Welding tool of breaker spindle connecting levers

A welding tooling and circuit breaker technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the arm cannot be positioned evenly, and the distance dimension accuracy of the arm is difficult to guarantee, so as to reduce the welding error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

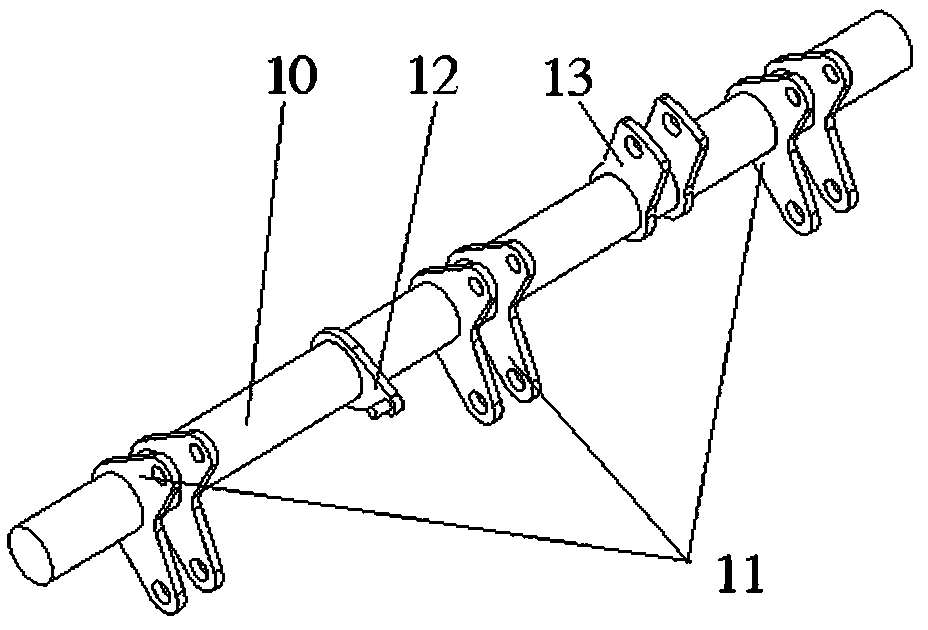

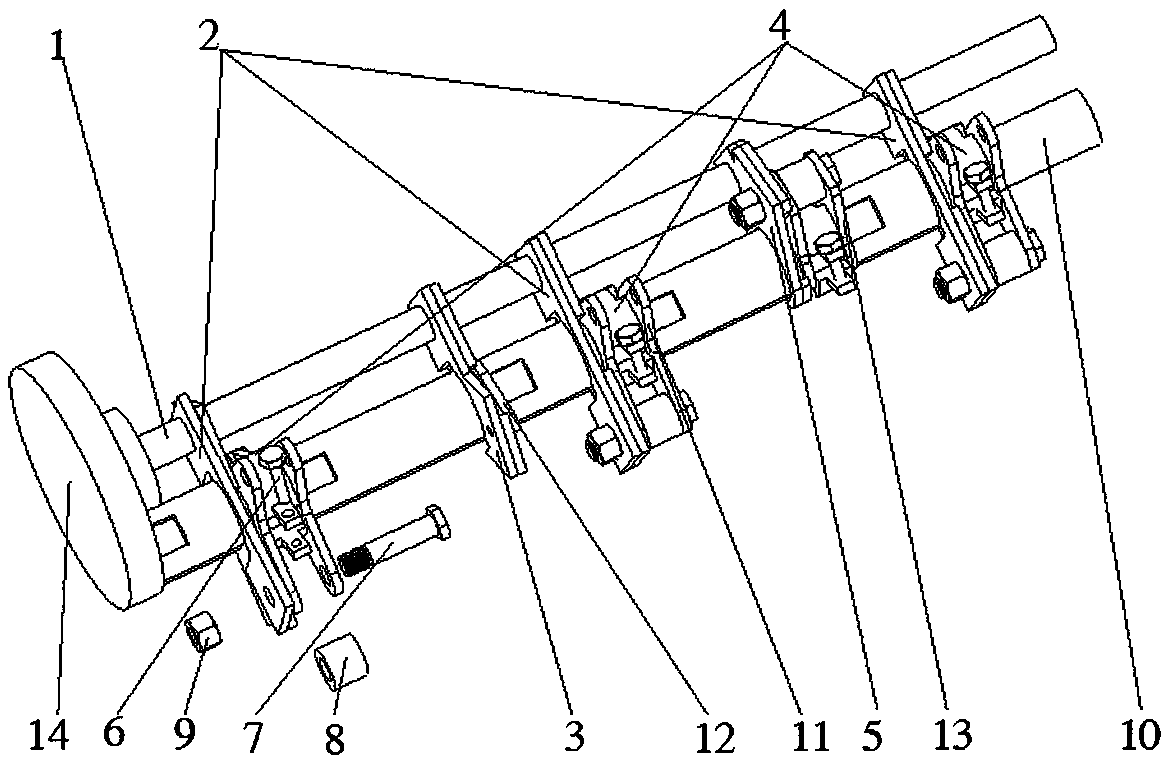

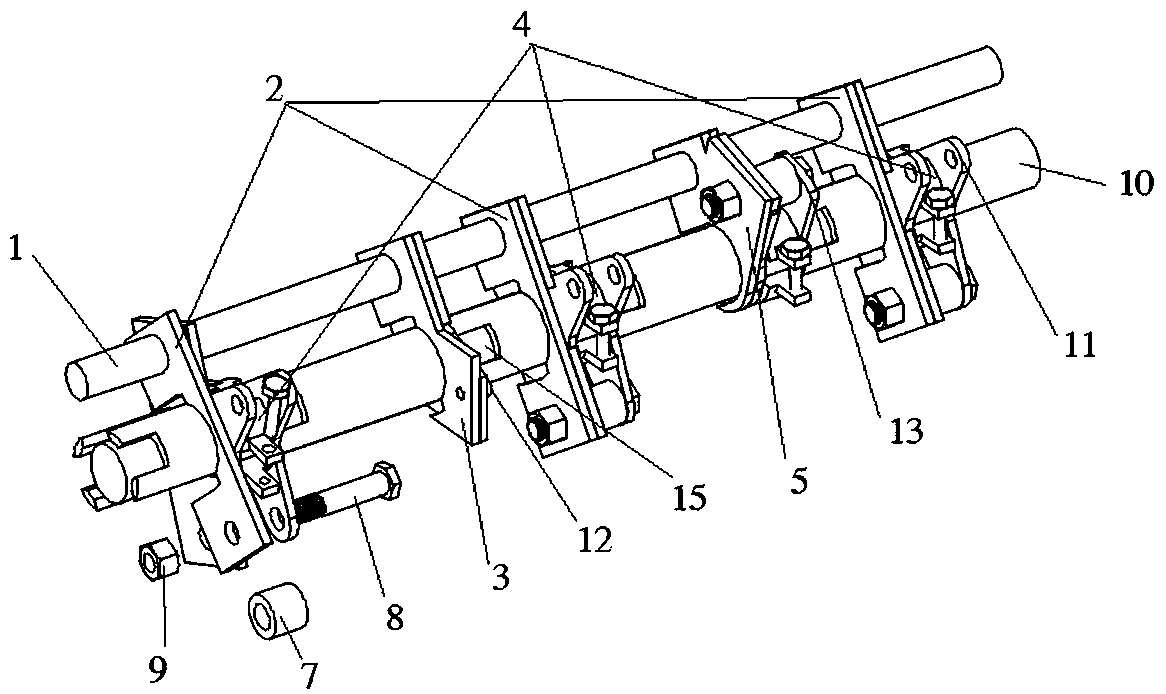

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0035] The specific embodiment of the circuit breaker spindle crank arm welding tool of the present invention, as figure 2 As shown, the circuit breaker main shaft crank arm welding tooling includes a support seat, and the support seat is provided with a crank arm positioning part for positioning and matching with the main shaft and positioning the corresponding crank arm on the main shaft 10. 10, the axial positioning part for matching the distance between the corresponding crank arms and the angular positioning part for positioning and cooperating with the corresponding crank arms to maintain a relative angle between the crank arms.

[0036] In this embodiment, taking the first crank arm positioning member 2 as an example, the first crank arm positioning member 2 includes a tile-shaped positioning plate that supports and extends axially for positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com