Patents

Literature

78results about How to "Help production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diffractive beam expander and a virtual display based on a diffractive beam expander

ActiveCN101688977AReduce the number of interactionsImprove parallelismDiffraction gratingsPlanar/plate-like light guidesBeam expanderGrating

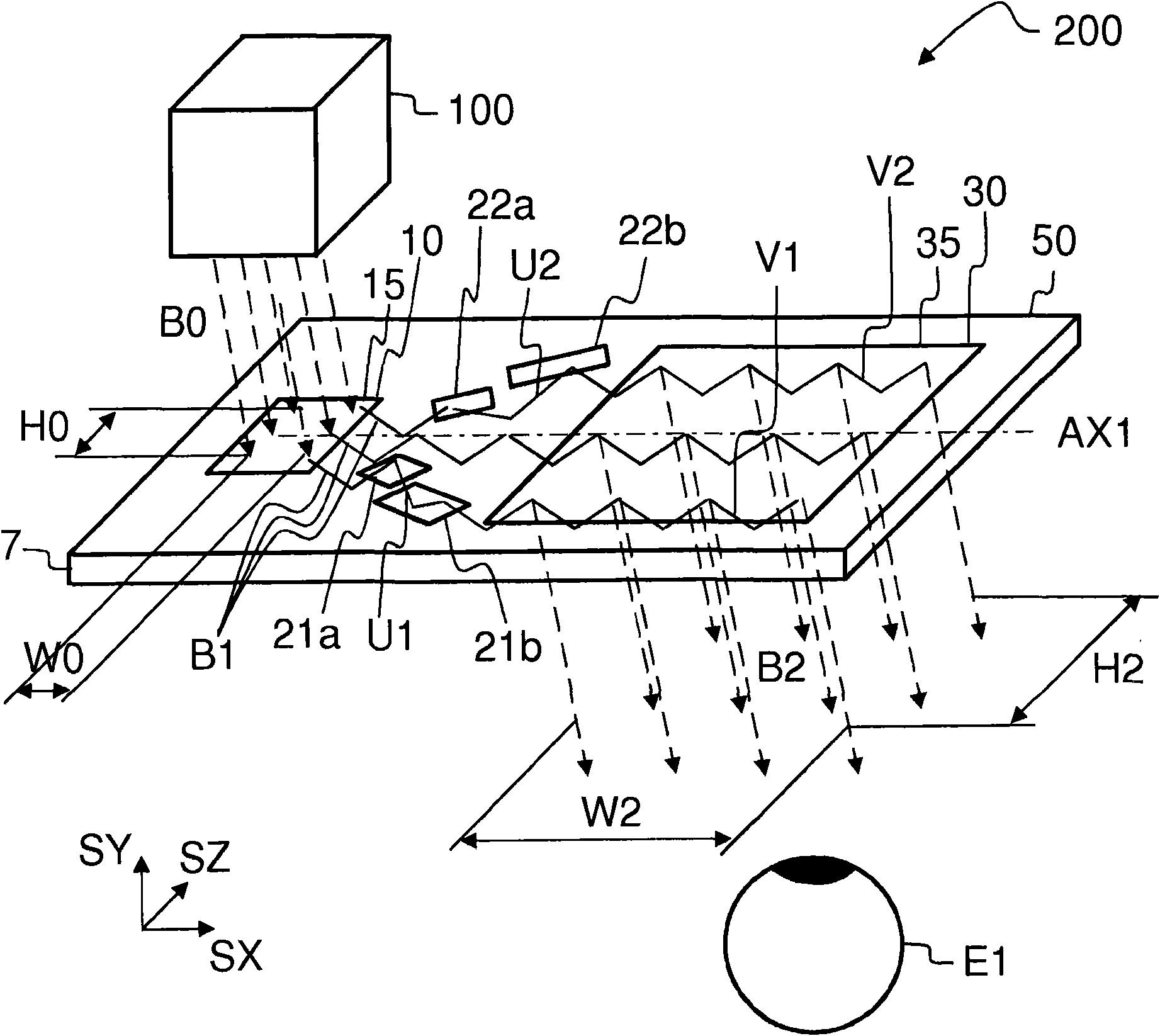

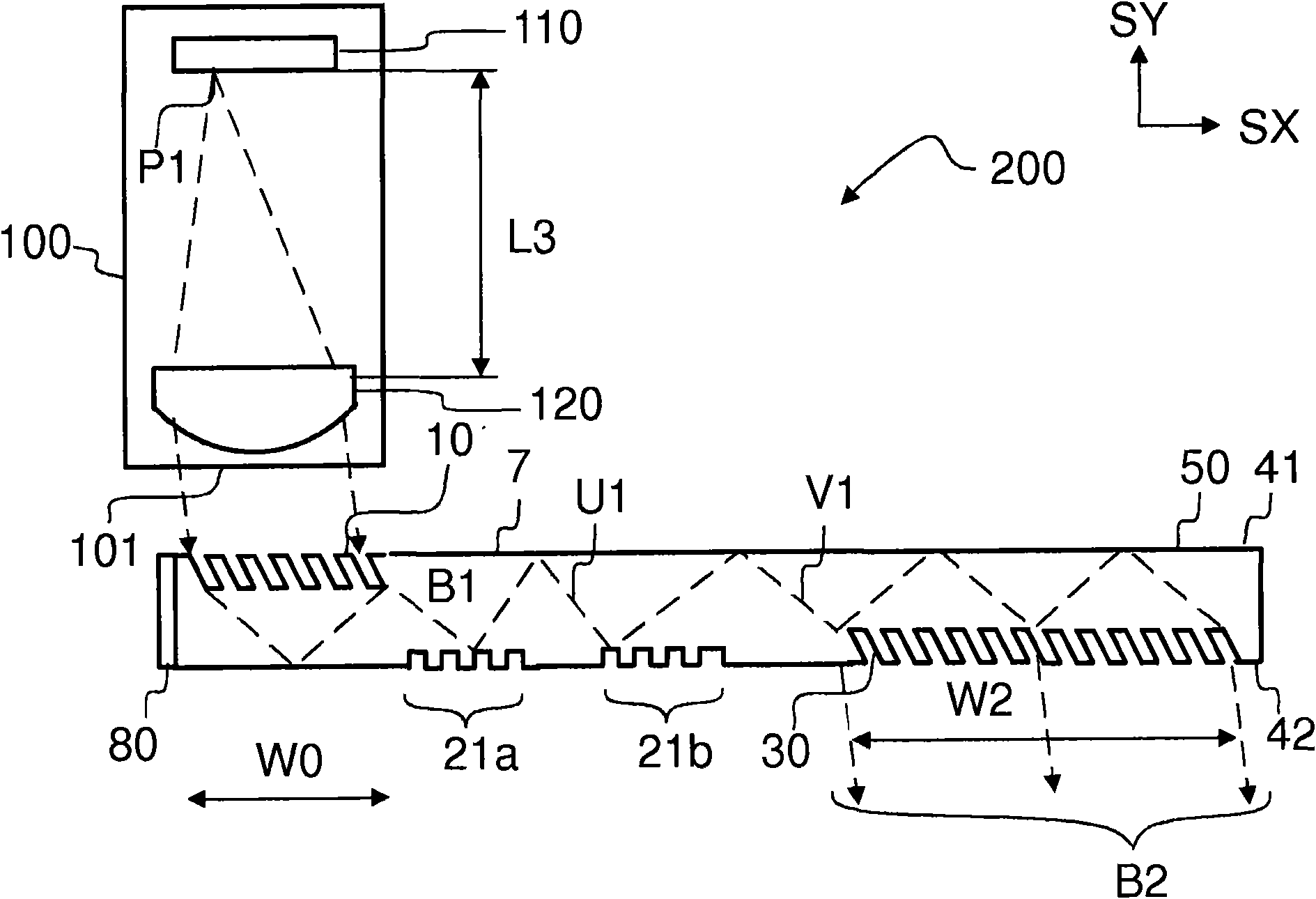

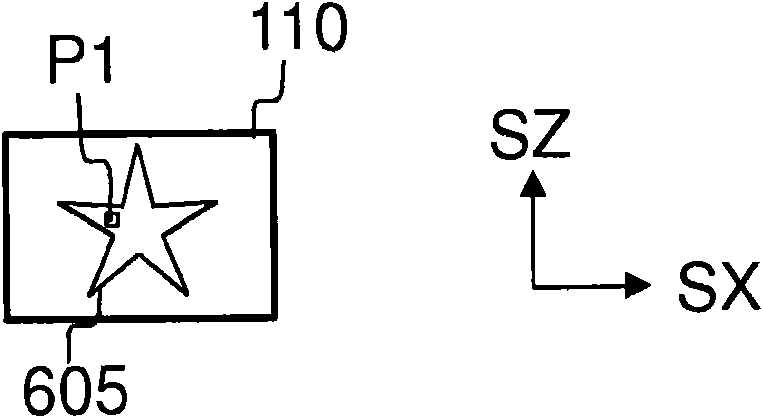

A diffractive beam expander (50) comprises a substantially planar waveguiding substrate, an input grating (10) to provide an in-coupled beam (B1) propagating within said substrate, and an output grating (30) to provide an out-coupled beam. The expander (50) comprises also four or more further grating portions to expand the height of the in-coupled beam (B1). A part of the in-coupled light is diffracted by a first deflecting grating portion (21a) to provide a first deflected beam. A part of the in-coupled light is diffracted by a second deflecting grating portion (22a) to provide a second deflected beam. The first deflected beam propagates downwards and the second deflected beam propagates upwards with respect to the in-coupled beam (B1). The first deflected beam impinges on a first direction-restoring grating portion (21b) and the second deflected beam impinges on a second direction-restoring grating portion (22b). The first restoring grating portion (21b) provides a first restored beam (V1) and the second restoring grating portion (22b) provides a second restored beam (V2), which both have the same direction as the in-coupled beam (B1). Out-coupling provides an output beam which is parallel to the input beam, and has a greater vertical dimension than said input beam.

