Injection molding process of fine-tune type dust collector shell

A vacuum cleaner and micro-adjustment technology, applied in the direction of coating, etc., can solve the problems of poor smoothness and flatness, low efficiency, poor exhaust, etc., and achieve the effect of improving anti-aging and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

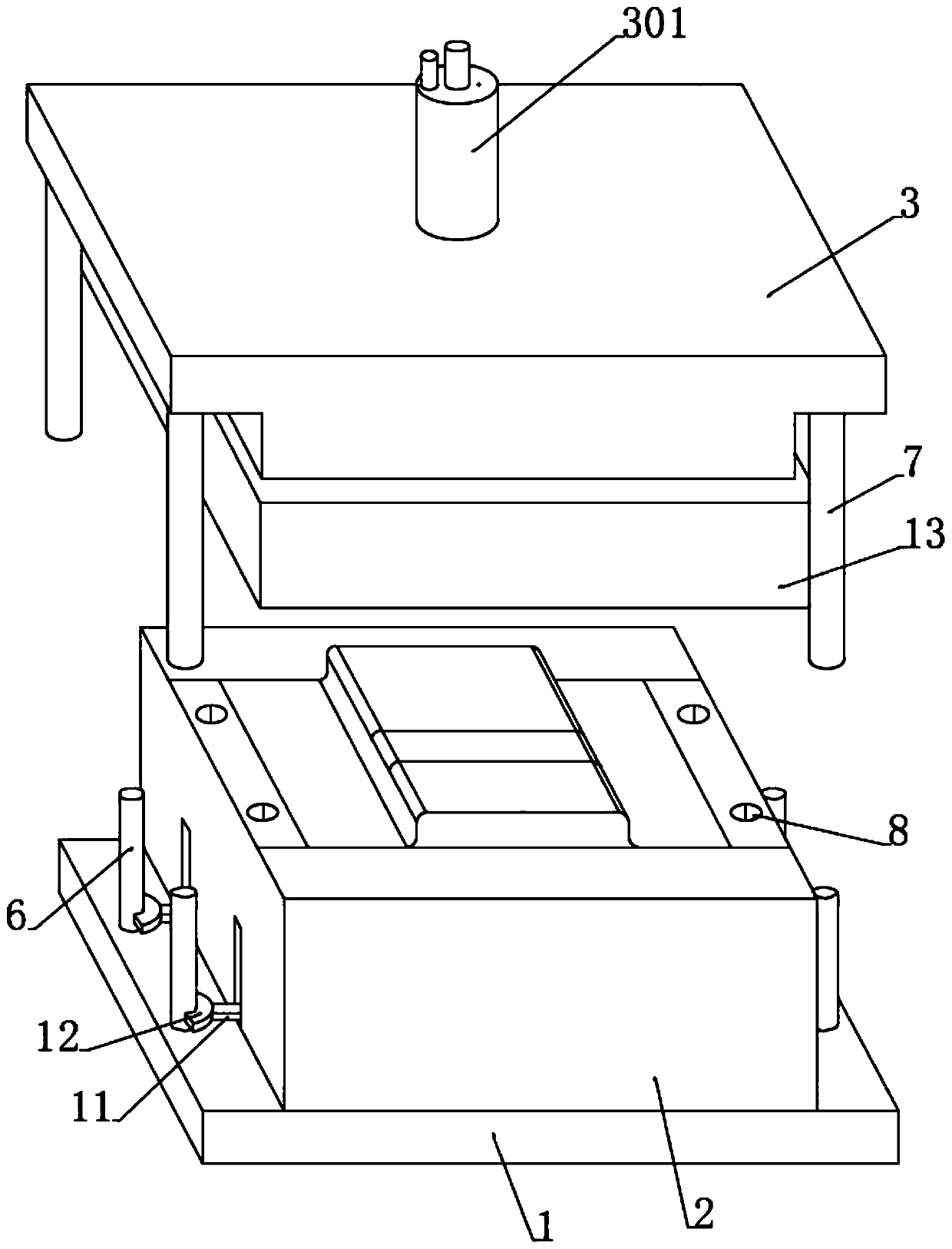

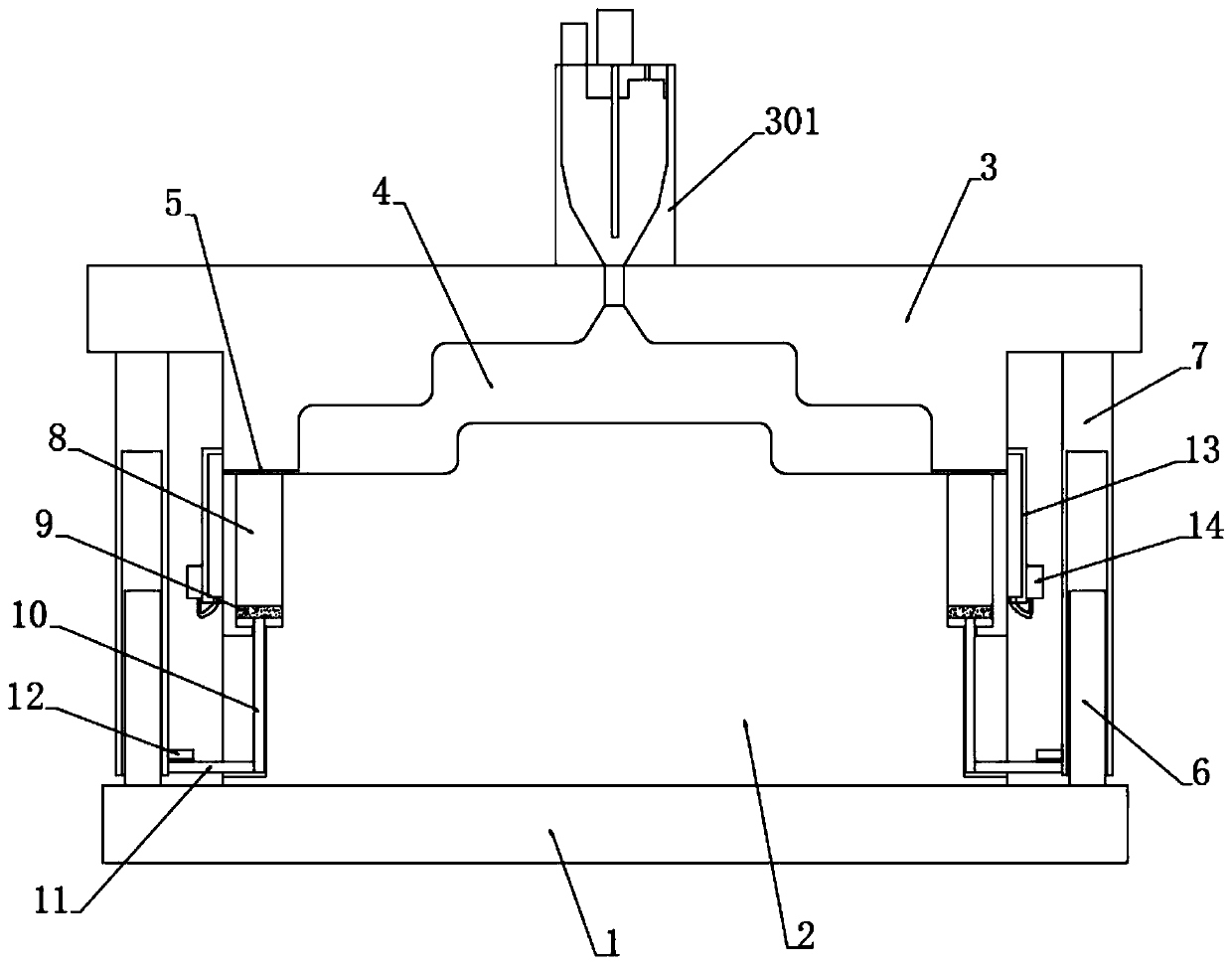

[0038] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

