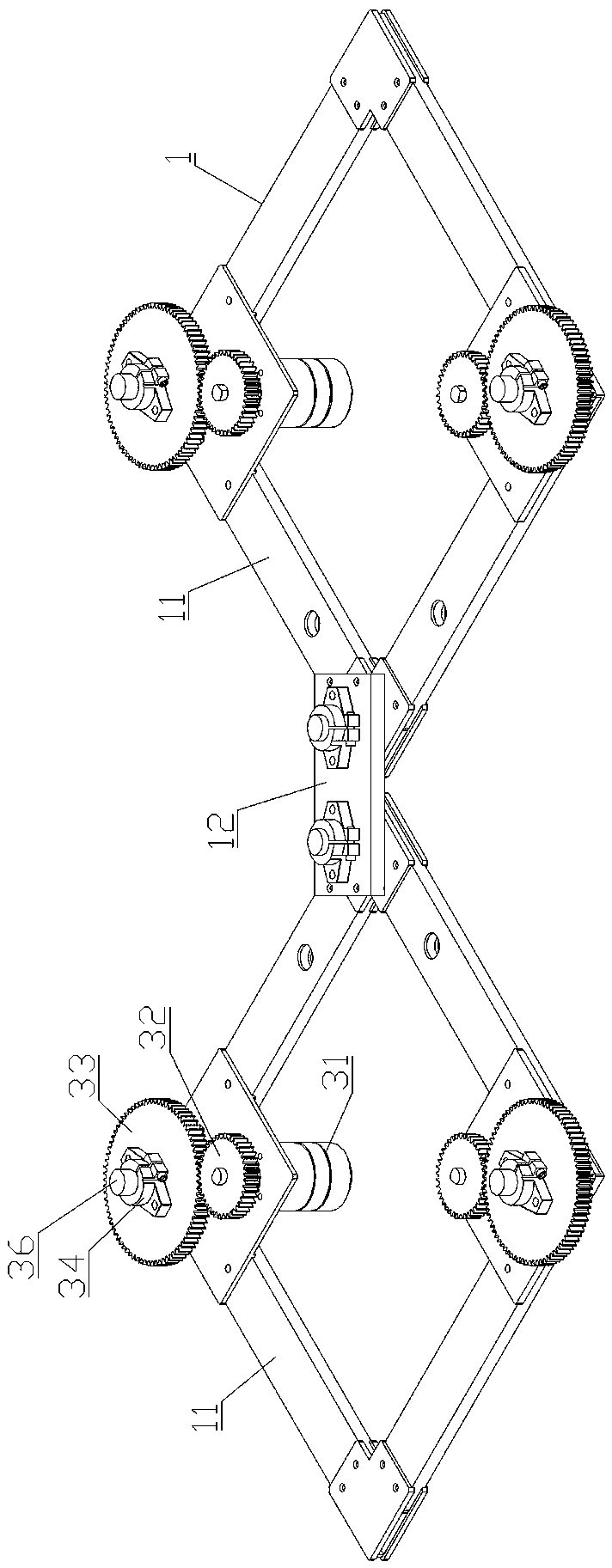

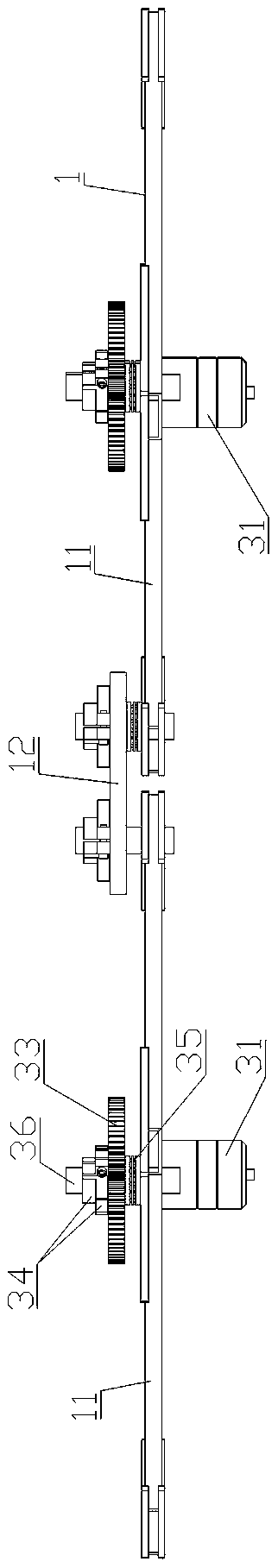

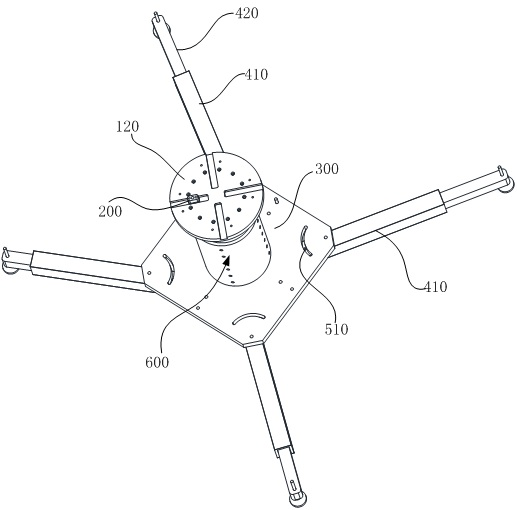

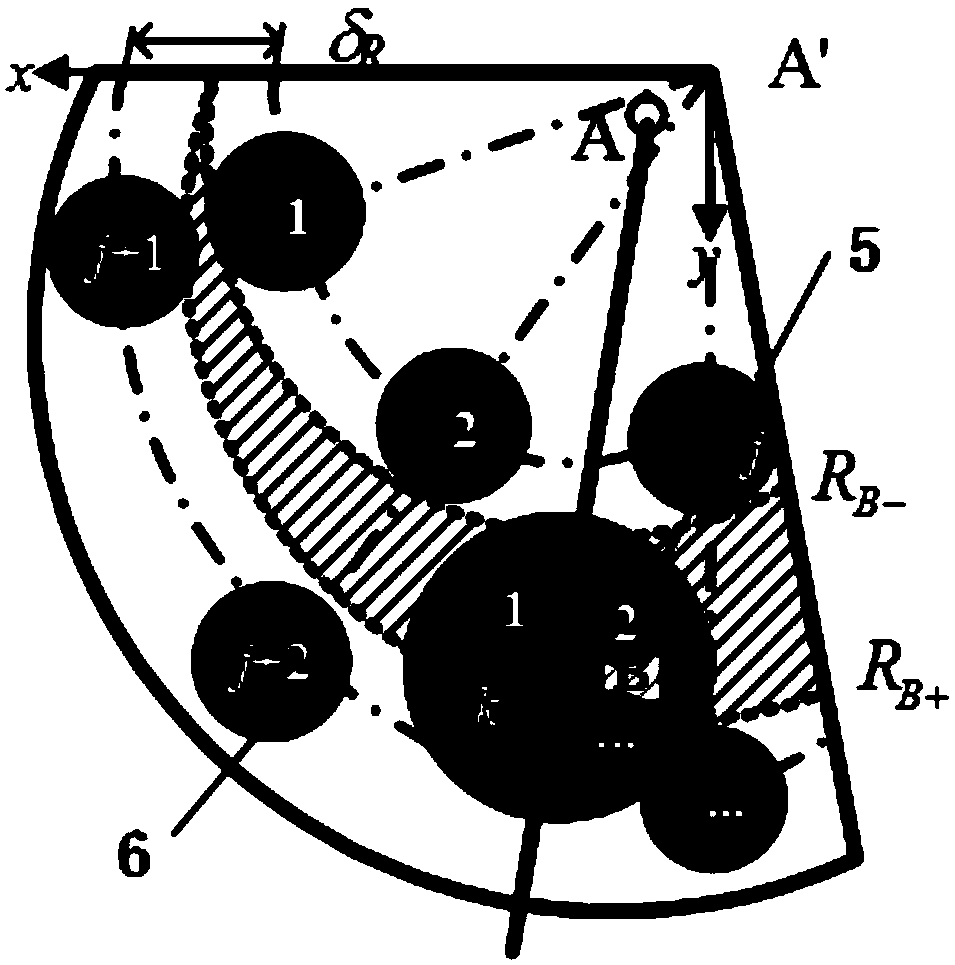

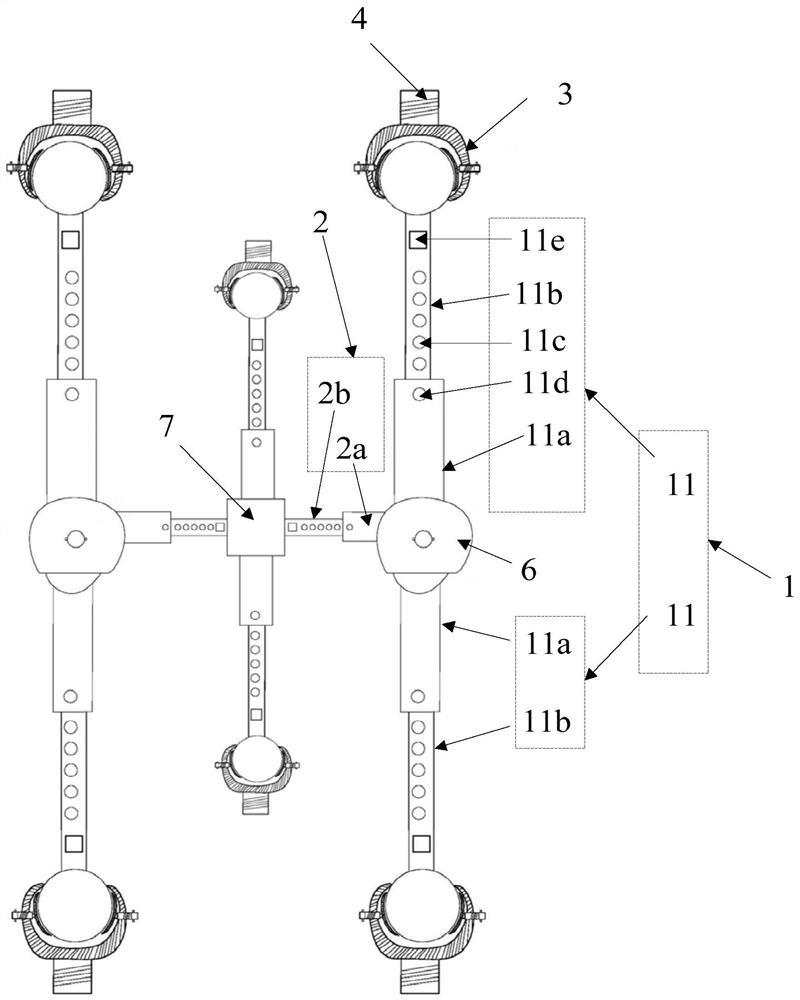

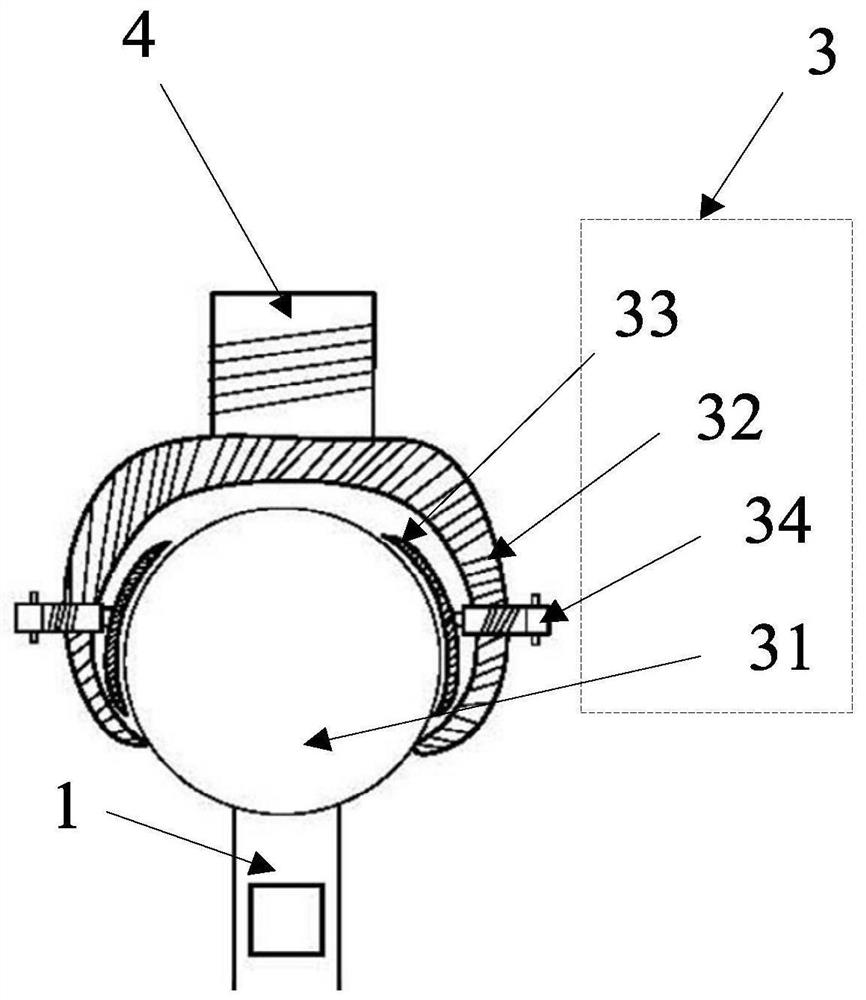

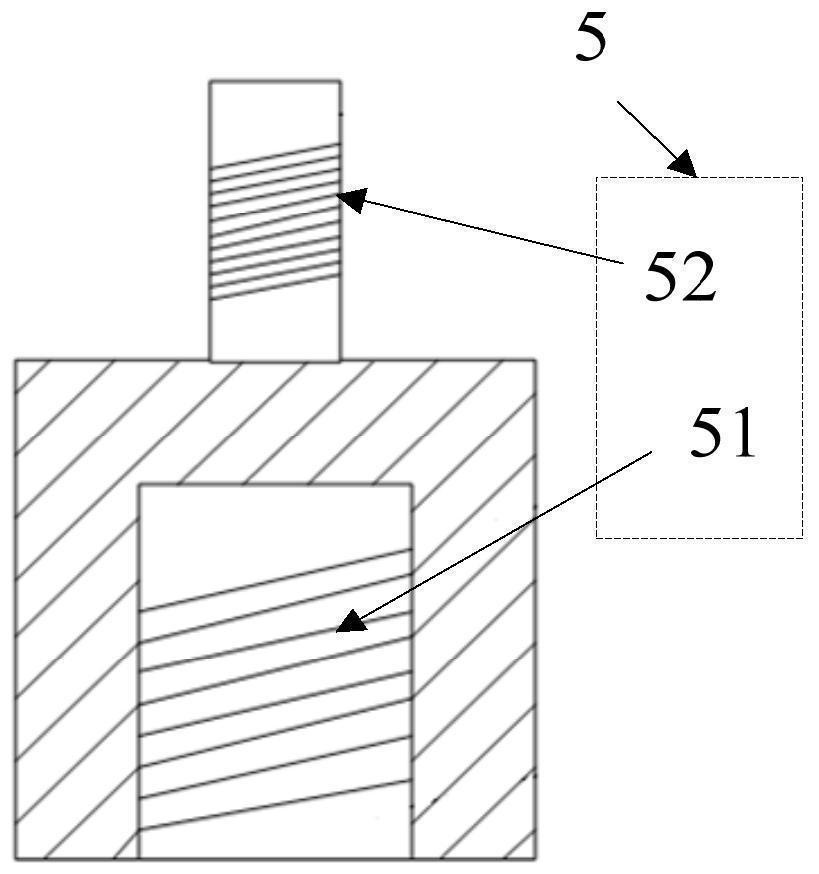

Quadruped robot based on four-bar mechanism

InactiveCN109606501AReduce manufacturing costElectronic control design is less difficultVehiclesVertical barCoupling

The invention discloses a quadruped robot based on a four-bar mechanism. The quadruped robot comprises a base and legs, wherein every two of the four legs are symmetrically arranged on two sides of the front end and two sides of the rear end of the base; the legs each comprise a pedestal, a four-bar mechanism, a motor B, a cross bar, a coupling, a vertical bar and a scissors fork telescopic frame;the four-bar mechanism is a planar pivot four-bar mechanism and comprises a crank, a rocker bar and connecting rods; the front ends of the crank and the rocker bar are respectively hinged onto the pedestal; the rear end of the crank is hinged with the front end of the hinged connecting rods; the rear end of the rocker bar is hinged with the middle of the connecting rods; the motor B drives the crank to rotate around the hinged joint at the front end of the crank; the scissors fork telescopic frame is provided with multiple hinge joints from the upper end to the lower end; the scissors fork telescopic frame is connected with the coupling at the hinged joint at the uppermost end, and connected with the lower end of the vertical bar by virtue of any hinged joint except the hinged joint at the lowest end. The quadruped robot based on the four-bar mechanism disclosed by the invention has the advantages that the legs of the quadruped robot are driven by the four-bar mechanism, the travelingfunction can be realized by virtue of drive of one motor only, the manufacturing cost is low, and the electric control design difficulty is low.