Owner:MAGIC LEAP

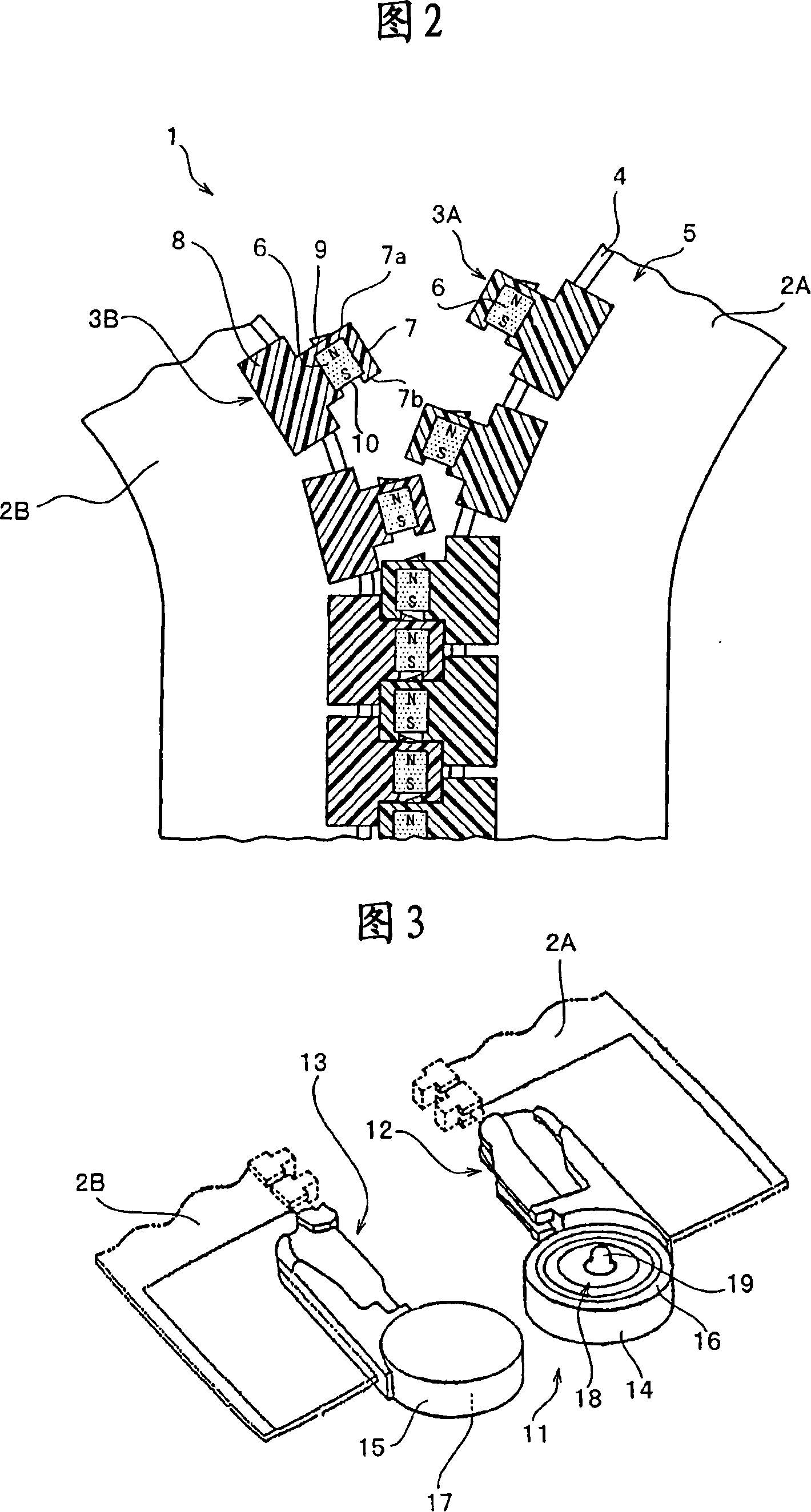

Verschluss

ActiveCN101081115AStay engagedPrevent openingSlide fastenersOther accessoriesMagnetic tension forcePull force

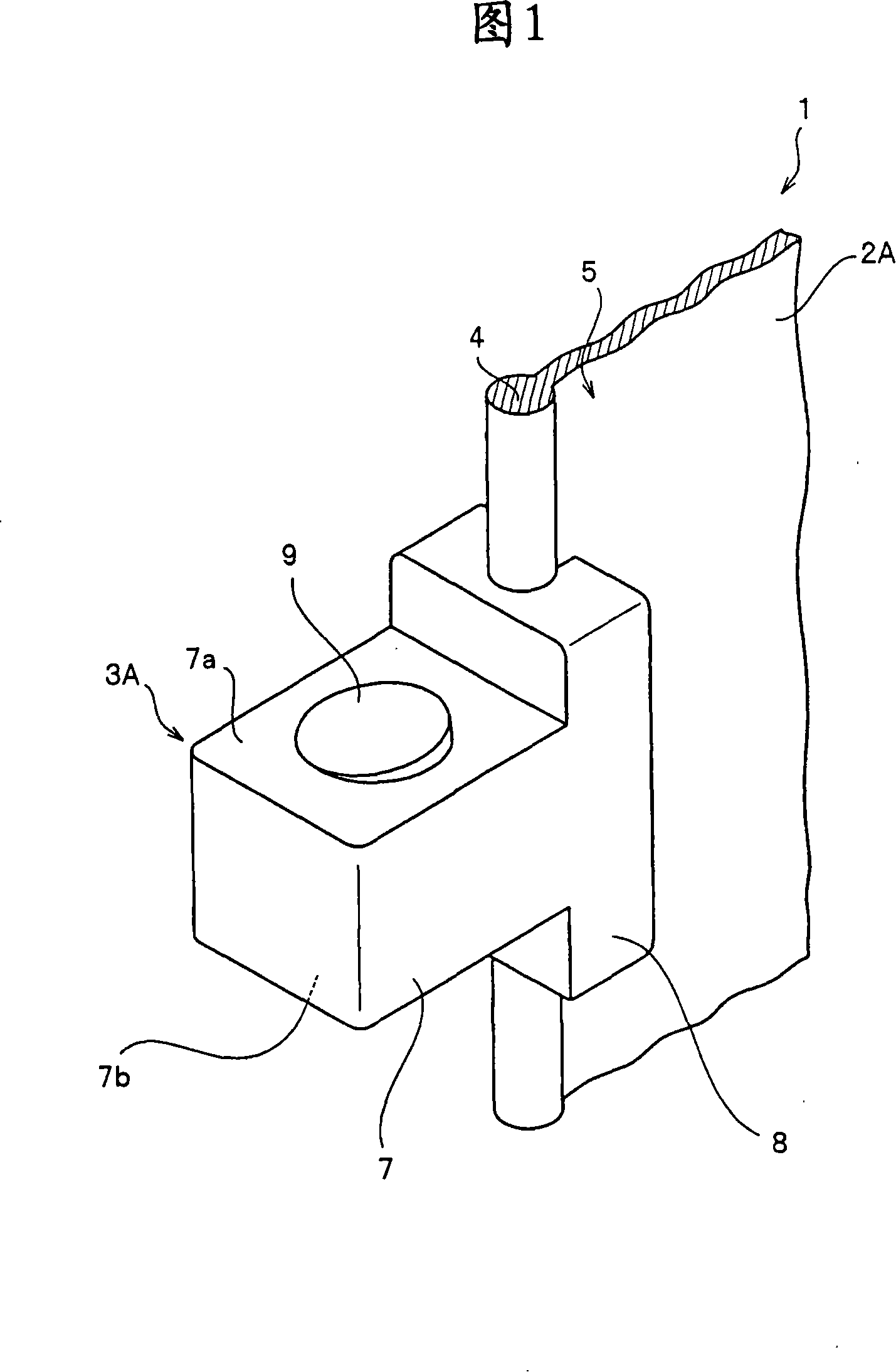

A fastener wherein right and left side edge portions can be engaged using a magnetic force, and which can be applied preferably for plastic article such as clothes and further prevented from being opened carelessly even if a lateral pulling force is applied when right and left elements are engaged. In the fastener, a plurality of first and second magnetic elements(3A,3B) having magnetism are provided in lines on a pair of first and second fastener tapes(3A,3B), the first and second magnetic elements(3A,3B) are adsorbed to each other using a magnetic force, characterized in that the first and second magnetic elements have head portions(7), a leg portion(8), and engagement / disengagement portions(9,10) formed at the head portions and mechanically engaged with or disengaged from each other between the first and second magnetic elements(3A,3B), the first and second magnetic elements are respectively disposed at predetermined intervals, the magnetic elements(3A) of one fastener tape(2A)(3B) are adsorbed to spaces between the adjacent magnetic elements of the other fastener tape(2B), and the first and second magnetic elements(3A,3B) are engaged with each other alternately.

