A flange connection device applied to a mechanical arm and its end effector

A technology of end effectors and connecting devices, which is applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve problems such as low utilization rate, cumbersome disassembly, and increased use costs, and achieve high versatility, convenient adjustment of distance and angle, and increased versatility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

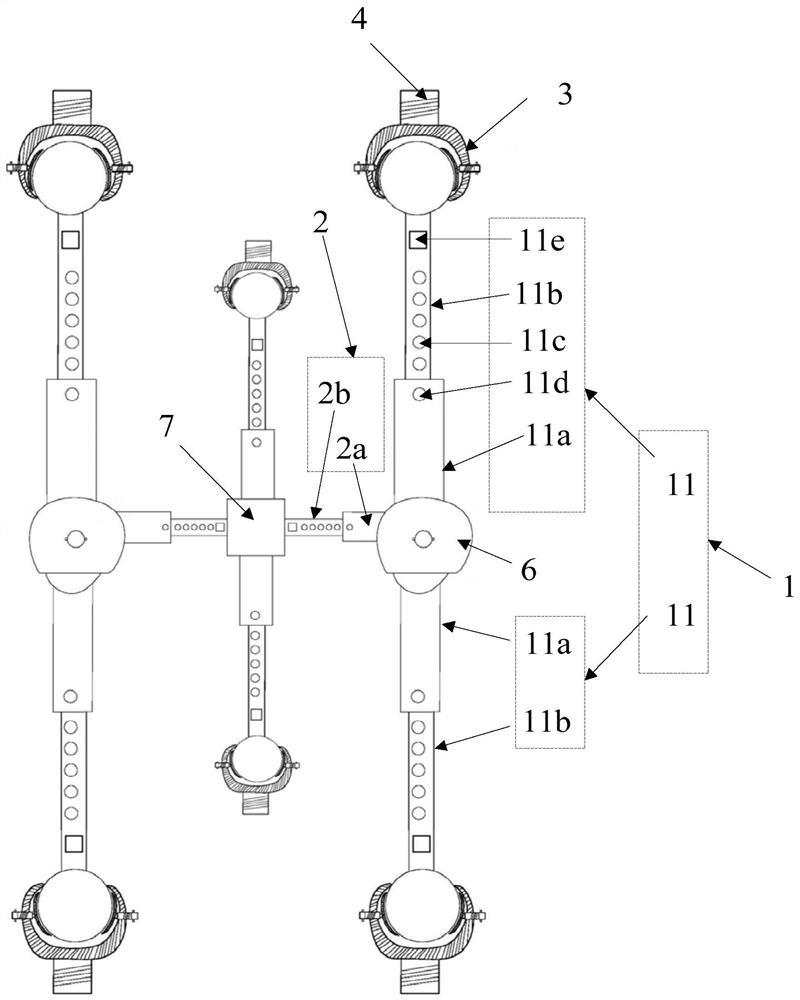

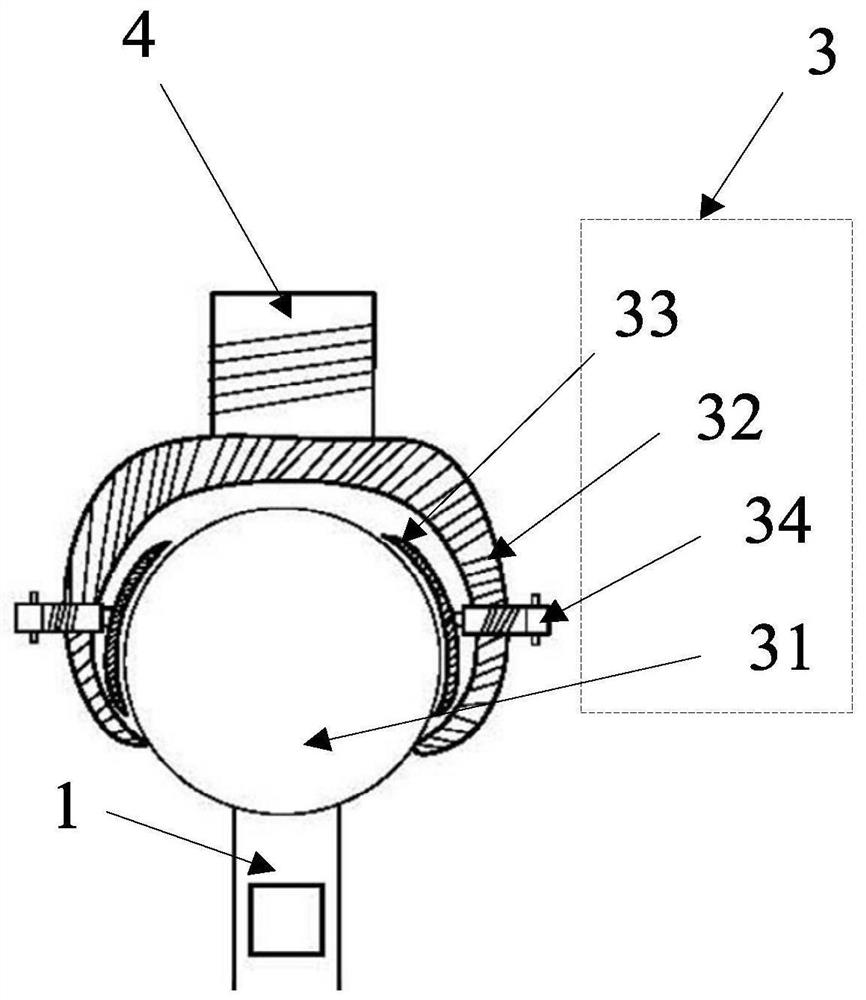

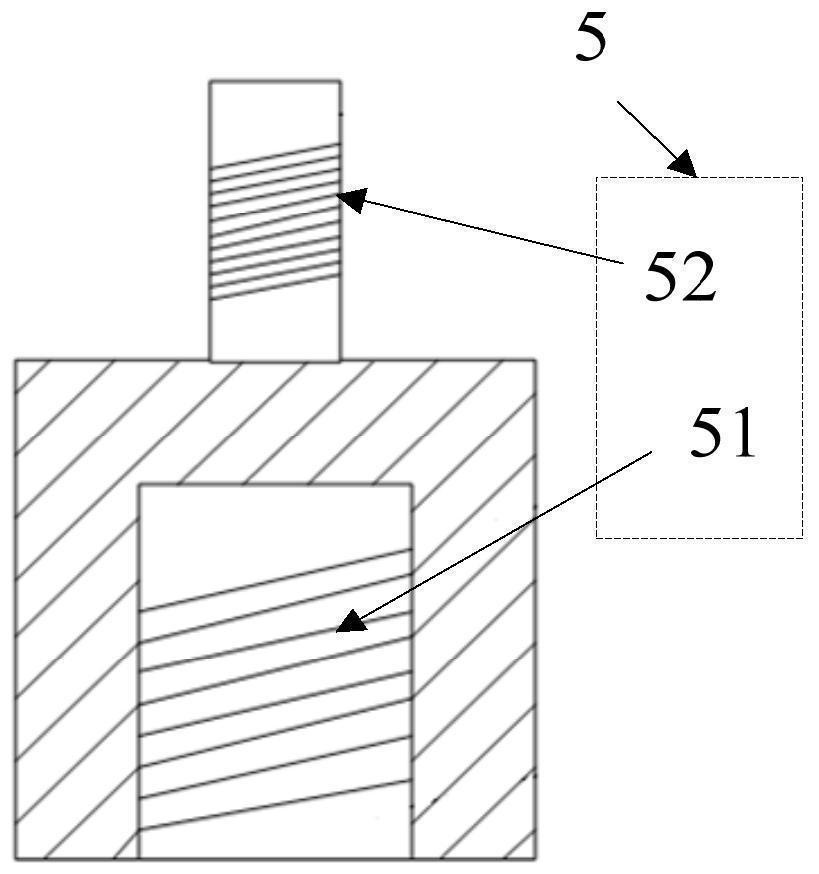

[0025] This application discloses a flange connection device applied to a robot arm and its end effector. The flange connection device is used to connect the connection flange of the robot arm to the connection flange of the end effector. Please refer to Figure 1-4 , the flange connection device includes several main rods 1. In the initial state, the rod length direction of each main rod 1 is the same, and the specific number of main rods 1 is configured according to the actual situation. The illustration in this application includes four main rods as example. Both ends of each main rod 1 are respectively provided with terminal spherical joints 3, such as figure 2 As shown, each end spherical joint 3 includes an inner sphere 31, a spherical shell 32, an arc-shaped patch 33 and an adjustment member 34. The inner sphere 31 is fixed at one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com