Owner:NANHUA UNIV

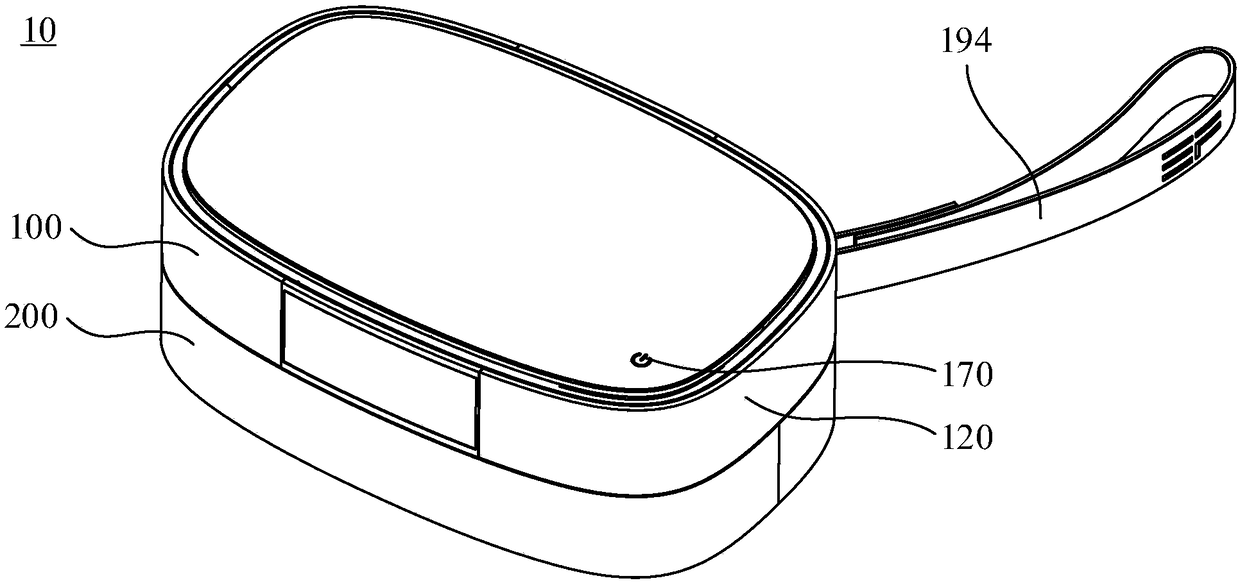

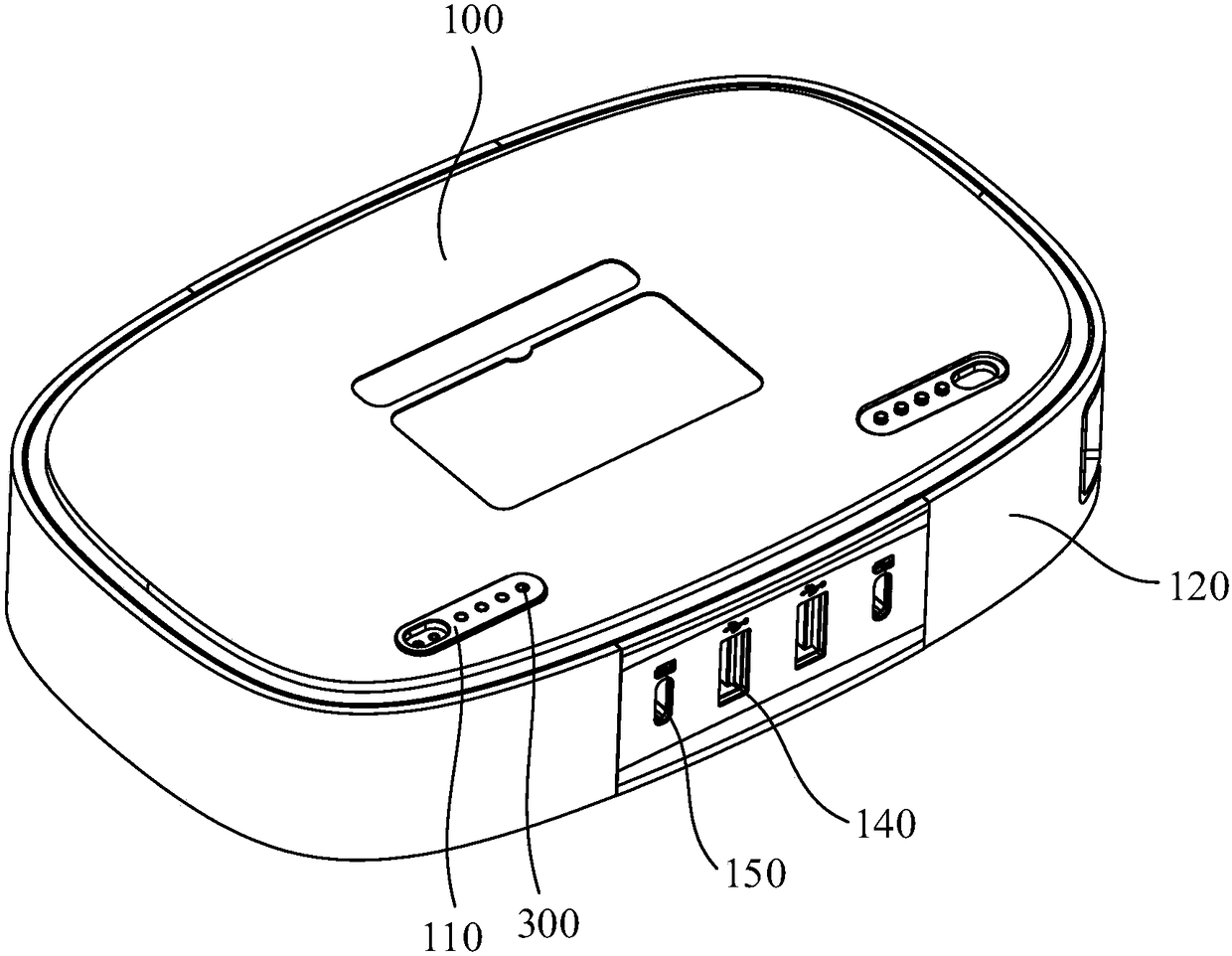

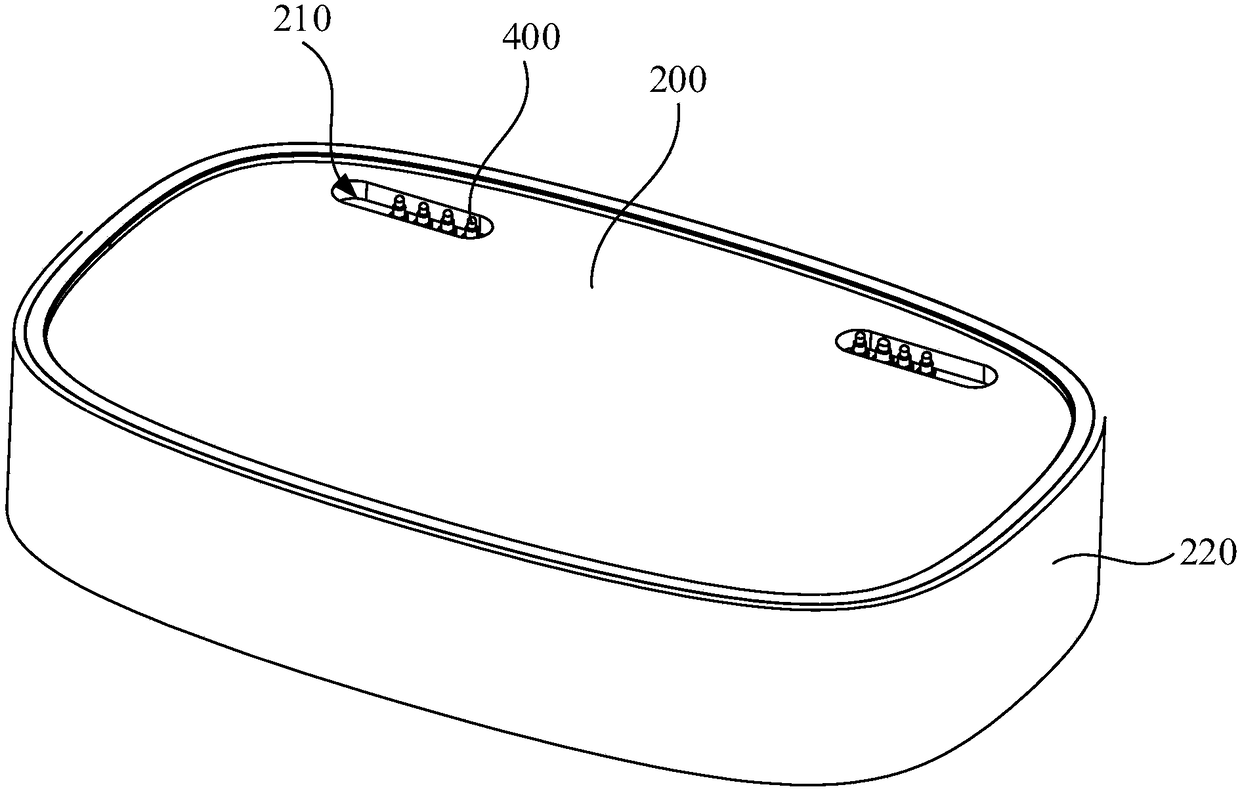

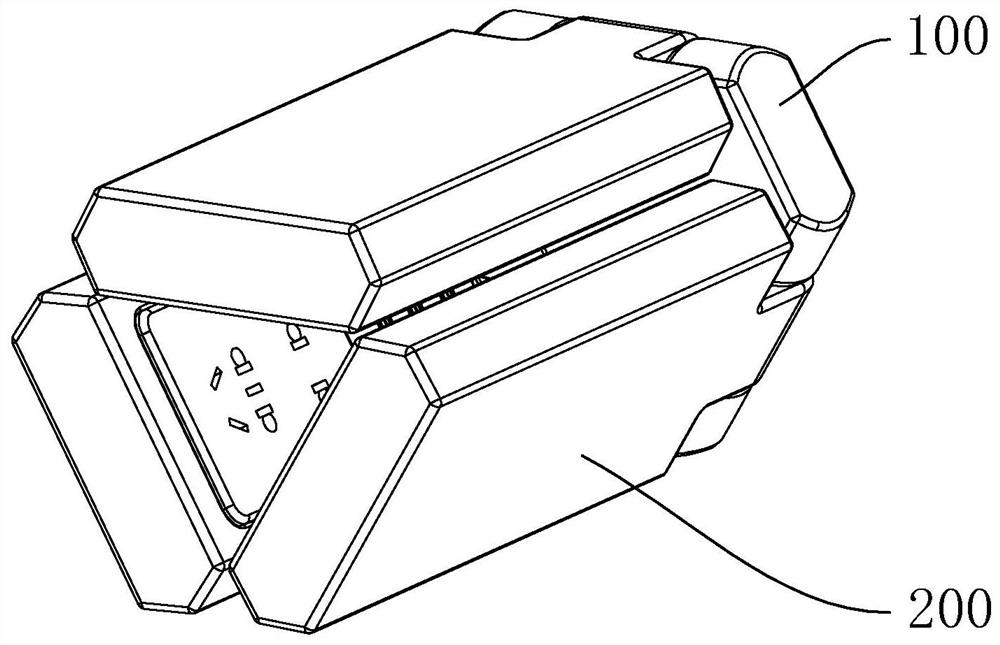

Mobile power

InactiveCN108258773AAdapt to use needsSimple structureCircuit monitoring/indicationDifferent batteries chargingEngineeringPower supply unit

The invention relates to a mobile power which comprises a first power supply unit and a second power supply unit. The first power supply unit is used for supplying power to electronic products and iselectrically connected with a first power connector part; the second power supply unit is also used for supplying power to the electronic products, is detachably mounted on the first power supply unitand electrically connected with a second power connector part. When the second power supply unit is detached from the first power supply unit, the first power supply unit and the second power supplyunit can charge the electronic products separately; when the second power supply unit is mounted on the first power supply unit, the second power connector part is in electric connection with the first power connector part so that the first power supply unit is in series connection or parallel connection with the second power supply unit to charge the electronic products. The mobile power can be selected reasonably according to voltage or current of the electronic products as needed to meet service requirements of the electronic products in different specifications, and has the advantages of simple structure and stable performance.