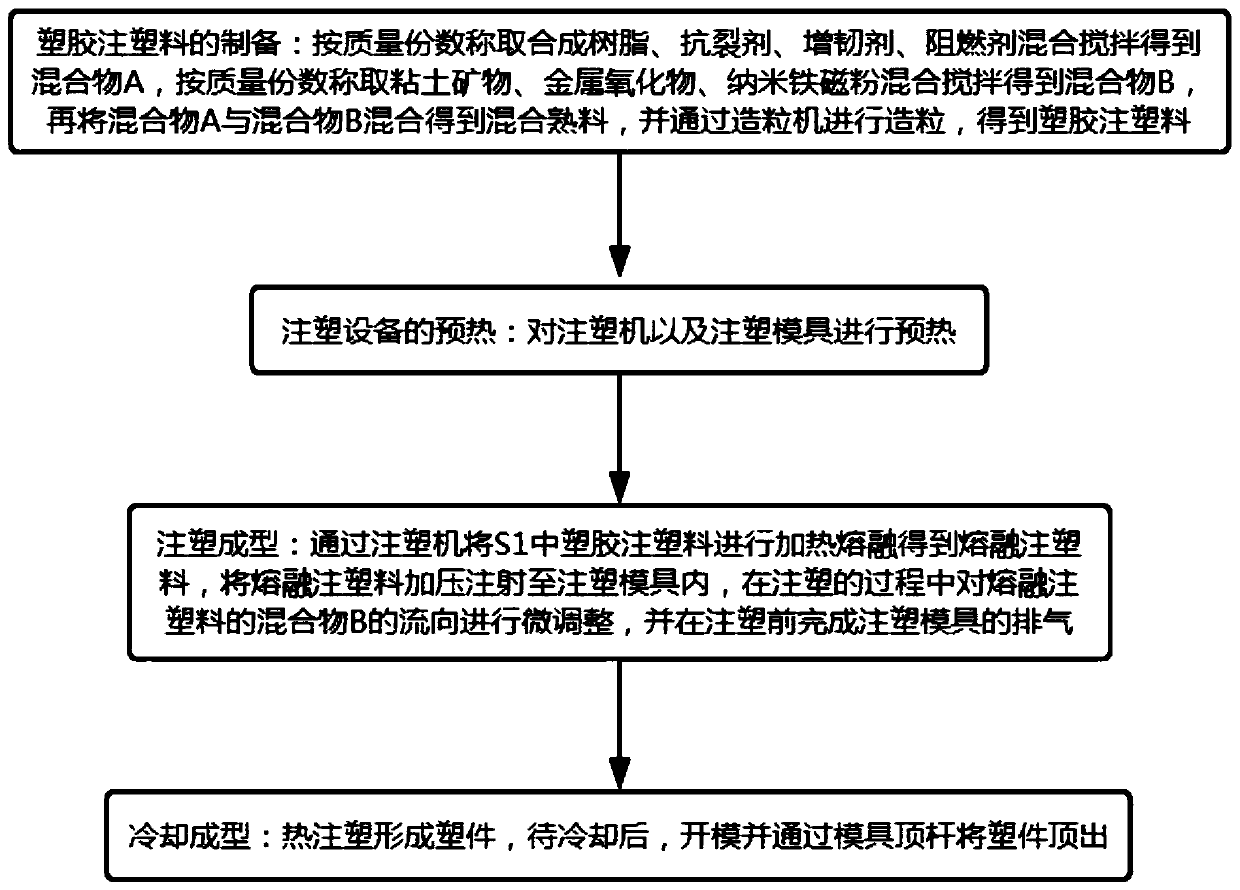

[0039] As attached figure 1 The injection molding process of a micro-adjustable vacuum cleaner housing according to the present invention is shown, and the specific injection molding process is as follows:

[0040] S1. Preparation of plastic injection molding: weigh out synthetic resin, anti-cracking agent, toughening agent, and flame retardant according to mass parts to obtain mixture A, weigh out clay minerals, metal oxides, and nano-ferromagnetic powder according to mass parts Mix and stir to obtain mixture B, and then mix mixture A and mixture B to obtain mixed clinker, which is granulated by a granulator to obtain a plastic injection molding compound;

[0041] S2. Preheating of injection molding equipment: preheating the injection molding machine and injection mold;

[0042] S3. Injection molding: The plastic injection molding material in S1 is heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com