Owner:YKK CORP

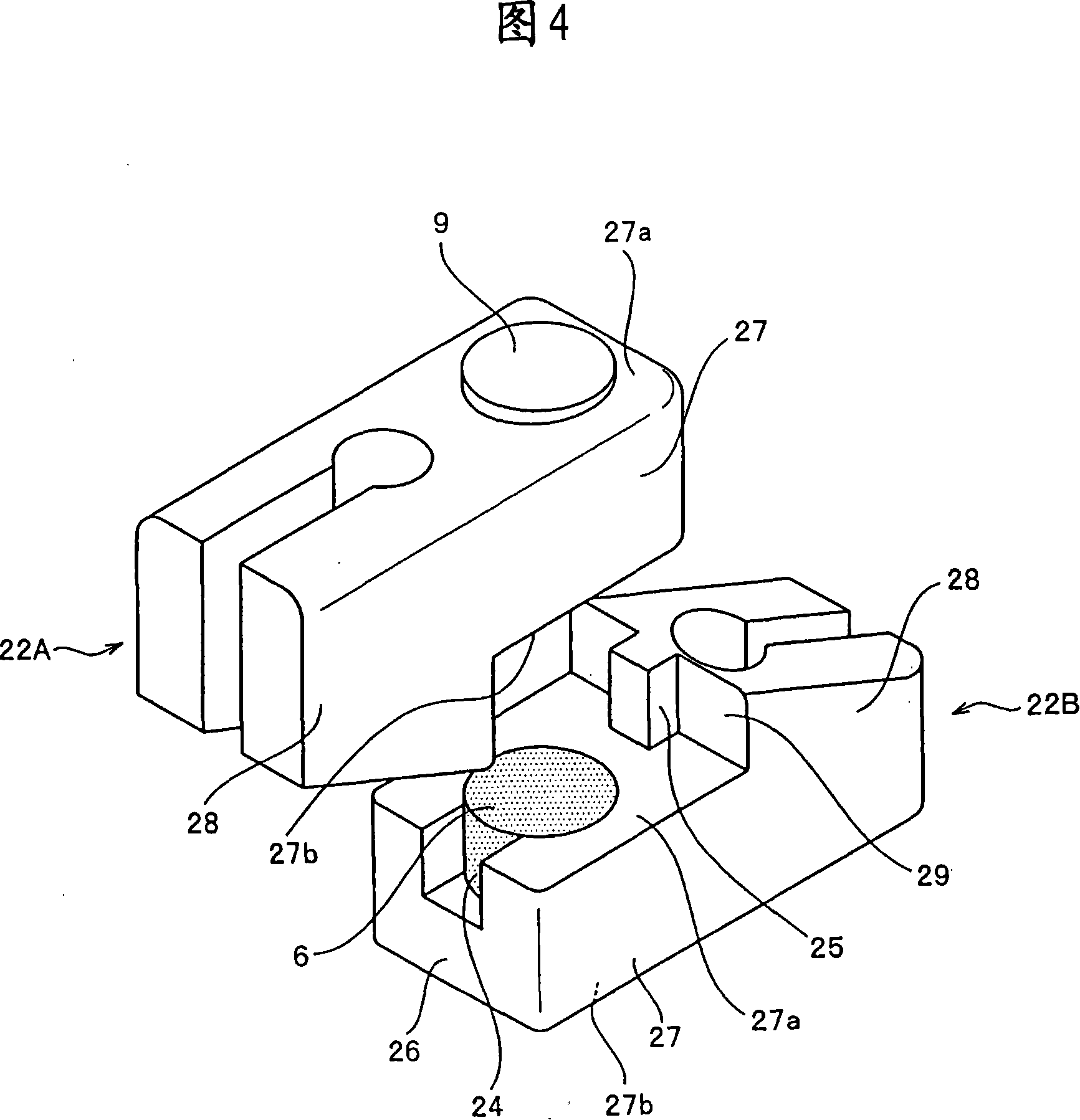

Method for producing capacitive carbon from rice husks

ActiveCN105329892ALow costReduce tar molecular weightCalcium/strontium/barium carbonatesCarbon compoundsTarChemical industry

The invention discloses a method for producing capacitive carbon from rice husks and belongs to the technical field of the biomass energy chemical industry. The method comprises the following steps: 1, the rice husks and a catalyst are mixed uniformly and subjected to pyrolysis, and pyrolytic gas and pyrolytic carbon are produced; 2, the pyrolytic gas and the pyrolytic carbon are subjected to constant-temperature catalytic decoking, volatile components of the pyrolytic carbon are reduced, and tar is pyrolysed into small molecules; 3, a horizontal reaction kettle is adopted and rotated, the pyrolytic carbon and alkali liquor are mixed uniformly, and a mixture is subjected to hot-pressing desilicication, washing and drying; 4, template carbon and an activator are ground, stirred at a high speed for homogenization and uniformly distributed; 5, a push type activation furnace is adopted, the heating rate and activation time are controlled, and an activation material is prepared; 6, the activation material is washed, pickled and washed to be neutral; 7, a product is dried, graded and packaged. The rice husks are adopted to produce the capacitive carbon, biomass is used for producing renewable energy sources and chemicals, the cost is low, the method is environment-friendly, a production process is safe and pollution-free, and large-scale production can be realized.

