Cutter head spindle spring positioning device

A technology of spring positioning and milling head, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of inability to connect, damage keys, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

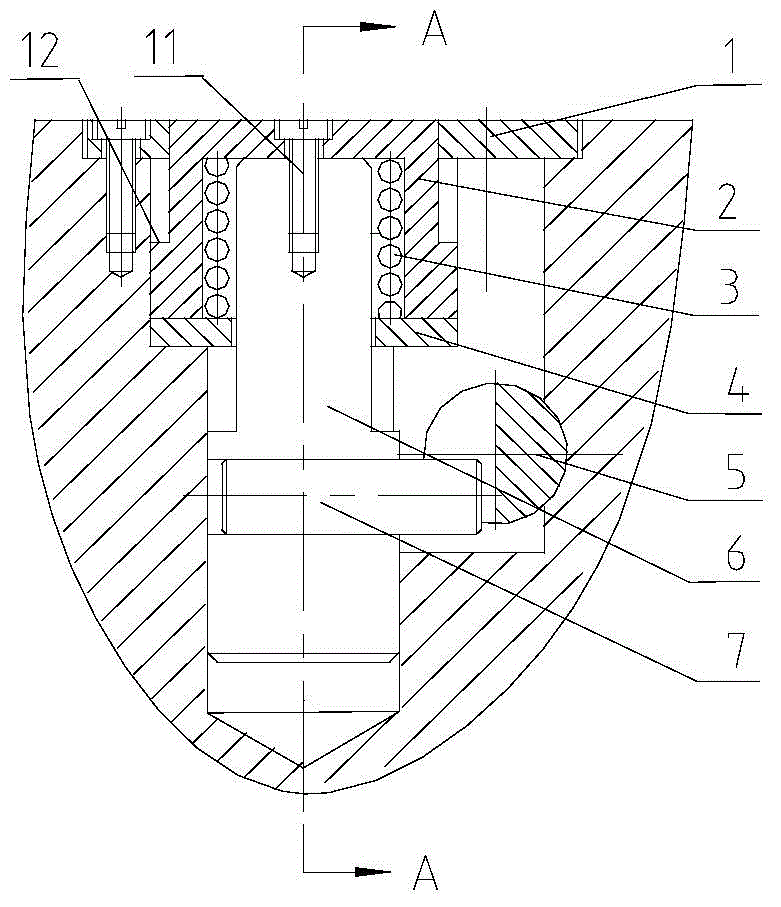

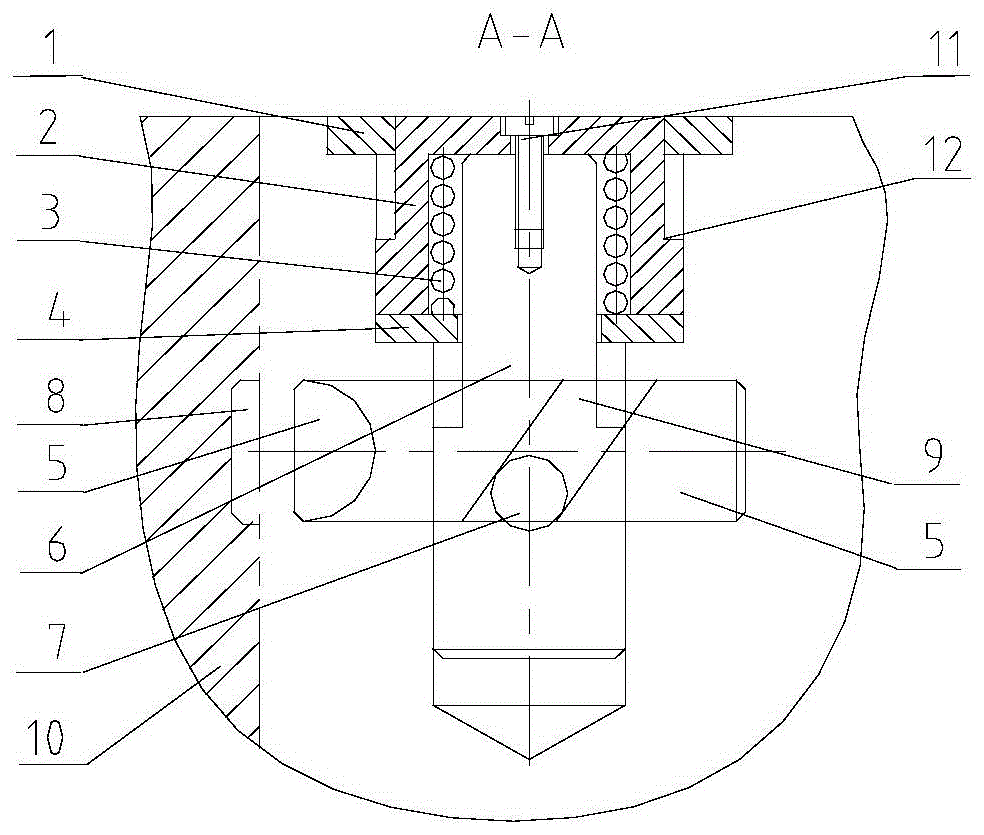

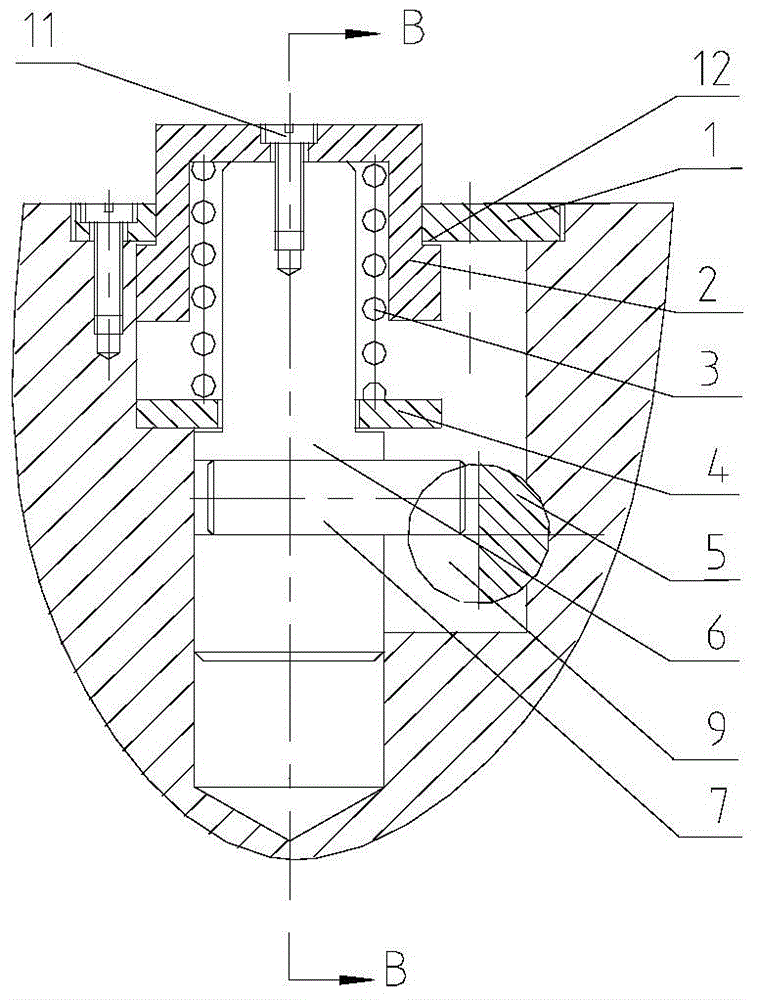

[0013] The milling spindle spindle spring positioning device mentioned in the present invention is placed in the accessory, the ejector rod 6 is placed in the pressure sleeve 2 and fixed together by the fastener 11, and the backing plate 4 fixes the spring 3 on the shaft of the ejector rod 6 and the pressure sleeve 2, a part of the pin 7 is arranged at the lower end of the push rod 6, and the other part of the pin 7 is inserted in the chute 9 provided on the latch 5. The gland 1 is arranged on the end face of the milling head attachment, and cooperates with the limit mechanism 12 provided on the pressure sleeve 2, and the entire positioning device is limited by the gland 1.

[0014] When the accessory is released from the ram, since the spring 3 is in a relaxed state, the pressure sleeve 2 and the push rod 6 are lifted up, and the pin 7 on the push rod 6 drives the latch 5 to move to the left (such as Figure 4 shown). Because the main shaft of the ram has a positioning funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com