Owner:ECOFLOW TECH LTD

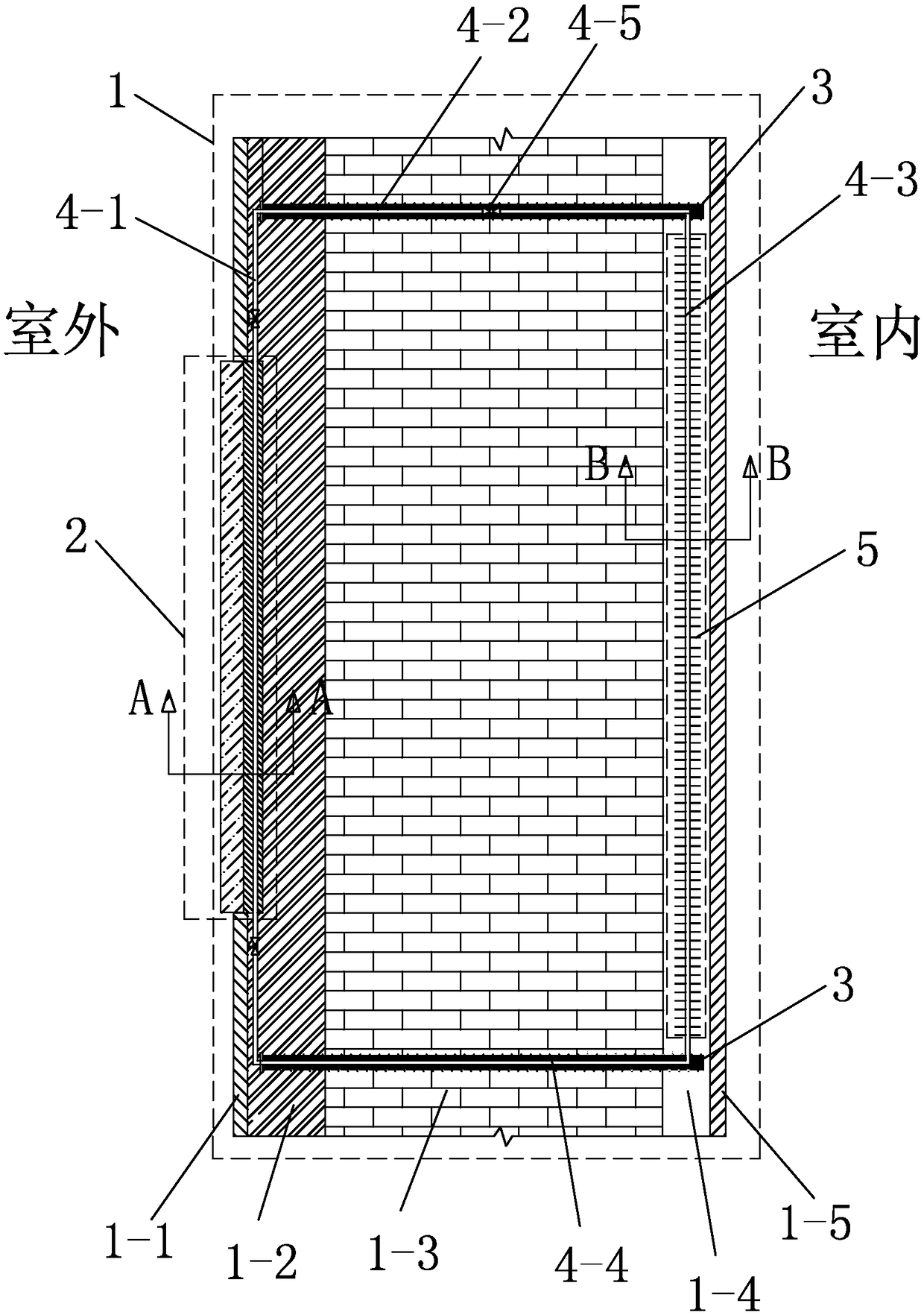

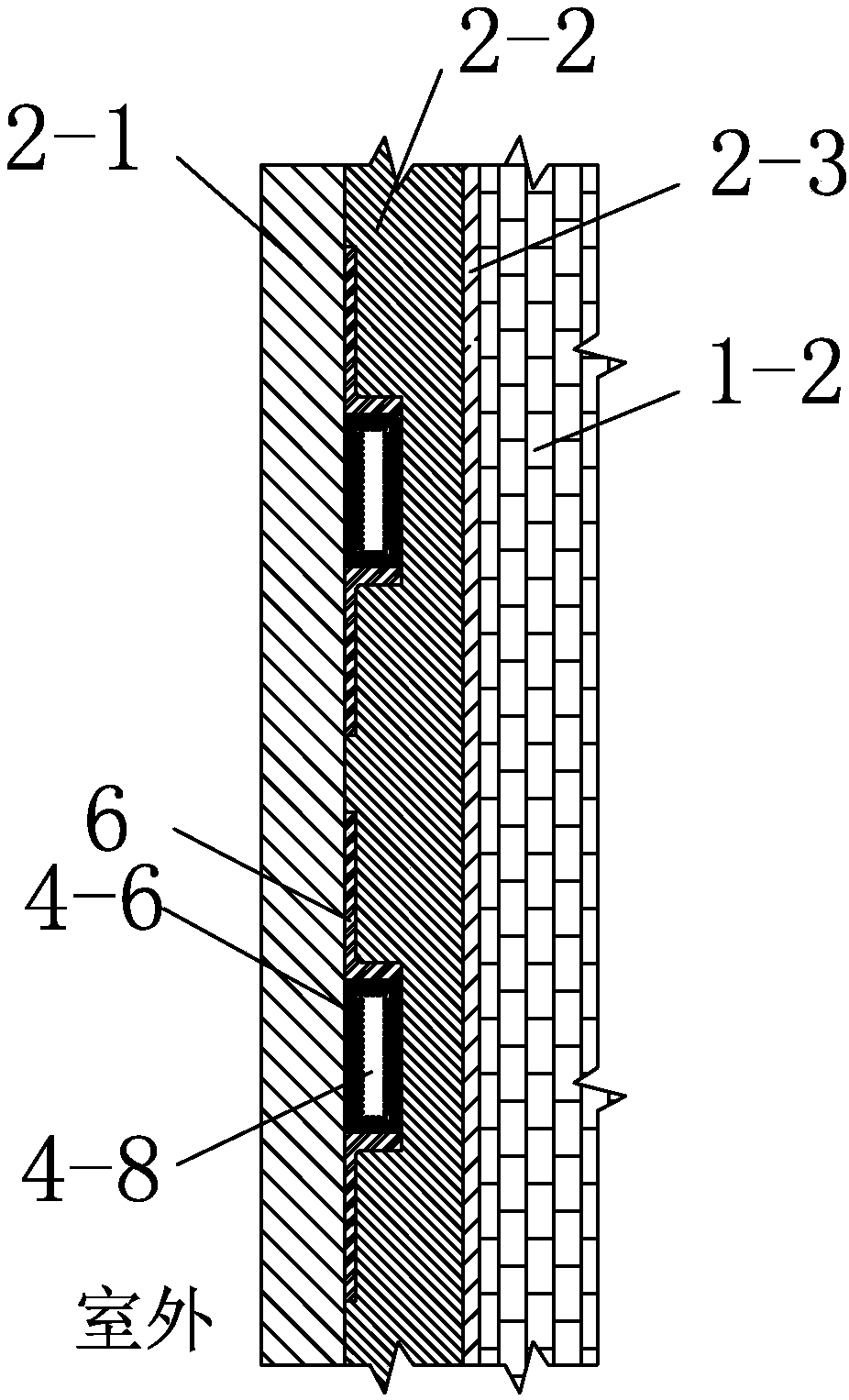

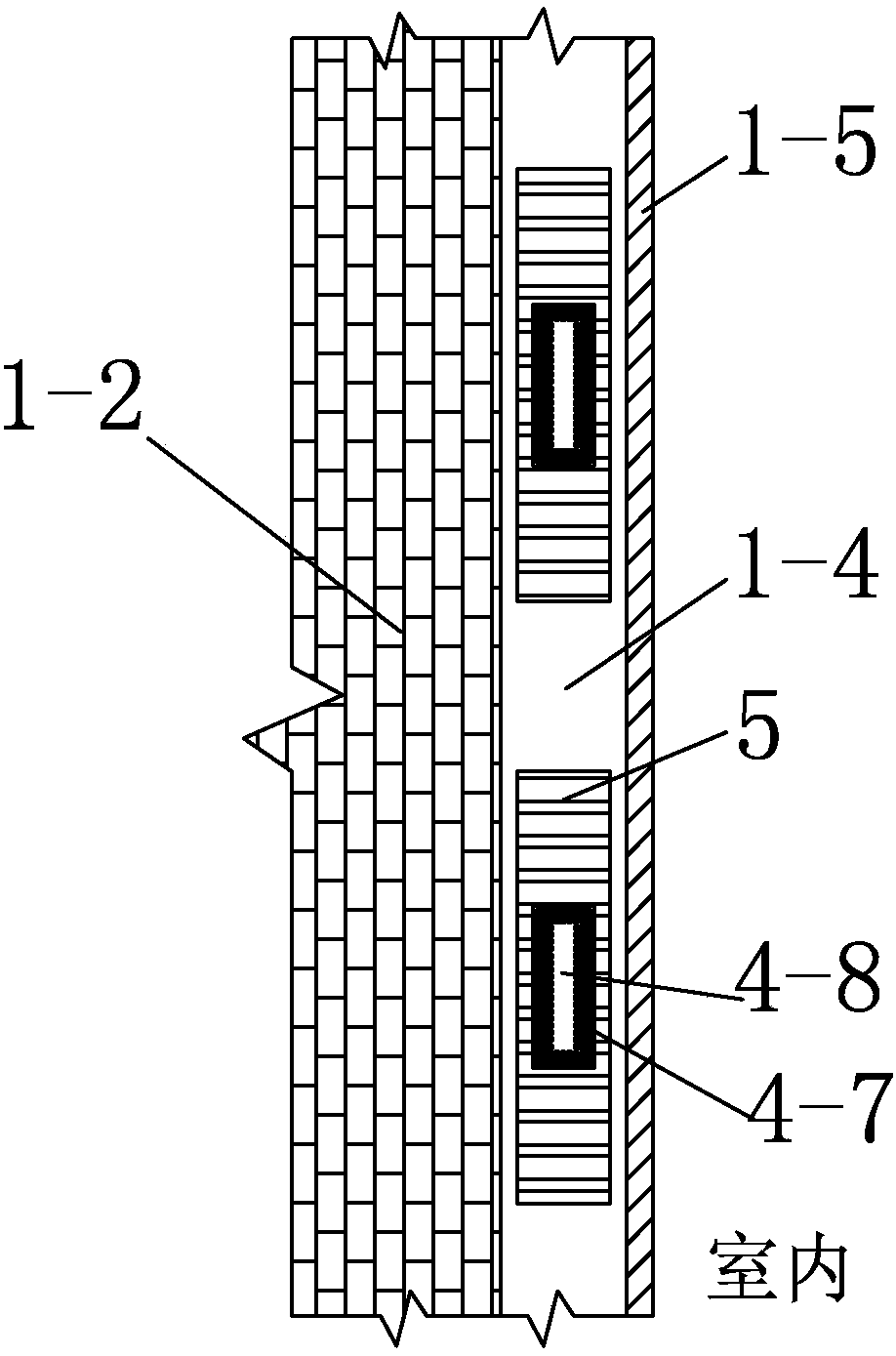

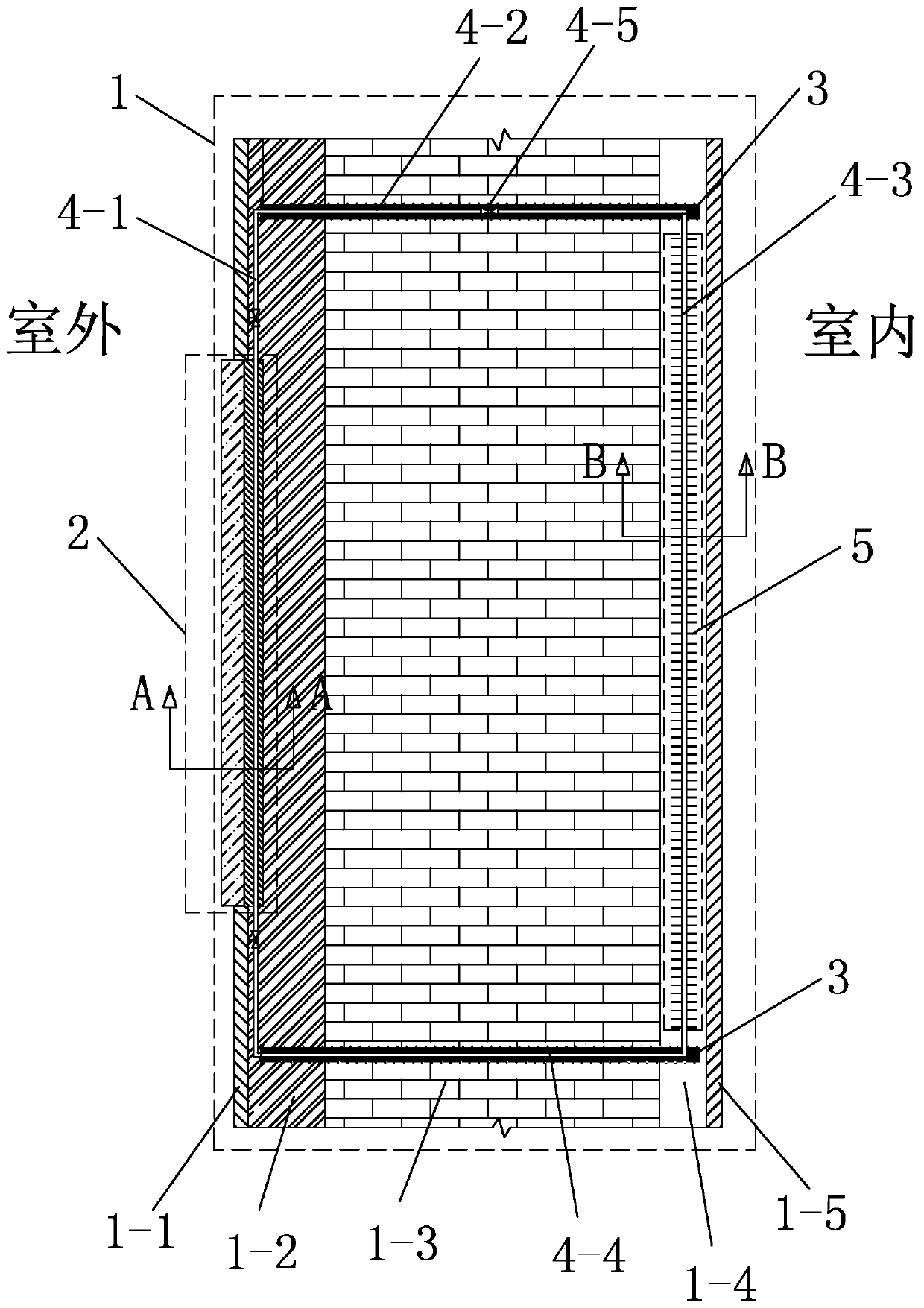

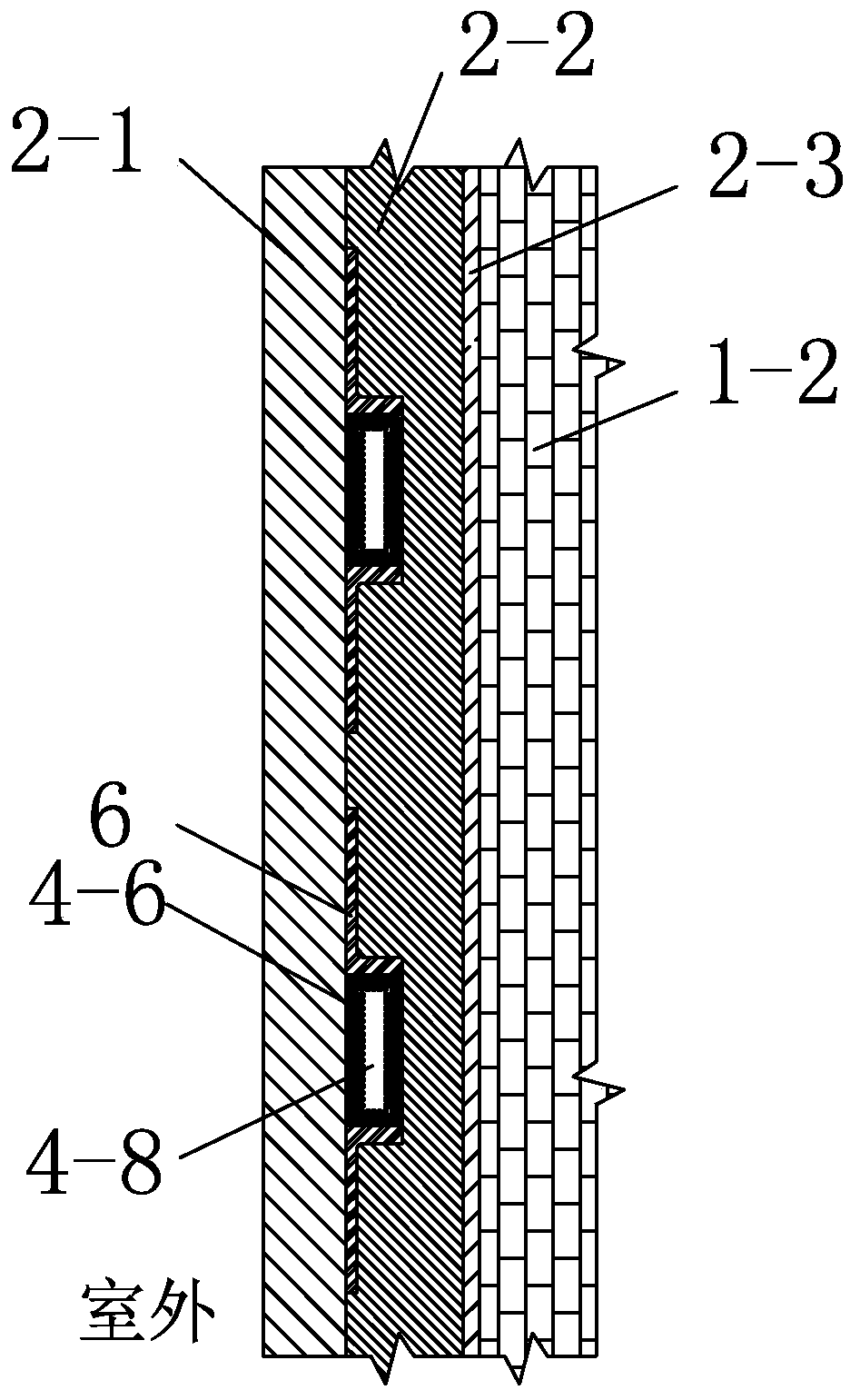

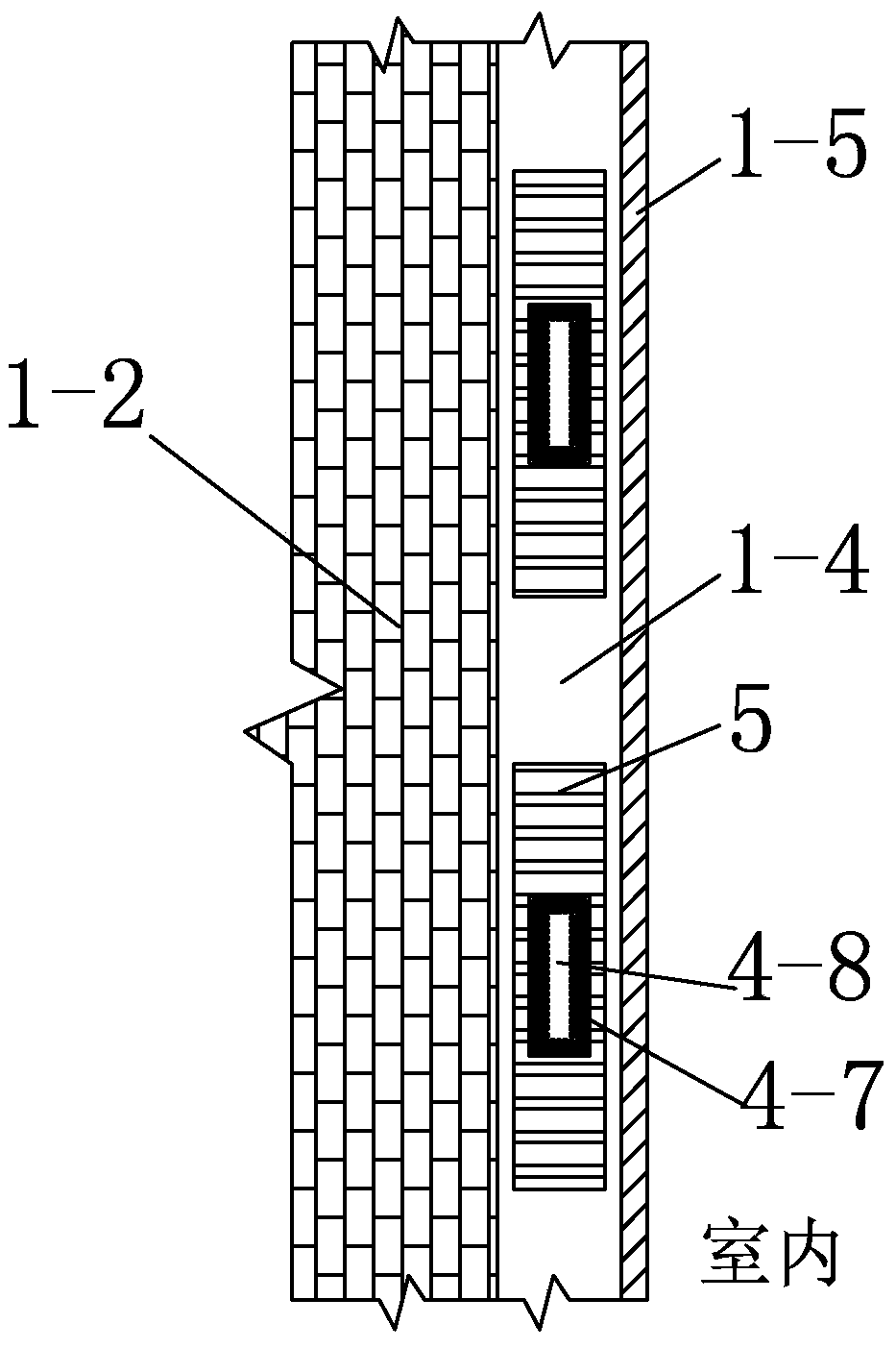

Passive composite wall for ultra-low energy construction

ActiveCN108487492AAchieve deliveryReduce complexityWallsClimate change adaptationInsulation layerLower grade

The invention discloses a passive composite wall for an ultra-low energy construction. The passive composite wall reduces the complexity of an energy supply system of the ultra-low energy constructionand reduces the operation and use costs. The passive composite wall comprises a composite wall body, a wall body outer side member and a plurality of loop heat pipe units; the wall body outer side member is an integrated structure composed of a photovoltaic module, a member heat-insulation layer and a base plate from outside to inside; each loop heat pipe unit comprises a closed circulation pipeline and a control valve, wherein each closed circulation pipeline is composed of a hollow outdoor end heat transfer pipe, an upper heat transfer pipe, an indoor end heat transfer pipe and a lower heattransfer pipe; an outdoor end wick corresponding to the back of the photovoltaic module is arranged in each outdoor end heat transfer pipe, each indoor end heat transfer pipe is internally provided with an indoor end wick, and the centers of each outdoor end wick and each indoor end wick are working medium flow channels; and the control valve is installed on the closed circulation pipeline. The passive composite wall makes full use of low-grade solar energy and night environment cold energy to supply and store cold energy and heat energy for the ultra-low energy construction, and the operation and use costs are reduced.