Owner:旗禾科技(吉林)有限责任公司

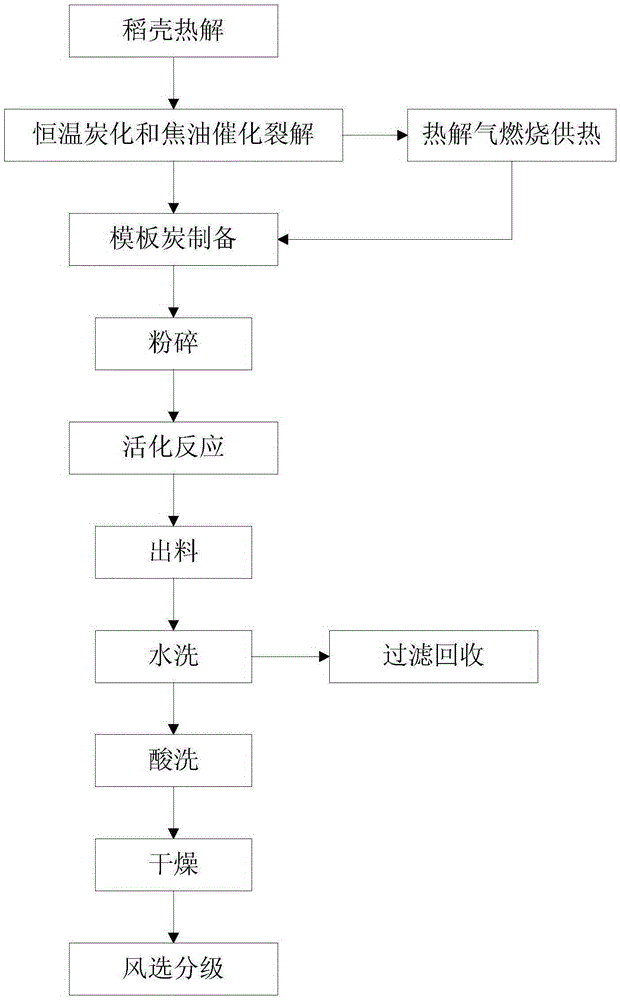

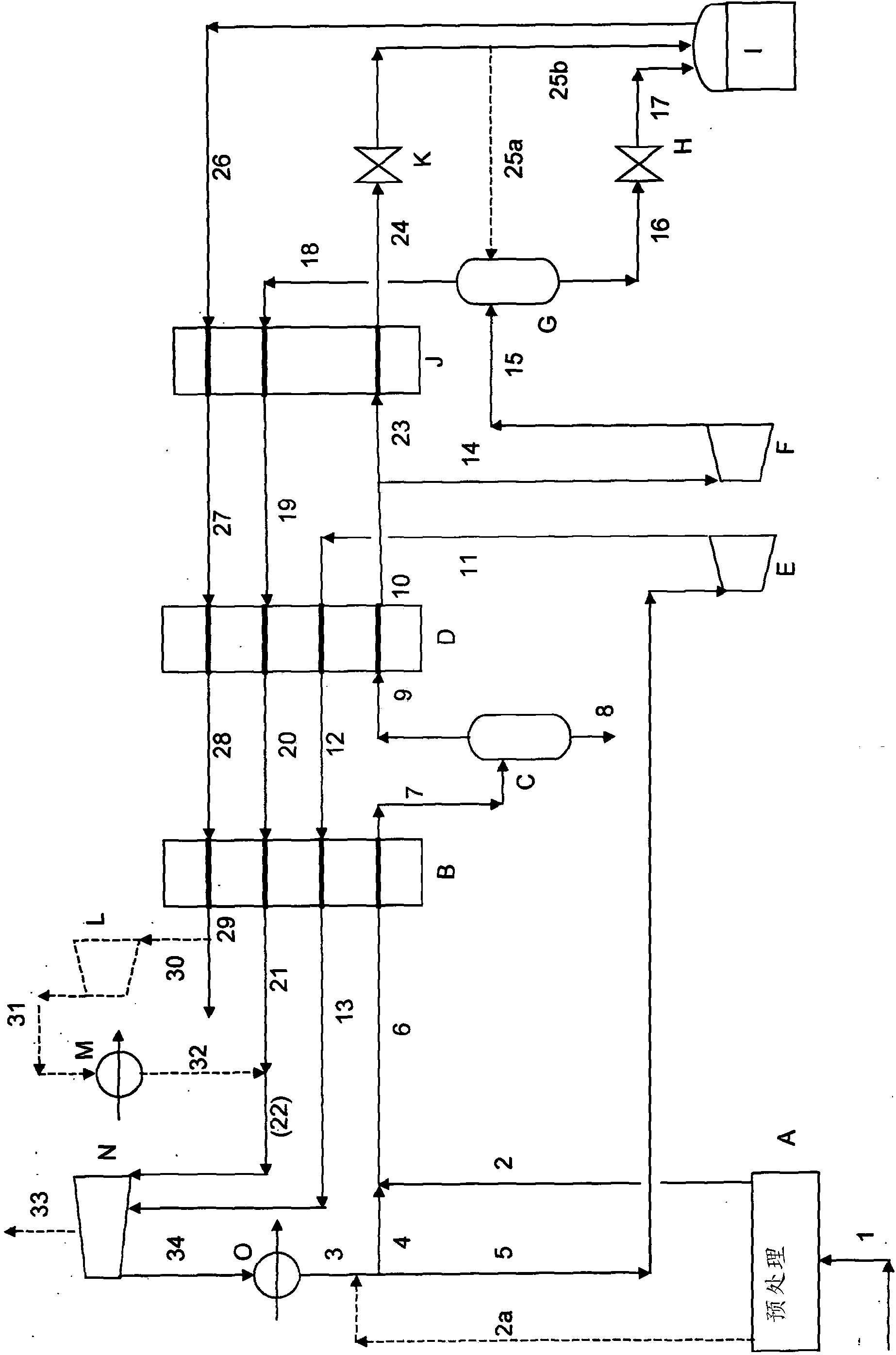

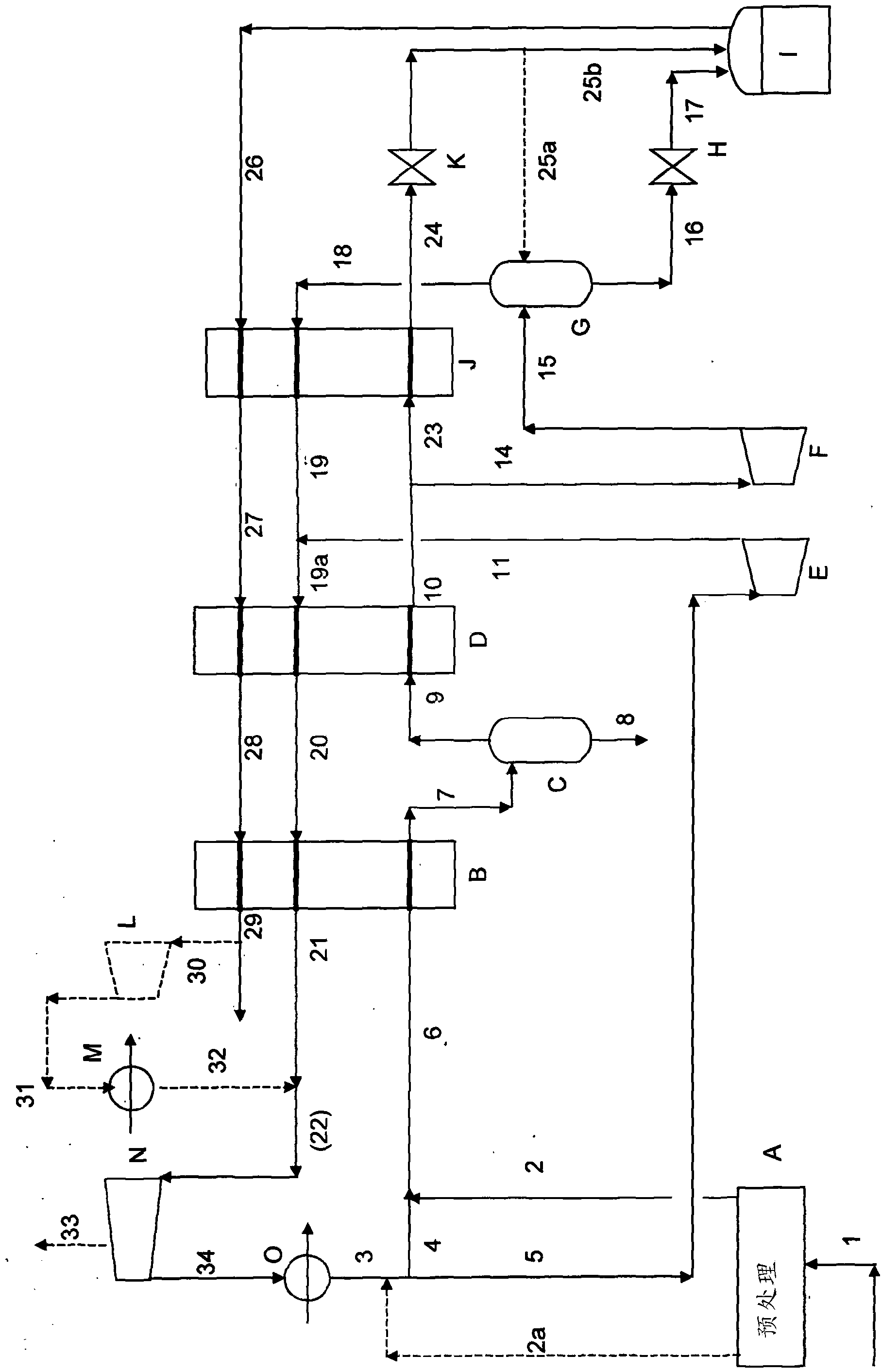

Controlling media particle size in slurried dense media separations

InactiveCN1688392ALess foamImprove separation performanceElectrostatic separationPlastic recyclingParticulate mediaChemistry

Methods, systems, and media for use in separating mixtures. A slurry including a separation liquid and one or more particulate media materials is provided. A classification separation is performed on the slurry to produce a classified media having a controlled particle size distribution of the particulate media materials. The classified media is combined with a mixture to be separated to generate a separation mixture. A density separation is performed on the separation mixture. The particle size distribution can be controlled based in part on characteristics of components of a separation system to be used in subsequent density separations.

Owner:MBA POLYMERS INC

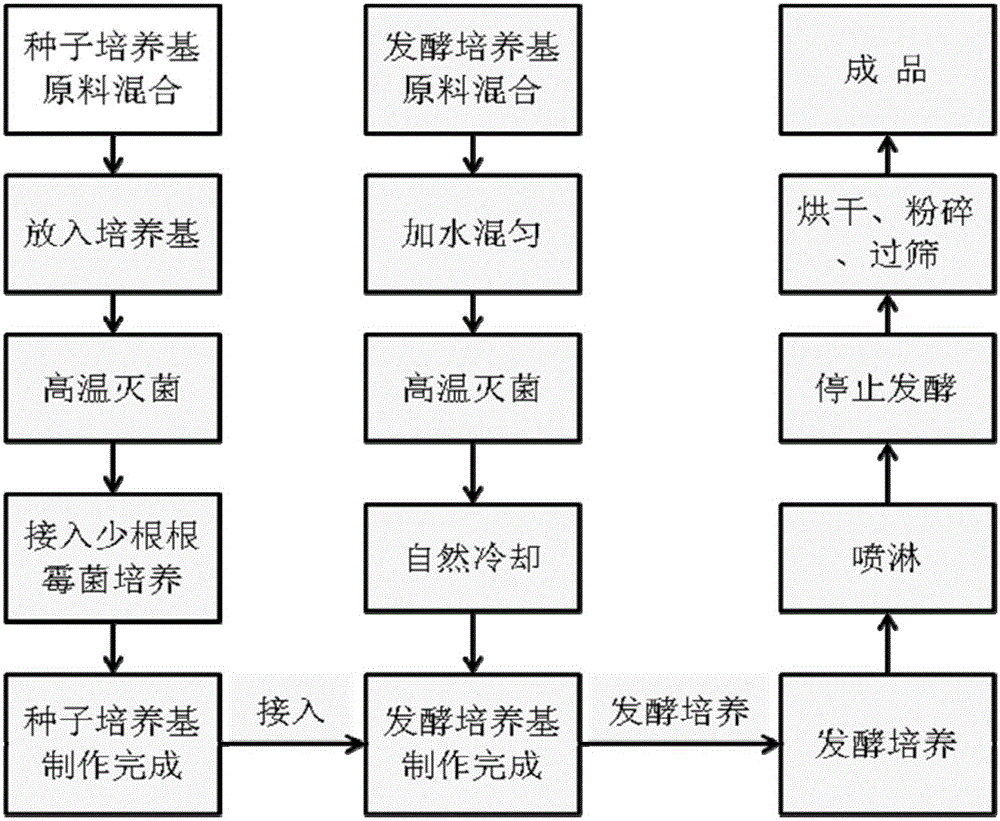

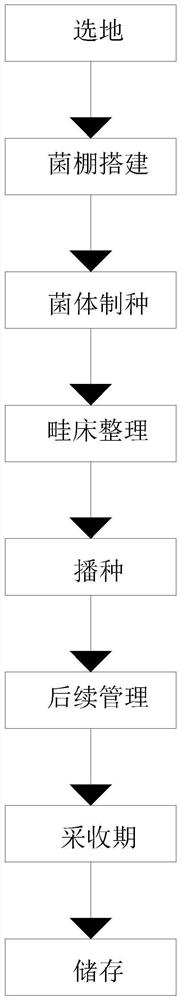

Process for producing dark tea through inoculation method

ActiveCN105494715AReduce distractionsIncreased and stable flower countPre-extraction tea treatmentMicroorganismInoculation methods

The present invention belongs to the technical field of microorganisms and food biology, and particularly relates to a process for producing a dark tea by inoculating bred Eurotium cristatum, wherein the process comprises that Eurotium cristatum with a classification name of Eurotium cristatum NHRI-BC-1.5.1, preserved in the China General Microbiological Culture Collection Center, and with a preservation number of CGMCC No.8730 is adopted as a fermentation strain, and inoculation is performed after stacking or before vapor steaming or after metering step and before secondary vapor steaming. According to the present invention, the prepared dark tea product has characteristics of high quality and good stability, and the controllability of the Eurotium cristatum fermentation is basically achieved so as to further achieve the standardized control of the dark tea product.

