Method and fixture for controlling welding deformation of igniter

A welding deformation and control point technology, applied in welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of insecure size, engine failure, wall thickness out of tolerance, etc. Reliability, effect of controlling welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method and jig for controlling the welding deformation of the igniter according to the present invention will be described in detail below in conjunction with the accompanying drawings.

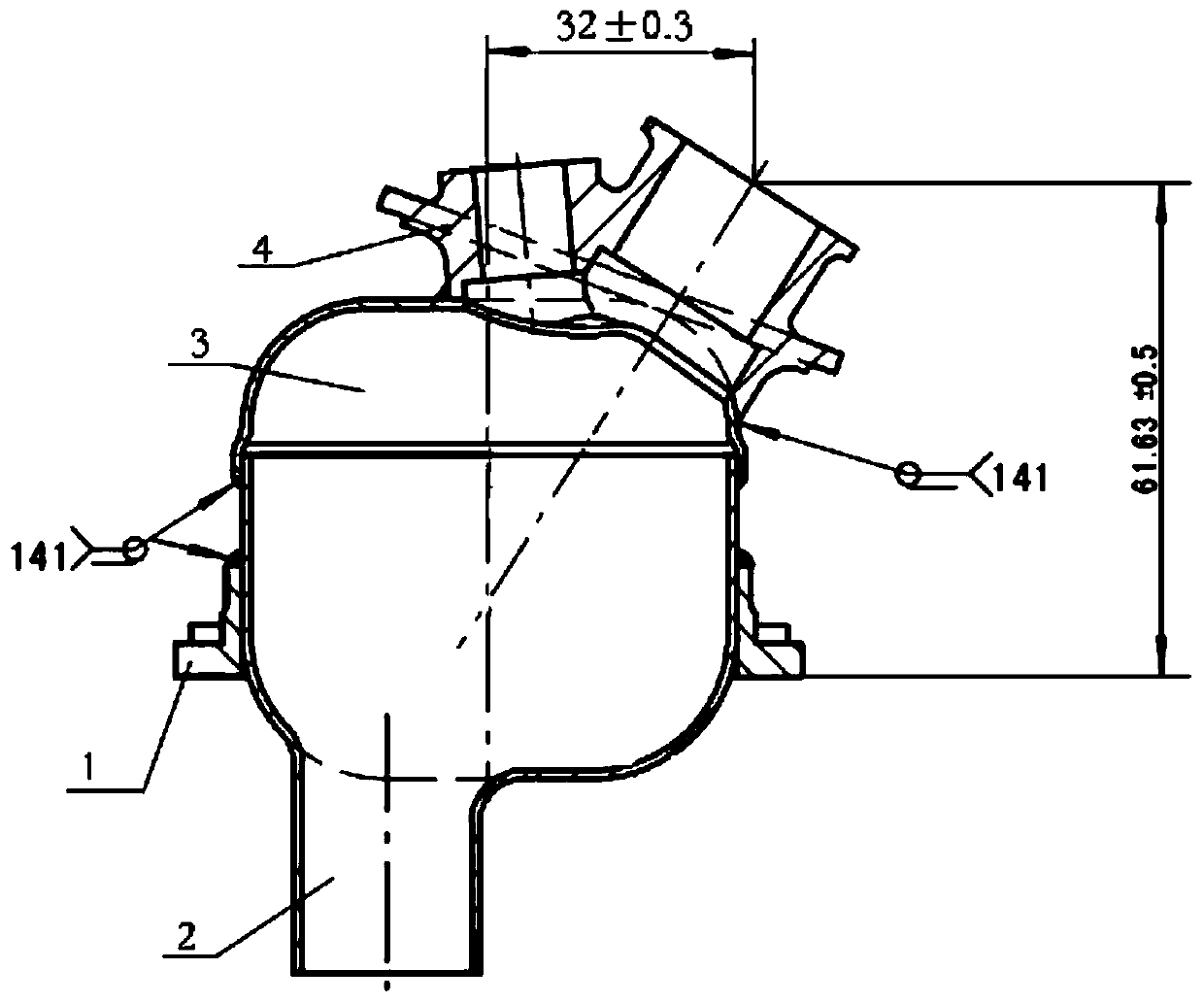

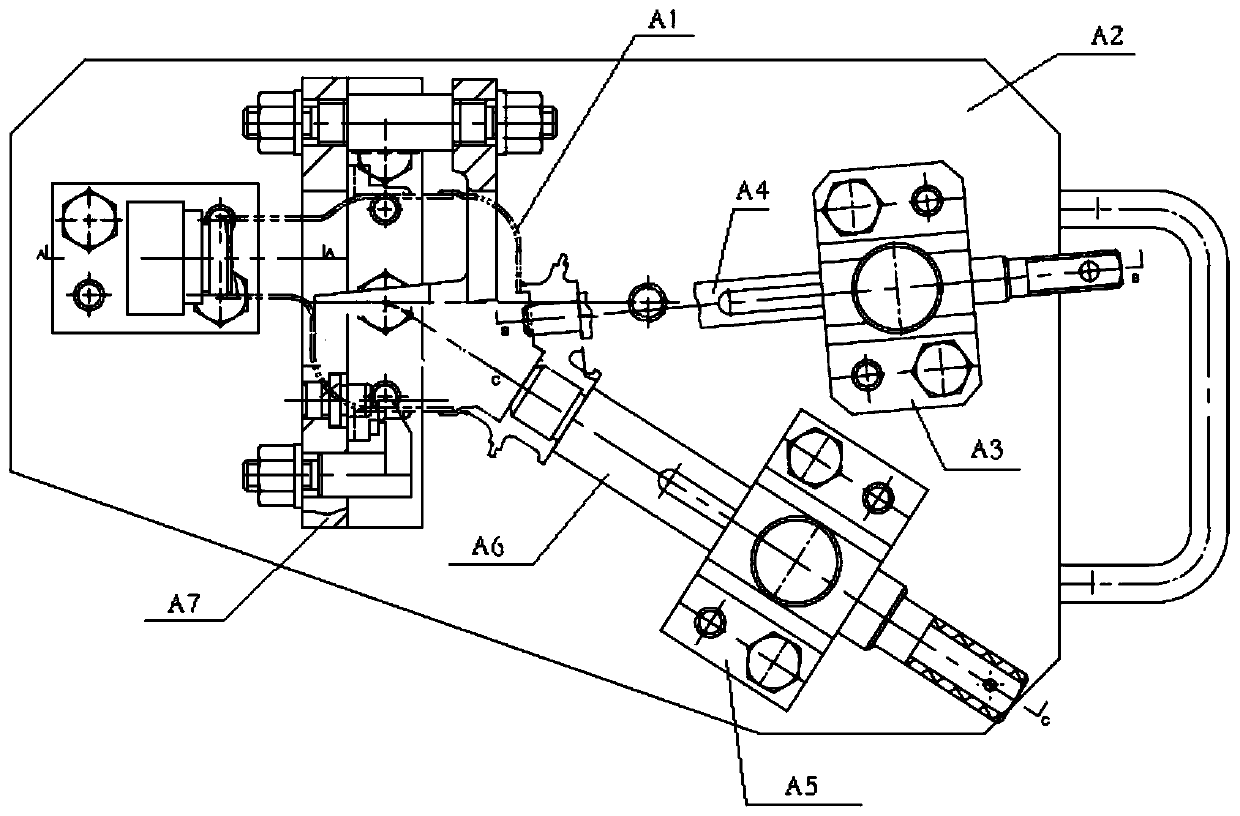

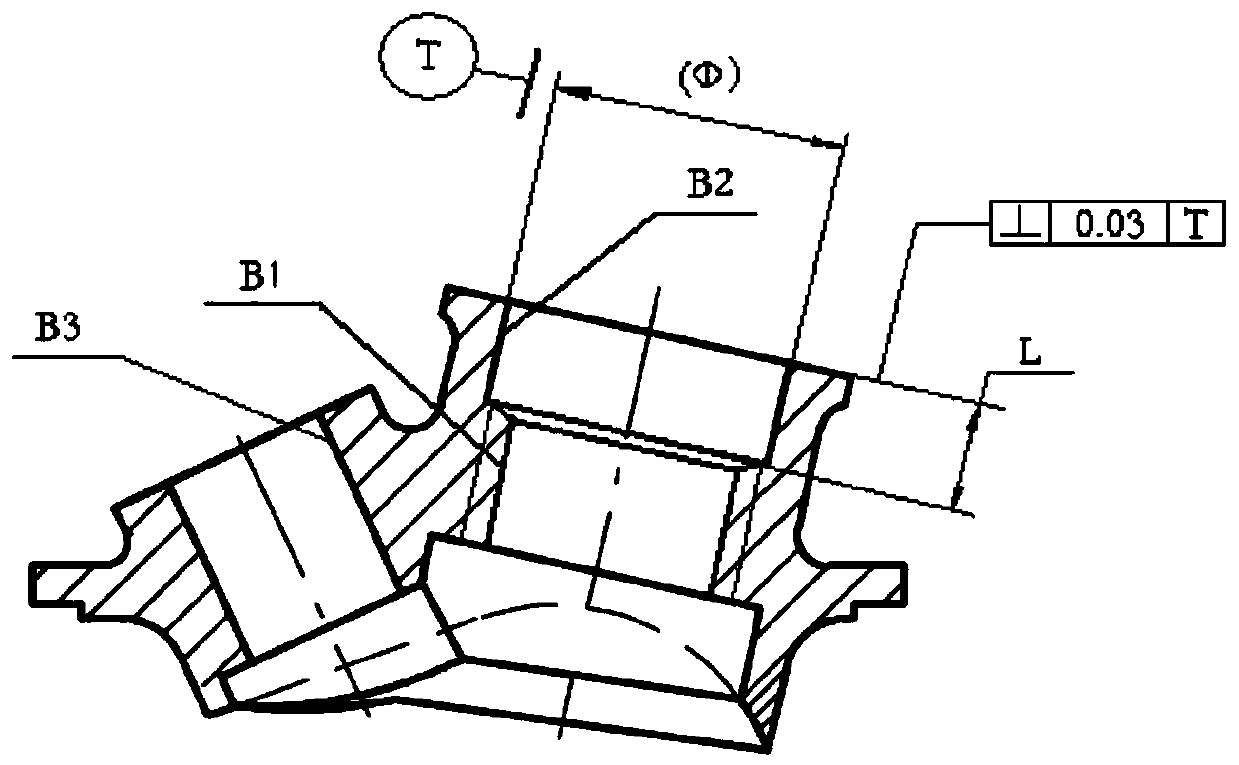

[0027] figure 1 The aero-engine igniter assembly is shown, and the assembly is formed by welding the mounting edge 1, the lower shell 2, the upper shell 3, and the boss 4. After welding, the inner cavity of the two joints of the mounting edge 1 and the boss 4 are machined. The boss 4 has two joints, a large joint and a small joint; during the welding of the original process, the size of the large joint of the boss is Φ18mm * 30mm, and the small joint Φ8mm * 18mm. The welding of the igniter requires that the size of the large joint joint of the boss be ensured, the height direction is 61.63mm±0.5mm, the length direction is 32mm±0.3mm, and the width direction is located on the center plane of the installation side. Now, using the method of the present invention, the method and jig f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com