Owner:TIANJIN UNIV

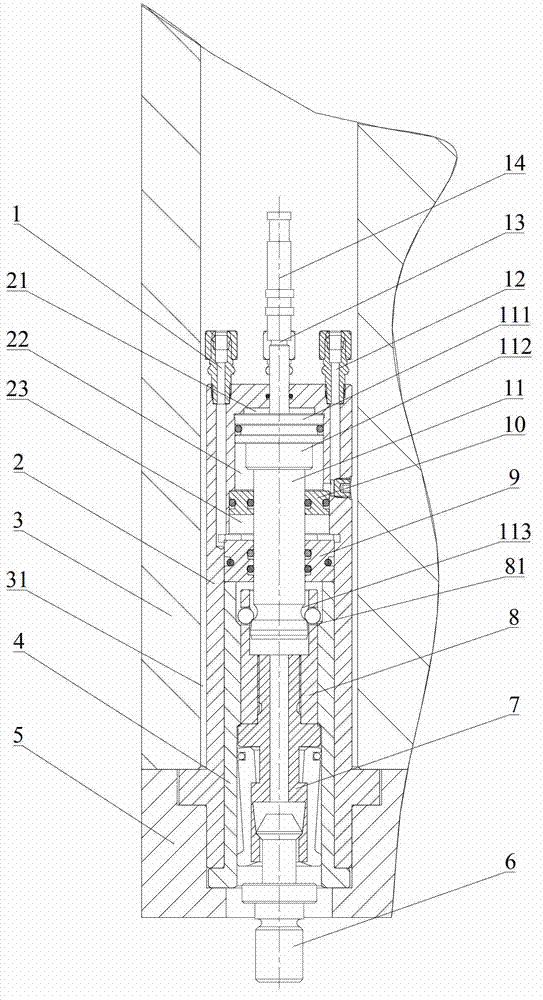

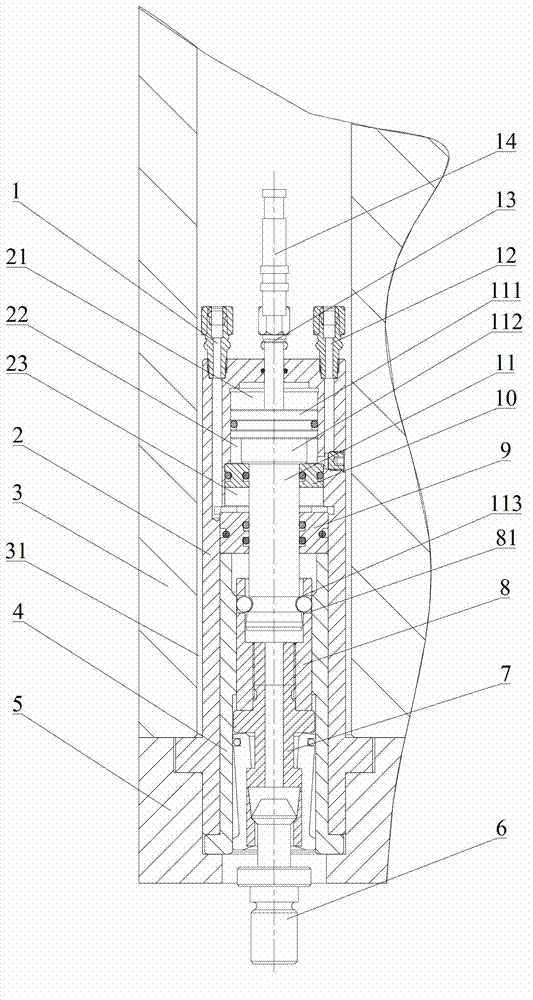

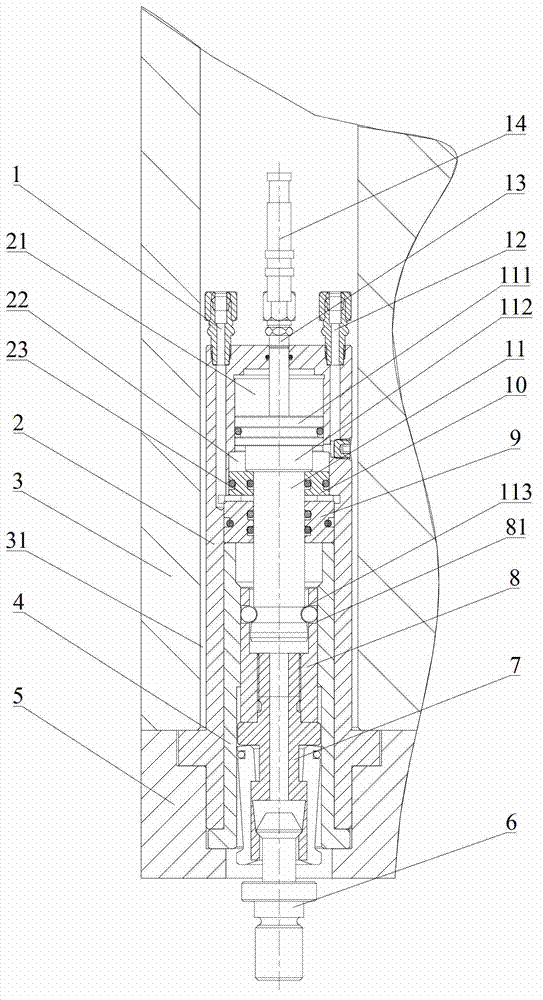

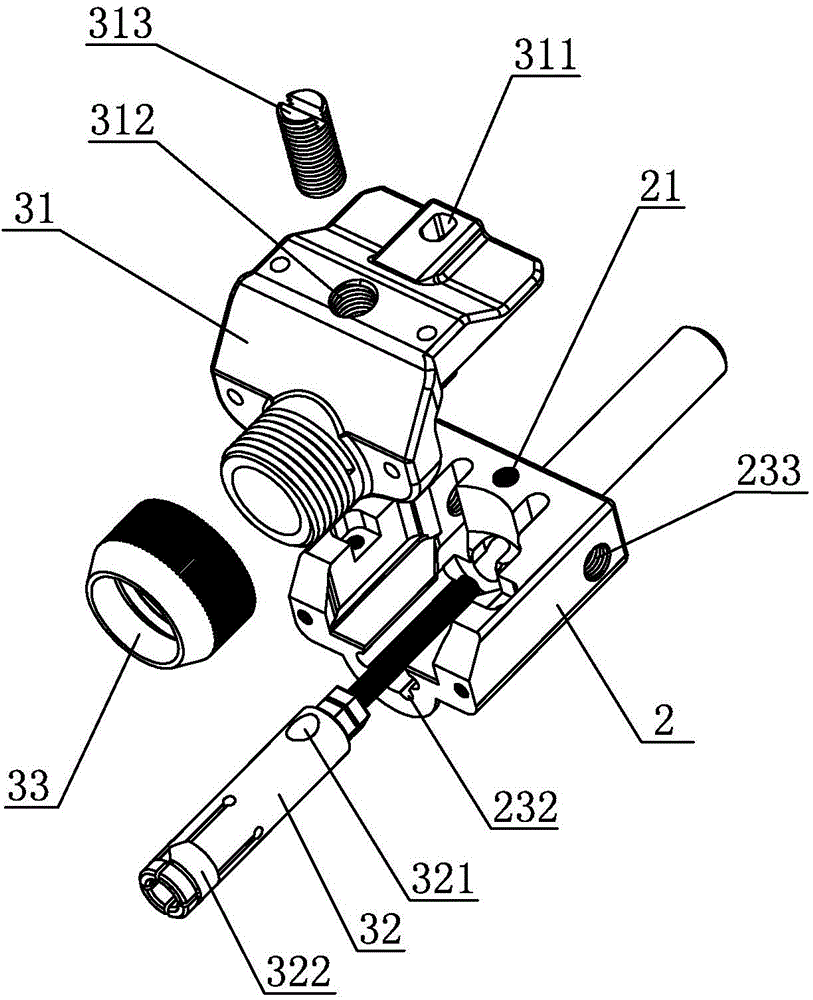

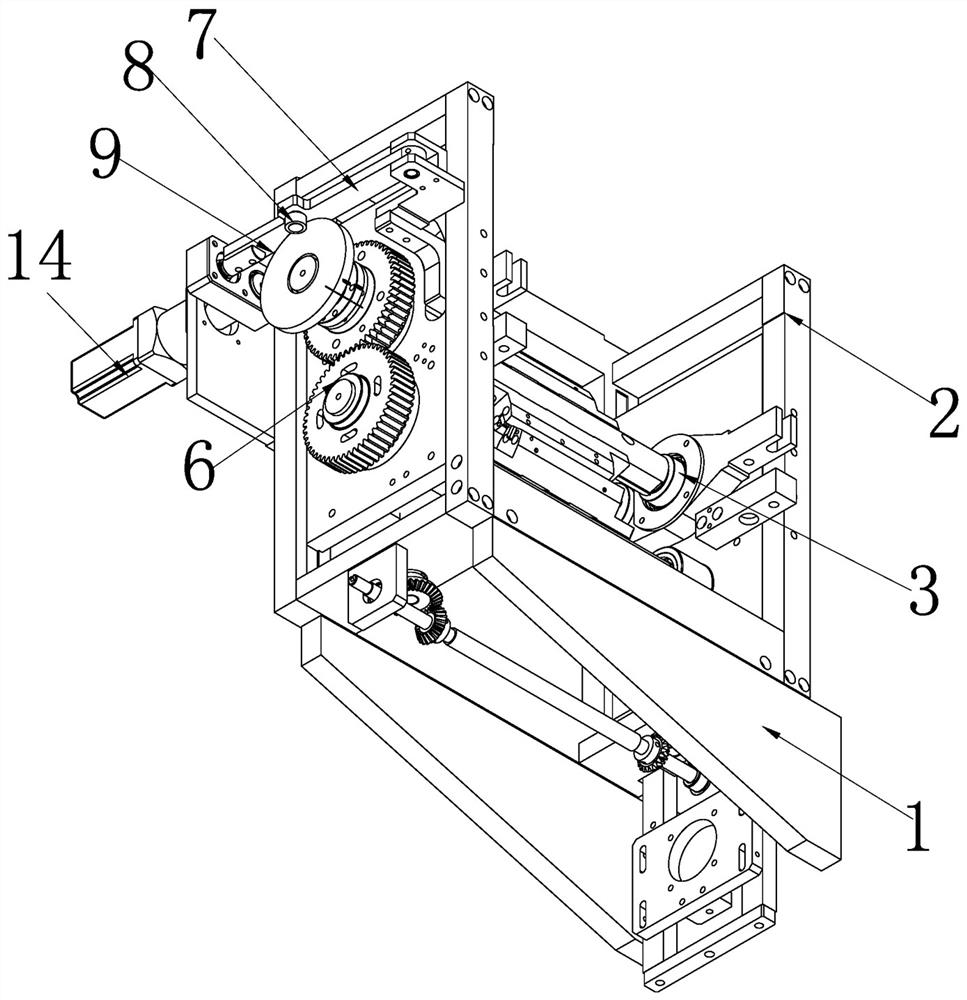

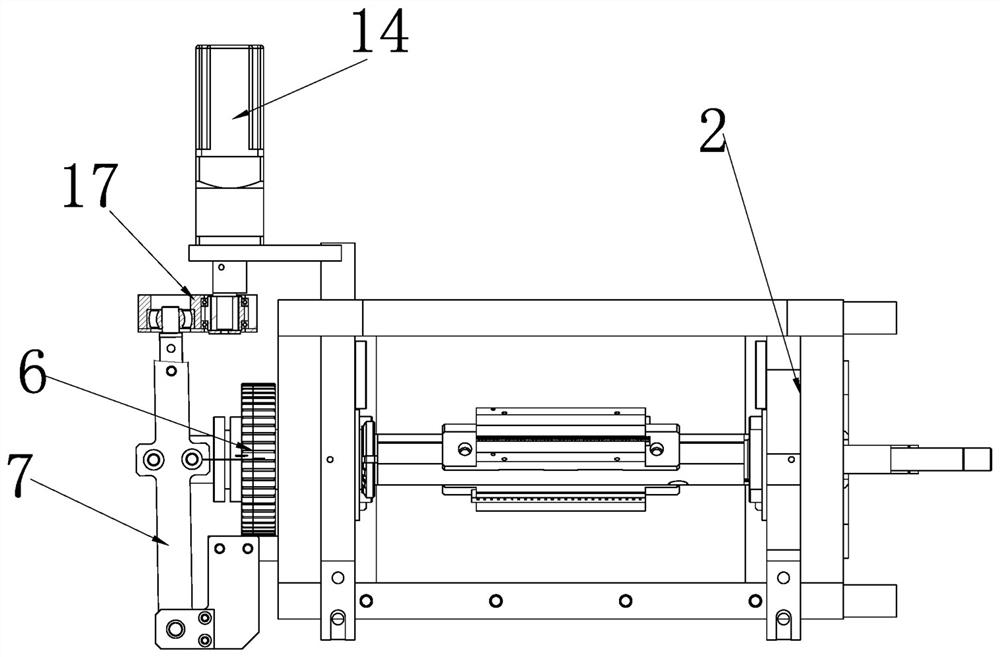

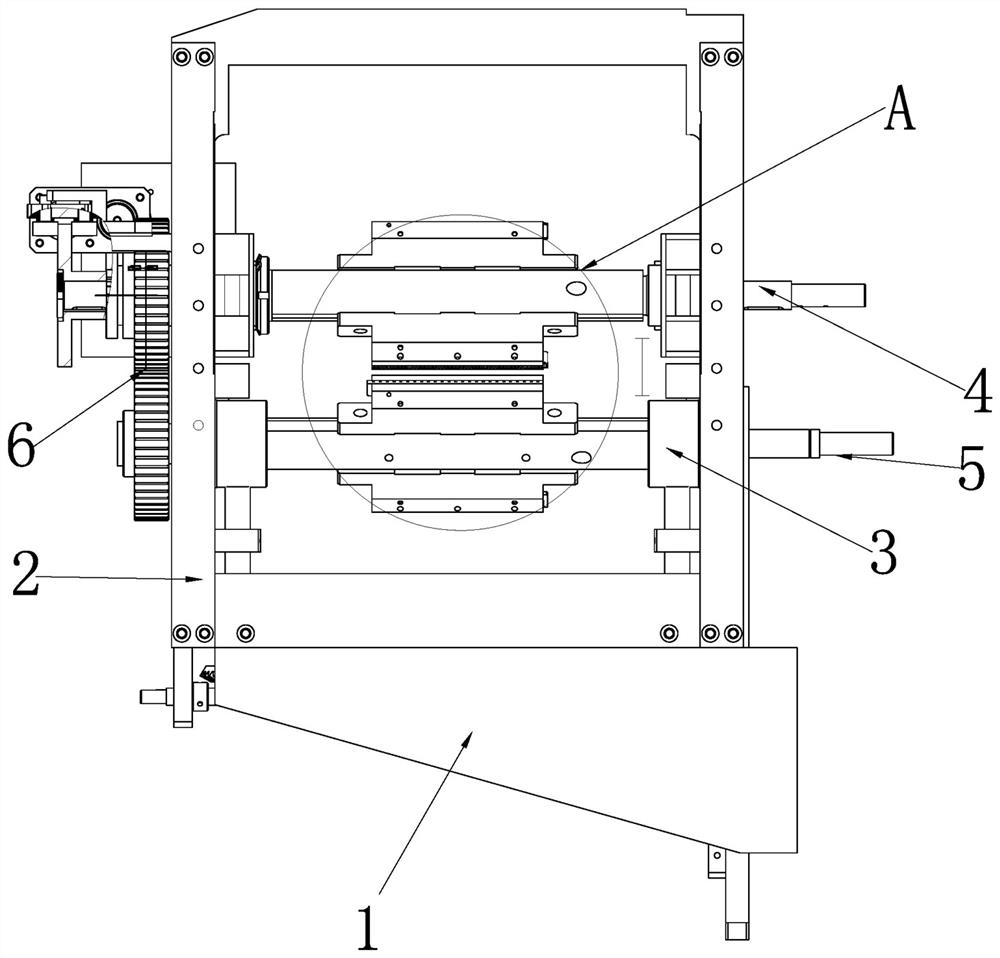

Accessory head tension device and machine tool

InactiveCN102806485AAdapt to use needsPrecision positioning equipmentPositioning apparatusEngineeringMachine tool

The invention relates to the field of a machine tool and discloses an accessory head tension device and a machine tool. The accessory head tension device comprises a blind rivet, a cylinder, a piston rod, a floating piston and a fixed piston, wherein one end of the blind rivet is connected with an accessory head, the cylinder is longitudinally arranged at the tail part of a ram, the piston rod is arranged in the cylinder, the top end of the piston rod is provided with a one-piece piston, a first coil cavity is formed between the top side of the one-piece piston and the top of the cylinder, the bottom end of the piston rod is connected with the other end of the blind rivet through a tension mechanism, the floating piston is sleeved on the piston rod in a sliding way, a second cavity is formed between the top side of the floating piston rod and the bottom side of the one-piece piston, the top side of the floating piston is limited by the steps in the cylinder, the fixed piston is movably arranged on the piston rod, a third cavity is formed between the top side of the fixed piston and the bottom side of the floating piston, and the fixed piston is fixed with the cylinder. The accessory head tension device can enable the accessory head to be in tensioned, divided and fully-loose states so as to be suitable for the use demands.

