A kind of remanufacturing method of steel piston

A steel piston, remanufacturing technology, applied in the field of engine friction pair repair, can solve the problem of waste of resources and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

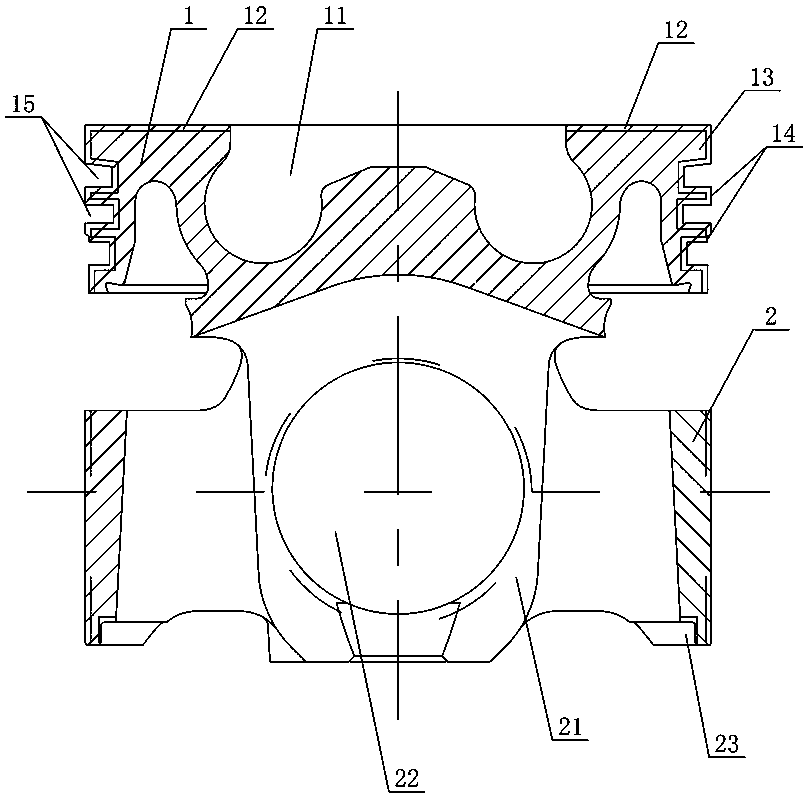

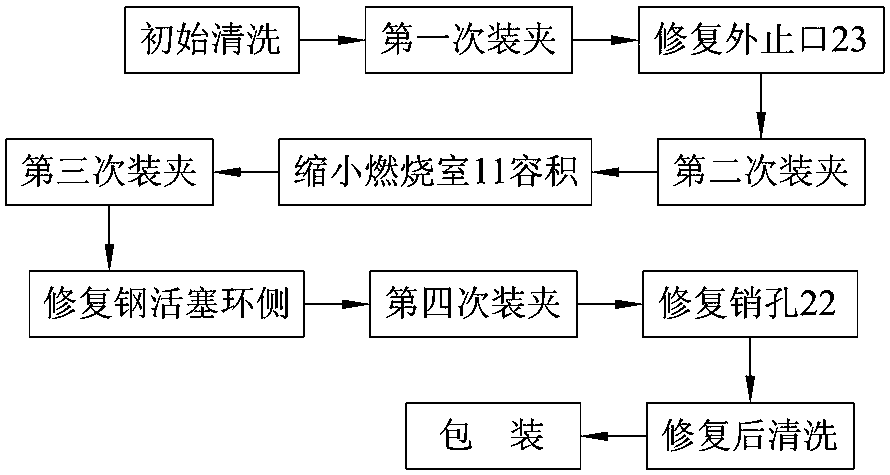

[0056] Such as figure 1 and figure 2 As shown, the first embodiment of the remanufacturing method of the steel piston of the present invention, the steel piston includes a piston head 1 and a piston skirt 2, the piston head 1 is provided with a combustion chamber 11 and a top plane 12, and the piston head 1 The ring side is provided with spaced fire bank 13 and ring bank 14, a ring groove 15 is formed between the fire bank 13, the ring bank 14 and the adjacent ring bank 14, and the piston skirt 2 is provided with an inner cavity 21 and a through pin hole 22 , the bottom end of the piston skirt 2 is provided with an outer seam 23, comprising the following steps:

[0057] S1: Initial cleaning: Clean the steel piston to be repaired to remove oil stains and other stains;

[0058]S2: Clamping for the first time: Clamping and fixing the steel piston based on the bottom diameter of one of the ring grooves 15 and the top plane 12;

[0059] S3: Repair the outer seam 23: remove mate...

