Combined type grinding head device

A combined, grinding head technology, applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of reduced processing efficiency, single function and processing effect, troublesome use and operation, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

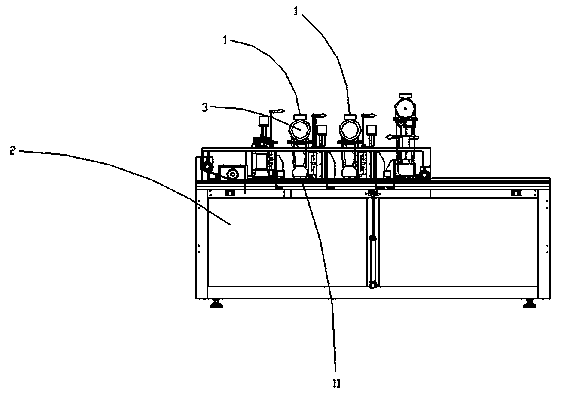

[0023] Such as figure 1 As shown, a combined grinding head device in this embodiment is arranged on the frame 2 and connected to the driving device 3. The driving device 3 uses a motor 3 to work. The combined grinding head device includes a base 5 and The plurality of grinding head mechanisms 1 detachably connected to the base 5 are provided with consistent installation interfaces 51 on the base 5 and the plurality of grinding head mechanisms 1 . Such as figure 1 Shown are two grinding head mechanisms 1 , which are arranged behind the workbench on the frame 2 , and the plurality of grinding head mechanisms 1 include a plurality of different grinding heads 11 . Further, the above-mentioned two grinding head mechanisms 1 are arranged behind the table.

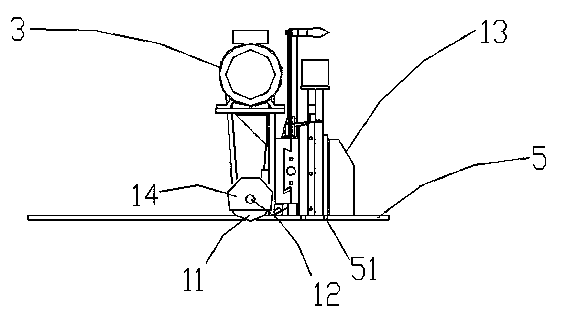

[0024] Such as figure 2 , image 3 As shown, the above-mentioned plurality of grinding head mechanisms 1 also each include a grinding head frame 13 and a grinding head shaft 12, the grinding head shaft 12 is movably connecte...

Embodiment 2

[0027] Others are the same as those described in Embodiment 1, except that the multiple grinding heads of the multiple grinding head mechanism are the same grinding head, which is suitable for the grinding processing needs of a large number of the same material for the same process requirements.

Embodiment 3

[0029] Others are the same as those described in Embodiment 1, except that the multiple grinding heads of the multiple grinding head mechanism are divided into the same and some of them are different grinding heads, which are applicable to the grinding needs with a small number of process requirements.

[0030] The working principle of the present invention is introduced below:

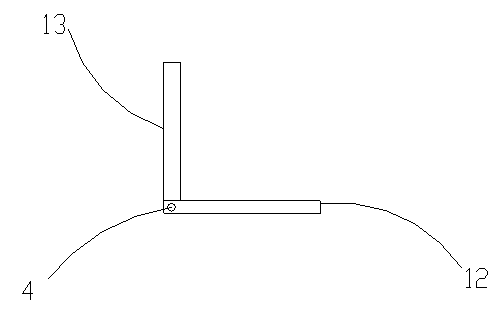

[0031] Use the corresponding grinding head 11 for processing according to the needs of use. If the processing of multiple processes is realized on one material, the same or different grinding heads 11 are installed in the grinding head mechanism 1 for processing according to the processing needs, without changing equipment Or it can be realized by frequently replacing the grinding head 11, and the processing efficiency is relatively high; according to the needs in use, the grinding head shaft 12 and the grinding head frame 13 are set to be movably connected by elements such as bolts 4 or universal join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com