Owner:SANY GRP

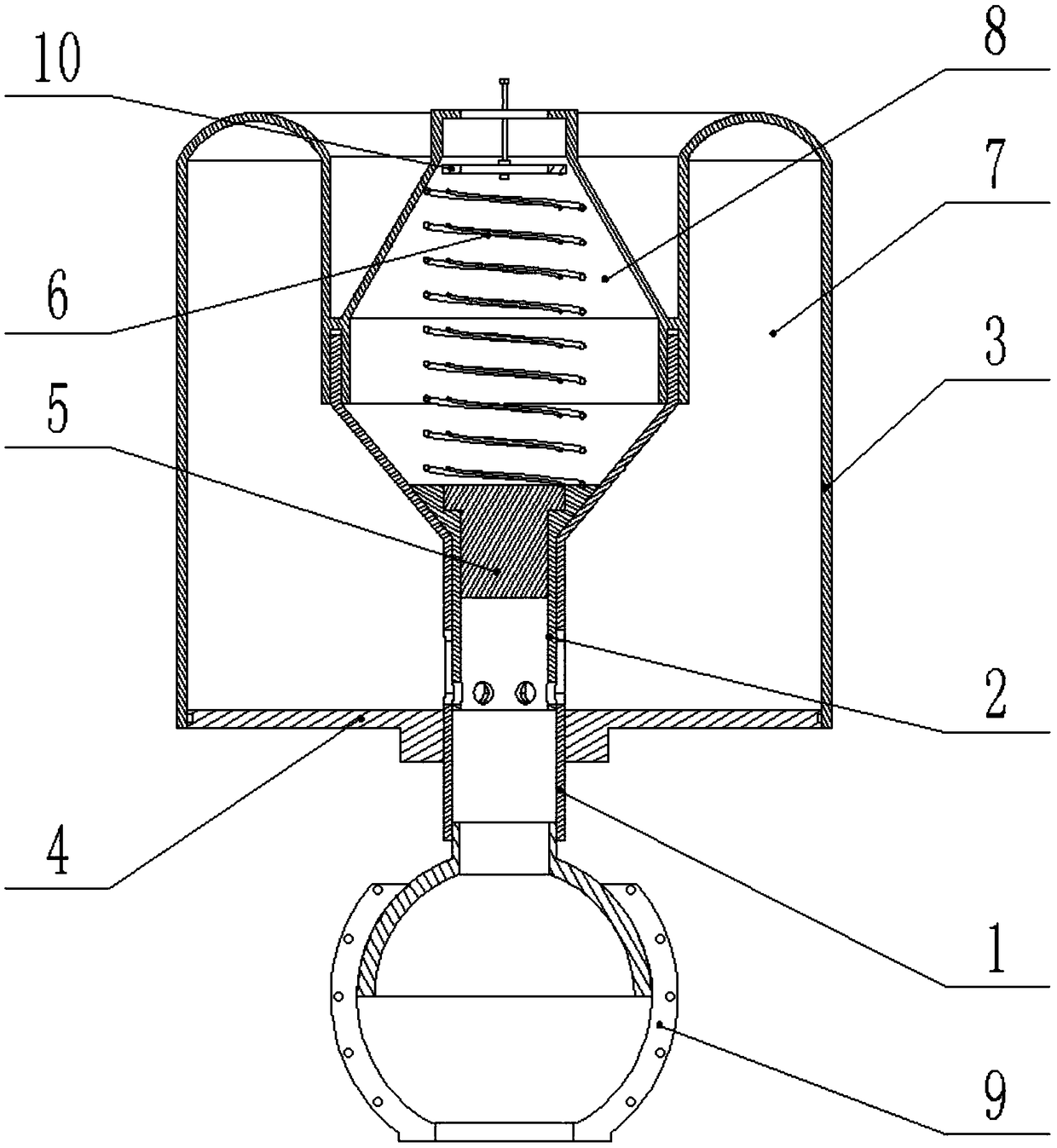

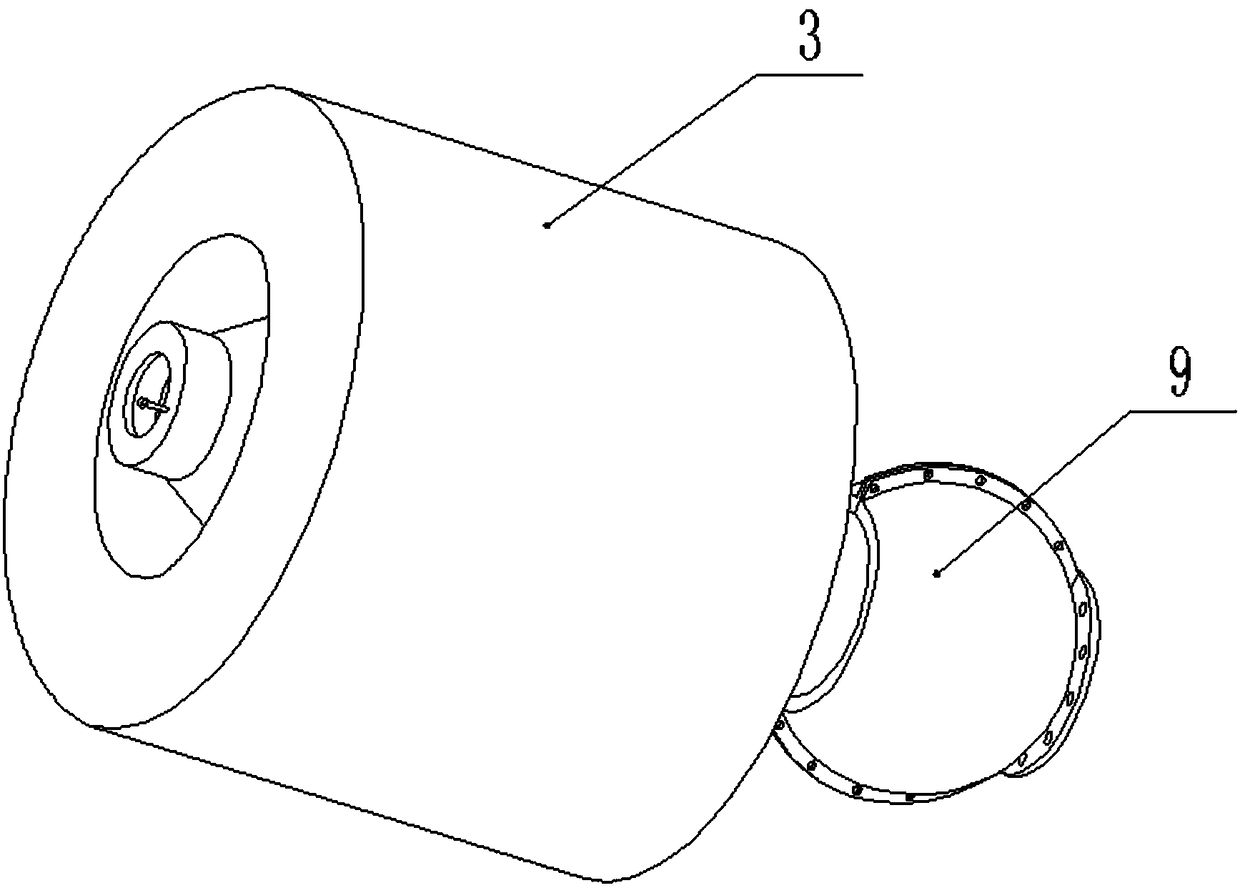

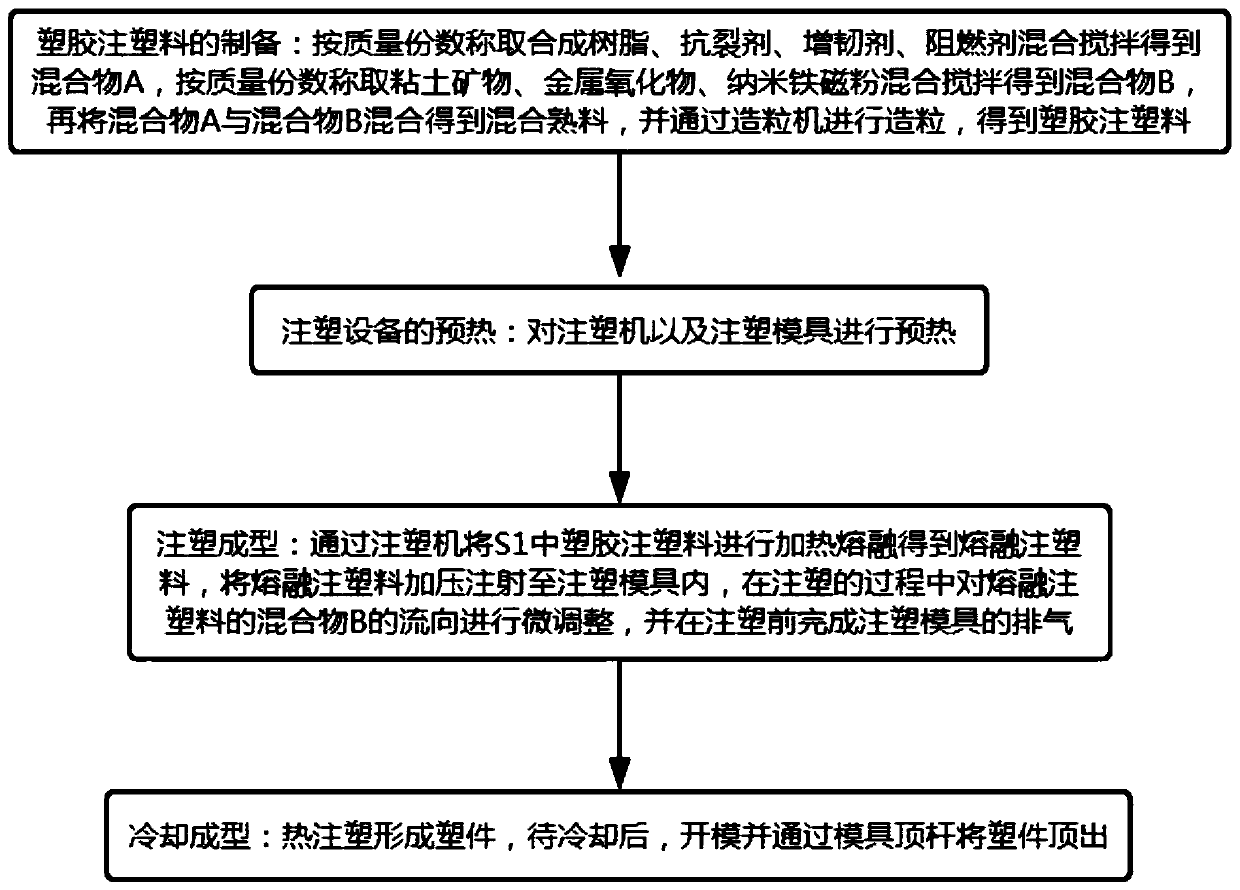

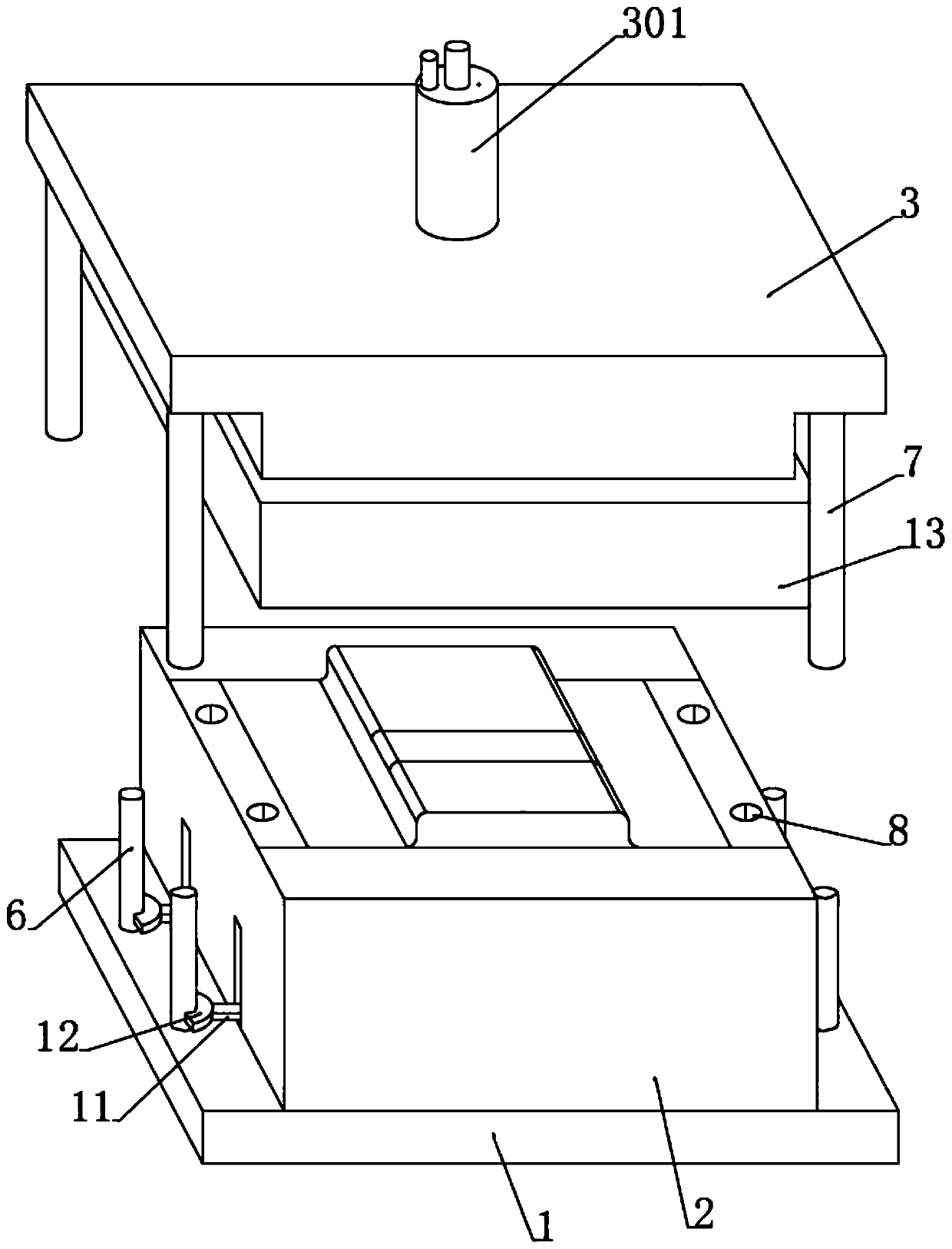

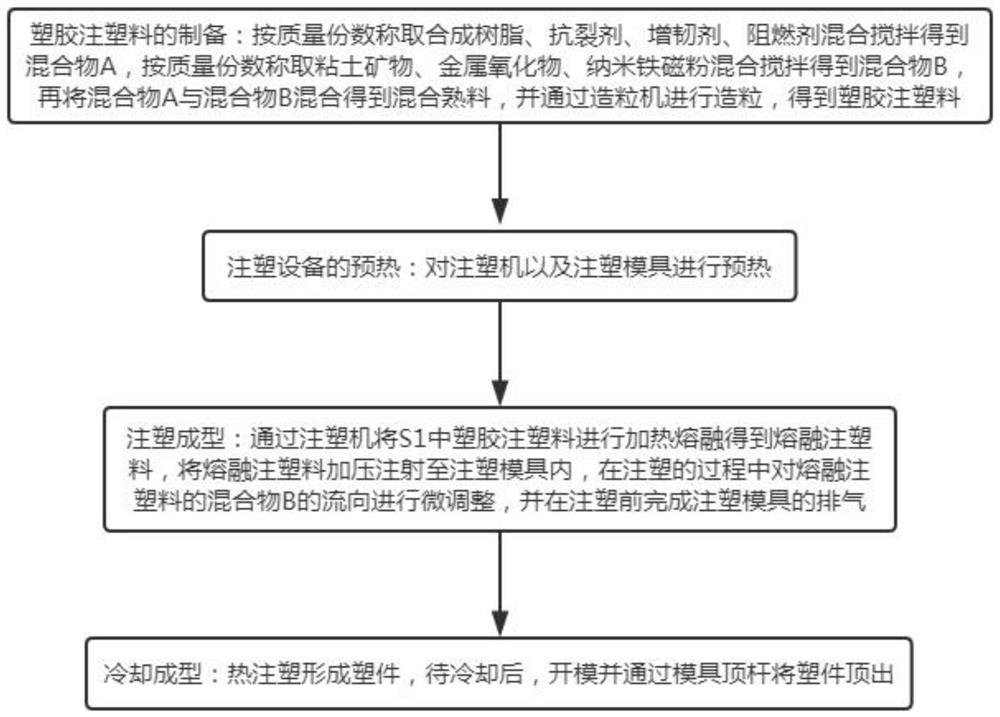

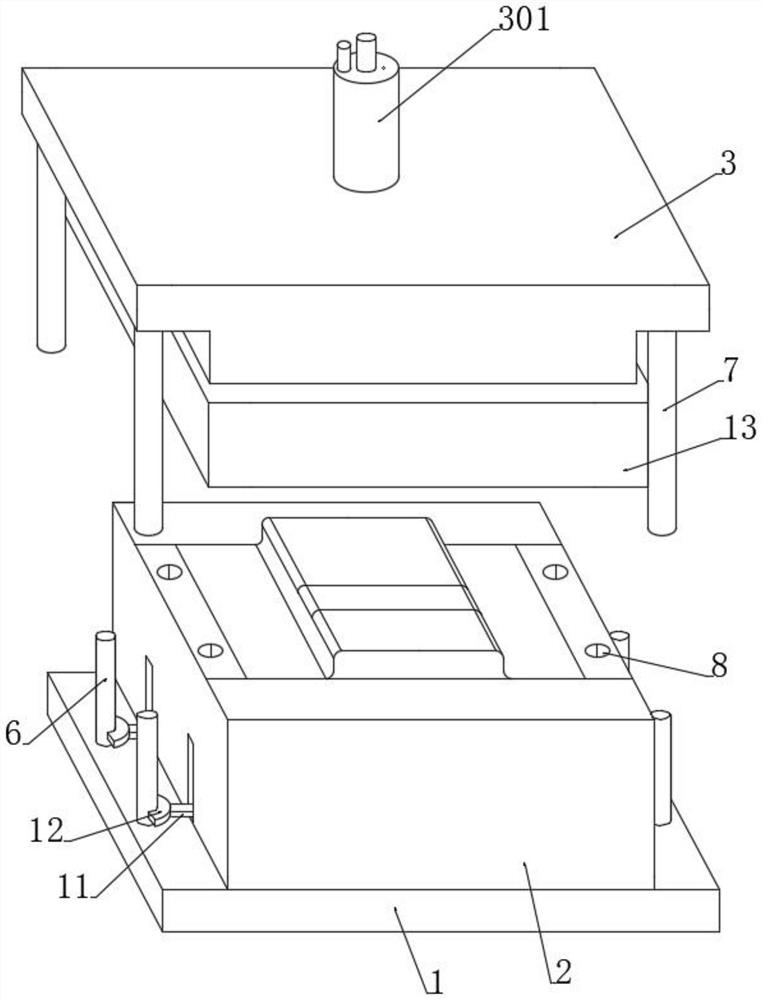

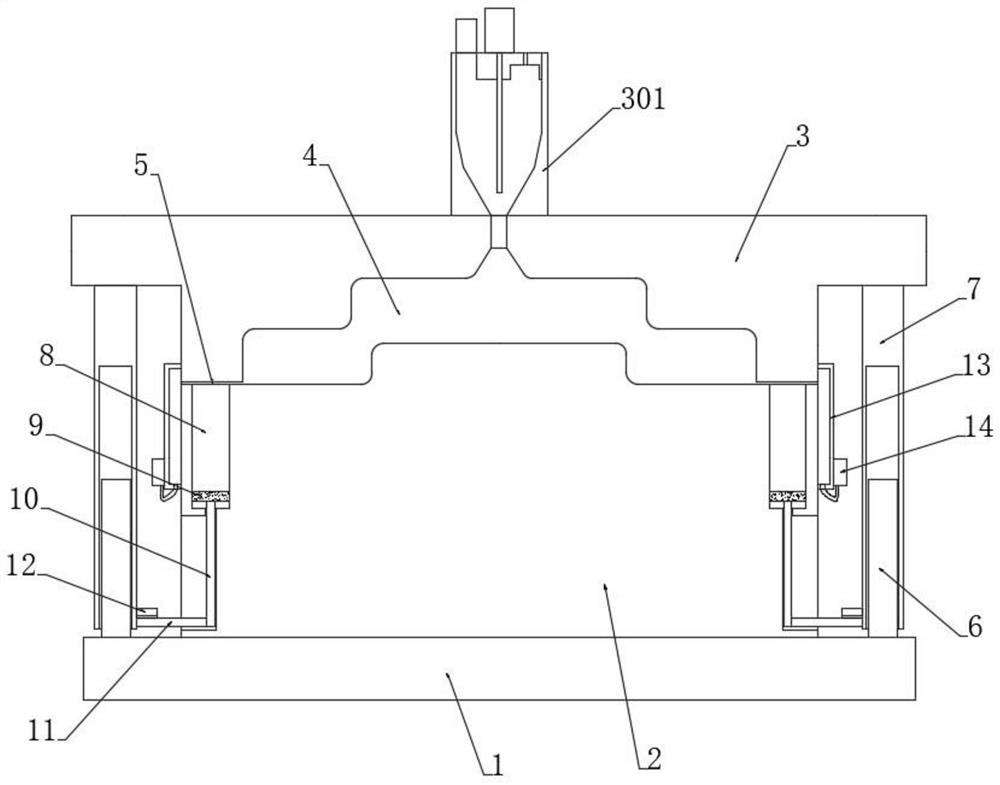

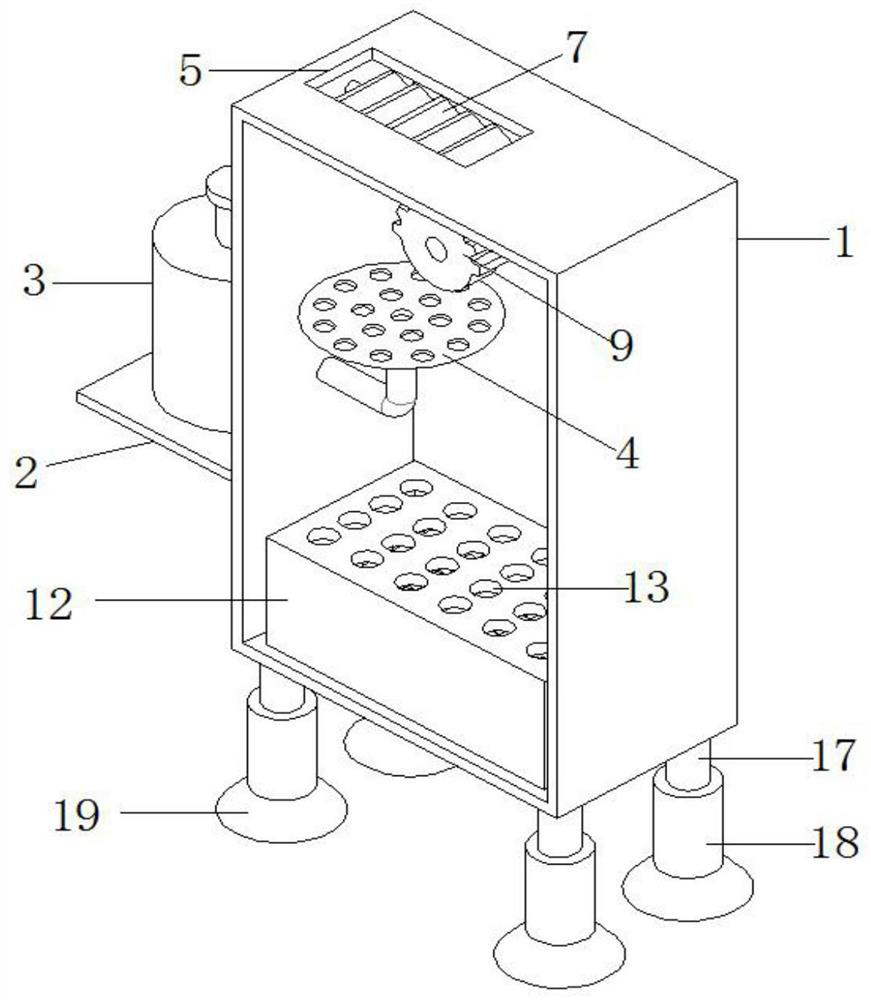

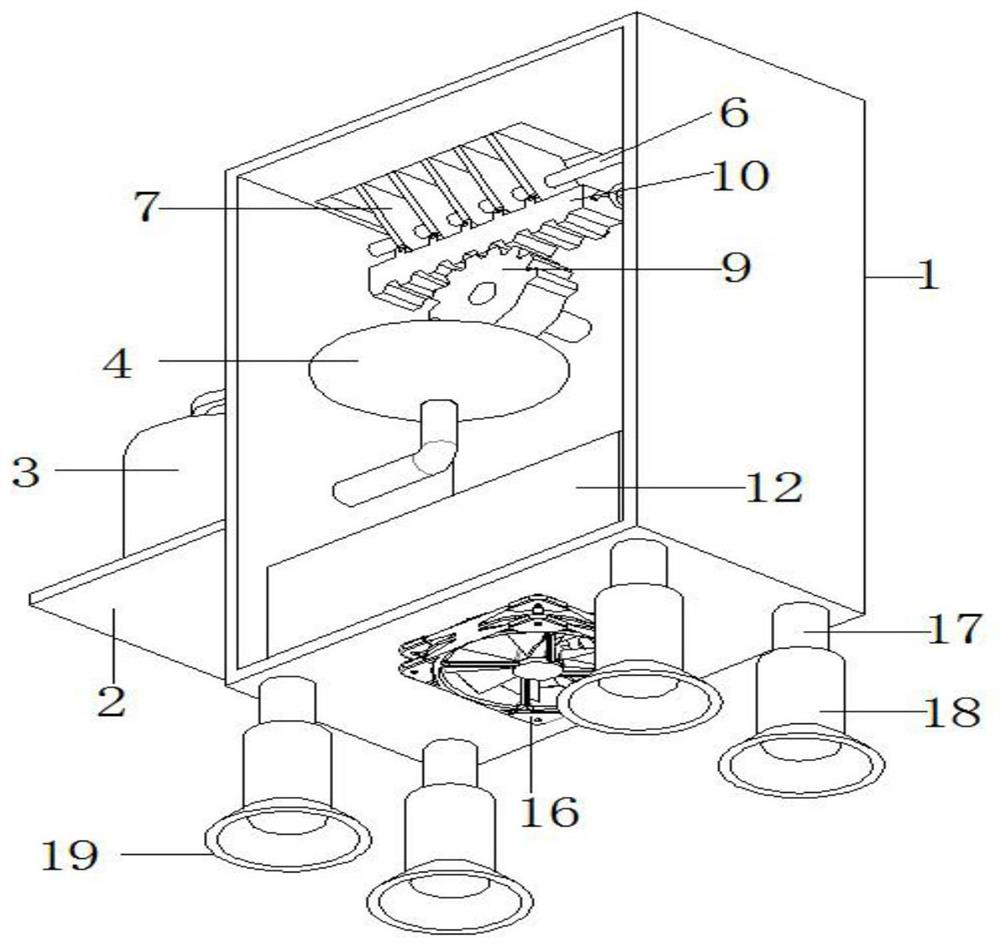

Injection molding process of fine-tune type dust collector shell

ActiveCN111497103AHigh mechanical strengthIncreased anti-aging strengthCoatingsMagnetic effectClay minerals

The invention relates to an injection molding process of a fine-tune type dust collector shell, and belongs to the technical field of injection molding processes. Clay minerals and metal oxides are added to injection molding raw materials, so that the mechanical strength and aging resistance of the injection molding materials are effectively improved. Moreover, materials with high mechanical strength are mixed with nano magnet powder, and the nano magnet powder is adsorbed in the porous-structure materials with high resistance. An external electromagnet is arranged at the corresponding position of a cavity of an injection mold, and after the external electromagnet is electrified, the flow direction of the injection molding materials with high mechanical strength is fine tuned in the injection molding process. Even if the materials with high mechanical strength are gathered to a designated position under the magnetic effect, the use requirements of the end face of an existing dust collector shell for different strengths can be better met. Gas in the injection mold can be easily absorbed and discharged in the mold closing process, and when the mold is opened, the gas which is pushedout effectively blows chips adhered to the parting surface of the mold.

