A new type of steel wire rope gear

A technology of steel wire rope and rope gear, which is applied in the field of new steel wire rope gear gear, to achieve the effects of easy promotion, avoiding inconvenient disassembly, and preventing the steel wire rope from slipping out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

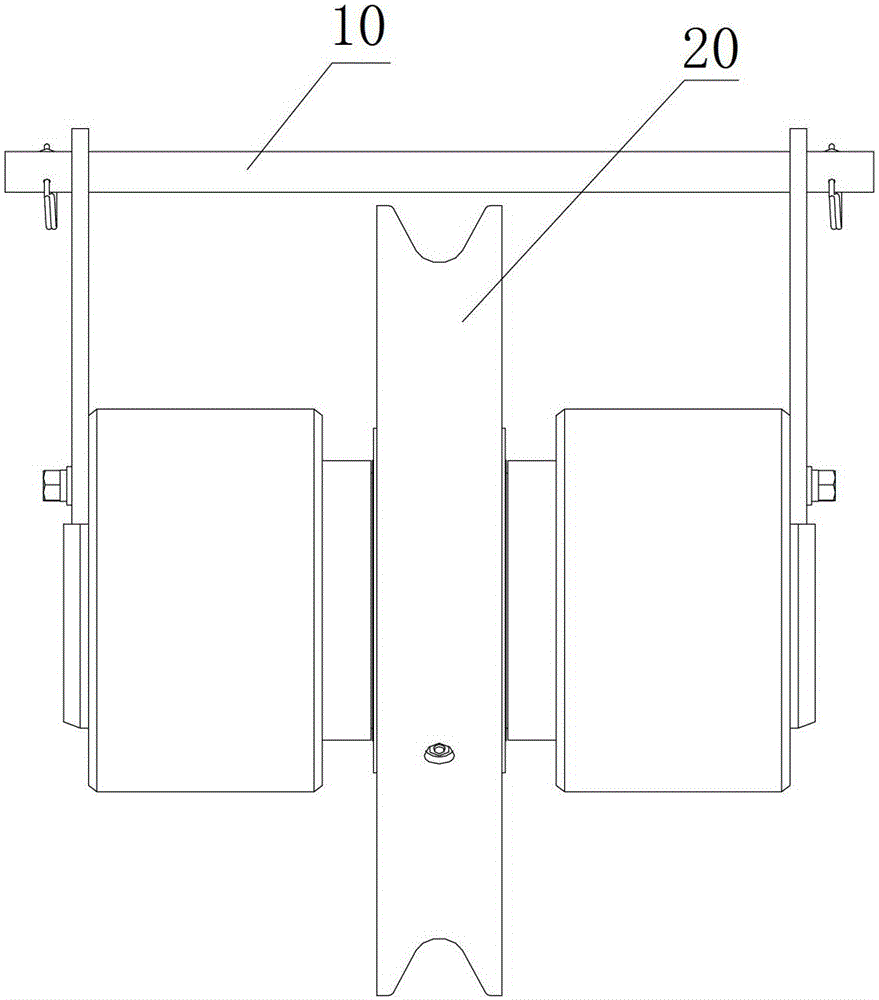

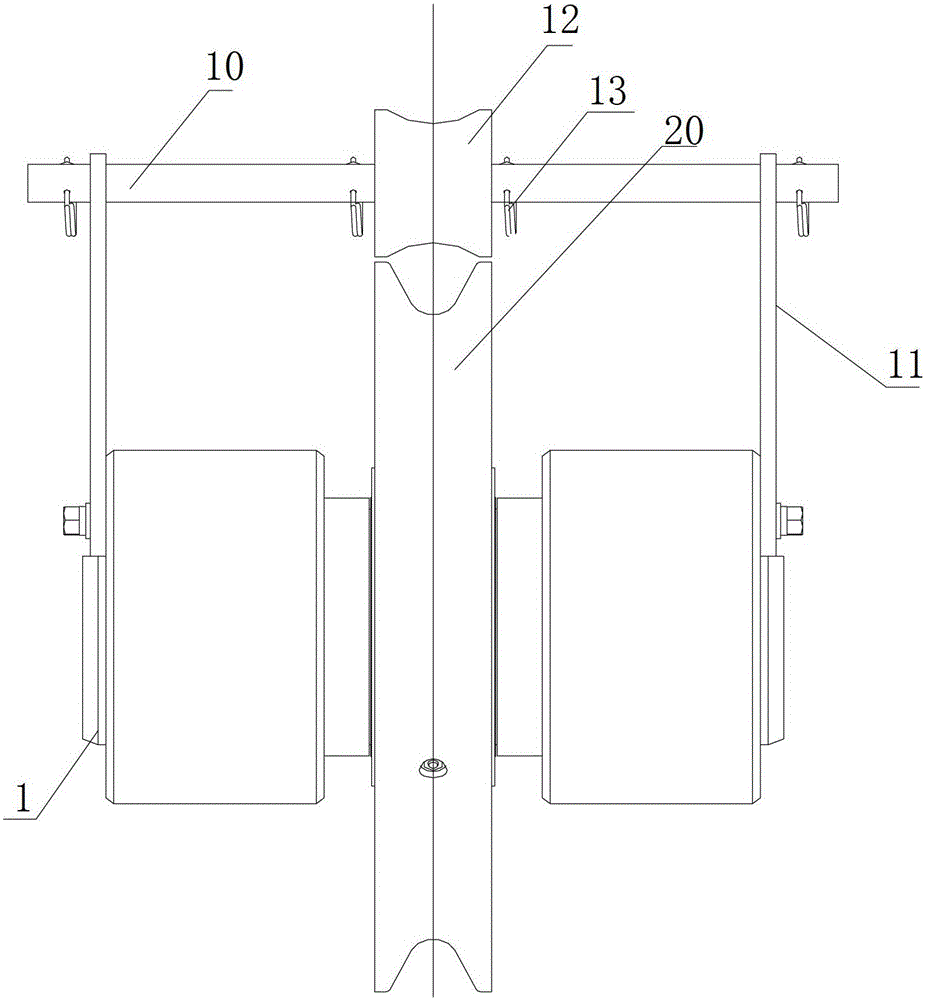

[0029] see figure 2 , which shows a preferred embodiment of a novel steel wire rope stall device of the present invention.

[0030] The novel wire rope rope stop device of the present invention comprises frame body 1, is provided with rotating shaft on described frame body 1, is provided with at least one pulley 20 on described rotating shaft, as figure 2 As shown, the pulley 20 of the novel wire rope gear gear device of the present invention can rotate around the axis of the rotating shaft to facilitate the movement of the wire rope.

[0031] The frame body 1 is also provided with a bracket 11 extending outwards and having a height greater than the radius of the pulley 20, such as figure 2 As shown, the bracket 11 is provided with a rope stop device 10, and the bracket 11 positions the rope stop device 10 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com