Owner:中国土产畜产进出口有限责任公司

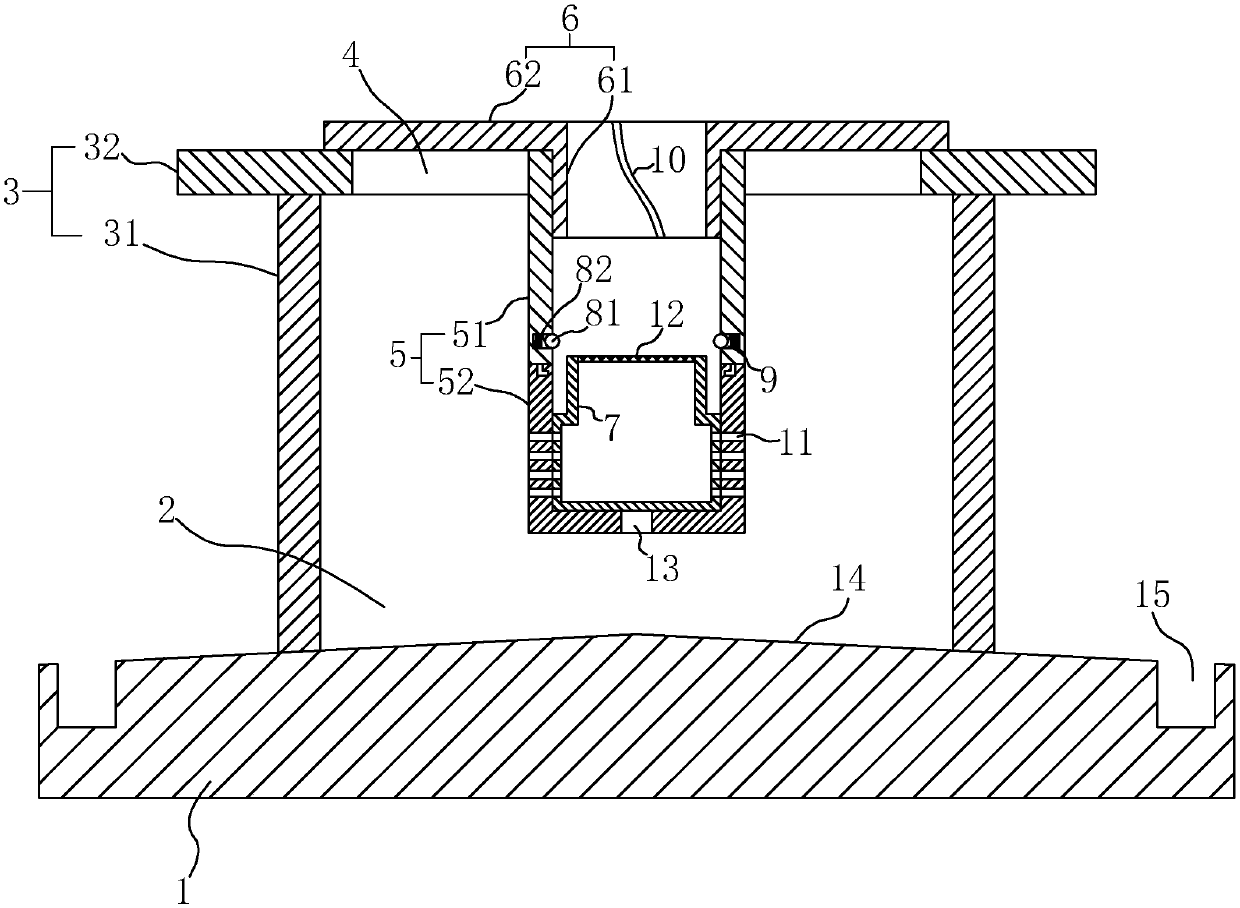

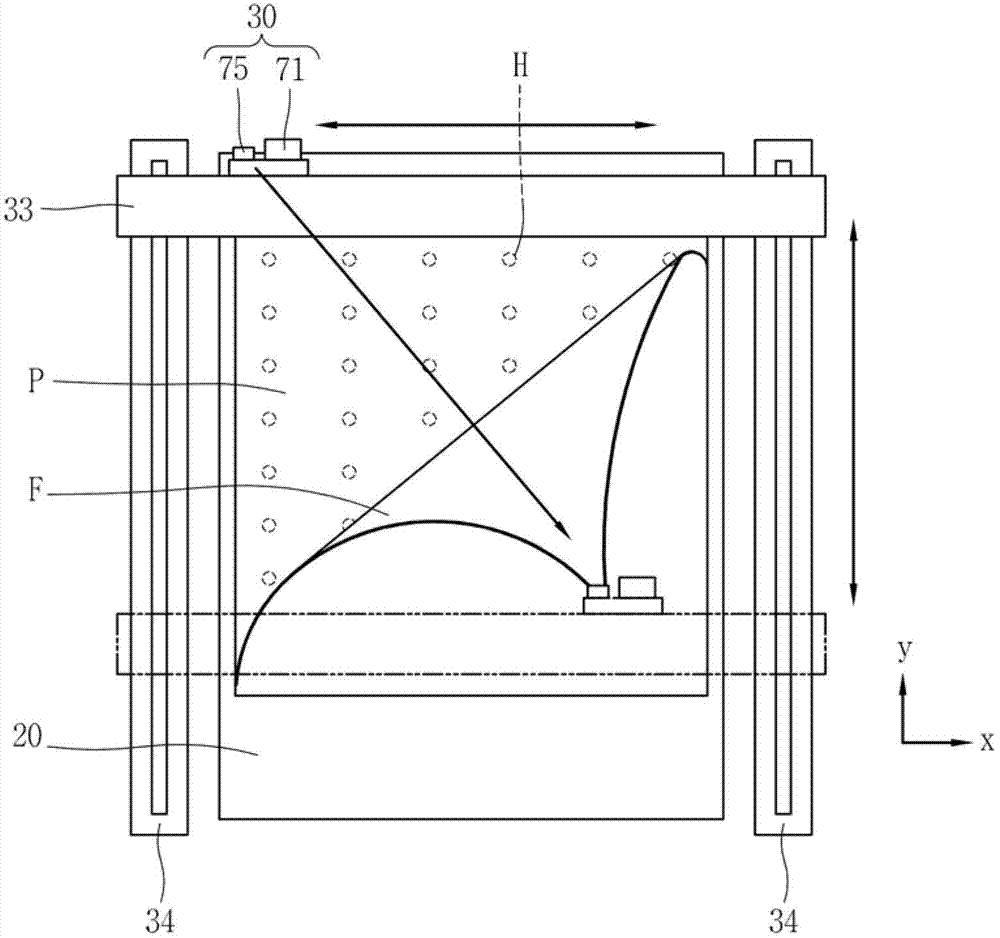

Improved cartridge for feeding a stereolithography machine, stereolithography machine comprising said cartridge and stereolithography method employing said machine

ActiveCN105451969AEasy to changeHelp productionManufacturing enclosuresTransportation and packagingEngineeringStereolithography