Owner:苏州博琪海电器有限公司

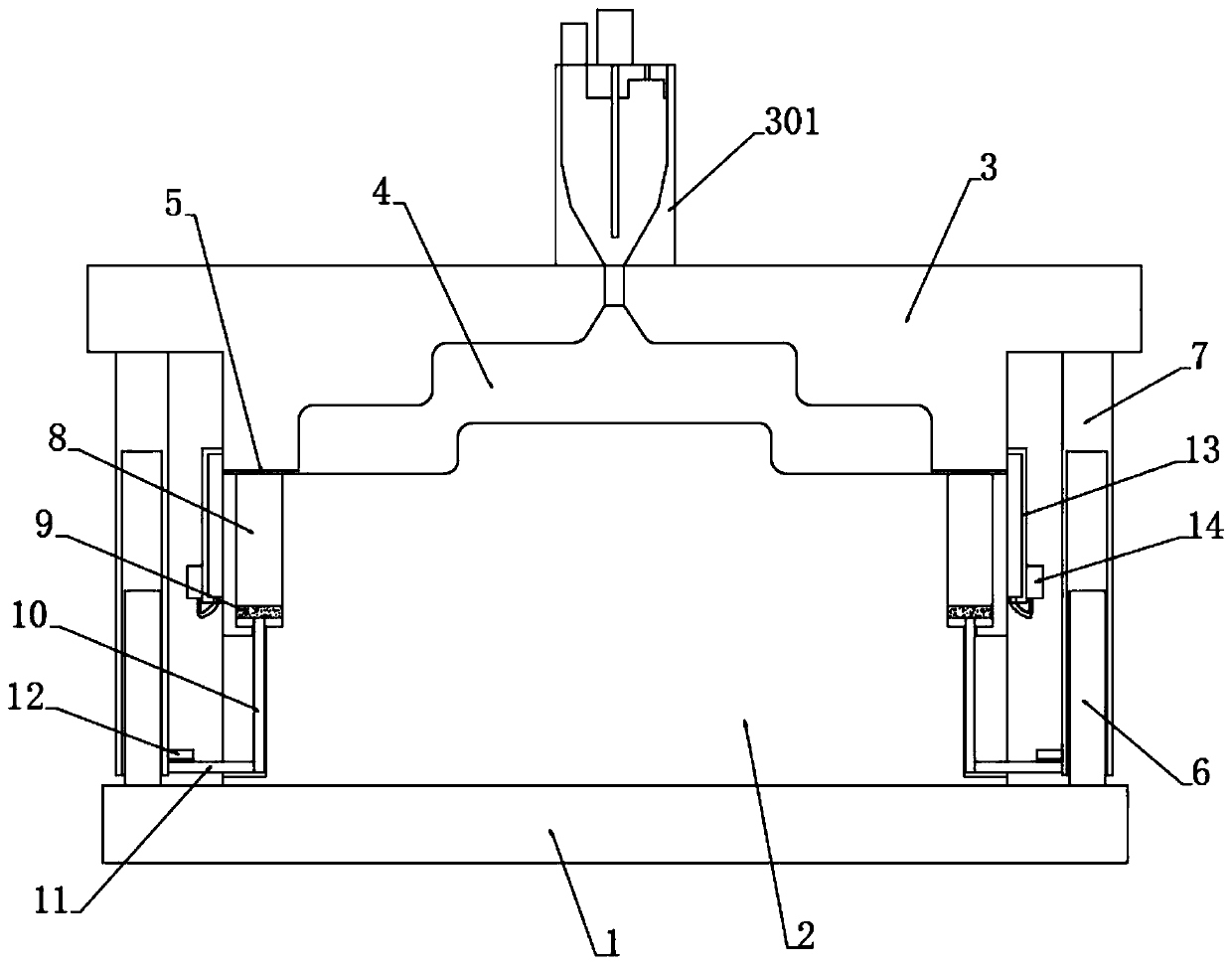

Miniature high-strength flexible optical cable

InactiveCN104834069AGood weather resistanceImprove mechanical propertiesFibre mechanical structuresShortest distanceEngineering

The invention relates to a miniature high-strength flexible optical cable. The miniature high-strength flexible optical cable includes a cable core and an outer sheath, and is characterized in that the cable core is wrapped in an ultrathin inner sheath, a nonmetal outer reinforced layer is laid outside the ultrathin inner sheath, and the outer sheath wraps the nonmetal outer reinforced layer. The miniature high-strength flexible optical cable is large in number of cores, thin in outer diameter, light in weight and excellent in bending performance, saves wiring space resources, and reduces construction cost; the optical cable has good weather resistance and mechanical property, and satisfies using requirements of multiple fields such as pipelines, indoor, short-distance overhead, jumper wire manufacture, machine rooms, medical treatment, wind power industry and so on; and the optical cable is of an all-dry type structure, all units are arranged reasonably, and the optical cable adapts to requirements for the outer diameter dimension, bending radius and tensile strength of the optical cable in a severe communication environment. A cable opening rope is arranged between the inner and outer sheaths, thereby facilitating direct access to a room after the outer sheath is removed to perform diverging connection, and the miniature high-strength flexible optical cable is more convenient to use and lay.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Replaceable gun head of multifunctional electric welding gun

ActiveCN103600161AThe overall structure is simpleGood effectShielding gas supply/evacuation devicesElectrode supporting devicesFusion weldingClosed cavity

The invention discloses a replaceable gun head of a multifunctional electric welding gun. The replaceable gun head comprises an electroconductive member made of metal and an insulated connecting member, a mounting groove is arranged on the electroconductive member, an insulated outer cover is covered above the mounting groove to enable a closed cavity to be formed between the electroconductive member and the outer cover, an opening allowing a fusion welding object connected with the electroconductive member to extend out is arranged at the front end of the cavity, and a welding column fixing member used for fixing a columnar fusion welding object or a compressing device used for compressing a sheet fusion welding object is arranged in the cavity. The columnar fusion welding object or the sheet fusion welding object can be mounted on the replaceable gun head by replacing part of accessories, and the replaceable gun head has various functions and can meet using needs of different using occasions.

Owner:JIANGMEN BOSJOB

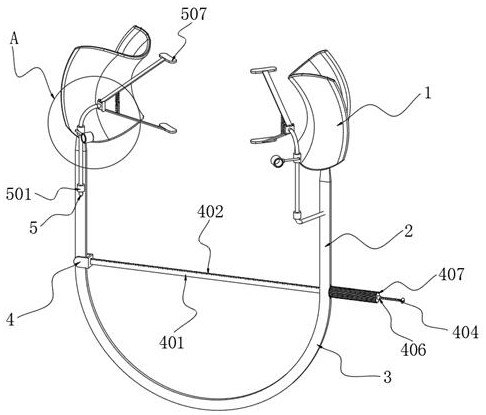

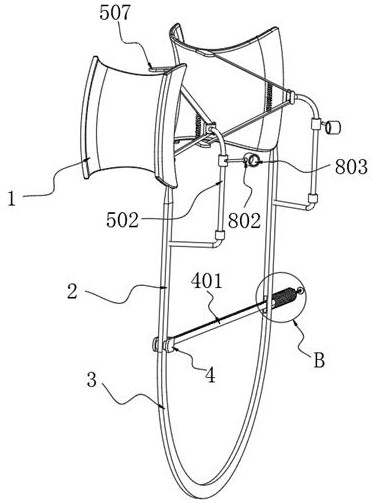

Pediatric oral cavity dilator

The invention provides a pediatric oral cavity dilator and belongs to the technical field of pediatric medical instruments, the pediatric oral cavity dilator comprises a lip supporting mechanism, the lip supporting mechanism is composed of two side lip supports, connecting plates and an arc-shaped connecting strip, the two connecting plates are fixed to the front sides of the bottoms of the two side lip supports respectively, the arc-shaped connecting strip is fixed to the bottoms of the two connecting plates, a fine adjustment mechanism is arranged between the two connecting plates, tooth supporting mechanisms are arranged on the front sides of the two connecting plates, each tooth supporting mechanism comprises a lower connecting rod, the lower connecting rod is fixed to the front side wall of the connecting plate, a bearing is fixed to the upper end of the lower connecting rod, an upper connecting rod is rotationally connected into the bearing, a kidney-shaped sleeve is fixed to the tail end of the upper connecting rod, an upper supporting plate and a lower supporting plate are rotationally connected into the kidney-shaped sleeve through two rotating shafts, a spring is arranged between the upper supporting plate and the lower supporting plate, and the whole device is reasonable in structural arrangement, ingenious in conception, flexible and convenient to use, convenient to clean, capable of being recycled, capable of avoiding resource waste and good in child oral cavity opening effect.

Owner:杭州中尚电子商务有限公司

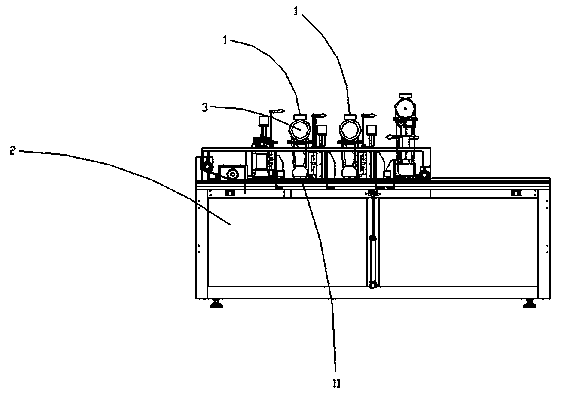

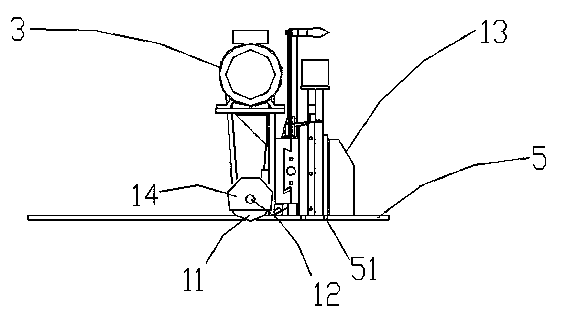

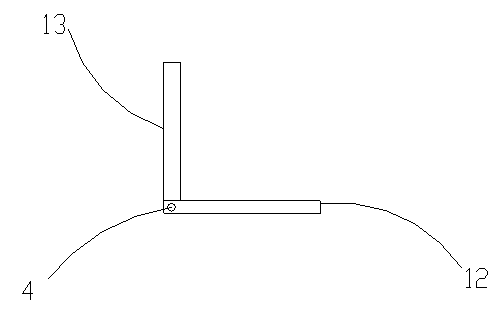

Automatic finished bag product quantitative cutting device for continuous packaging machine

PendingCN111792128ASimple structureReduce manufacturing costPackagingManufacturing engineeringDrive wheel

The invention provides an automatic finished bag product quantitative cutting device for a continuous packaging machine. The automatic finished bag product quantitative cutting device comprises a base; the two sides of the base are each provided with a rack, an upper cutter shaft and a lower cutter shaft are arranged between the two racks in a transverse-crossing mode through a bearing seat, one end of the upper cutter shaft and one end of the lower cutter shaft are connected to rotate through a synchronous gear, the other end of the upper cutter shaft and the other end of the lower cutter shaft are connected with a power mechanism, and the power mechanism drives the upper cutter shaft and the lower cutter shaft to rotate synchronously; the automatic finished bag product quantitative cutting device further comprises a switching device arranged on one sides of the racks, the switching device comprises a driving arm with one end being mounted on the racks in a hinged mode, a limiting device is arranged on the driving arm, and a driving wheel mounted on the upper cutter shaft is clamped in the limiting device; and a switching mechanism is further arranged on the racks, and the switching mechanism drives the driving arm to swing to drive the upper cutter shaft to axially move. The automatic finished bag product quantitative cutting device has the beneficial effects that tooth press-forming or cutting-off operation of packages can be completed on the same equipment, structure simplification is facilitated, the production cost of the equipment is lowered, and stability of the equipment is improved.

Owner:广东洛波特机器人自动化技术有限公司

Combined type grinding head device

InactiveCN103831714AImprove processing efficiencyImprove grinding effectGrinding machine componentsGrinding machinesEngineeringChanging equipment

The invention discloses a combined type grinding head device which is arranged on a machine frame and is connected with a driving device. The combined type grinding head device comprises a base and a plurality of grinding head mechanisms connected with the base detachably, wherein the grinding head mechanisms include multiple identical or different grinding heads. Due to the fact that the combined type grinding head device comprises a plurality of grinding head mechanisms which include multiple identical or different grinding heads, multiple grinding operations can be achieved on one machine tool to meet different grinding requirements, equipment replacement or frequent grinding head replacement is not needed any more, machining efficiency is improved, different grinding heads can be combined for use according to technique requirements, and then an ideal grinding effect is realized.

Owner:SUZHOU IND ROBOT TECH

Disposable arteria femoralis compression hemostat

Owner:杭州艾力康医药科技有限公司

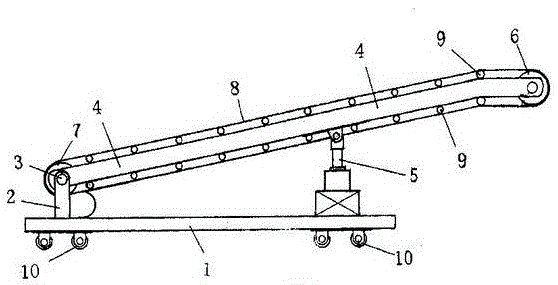

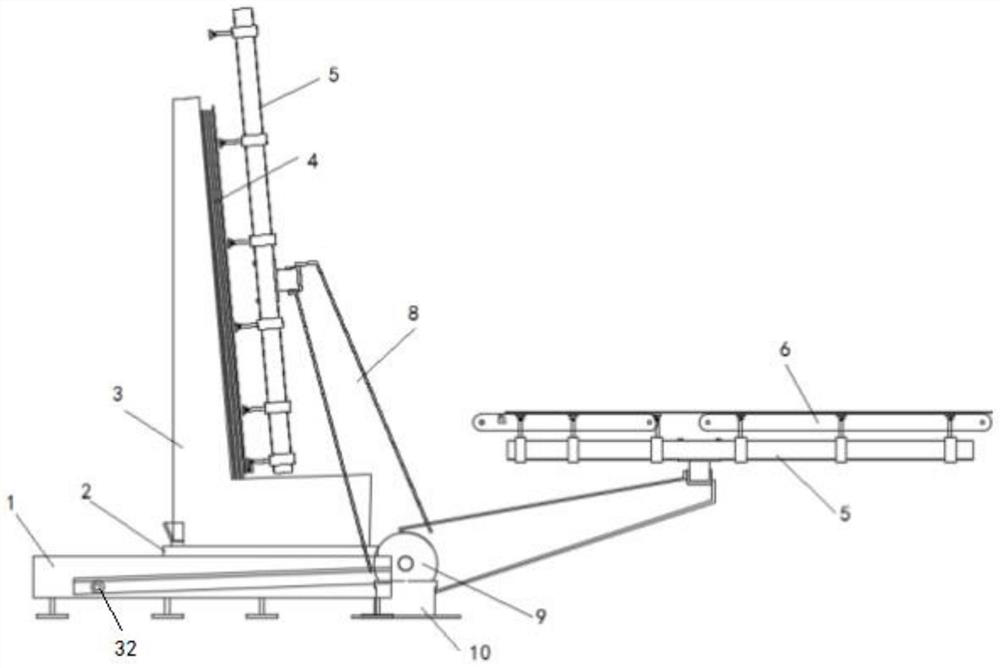

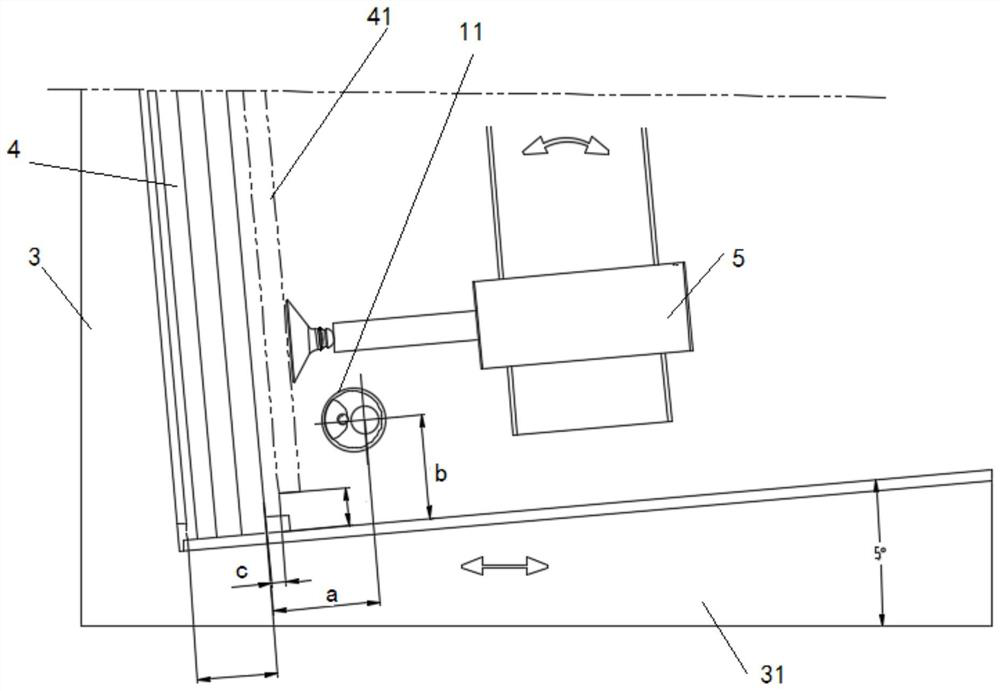

Movable liftable belt conveyer

InactiveCN105752598AEasy to moveSolve many inconveniences in useConveyorsEngineeringFront and back ends

Owner:XIANGYANG GAOMING MINING IND CO LTD

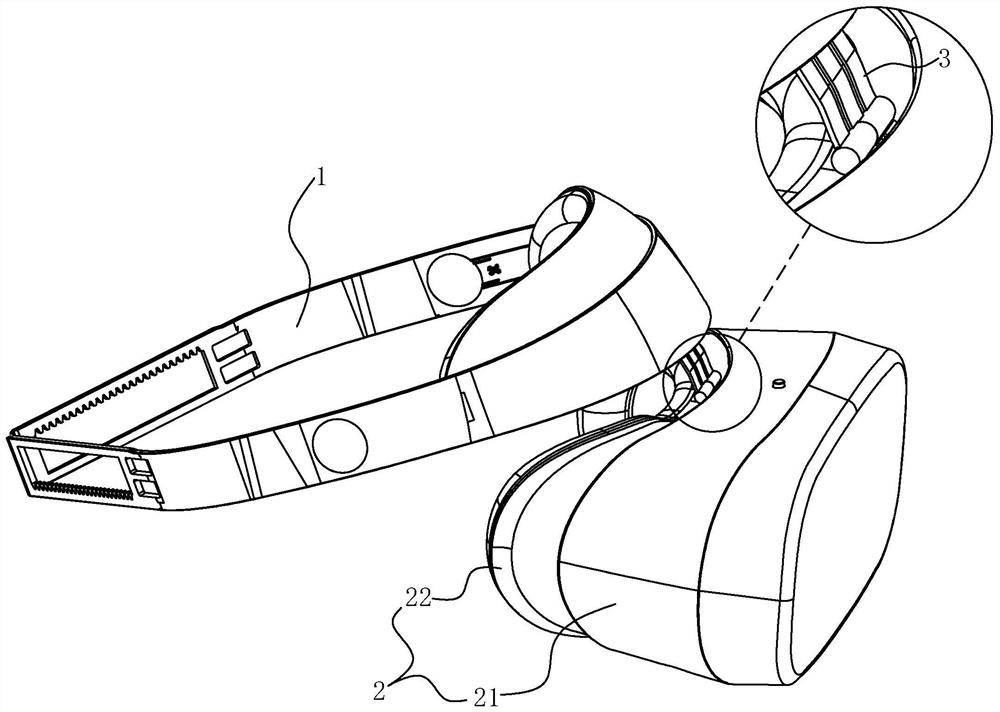

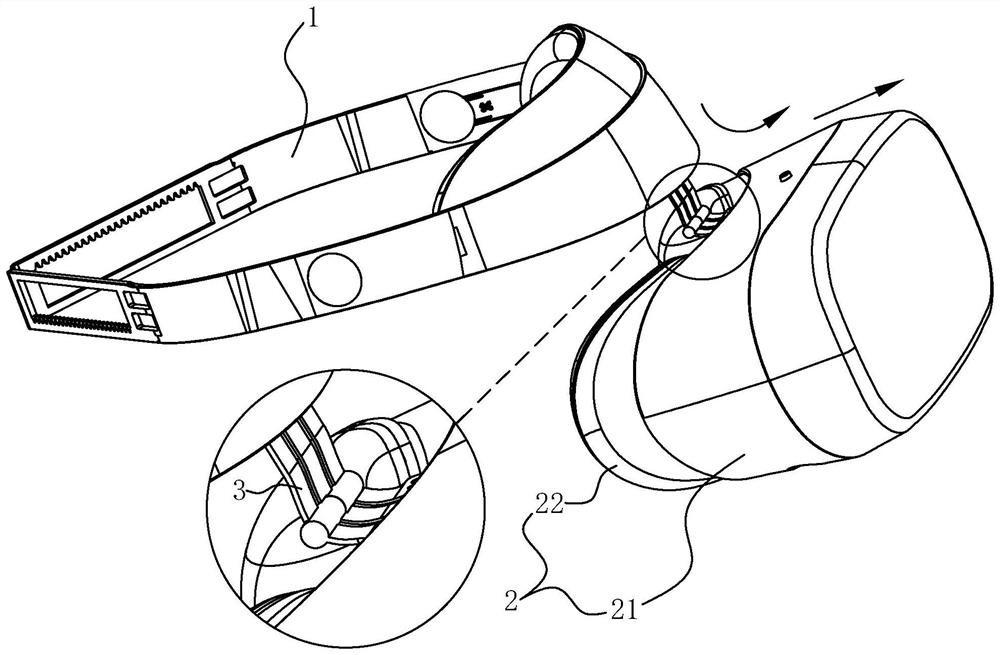

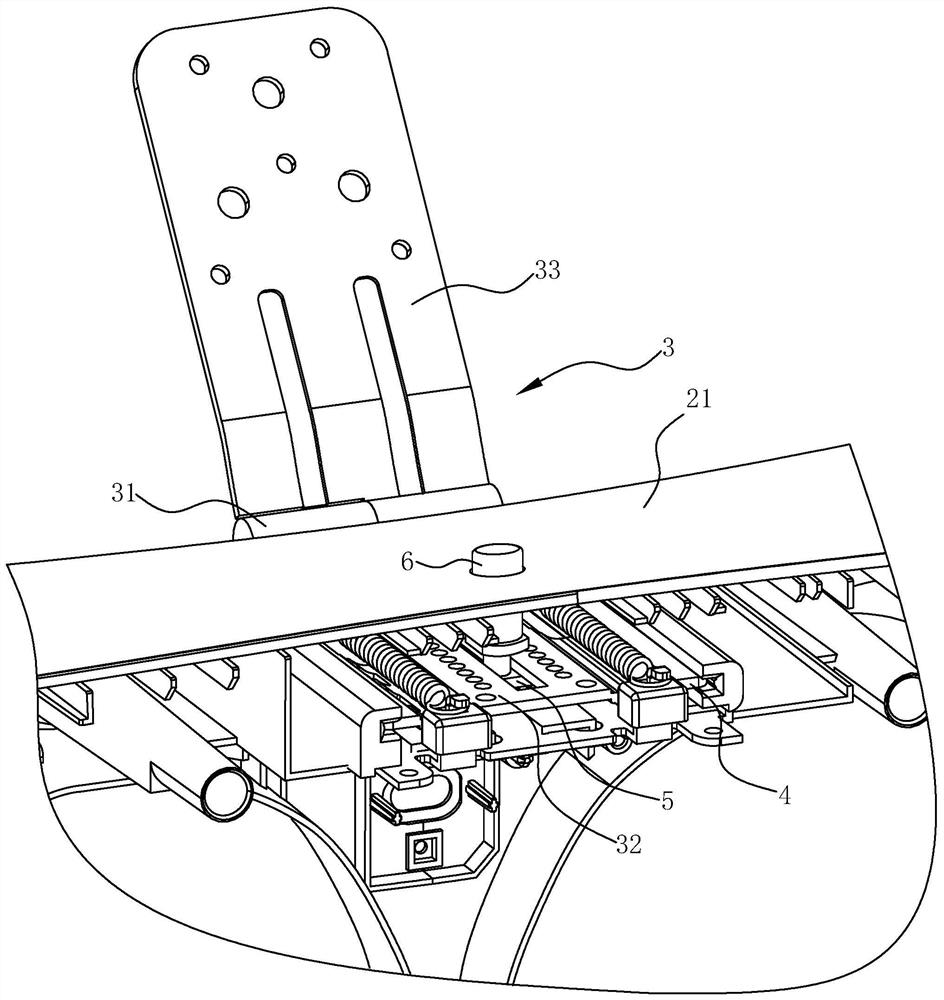

Intelligent head-mounted device

PendingCN114690424AAdapt to use needsEasy and flexible operationOptical elementsComputer hardwareMechanical engineering

