Water gun nozzle for fire fighting

A technology of water guns and nozzles, applied in fire rescue and other directions, can solve the problems of inappropriate adjustment of the direction of water gun nozzles, inability to converge and spray, and the water pipes are not easy to bend.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

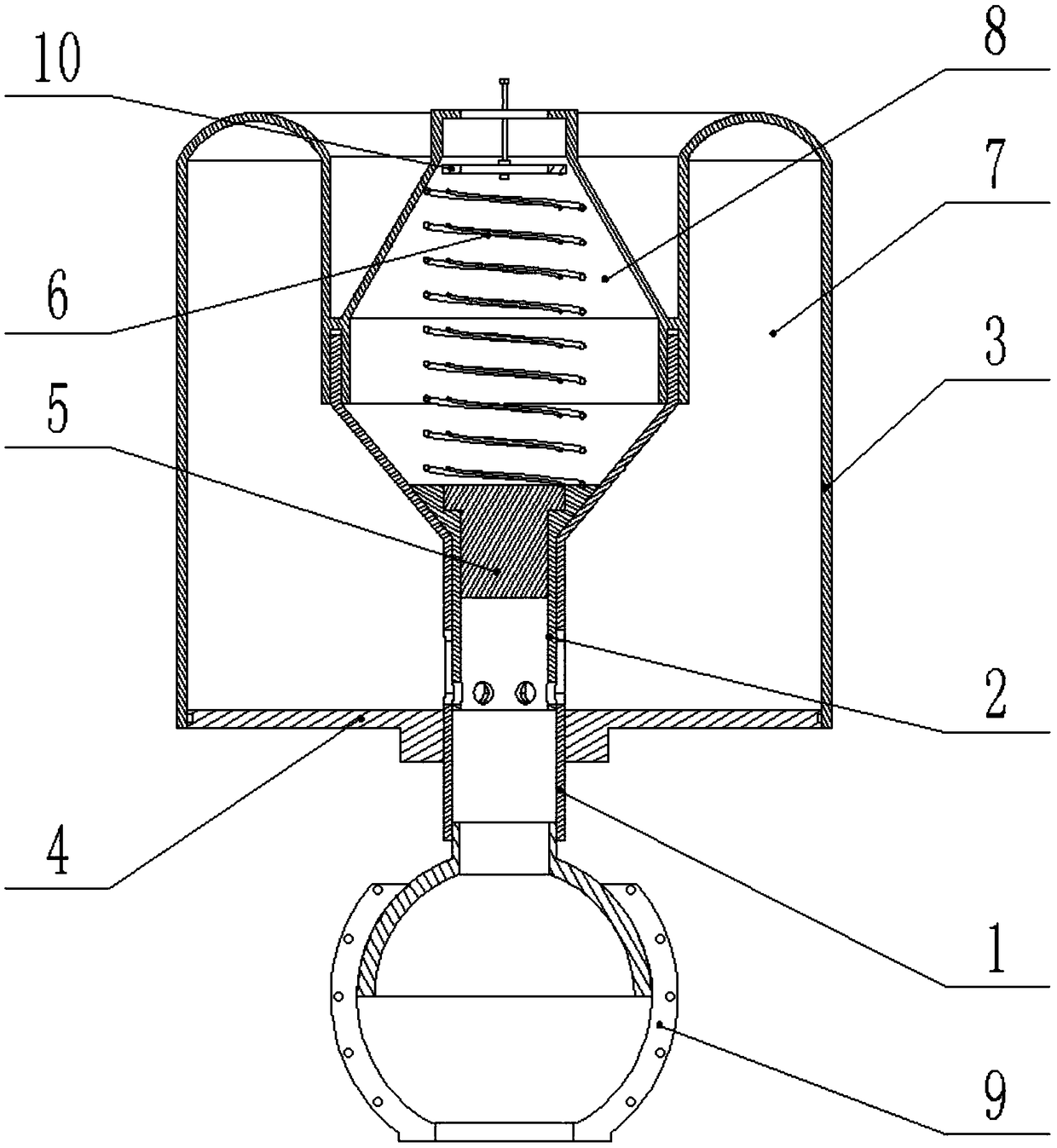

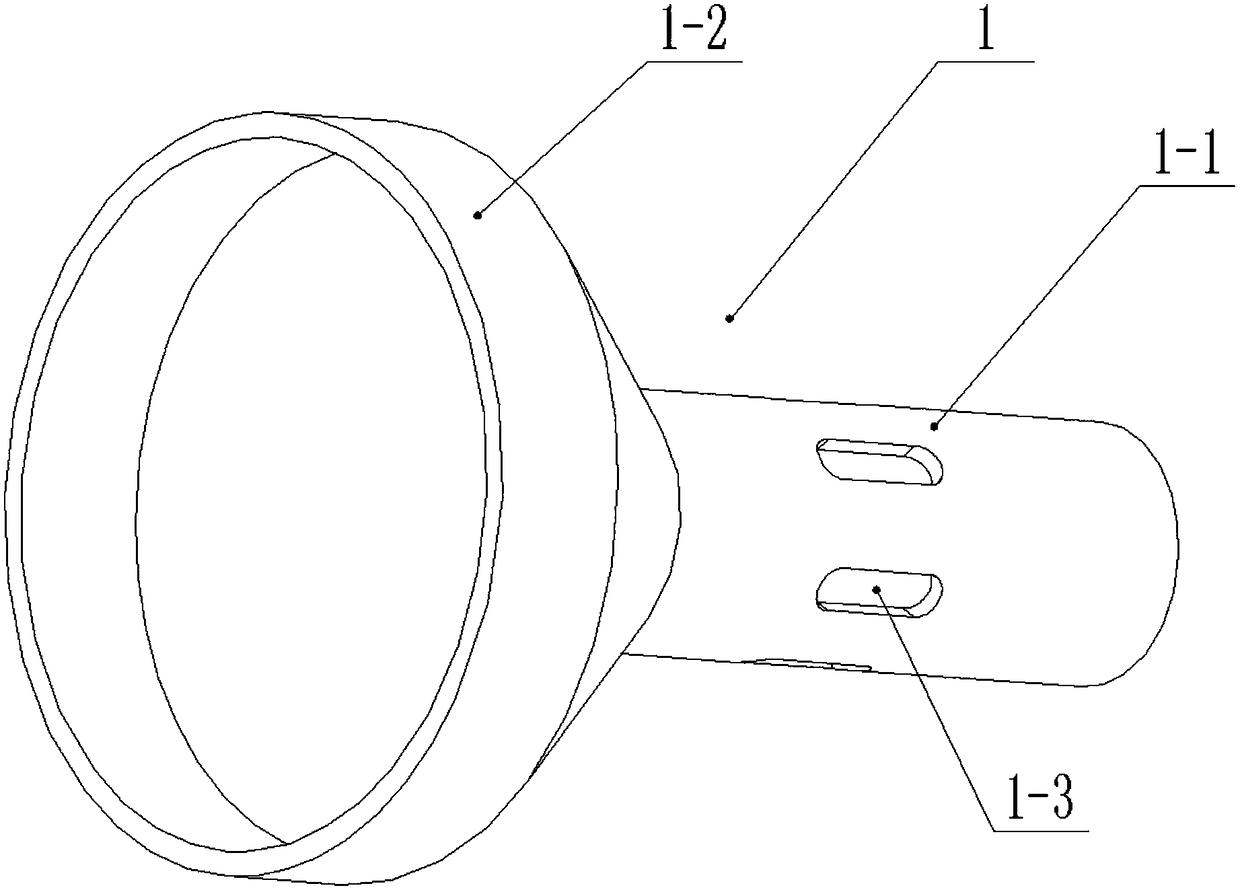

[0030] Combine below Figure 1-12 Describe this embodiment, a fire-fighting water gun nozzle, including a nozzle water pipe 1, a valve core 2, a nozzle 3, a nozzle plug cover 4, a valve core plug 5 and a spring assembly 6, and a valve core 2 is slidably connected to the nozzle water pipe 1 , the inside of the spool 2 is slidingly connected to the spool plug 5, the nozzle 3 is fixedly connected to the nozzle water pipe 1, and the nozzle plug cover 4 is connected between the nozzle water pipe 1 and the nozzle 3 through thread fit, and the spring Assembly 6 includes spring I and spring II, said spring I is located inside spring II, said spring I is located between spool plug 5 and nozzle 3, said spring II is located between spool 2 and nozzle 3, said A low-pressure water chamber 7 is formed between the nozzle water pipe 1, the nozzle 3 and the nozzle plug cover 4, and the middle end of the nozzle water pipe 1 and the nozzle 3 forms a high-pressure water chamber 8; when in use, wa...