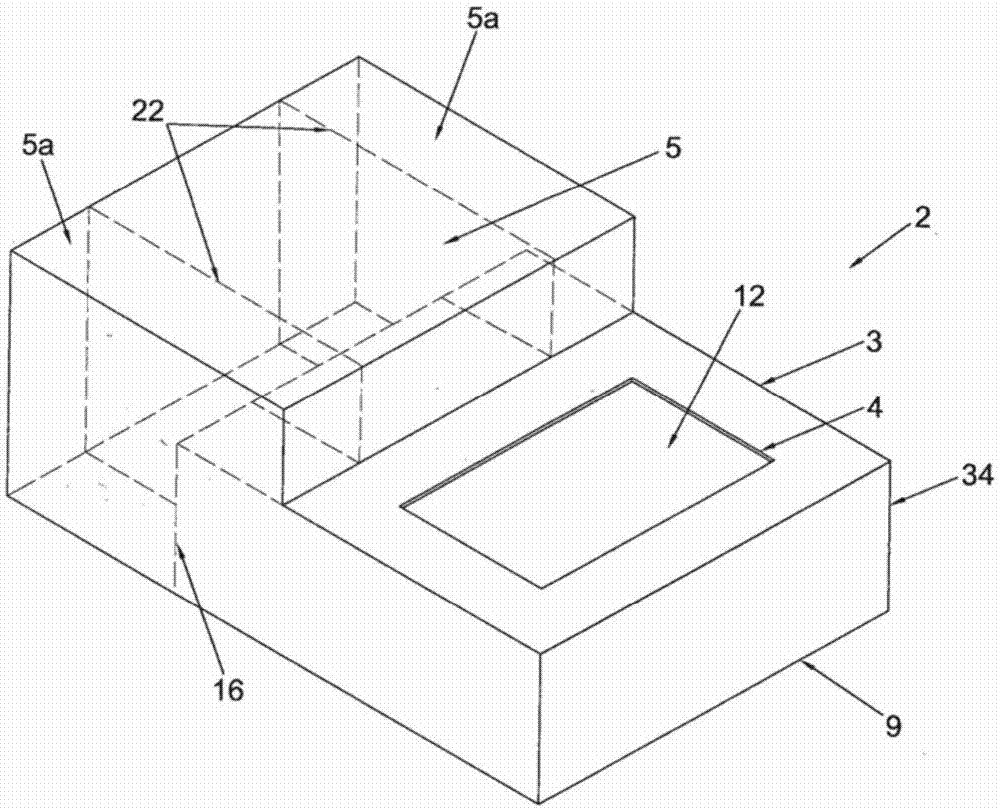

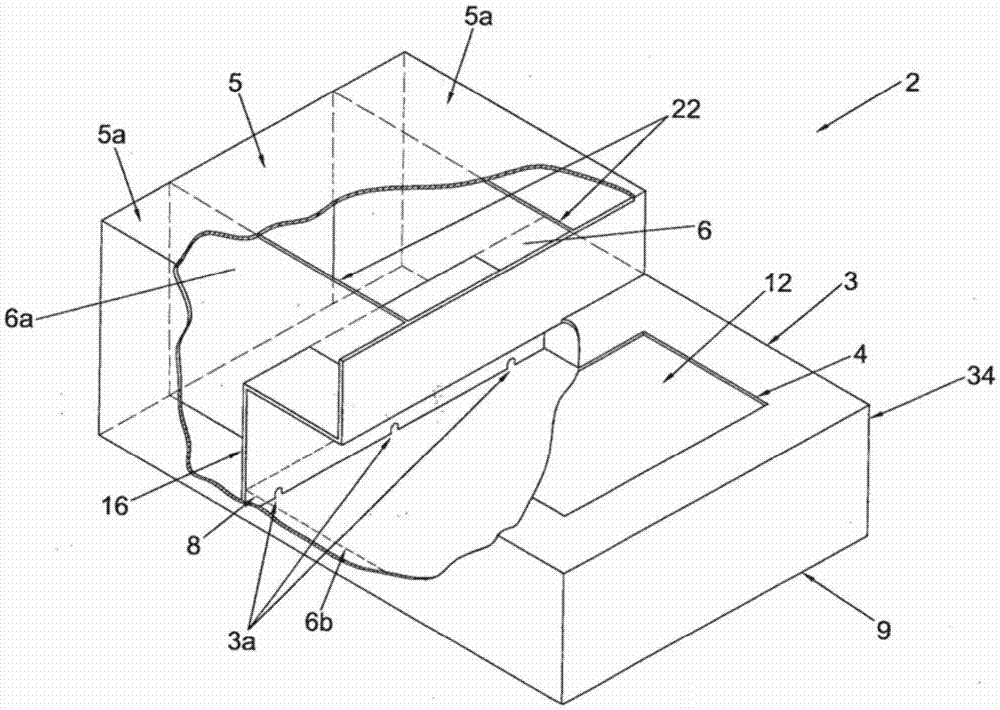

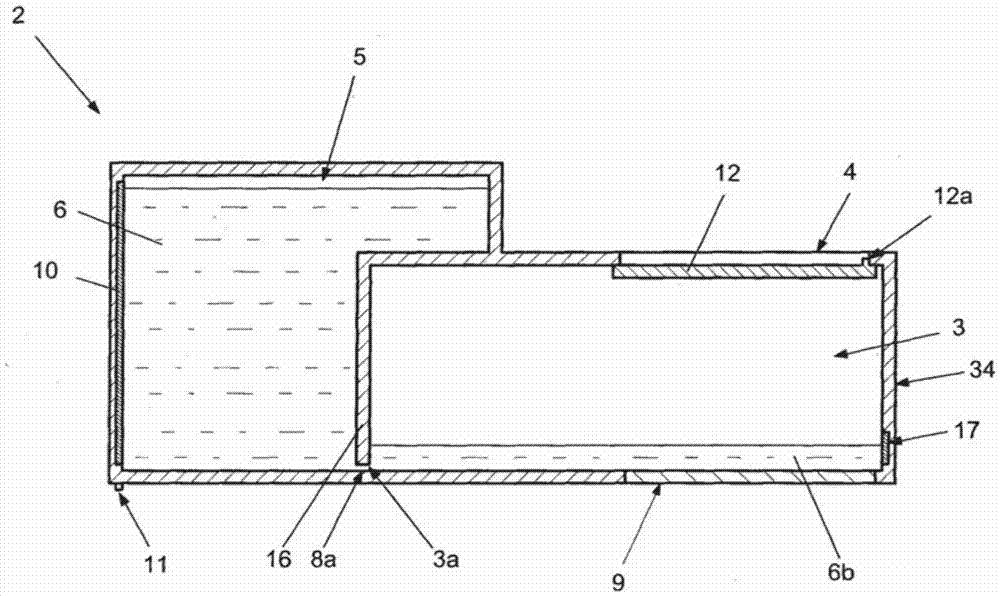

The invention is a cartridge (2; 30; 31; 32; 33) for a stereolithography machine (1), comprising: a supporting structure (34) suited to be removably associated with the stereolithography machine (1); a container (3) provided with an access opening (4) and associated with the supporting structure (34); a first reservoir (5) associated with the supporting structure (34) for containing a first material (6), liquid or pasty, suited to solidify following exposure to a predefined radiation (7); a second reservoir (5a) associated with the supporting structure (34) for containing a second material (6a), liquid or pasty, different from the first material (6); feeding means (8) associated with the supporting structure (34) to convey the first material (6) and the second material (6a) from the reservoirs (5, 5a) towards the container (3).

Owner:DWS SRL

Seed wrapping agent and process, and seeds thereof

InactiveCN1582667AImprove germination rateConvenient supplementBiocideAnimal repellantsSodium BentonitePhosphate

Owner:刘及东 +1

Process for liquefaction of natural gas

ActiveCN103582792AHelp productionReduce power consumptionSolidificationLiquefactionProcess engineeringHigh pressure

Owner:GASCONSULT

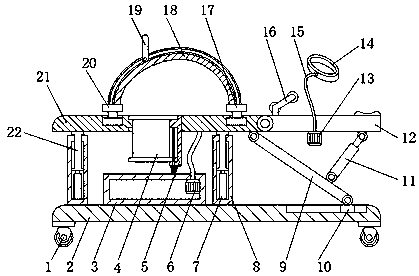

Gynecology and obstetrics medical midwifery device

InactiveCN108379022AHeight adjustableAdjust postureOperating tablesDevices for pressing relfex pointsHydraulic cylinderObstetric history

The invention belongs to the technical field of medical instruments and devices and particularly relates to a gynecology and obstetrics medical midwifery device. For solving the problem of adjustmentinconvenience of gynecology and obstetrics midwifery devices, the technical scheme of the gynecology and obstetrics medical midwifery device comprises a bottom plate, the four corners of the bottom outer wall of the bottom plate are fixedly provided with universal wheels through screws, and the top outer wall of the bottom plate is fixedly provided with a support column through a screw; the innerwall of one side of the support column is provided with a sliding bar sliding groove, and the inner wall of the sliding bar sliding groove is slidingly connected with a sliding bar; the bottom inner wall of the support column is fixedly provided with a first hydraulic cylinder through a screw, and one end of the piston rod of the first hydraulic cylinder is fixed onto the bottom outer wall of thesliding bar; the top outer wall of the bottom plate is provided with a slider sliding groove. The gynecology and obstetrics medical midwifery device can conveniently adjust the height of a fixed bed board and the posture of a pregnant woman to improve the comfort level and the operation environment, and meanwhile, can reduce influence of amniotic fluid and blood on operation of medical personnel,enhance the midwifery effects and provide sufficient operation space for the medical personnel.