Owner:GEER INTELLIGENT TECH CO LTD

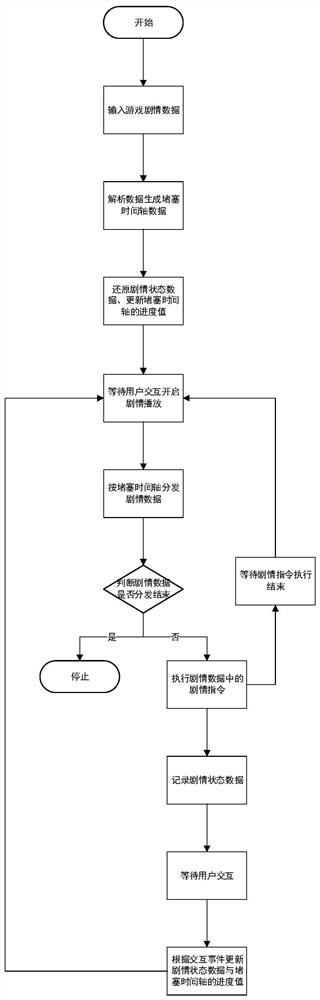

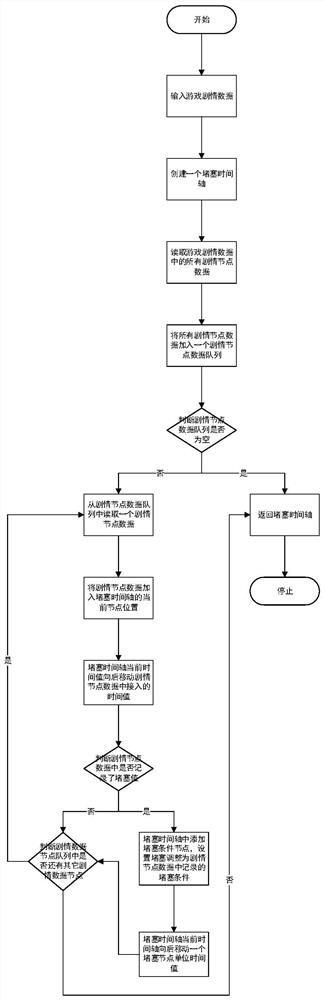

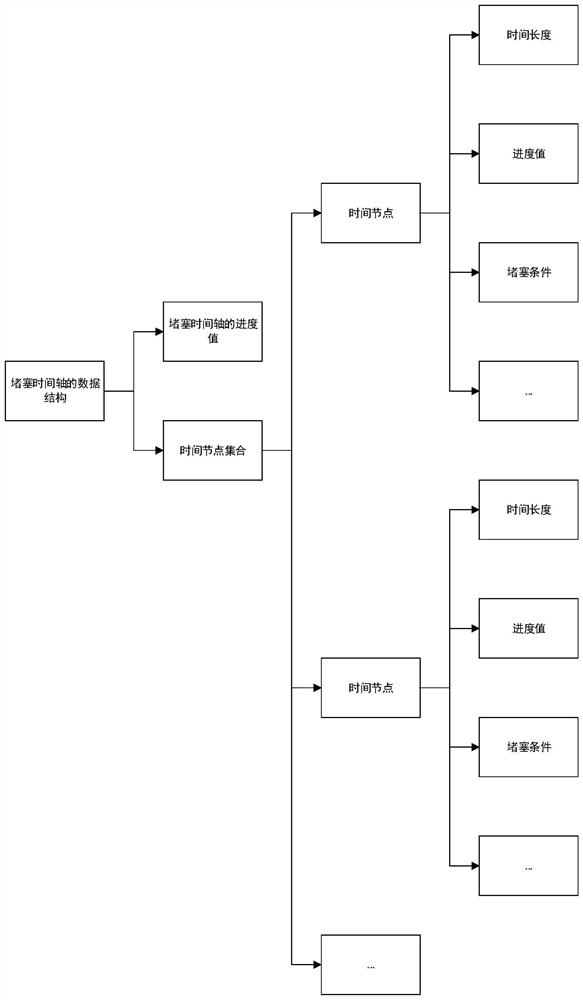

Implementation method and system for game plot state management

PendingCN113893529AShorten the development cycleEasy to manageProgram initiation/switchingResource allocationAlgorithmTheoretical computer science

The invention provides a method for game plot state management. The method comprises the following steps of: 1, inputting game plot data, and analyzing the game plot data to generate a blockage time axis; 2, restoring plot state data in the game plot data, and updating a progress value of the blockage time axis; 3, waiting for user interaction to start plot playing, and distributing plot state data corresponding to the blockage time axis according to the blockage time axis, judging whether the plot state data corresponding to the blockage time axis is distributed or not, and if so, stopping an ending process, or if not, executing the step 4; 4, executing a plot instruction in the plot state data, continuing to distribute the plot state data corresponding to the blockage time axis according to the blockage time axis, and waiting for completion of the execution of the plot instruction; and 5, recording the plot state data, waiting for user interaction, and updating the plot state data and the progress value of the blockage time axis according to an interaction event. According to the invention, game plots can be quickly accessed and used, state management is supported, and development and maintenance are simple and efficient.

Owner:FUJIAN TQ DIGITAL

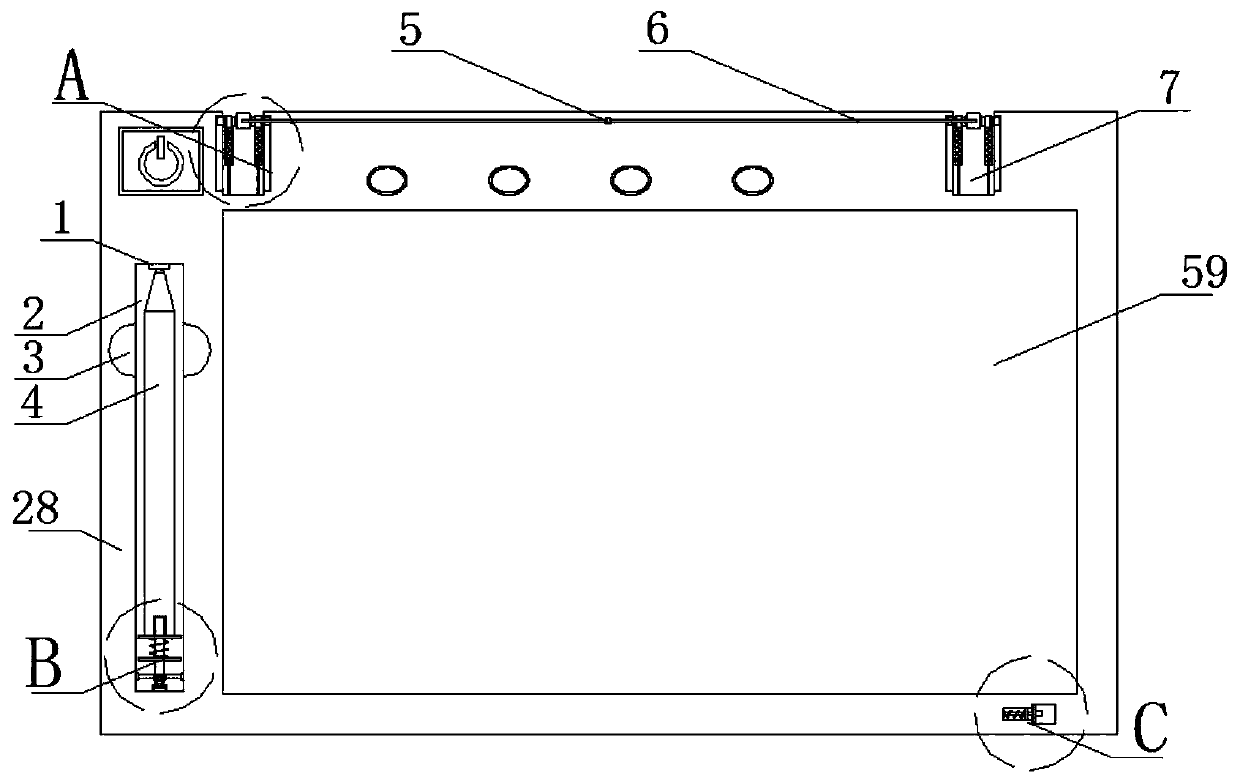

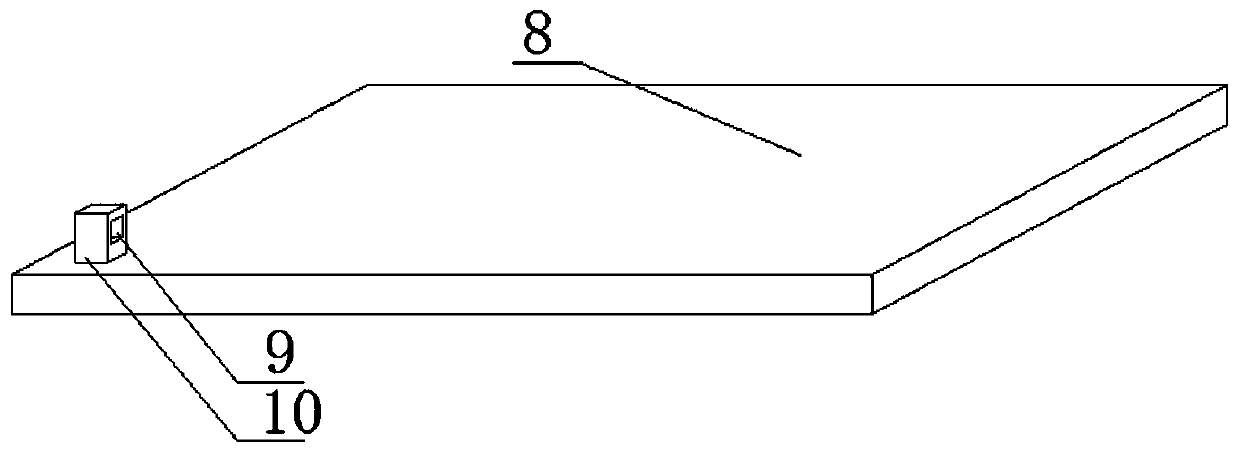

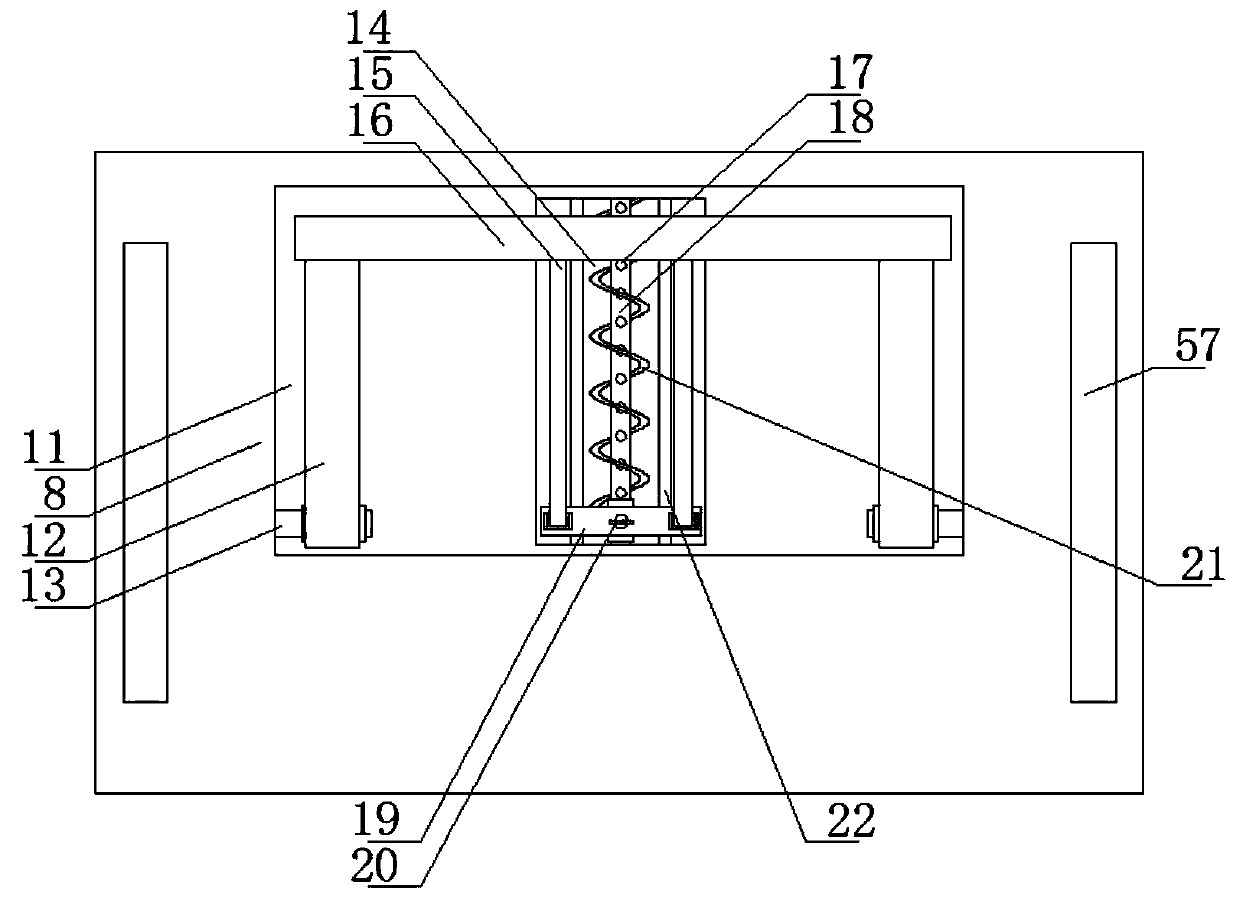

Handwriting board for computer

InactiveCN111290664AEasy to placeEasy to take outInput/output processes for data processingHandwritingSimulation

The invention discloses a handwriting board for a computer. The board comprises a machine body, a bearing groove is formed in one side of the machine body, an abutting mechanism is arranged in the bearing groove, two openings are formed in one end of the machine body, reset mechanisms are arranged in the openings, second rotating shafts are arranged on the reset mechanisms, the second rotating shafts are rotatably sleeved with fixing blocks, and a cross rod is jointly fixed to the two fixing blocks. According to the invention, the inclination degree of the panel can be adjusted according to the use requirements of a user; the adjusting range is wide, in addition, stable support can be realized after the adjustment is completed, stability of the machine body is ensured, the handwriting board is convenient for a user to stably perform writing operation, capable of well meeting the use requirements of different users, beneficial to improving the work efficiency, capable of well guaranteeing the panel and the handwriting pen when not in use, capable of effectively avoiding damage to the handwriting pen and the panel caused by collision and falling of foreign objects, and beneficial toprolonging the service life of the handwriting board.

Owner:汪华衡

Injection Molding Process of a Micro-adjustable Vacuum Cleaner Shell

ActiveCN111497103BHigh mechanical strengthIncreased anti-aging strengthCoatingsPlastic injection moldingClay minerals

The invention relates to an injection molding process of a micro-adjustable vacuum cleaner shell, which belongs to the technical field of injection molding technology. By adding clay minerals and metal oxides to the raw materials of plastic injection materials, the mechanical strength and anti-aging strength of the injection materials can be effectively improved, and at the same time, the Raw materials with high mechanical strength are mixed with nano-magnetic powder, and nano-magnetic powder is adsorbed in these porous and resistant materials, and by setting an external electromagnet at the corresponding position of the cavity of the injection mold, after the external electromagnet is energized, thereby In the process of injection molding, the flow direction of the material with high mechanical strength of the molten injection plastic can be fine-tuned, that is, the material with high mechanical strength can be gathered to the designated position under the action of magnetism, so as to better adapt to the different end faces of the existing vacuum cleaner shell The strength needs to be used. At the same time, it is easy to absorb and discharge the gas in the injection mold during the mold closing process. When the mold is opened, the released gas can effectively blow out the debris adhering to the parting surface of the mold.

Owner:苏州博琪海电器有限公司

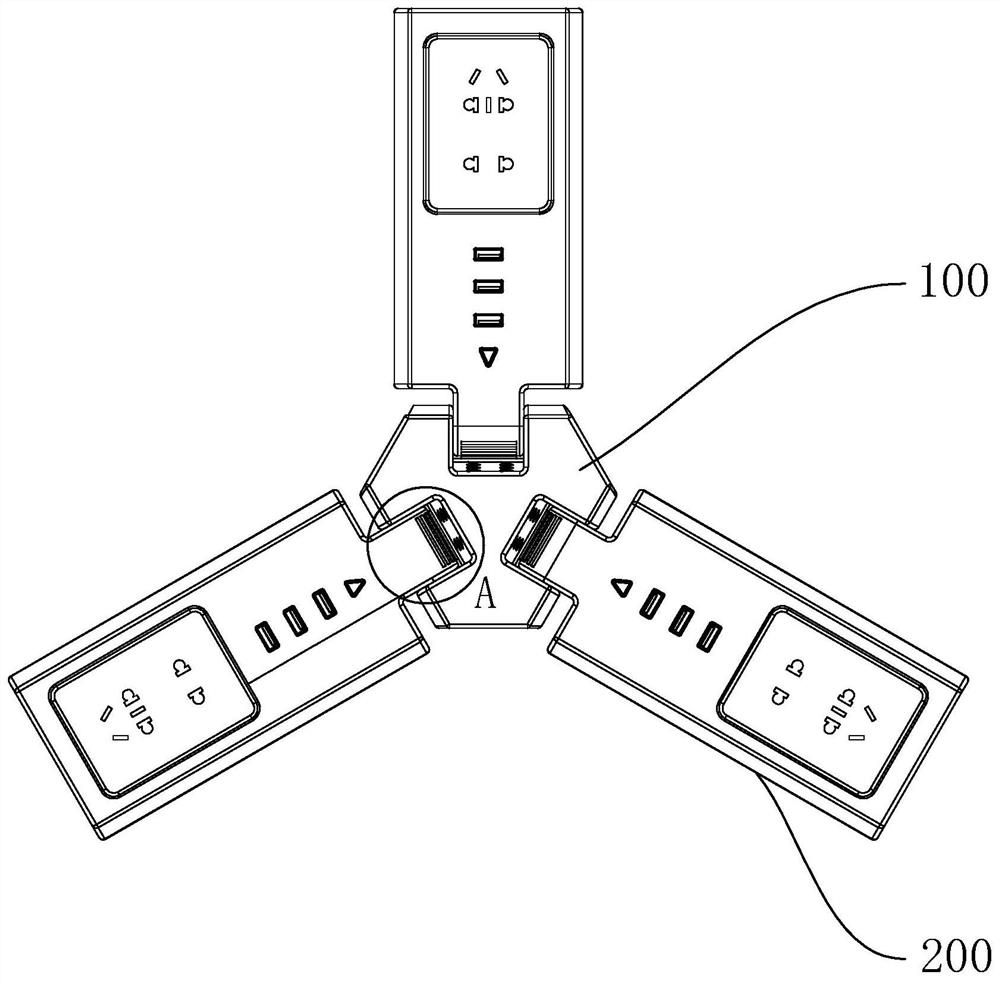

Folding extension socket

PendingCN112886350AVarious structural formsAdapt to use needsCouplings bases/casesStructural engineeringMechanical engineering

Owner:FOSHAN POLYTECHNIC

Spraying system of beauty and skin care spraying instrument

PendingCN113559370AImprove the range of skin careEasy to useMedical devicesMedical atomisersPediatricsEngineering

The invention belongs to the technical field of beauty instruments, and particularly relates to a spraying system of a beauty and skin care spraying instrument. In order to solve the problems in the background technology, the following scheme is provided, the spraying system comprises a shell, wherein threaded lifting devices are arranged at the four corners of the bottom of the shell; a mounting plate is fixed to the outer wall of the side of the shell; a sprayer is fixed to the outer wall of the top of the mounting plate; the sprayer is communicated with an atomizing nozzle through a pipeline; a mist outlet is formed in the inner wall of the top of the shell; the same rotating rod is fixed to the inner walls of the two sides of the shell; swing blades distributed at equal intervals are movably installed on the rotating rod; and mist outlet direction adjusting devices are sequentially arranged on the shell. The mist outlet direction adjusting devices are arranged, so that the skin care range of the spraying system of the beauty and skin care spraying instrument is widened, use is convenient, the skin care effect is better, and diversified skin care requirements of users can be met; and an air supply device is arranged, so that the spraying system of the beauty and skin care spraying instrument can meet the use requirements of the users in different seasons.