specific Embodiment approach 2

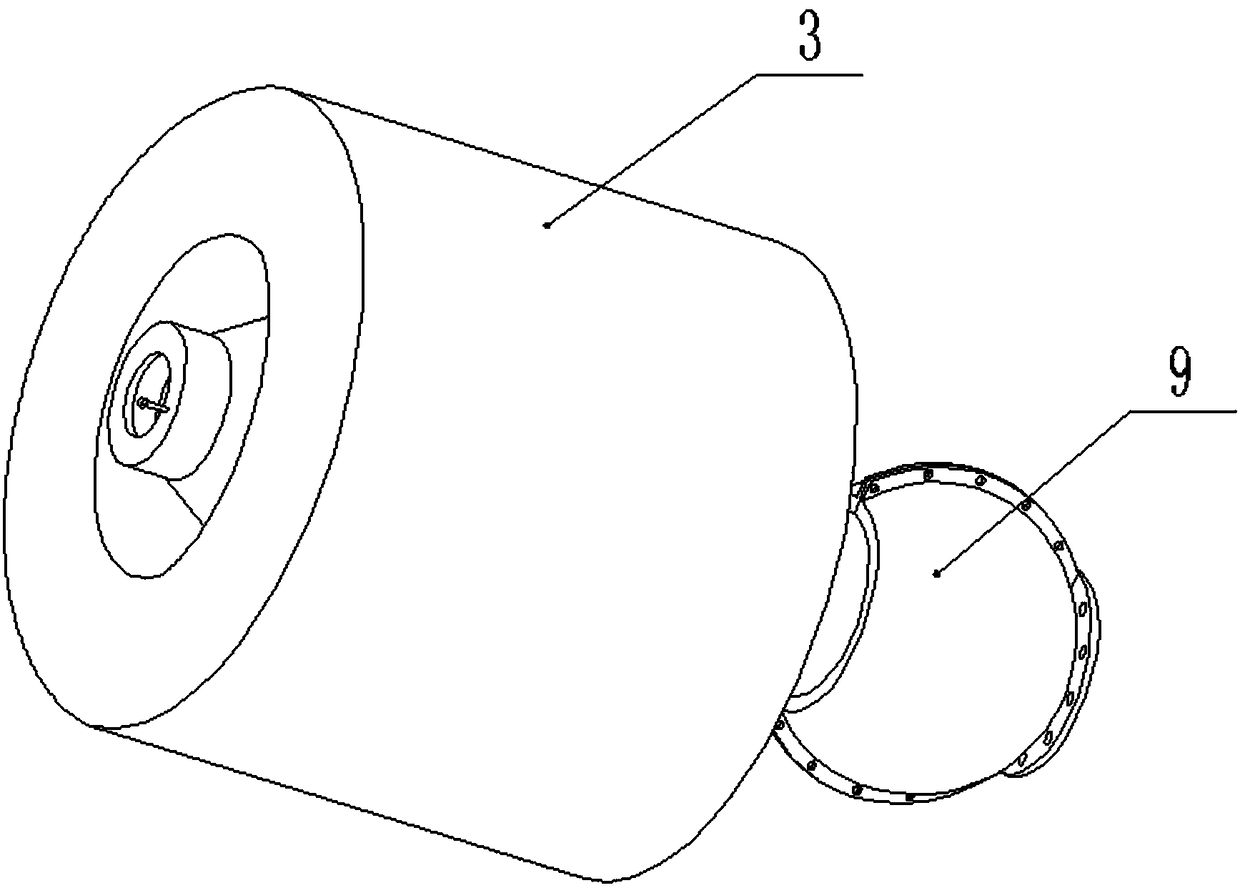

[0031] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain Embodiment 1, the nozzle 3 includes a high-pressure nozzle 3-1 and a low-pressure nozzle 3-2, and the low-pressure nozzle 3-2 is welded and connected to the high-pressure nozzle 3-1 At the outer end, the high-pressure nozzle 3-1 is provided with a high-pressure spray hole, and the low-pressure nozzle 3-2 is provided with a plurality of low-pressure spray holes, and the plurality of low-pressure nozzles are evenly distributed on the low-pressure nozzle 3-2. On the arc surface of the front end; the high-pressure water is sprayed together through a high-pressure water spray hole on the high-pressure nozzle 3-1, and the low-pressure water is dispersed and sprayed through a plurality of low-pressure water spray holes on the low-pressure nozzle 3-2.

specific Embodiment approach 3

[0032] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain the second embodiment, the fire water gun nozzle described above also includes a pressure regulating assembly 10, and the pressure regulating assembly 10 includes an annular pressing piece 10-1 and an adjusting screw 10 -2, the adjusting screw 10-2 is rotatably connected to the annular pressing piece 10-1, and the adjusting screw 10-2 is connected to the threaded hole on the high-pressure nozzle 3-1 through thread fit, and the annular pressing piece 10 -1 is located in the high-pressure nozzle 3-1, the spring I is located between the spool plug 5 and the annular pressing piece 10-1, and two positioning snap rings are fixedly connected to the adjusting screw 10-2, and the annular pressing piece The piece 10-1 is located between the two positioning snap rings; by rotating the adjusting screw 10-2, the adjusting screw 10-2 pushes the adjusting screw 10-2 to squeeze the spring I, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com