Owner:于祥兰

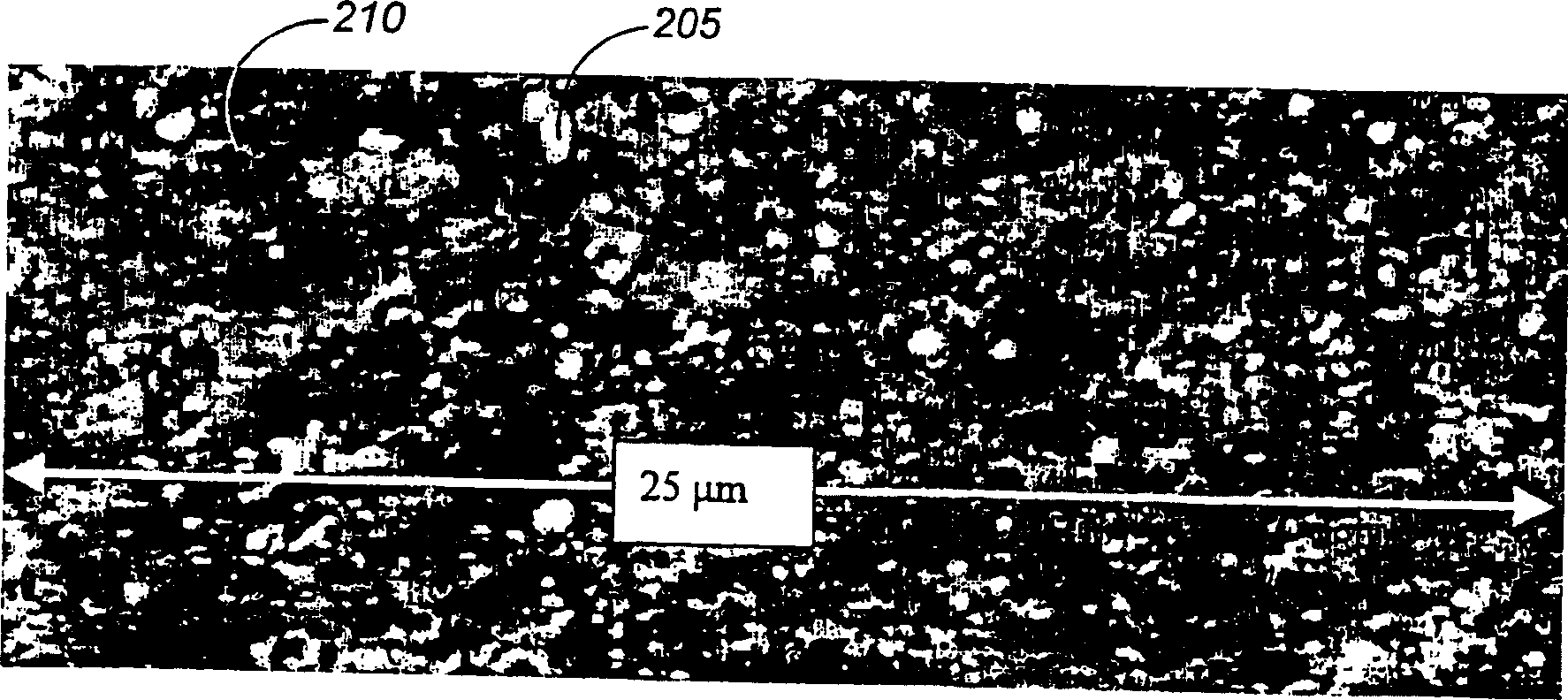

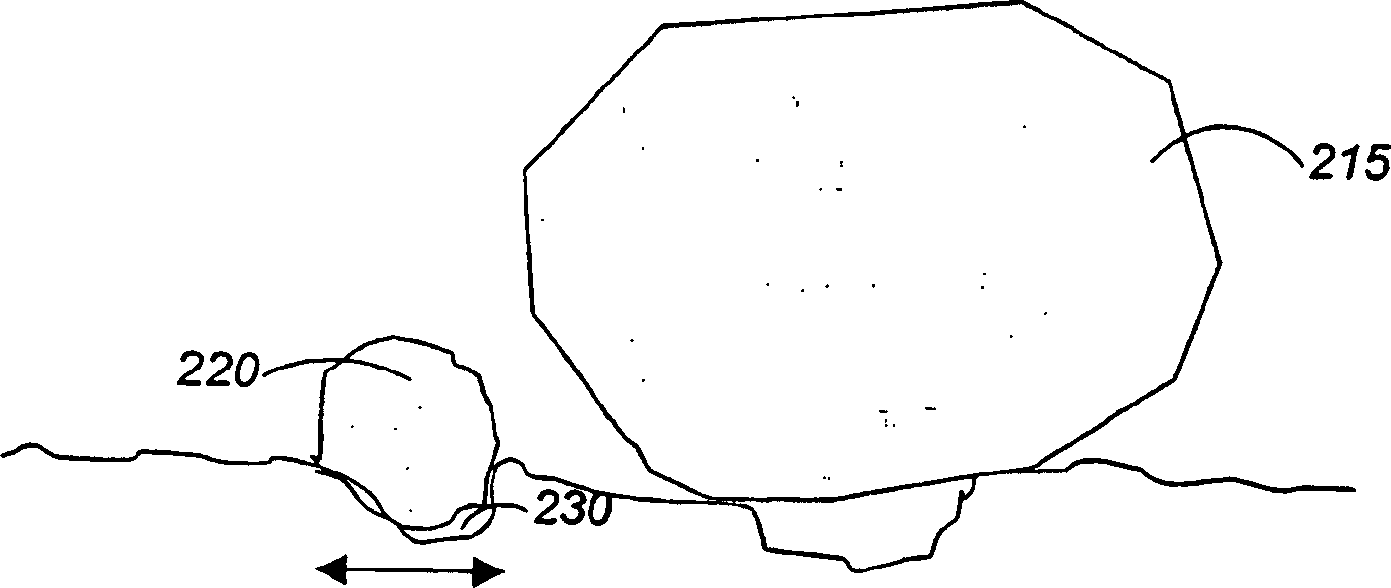

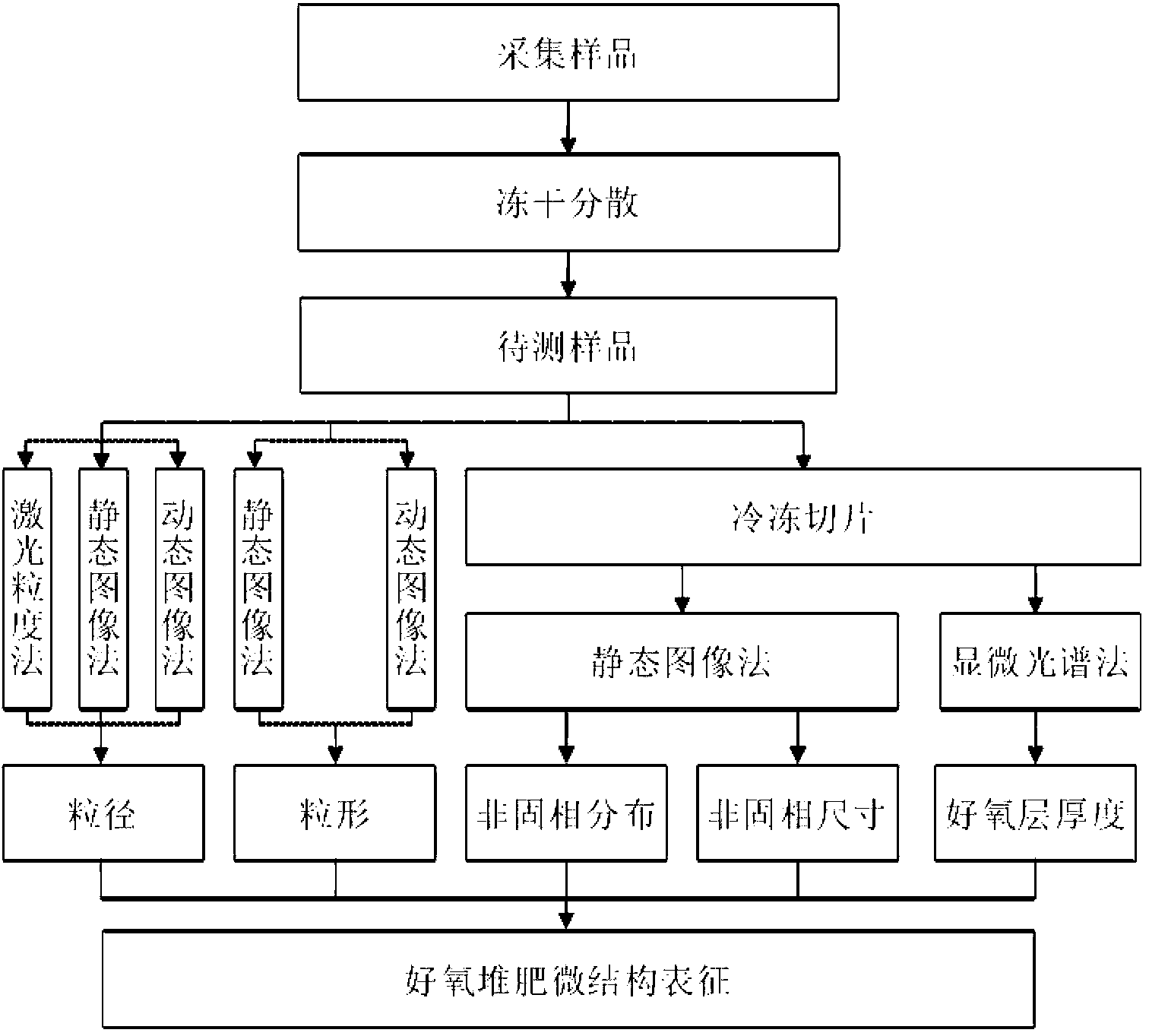

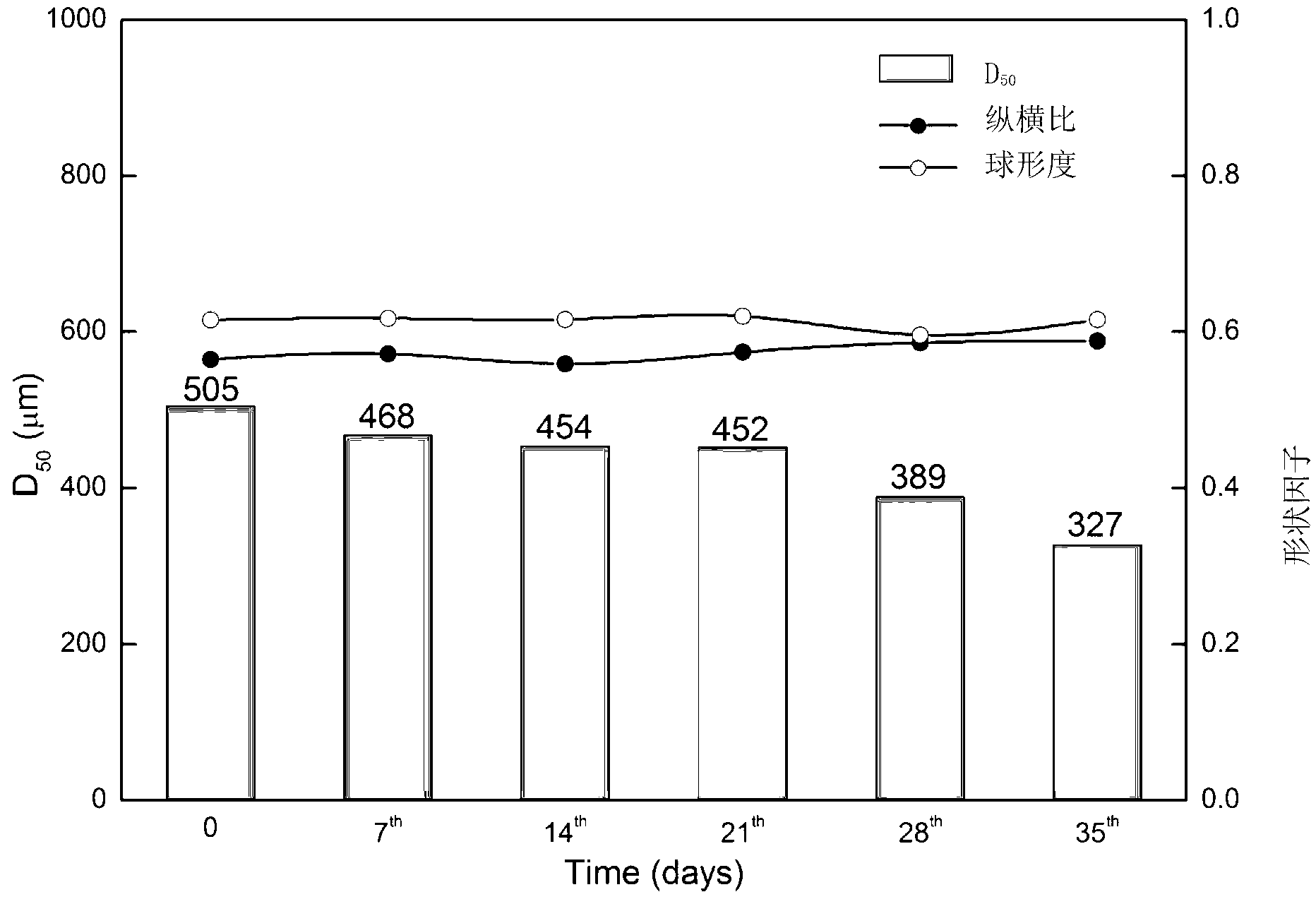

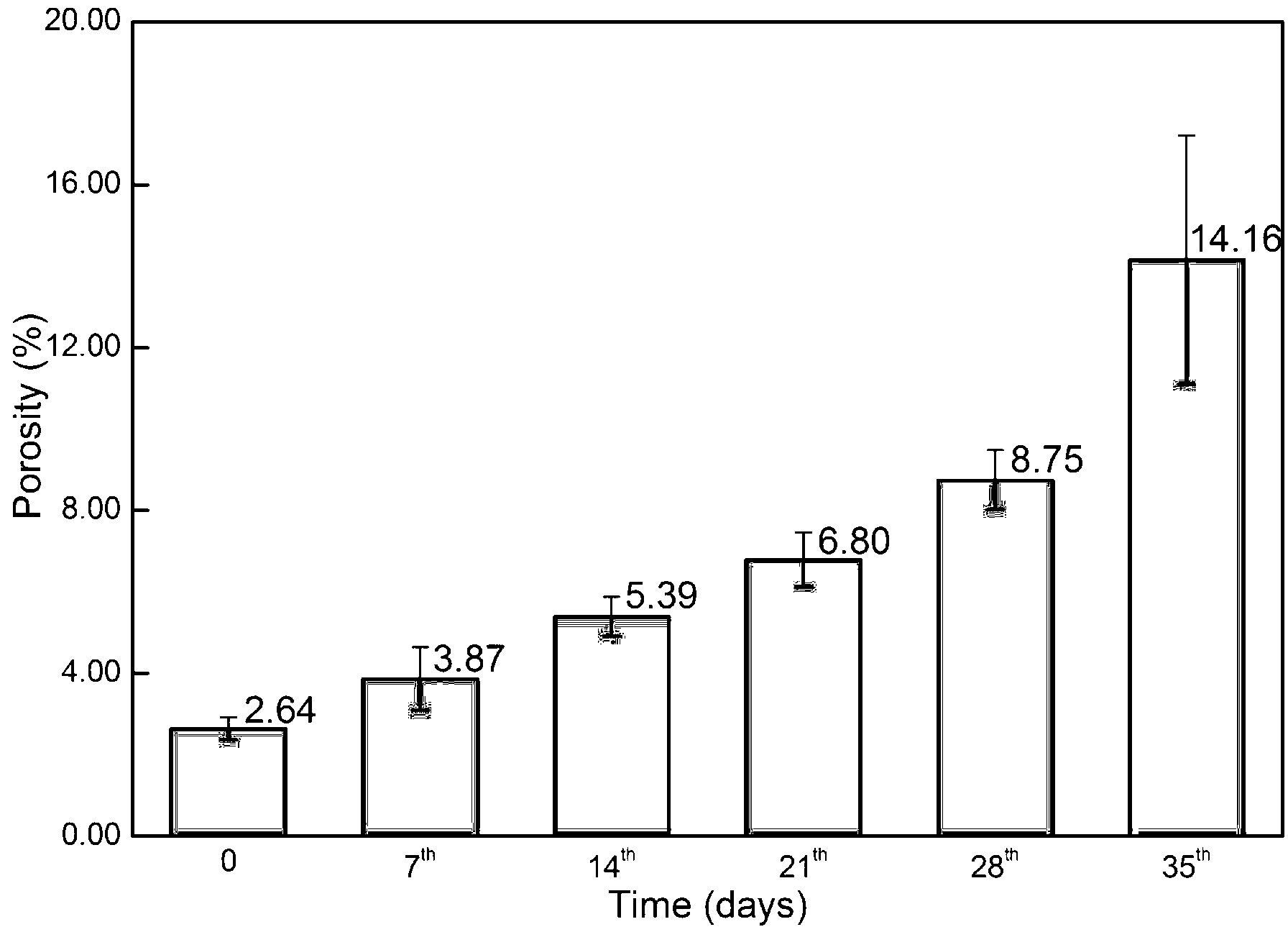

Method of obtaining characteristic parameters of aerobic composting microstructure

ActiveCN103234876AReduce the impactLow hardware requirementsParticle size analysisPermeability/surface area analysisPorosityFreeze-drying

The invention discloses a method of obtaining characteristic parameters of an aerobic composting microstructure. The method provided by the invention comprises the following steps: (1) respectively blending and sampling a composting body in an aerobic composting process at more than two time points; (2) vacuum freeze drying the obtained sample to obtain a granular sample to be measured with particle diameter smaller than 2mm; (3) detecting the median particle diameter D50 of the granular sample to be measured, and drawing a change trend chart; (4) detecting the shape factors of the granular sample to be measured, and drawing a change trend chart; (5) obtaining the average porosity of a composting micro-unit, and drawing a change trend chart; and (6) determining the thickness of an aerobic layer, and drawing a change trend chart. The method provided by the invention can be used for effectively solving the realistic problem of creation and characterization difficulty of the microstructure in the existing aerobic composting numerical simulation and mechanism research processes, and facilitating the energy saving and emission reduction in the composting process, improving the reaction mechanism research and enhancing scientific and practical engineering technology and equipment research and development.

Owner:CHINA AGRI UNIV

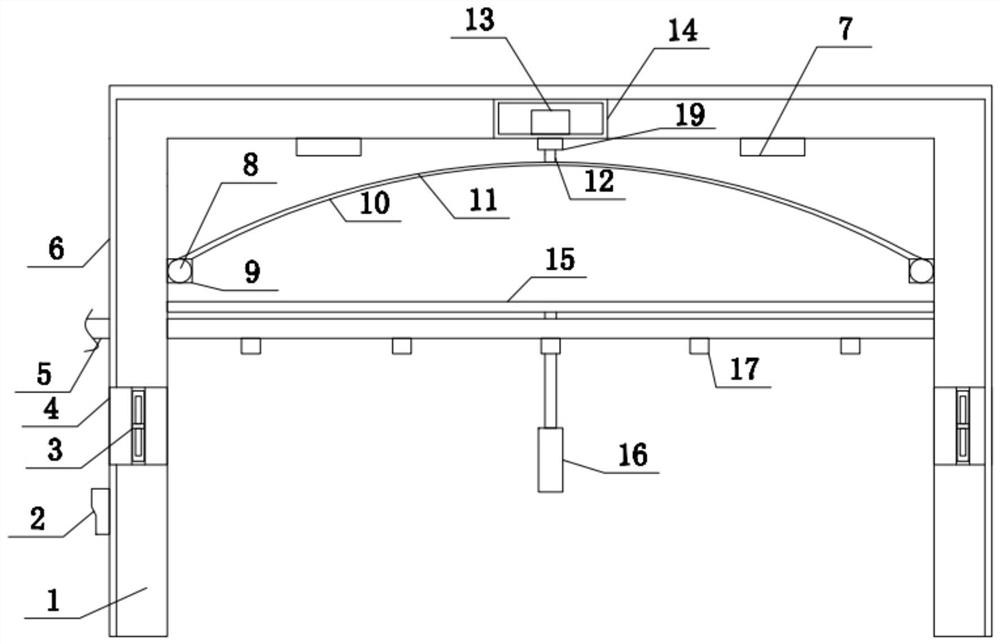

Water collection type green roof structure

