Thread guide bar improved arrangement for circular knitting machines

The technology of a yarn guide rod and a circular knitting machine is applied in the directions of weft knitting, textiles, papermaking, knitting, etc., and can solve the problems of inconvenient assembly of the yarn support rod seat, difficulty and difficulty in connecting and installing the linkage mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

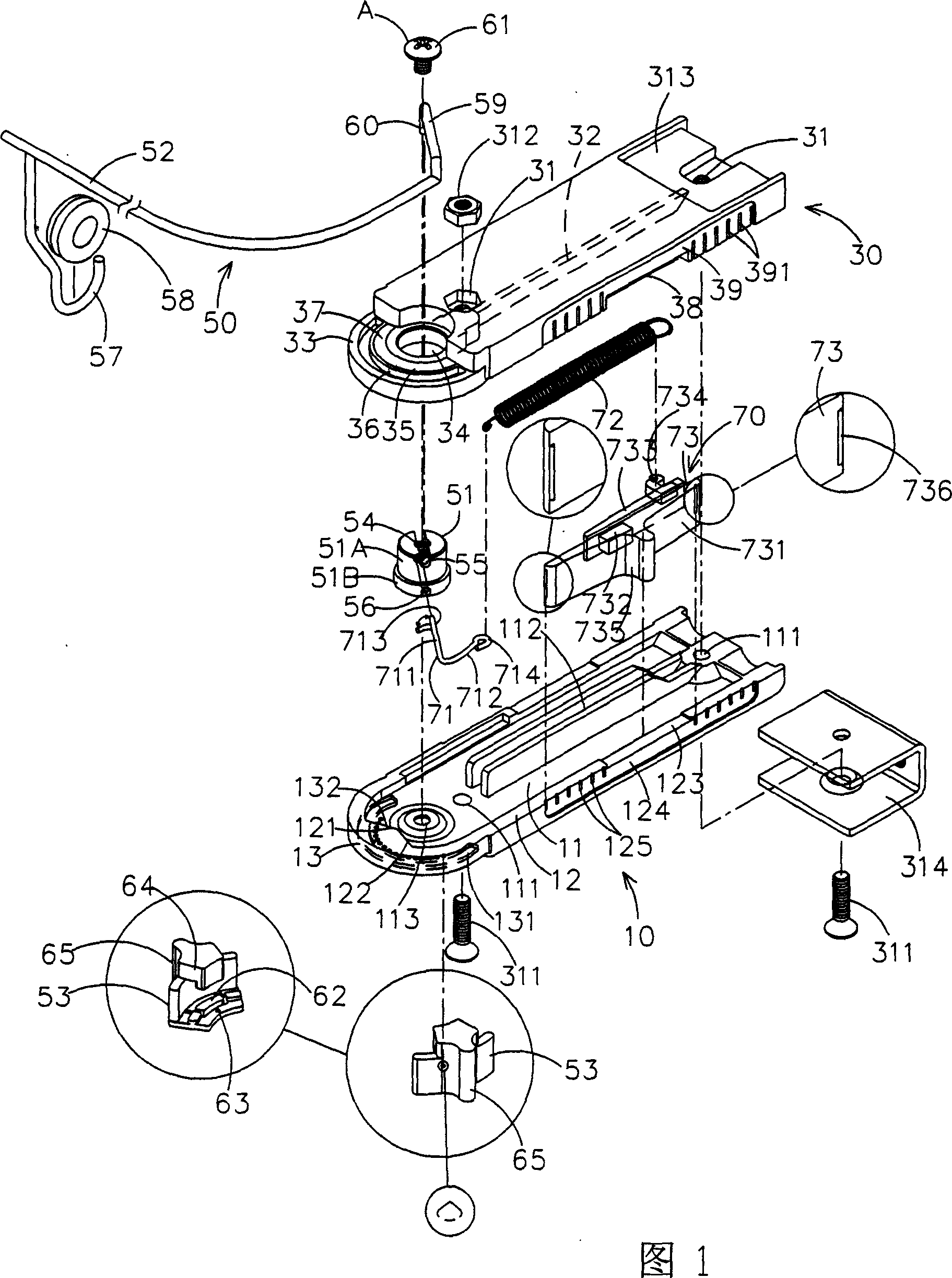

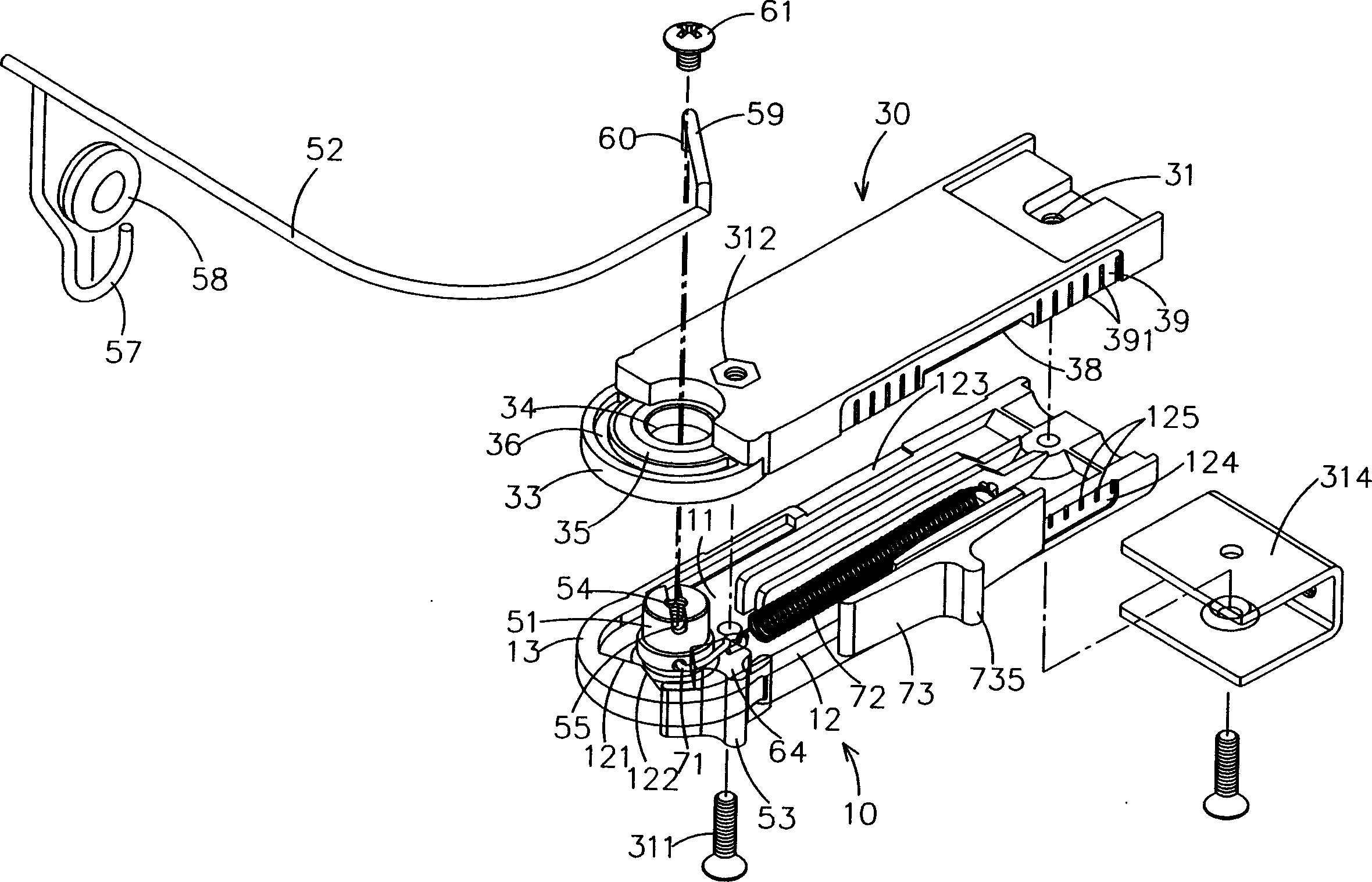

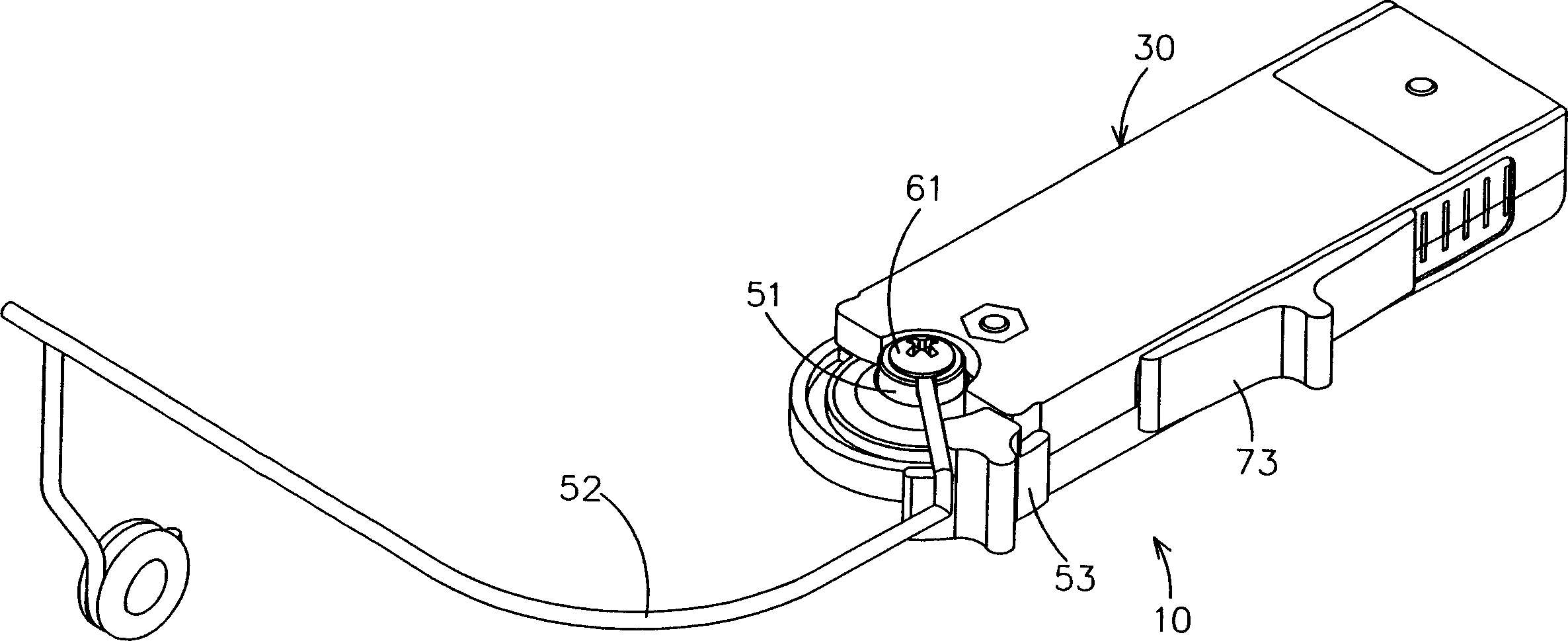

[0023] Please refer to Figures 1 to 3, the improved device of the yarn guide rod device of the circular knitting machine of the present invention includes a base 10, a cover body 30, a swing mechanism 50 and a tension mechanism 70, the base 10 includes a bottom surface 11 and a convex peripheral edge 12, And the front end of the base 10 is an arc joint 13, the bottom surface 11 is provided with a positioning hole 111 and a groove rib 112, and the front end of the bottom surface 11 is provided with a convex mandrel positioning portion 113, the positioning portion 113 can be a flange or a shaft hole. The convex peripheral edge 12 is provided with a mountain-shaped part 121 at the arc joint 13. The mountain-shaped part 121 has an inclined contact surface 122. The convex peripheral edge 12 is on both sides of the bottom surface 11. The recess 123 on the top surface and the groove 124 on the side are symmetrically provided, and the groove 124 is provided with a plurality of position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com