Novel hand-held electric shears with adjustable shearing force

A technology of electric scissors and shearing force, applied in the direction of hand-held metal shearing equipment, shearing devices, shearing machine equipment, etc., can solve the problems of high labor intensity, low production efficiency, inconvenient movement, etc., to reduce labor intensity, The effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

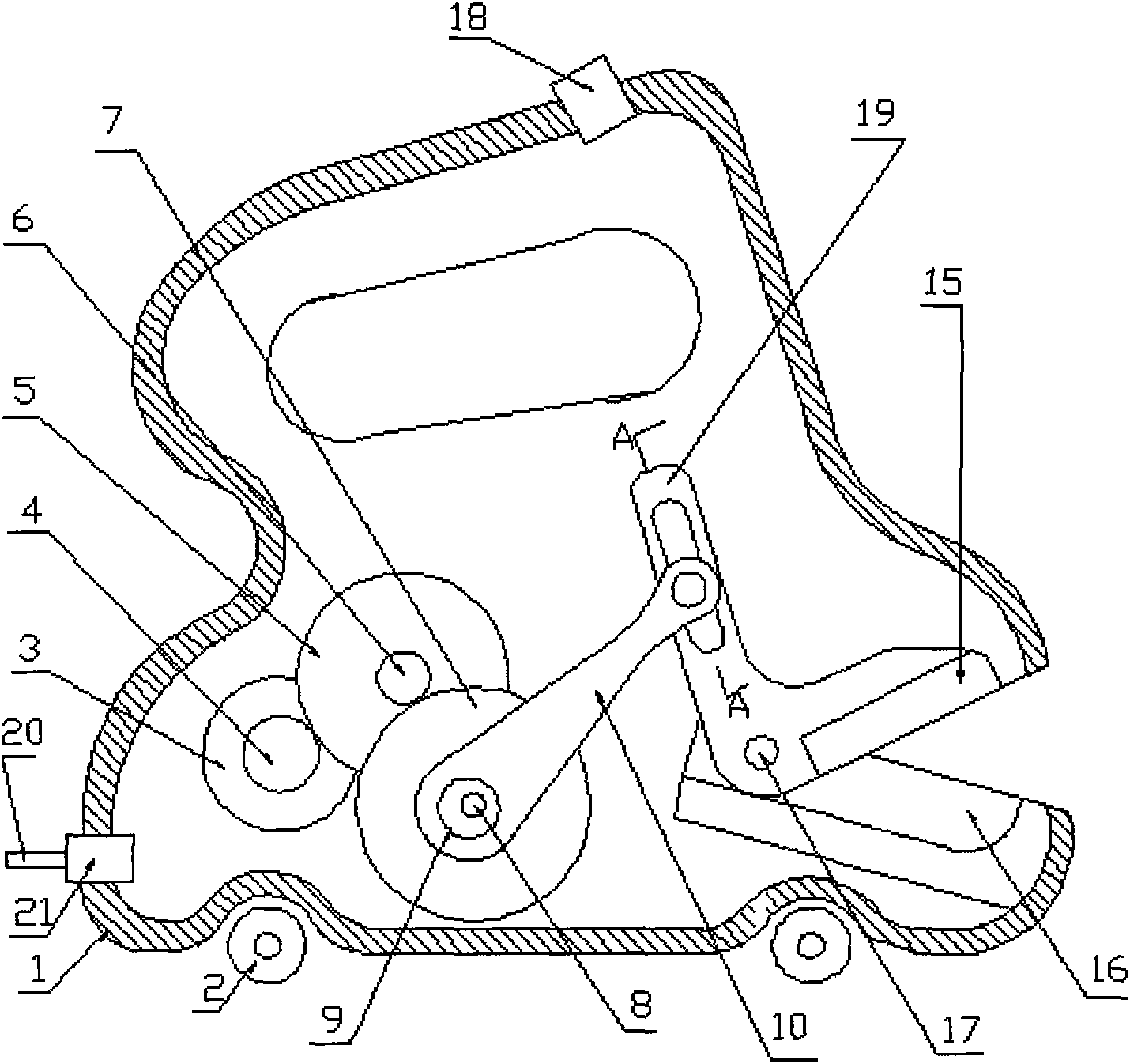

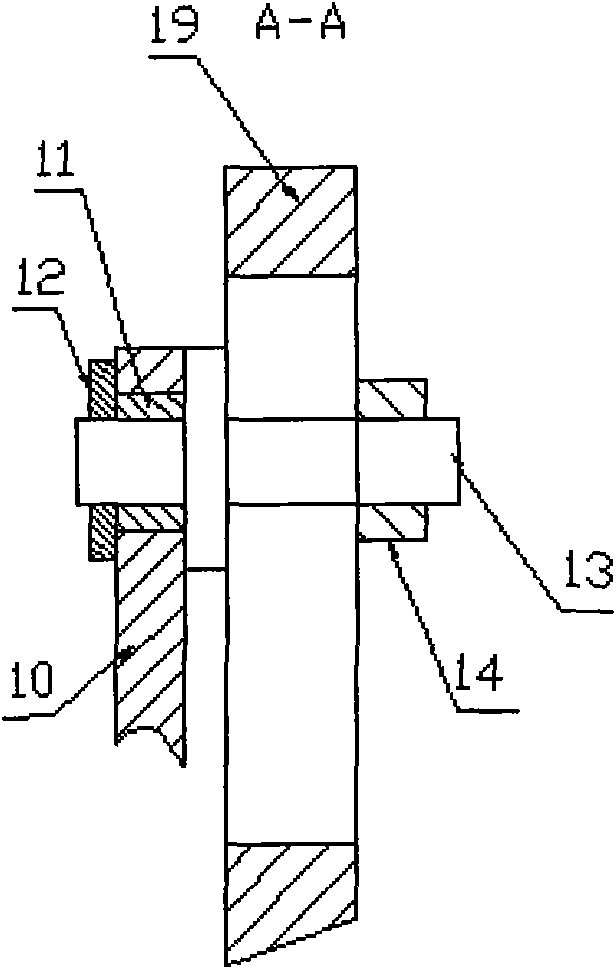

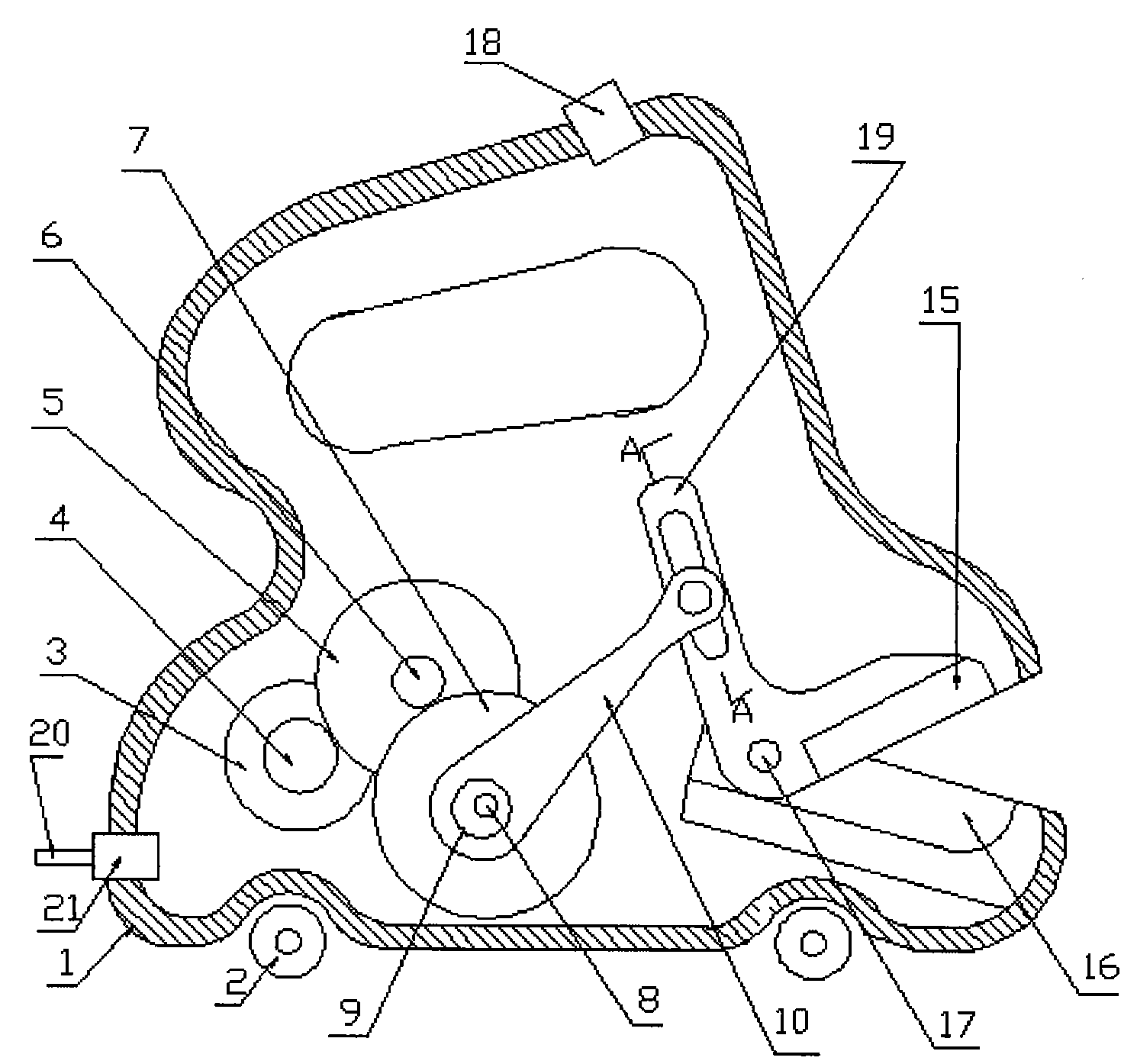

[0010] There is a cavity in the middle of the two scissors bodies (1), and a motor (3) is installed and fixed in the cavity in the middle of the two scissors bodies, and a first-stage gear (4) is installed on the output shaft of the motor (3), The first-stage gear (4) and the second-stage gear (5) form a meshing relationship, the second-stage gear (5) and the third-stage gear (6) are coaxially fixedly installed, and the fourth-stage gear (7) and the eccentric shaft (9) At the same time, it is installed and fixed on the rotary shaft of the fourth-stage gear (8), and the meshing relationship is formed between the third-stage gear (6) and the fourth-stage gear (7). One end of the connecting rod (10) is installed on the eccentric shaft (9), and the other end is installed and fixed on the pin shaft (13) through the bearing (11). There is a flange in the middle of the pin shaft. One end face is close to the end face of the oblong hole on the fork (19), and on the other end face of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com