Owner:SUZHOU JING XIAN TING INTELLIGENT TECH CO LTD

Quadruped Robot Based on Four-bar Linkage

InactiveCN109606501BReduce manufacturing costElectronic control design is less difficultVehiclesVertical barCoupling

The invention discloses a quadruped robot based on a four-bar mechanism. The quadruped robot comprises a base and legs, wherein every two of the four legs are symmetrically arranged on two sides of the front end and two sides of the rear end of the base; the legs each comprise a pedestal, a four-bar mechanism, a motor B, a cross bar, a coupling, a vertical bar and a scissors fork telescopic frame;the four-bar mechanism is a planar pivot four-bar mechanism and comprises a crank, a rocker bar and connecting rods; the front ends of the crank and the rocker bar are respectively hinged onto the pedestal; the rear end of the crank is hinged with the front end of the hinged connecting rods; the rear end of the rocker bar is hinged with the middle of the connecting rods; the motor B drives the crank to rotate around the hinged joint at the front end of the crank; the scissors fork telescopic frame is provided with multiple hinge joints from the upper end to the lower end; the scissors fork telescopic frame is connected with the coupling at the hinged joint at the uppermost end, and connected with the lower end of the vertical bar by virtue of any hinged joint except the hinged joint at the lowest end. The quadruped robot based on the four-bar mechanism disclosed by the invention has the advantages that the legs of the quadruped robot are driven by the four-bar mechanism, the travelingfunction can be realized by virtue of drive of one motor only, the manufacturing cost is low, and the electric control design difficulty is low.

Owner:NANHUA UNIV

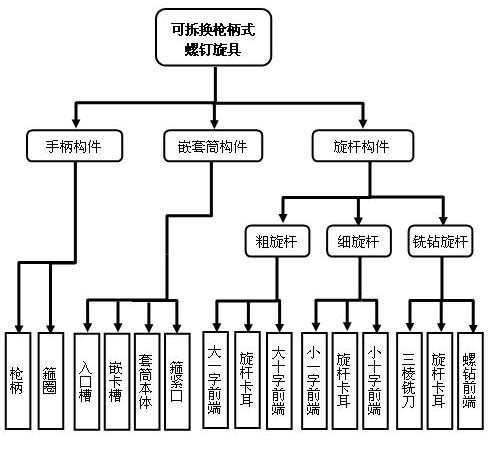

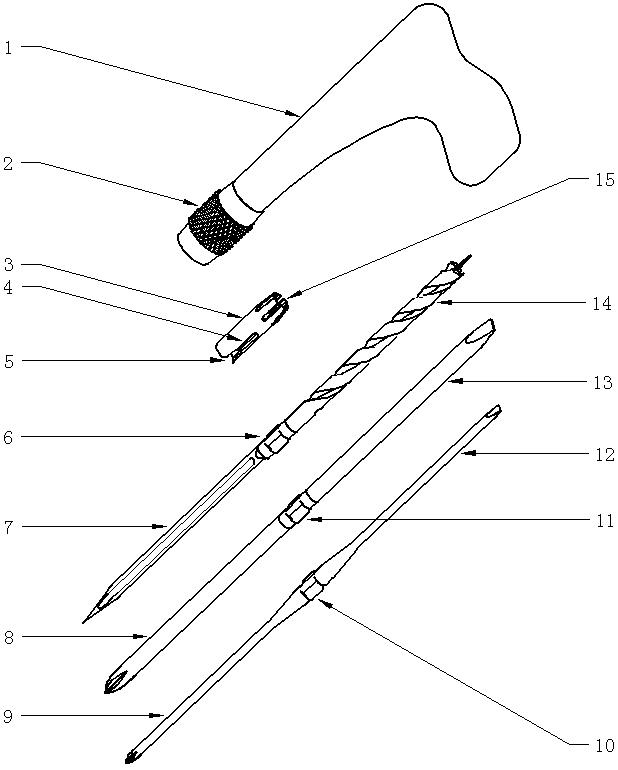

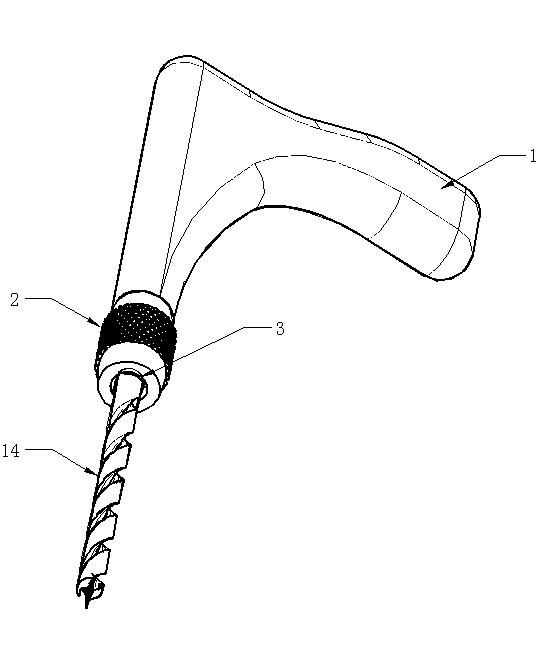

Screw screwdriver capable of detaching and replacing pistol grip

ActiveCN102101282AAdapt to tightnessAdapt to dismantling needsMulti-purpose toolsMilling cutterMechanical engineering

The invention relates to a screwdriver, in particular to a screw screwdriver which can replace a pistol grip at the front end of a screw bar. The screw screwdriver consists of only three components, namely a handle, an embedding sleeve and the screw bar. The screw screwdriver comprises fifteen components, namely the pistol grip, a cranse, an inlet groove, an embedding and buckling groove, a hoping opening, a big straight front end, a big cross front end, a small straight front end, a small cross front end, a three-square milling cutter, a screw drilling front end, a screw bar blocking ear and the like. An operator can detach and fasten bolts of multiple models and specifications in a way of rotating a product handle around the axle center of the screw bar simply, even can perform operation of relatively high strength, such as drilling, hole expanding and the like, on a special target. The formed product is elegant, firm and durable, and can meet requirement of use at multiple occasions. The screw screwdriver has the characteristics of simple implementation, simple manufacturing and the like, is easy to manufacture and convenient to use and has a wide market space and relatively high social and economic values.

Owner:CHINA AIRCRAFT MAINTENANCE & ENG

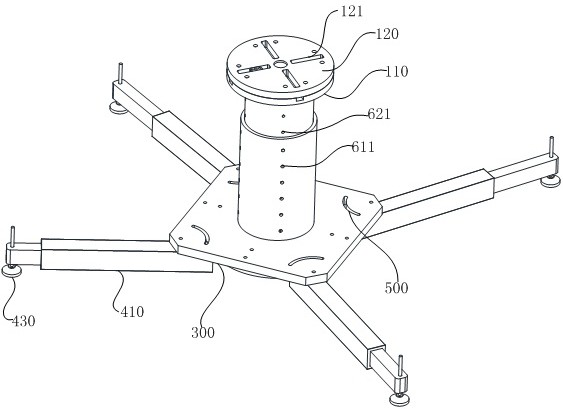

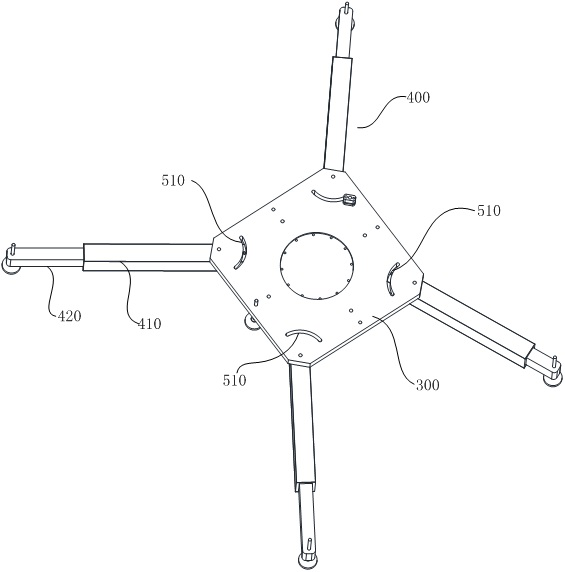

Base for robot installation

PendingCN114484162AChange positionAdapt to use needsStands/trestlesControl engineeringStructural engineering

The invention discloses a base for mounting a robot. The base comprises a bearing part, the multiple sliding parts are arranged in the circumferential direction of the bearing part, each sliding part can slide in the radial direction of the bearing part, and multiple connecting parts are arranged on the sliding parts; a counterweight part and a plurality of supporting legs are arranged at the bottom of the supporting base body, the supporting legs are arranged in the circumferential direction of the supporting base body, and angle adjusting structures capable of adjusting the positions of the supporting legs relative to the supporting base body are arranged between the supporting legs and the supporting base body; and the connecting body is connected between the bearing piece and the supporting base body. According to the base, the problem that in the prior art, a base for robot installation is poor in universality is solved.

Owner:深圳慧智星晨科技有限公司

Photovoltaic rolled glass sheet unloading method

ActiveCN114014017ANot affected by generated sizeSmooth air flowFinal product manufactureCharge manipulationProduction lineGlass chip

The invention discloses a photovoltaic rolled glass sheet unloading method. A glass frame stack position calculation method is utilized. When glass sheets are placed on a suction cup frame, the distance between the horizontal position and the stack position is accurate and fixed, meanwhile, the height of the placed glass sheets and the height of a glass stack bottom support are controlled, the lower portions of the stacked glass sheets can be tightly attached to the glass stack, no gap exists between the glass sheets, and the problem that the thickness difference of the upper portion and the lower portion of the glass stack is too large is solved. After a certain number of pieces of glass are stacked, the deviation is controlled within a reasonable range by tracking and calculating the automatic retreating accumulated distance and performing turnover angle supplement on the parallel difference between the outer edge surface of the stack position and the plane of the glass sheets to be stacked after turnover, so that parallel attachment is ensured, the phenomenon of scratching among the glass sheets is avoided, and the quality of the glass stack is greatly improved. No extra time is added in the whole batch-off period. Position pairing of a glass frame and a suction cup frame is not needed during first sheet stacking, the first sheet stacking time is not increased, operation is completely automatic, and the high-speed sheet unloading requirement of a production line is better met.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

A replaceable torch head of a multifunctional electric welding torch

ActiveCN103600161BAdapt to use needsProtective cooling effectShielding gas supply/evacuation devicesElectrode supporting devicesTorchFusion welding

The invention discloses a replaceable gun head of a multifunctional electric welding gun. The replaceable gun head comprises an electroconductive member made of metal and an insulated connecting member, a mounting groove is arranged on the electroconductive member, an insulated outer cover is covered above the mounting groove to enable a closed cavity to be formed between the electroconductive member and the outer cover, an opening allowing a fusion welding object connected with the electroconductive member to extend out is arranged at the front end of the cavity, and a welding column fixing member used for fixing a columnar fusion welding object or a compressing device used for compressing a sheet fusion welding object is arranged in the cavity. The columnar fusion welding object or the sheet fusion welding object can be mounted on the replaceable gun head by replacing part of accessories, and the replaceable gun head has various functions and can meet using needs of different using occasions.

Owner:JIANGMEN BOSJOB

Composite wall for passive ultra-low energy buildings

ActiveCN108487492BAchieve deliveryReduce complexityWallsClimate change adaptationInsulation layerLower grade

The invention discloses a passive composite wall for an ultra-low energy construction. The passive composite wall reduces the complexity of an energy supply system of the ultra-low energy constructionand reduces the operation and use costs. The passive composite wall comprises a composite wall body, a wall body outer side member and a plurality of loop heat pipe units; the wall body outer side member is an integrated structure composed of a photovoltaic module, a member heat-insulation layer and a base plate from outside to inside; each loop heat pipe unit comprises a closed circulation pipeline and a control valve, wherein each closed circulation pipeline is composed of a hollow outdoor end heat transfer pipe, an upper heat transfer pipe, an indoor end heat transfer pipe and a lower heattransfer pipe; an outdoor end wick corresponding to the back of the photovoltaic module is arranged in each outdoor end heat transfer pipe, each indoor end heat transfer pipe is internally provided with an indoor end wick, and the centers of each outdoor end wick and each indoor end wick are working medium flow channels; and the control valve is installed on the closed circulation pipeline. The passive composite wall makes full use of low-grade solar energy and night environment cold energy to supply and store cold energy and heat energy for the ultra-low energy construction, and the operation and use costs are reduced.

Owner:TIANJIN UNIV

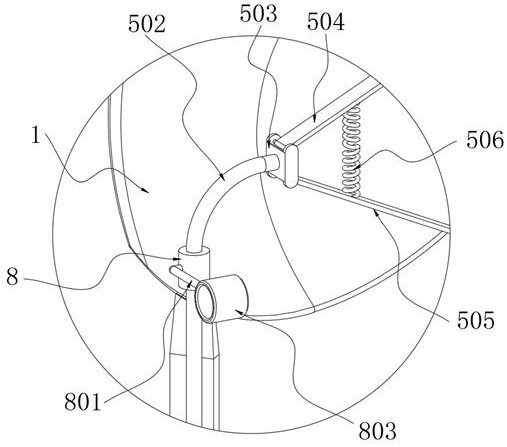

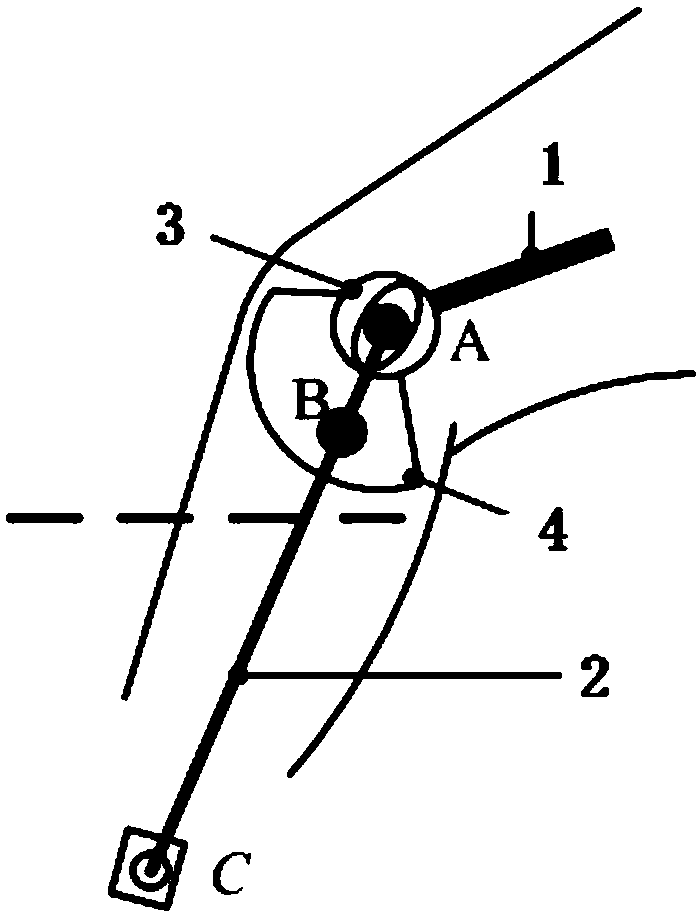

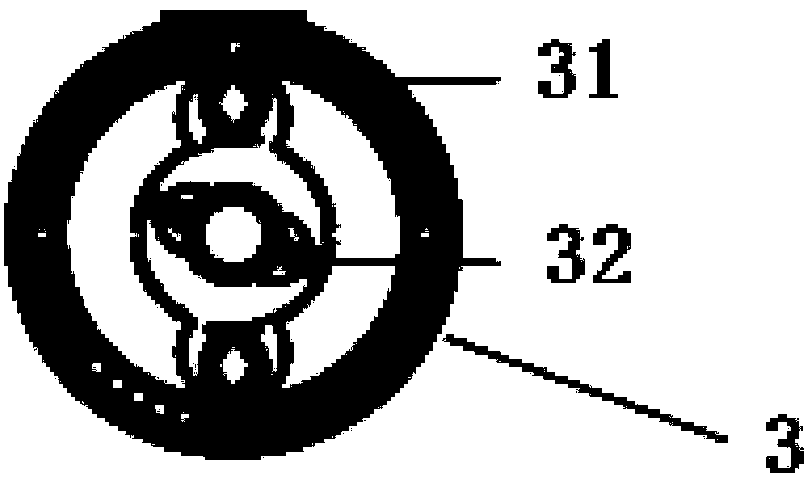

A driving method based on a flexible knee joint exoskeleton device

The invention belongs to the medical rehabilitation training equipment-dependent field and in particular relates to a flexible knee joint exoskeleton device and a driving method thereof. The flexible knee joint exoskeleton device comprises an upper connecting rod, a lower connecting rod, a flexible joint mechanism and a driving device, wherein the driving device is arranged at the lower end of a flexible joint device, a permanent magnetic is arranged at the lower connecting rod close to a flexible joint structure, coils are arranged at the two sides of an oscillating range of the permanent magnet on the driving device, and one three-axis magnetic sensor is arranged at the center of each coil. The invention also discloses a driving method of the flexible knee joint exoskeleton device. The flexible knee joint exoskeleton device provided by the invention is directly driven by adopting an electromagnetic force, rotation of a joint in multiple freedom degrees can be realized, and real-time driving on the whole flexible knee joint exoskeleton device also can be realized by adjusting an electric current; and the flexible knee joint exoskeleton device can adapt irregularity of a joint of a human body, is applicable to different wearers and also has the advantages of simple structure, easiness in processing, low cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

A flange connection device applied to a mechanical arm and its end effector

ActiveCN113510733BImprove versatilityImprove convenienceGripping headsClassical mechanicsSpherical joint

The invention discloses a flange connection device applied to a mechanical arm and its end effector, and relates to the field of flange connection devices. The flange connection device includes a plurality of main rods, each of which is provided with a terminal at both ends. Spherical joints, the inner sphere in each end spherical joint rotates relative to the spherical shell, so that the flange threaded rod on each end spherical joint and the main rod where it is located form a predetermined angle, and the angle adjustment is completed through the two ends of each main rod Each end spherical joint is respectively fixed to each flange threaded hole on the connecting flange of the manipulator and the end effector through the flange threaded rod, regardless of the specification of the connecting flange of the manipulator and the end effector / the size of the flange threaded hole Whether the position is the same, the connection and fixation of the two can be realized, and the versatility is high, and it also indirectly increases the versatility of the end effector and the convenience of installing the end effector.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com