Binding machine

A technology for binding machines and binding holes, which is applied in the field of binding machines, can solve the problems of increased thickness and dislocation of joints, etc., and achieves the effects of suppressing the increase in thickness, making binding easier, and avoiding excessive thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0059] A first embodiment of the invention will be described below with reference to the drawings.

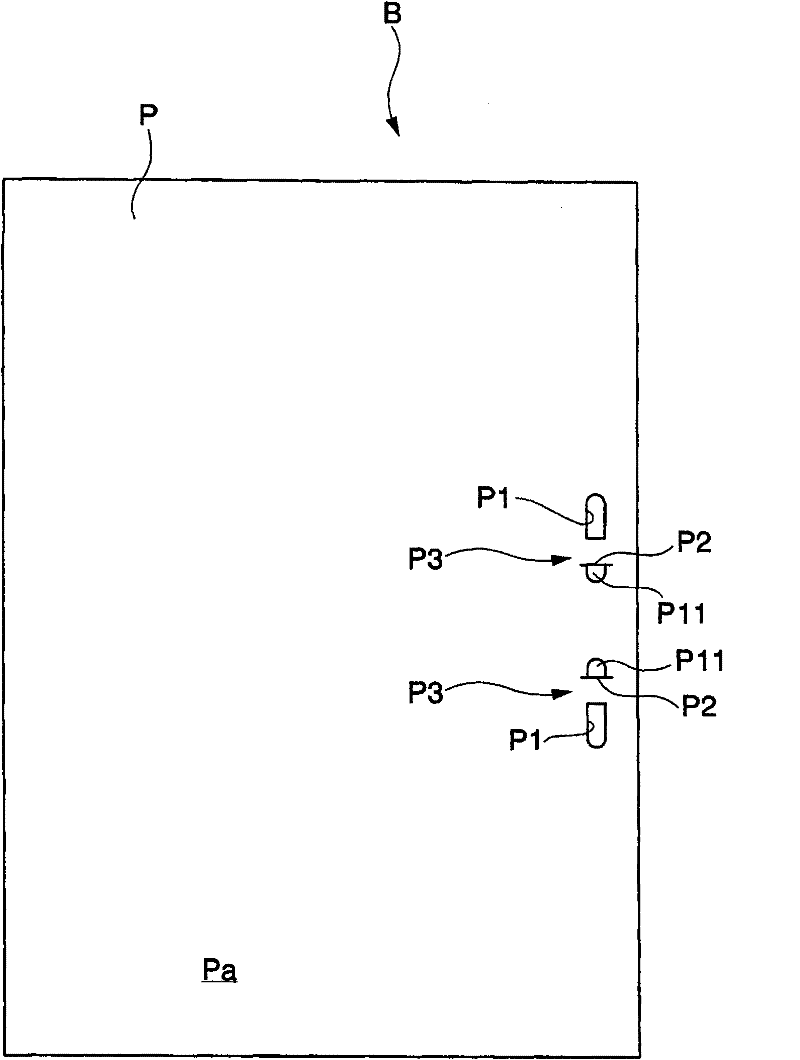

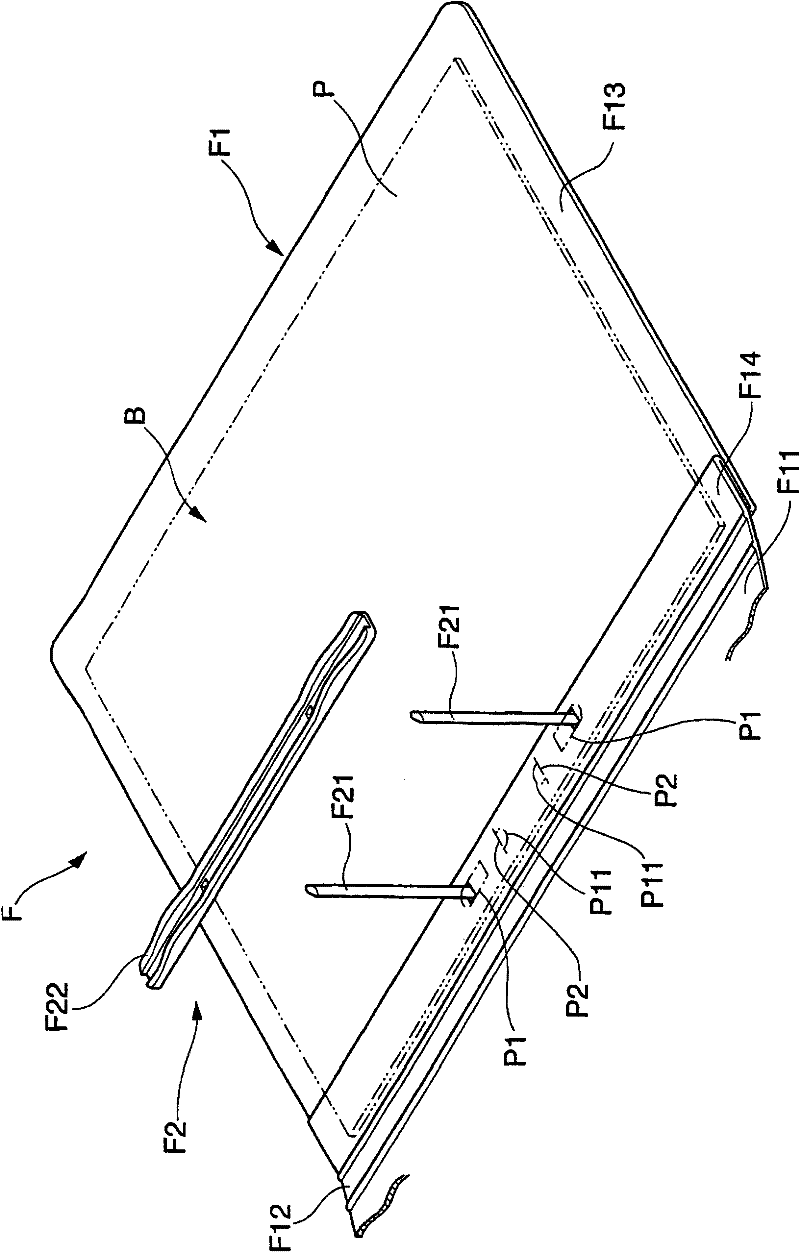

[0060] The binding machine 1 that this embodiment relates to, as Figure 1 to Figure 3 As shown, it can be suitably applied to the folder system of the booklet B in which one or more volumes are bound by the folder F. FIG.

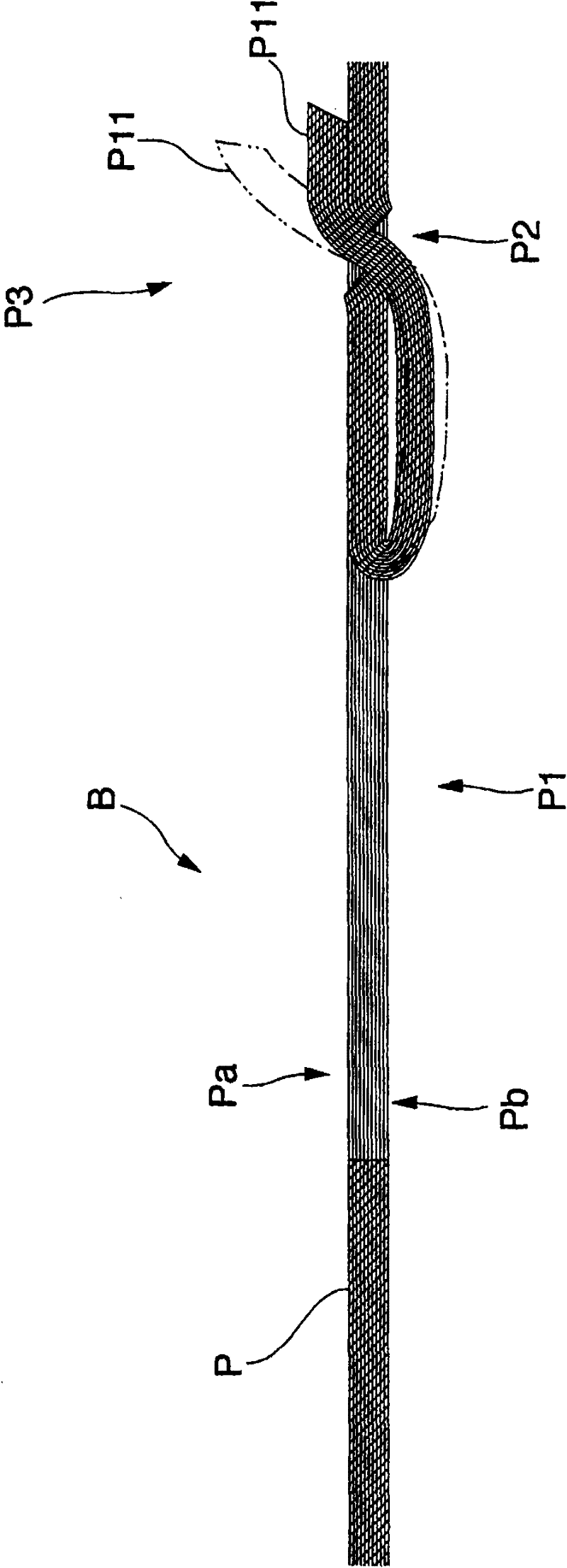

[0061] Such as figure 1 and figure 2 As shown, the booklet B is formed by bundling a plurality of sheets made of homogeneous materials, for example, a plurality of sheets P, and these sheets P are joined to each other at two joining portions P3 set on the binding side. Each joint portion P3 is composed of: a binding hole P1 formed on each paper P by a punching blade 92 penetrating from the side Pa of the paper P; a pull-up cutting hole P2 adjacent to the binding hole P1 and Formed on each of the above-mentioned paper sheets P; the cut-out piece P11 is cut from the above-mentioned binding hole P1 toward the reverse side Pb of the paper sheet P. Then, by...

no. 2 approach

[0093] Next, refer to Figure 17 to Figure 33 The binding machine A1 that is directly used for implementing such a file system will be described.

[0094] This bookbinding machine A1 is a device for joining a plurality of sheets of paper P as sheets to produce the above-mentioned booklet B, such as Figure 17 As shown, it is provided with: a stage A2 placed on the table; a main body A3 fixedly arranged on the stage A2; ユニツト), which can be lifted and accommodated in the main body A3 and equipped with a punching blade A92 and a cutting blade A91 described later; a paper holder A8 (paper base, paper tape reel seat), which ends the perforation at the blade changing unit A4 When moving up, it is used to lift the above-mentioned bound paper P; the operating handle A5 is installed on the above-mentioned main body A3 so as to be rotatable up and down in order to make the paper holder A8 and the blade changing unit A4 move.

[0095] Such as Figure 17 , Figure 21 and Figure 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com