Cam conveying guide rail for doffer of ring spinning frame

A technology for conveying guide rails and spinning frames, which is used in textiles and paper making, etc., can solve problems such as inconvenient installation, deformed convex discs, and stuck, and achieve stable and reliable transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

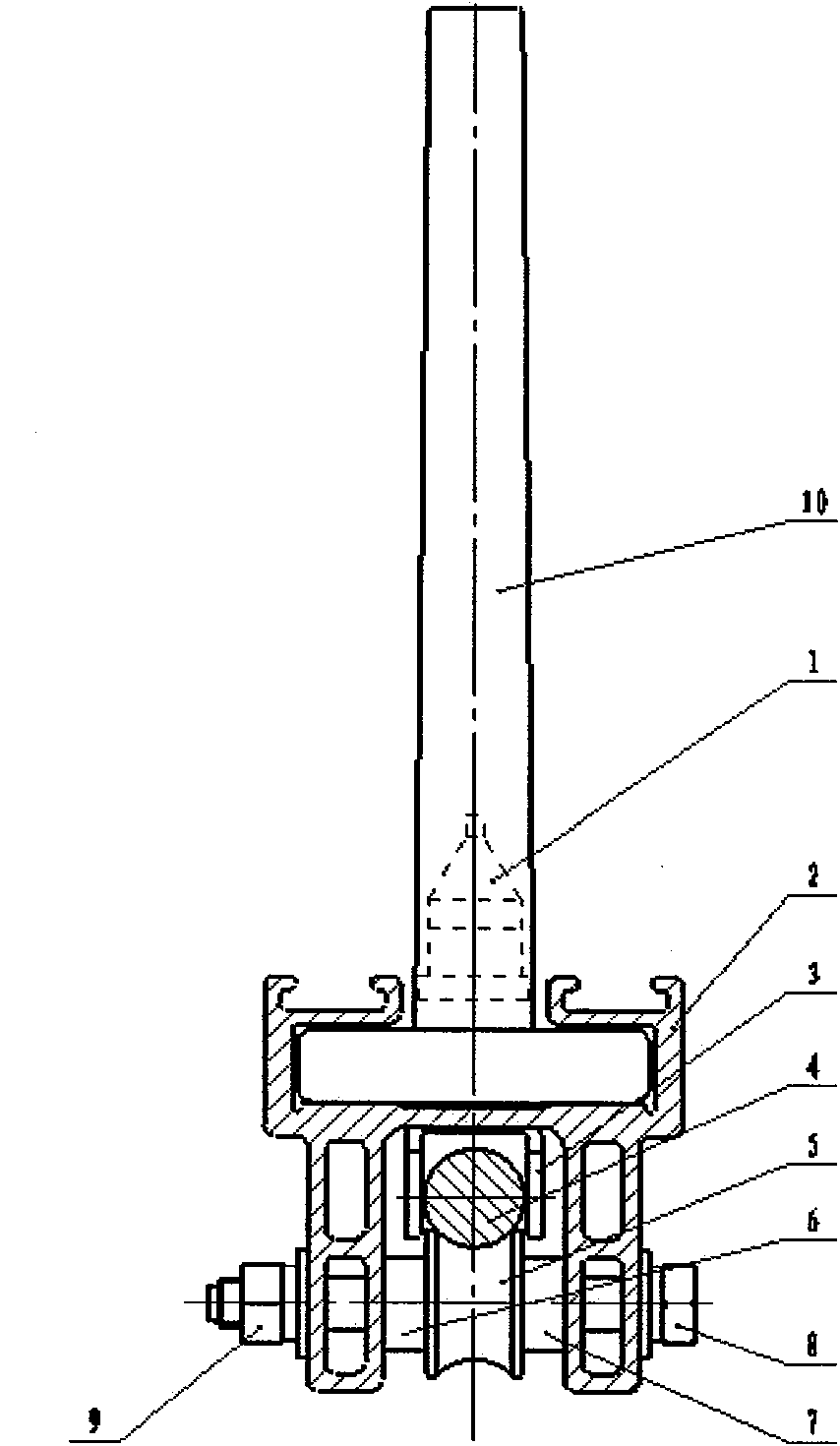

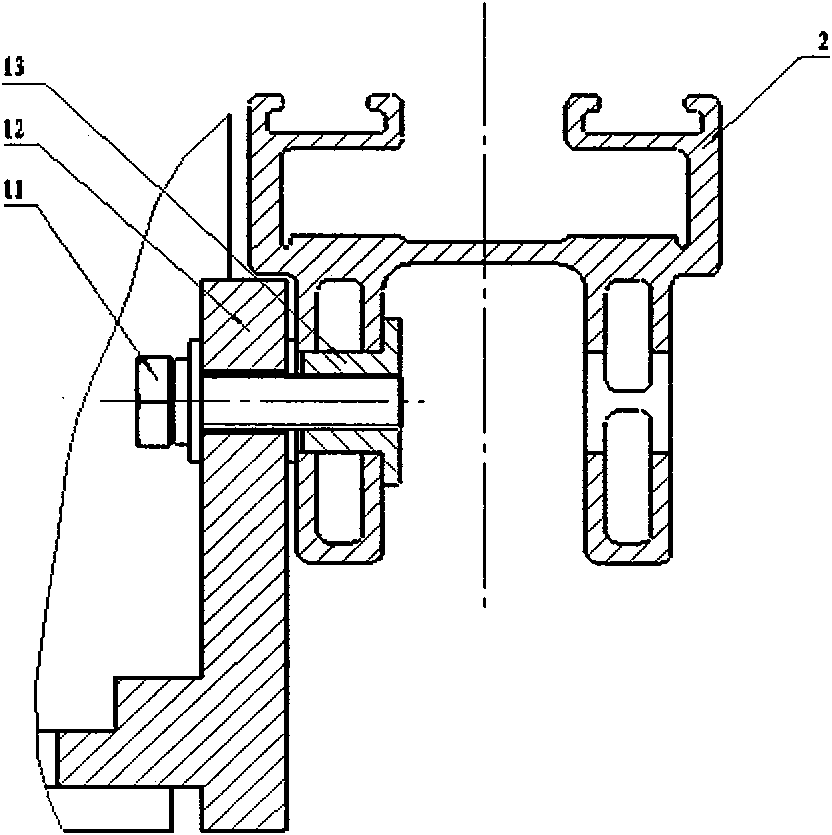

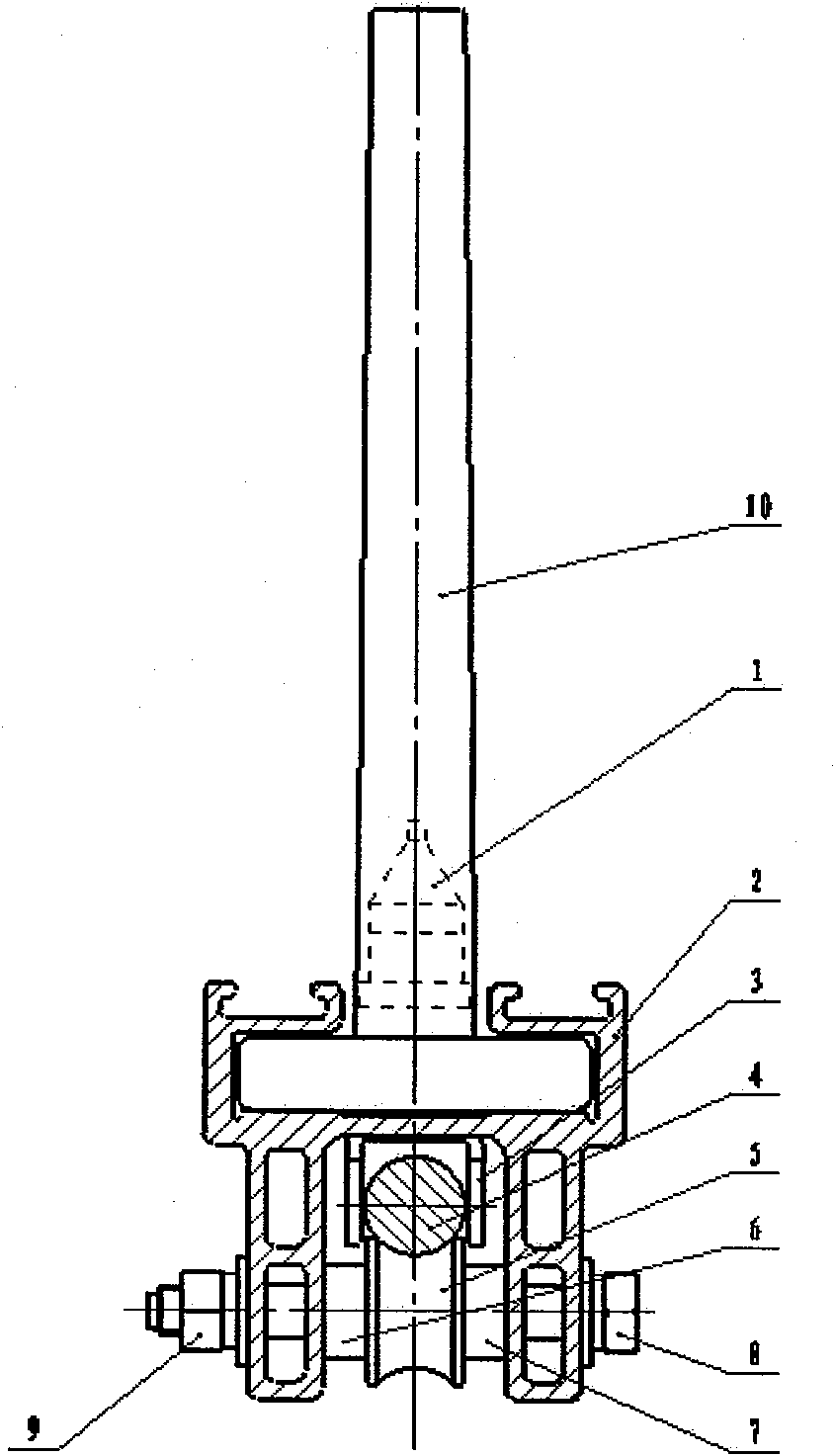

[0008] A cam conveying guide rail for collective doffing of a ring spinning machine, comprising a cam 1, a cam conveying guide 2, a claw 3, a transmission rod 4, a pulley 5, a first bush 6, a second bush 7, First bolt 8 , nut 9 , bobbin 10 , second bolt 11 , standoff 12 and positioning sleeve 13 . The convex plate conveying guide rail 2 is fixed on the supporting foot 12 through the second bolt 11 and the positioning sleeve 13, the bobbin 10 is set on the convex plate 1, the convex plate 1 is arranged on the working surface of the convex plate conveying guide rail 2, and the supporting claw 3 passes through The pin shaft is fixed on the transmission rod 4, the supporting claw 3 is connected with the convex plate 1, the transmission rod 4 is connected with the pulley 5, the first bolt 8 is arranged on the lower part of the convex disk conveying guide rail 2, and the pulley is arranged on the first bolt 8 5. Both sides of the pulley 5 are provided with a first sleeve 6 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com