Embodiment 2

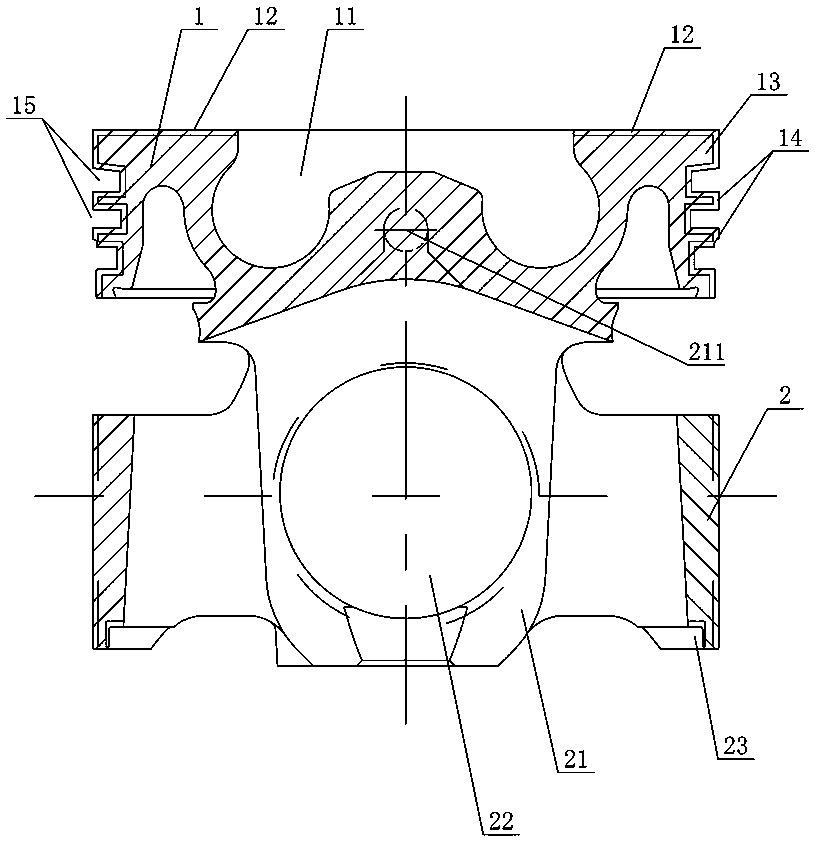

[0074] Figure 3 to Figure 5 The second embodiment of the remanufacturing method of the steel piston of the present invention is shown, the steel piston comprises a piston head 1 and a piston skirt 2, the piston head 1 is provided with a combustion chamber 11 and a top plane 12, the piston head 1 The ring side is provided with spaced fire bank 13 and ring bank 14, a ring groove 15 is formed between the fire bank 13, the ring bank 14 and the adjacent ring bank 14, and the piston skirt 2 is provided with an inner cavity 21 and a through pin hole 22 , the bottom end of the piston skirt 2 is provided with an outer seam 23, comprising the following steps:

[0075] S1: Initial cleaning: Clean the steel piston to be repaired to remove oil stains and other stains;

[0076] S2: Clamping for the first time: Clamping and fixing the steel piston based on the bottom diameter of one of the ring grooves 15 and the top plane 12;

[0077] S3: Machining the internal positioning reference: mac...

Embodiment 3

[0094] Figure 5 to Figure 7 The third embodiment of the remanufacturing method of the steel piston of the present invention is shown, the remanufacturing method is basically the same as Embodiment 2, the only difference is that in this embodiment, in step S3, the two sides of the top of the cavity 21 are The inner positioning part 211 is processed on the side, and the inner positioning part 211 is an inner stop structure. Adopting the internal stop structure, the clamping and positioning of the steel piston can be completed by using the tooling to extend to the inner cavity 21 and withstand the inner stop and cooperate with the top plane 12, and the operation is convenient.

[0095] In this embodiment, in step S3, milling is used to process the inner spigot. Milling is adopted, and the processing is simple and easy to realize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com