Replaceable gun head of multifunctional electric welding gun

An electric welding torch and replaceable technology, which is applied in the direction of arc welding equipment, welding rod characteristics, welding equipment, etc., can solve the problems of high cost, single function, inconvenient use, etc., achieve good effect and simplify the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

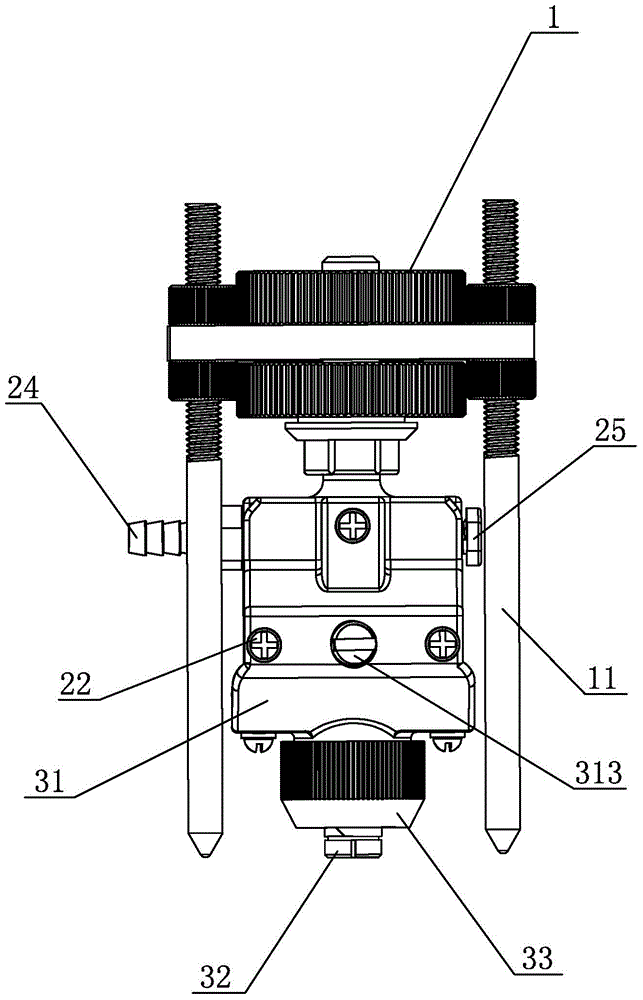

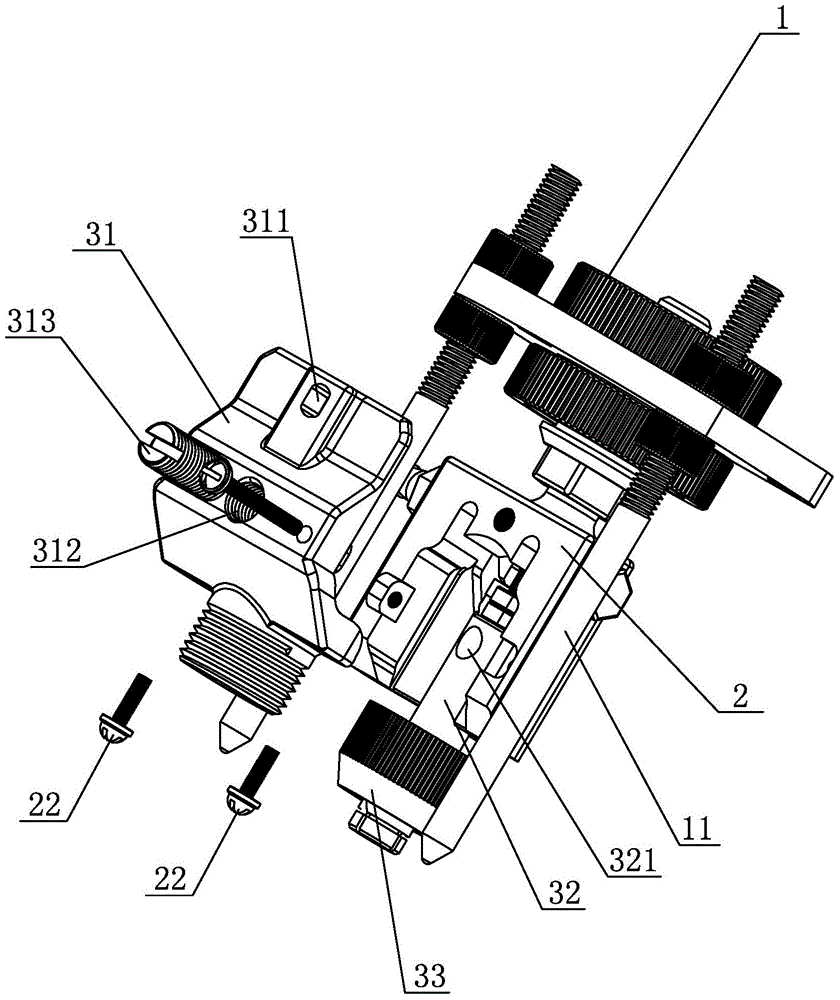

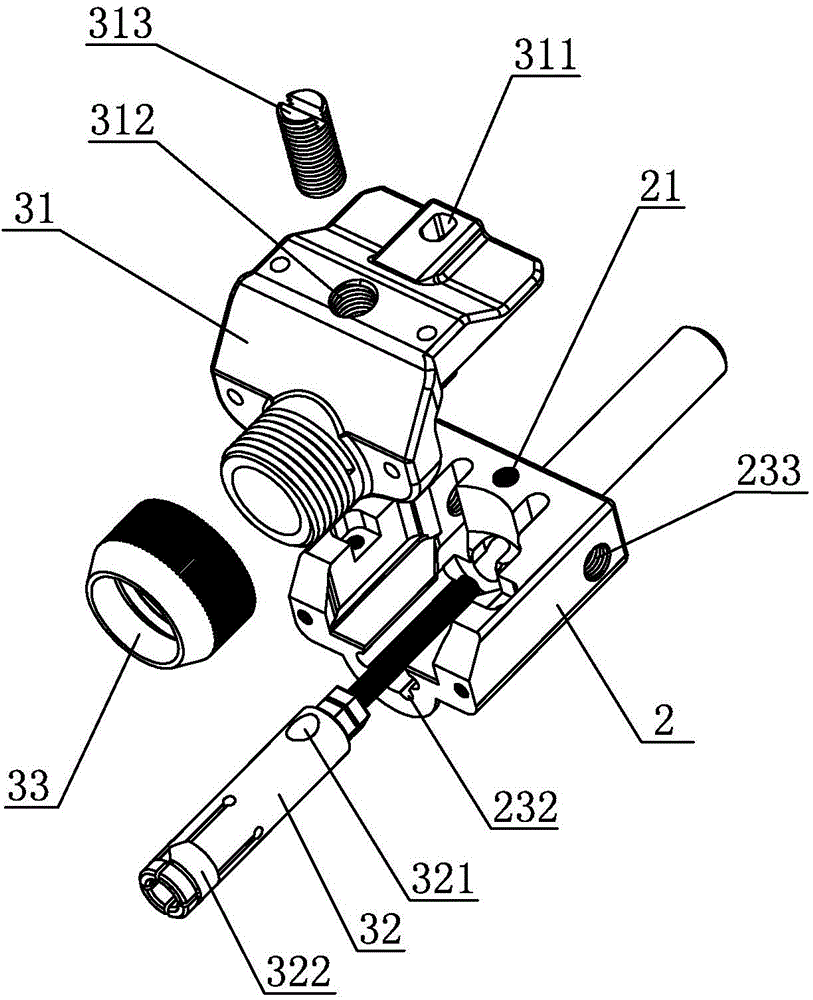

[0027] Reference figure 1 , figure 2 , The multifunctional electric welding gun of the present invention is a schematic structural diagram when a welding column type gun head is used, and includes a connecting piece 1 and a metal conductive piece 2. The conductive piece 2 is connected to the gun body part of the welding gun through the connecting piece 1. 1 is made of insulating material or is electrically isolated from conductive member 2. The conductive member 2 is covered with a cover I 31 made of insulating plastic, and a closed chamber is formed between the cover I 31 and the conductive member 2. A plurality of through holes 311 are provided on the outer cover I 31, and a plurality of screw holes 21 are correspondingly provided on the conductive member 2. The bolts 22 through the through holes 311 are connected to the conductive member 2 so that the outer cover I 31 is fixed on the conductive member 2. The welded object connected with the conductive member 2 protrudes from...

Embodiment 2

[0034] Reference Figure 5 to Figure 7 , The multifunctional electric welding gun of the present invention is a schematic diagram of the structure when the welding blade gun head is used. It includes a connecting piece 1 and a conductive piece 2 that are the same as the first embodiment. The conductive piece 2 is connected to the body part of the welding gun through the connecting piece 1. The connecting member 1 is made of insulating material or is electrically isolated from the conductive member 2 by using an insulating device. The conductive member 2 is covered with a cover II 41 made of insulating plastic, and the cover II 4 is fixed on the conductive member 2 by bolts 22, A closed chamber is formed between the cover II 41 and the conductive member 2. A piece of welded object 42 is set in the installation groove 23 of the conductive member 2, and is pressed by the pressing device 43 to make it close to the conductive member 2, and the front end of the piece of welded object...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com