Miniature high-strength flexible optical cable

A high-strength, optical cable technology, applied in the directions of light guides, optics, optical components, etc., can solve the problem that transmission capacity, weather resistance and tensile properties cannot meet wiring requirements, unfavorable cable wiring needs, poor tensile properties and weather resistance, etc. problems, to achieve the effect of saving wiring space resources, light weight, and excellent bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

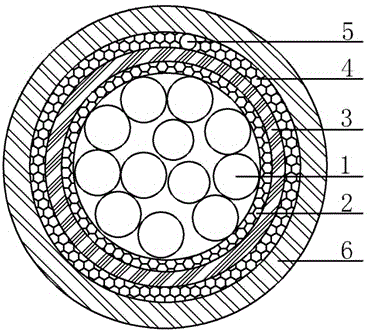

[0019] It includes a cable core and an outer sheath, the cable core is wrapped in an ultra-thin inner sheath 3, the cable core contains 12 colored optical fibers 1, and a non-metallic The inner reinforcement layer 2 is composed of 16 pieces of 220dtex aramid fibers, and the ultra-thin inner sheath 3 is made of light-cured acrylic resin, and its outer diameter is less than or equal to Φ1.4mm; a non-metallic external reinforcement is laid outside the ultra-thin inner sheath Layer 4, the non-metallic outer reinforcement layer is composed of eight 1610dtex aramid fibers, and the non-metallic outer reinforcement layer is covered with an outer sheath 6, the outer sheath is made of flexible thermoplastic polyurethane polymer material, and its outer diameter is less than or equal to Φ3.0mm. An opening cable 5 is arranged in the non-metal outer reinforcing layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com