ActiveCN109680882AHelp productionPromote growthGeneral water supply conservationWatering devicesWater storageEngineering

The invention discloses a water collection type green roof structure which comprises a roof; the roof is provided with a planting region used for planting plants; the position, corresponding to the planting region, of the roof is fixed with a rain shelter; the rain shelter comprises a ceiling; the ceiling is uniformly provided with rain leakage through grooves around the circumference; a shutter is rotationally connected to the ceiling and comprises a rotary barrel and multiple plate bodies which are fixed with the rotary barrel and are used for covering the rain leakage through grooves; the center of the ceiling is provided with a water storage cavity; a water receiving barrel is vertically connected to the interior of the water storage cavity in a sliding manner; the middle part of the inner wall of the water storage cavity is provided with an elastic supporting block for performing initial temporary supporting on the bottom of the water receiving barrel; and the water receiving barrel is provided with a linkage mechanism for linking the plate bodies to close the corresponding rain leakage through grooves when moving downward. By adopting the water collection type green roof structure, rainwater enters the structure through the rain leakage through grooves in a rainy day; when the rainfall capacity is relatively large, after the weight of deposited water in the water receiving barrel reaches a certain degree and the water receiving barrel overcomes a clamping force of the elastic supporting block, the water receiving barrel can slide downward to the bottom of the water storage cavity to drive the shutter to rotate until the plate bodies close the corresponding rain leakage through grooves, and overmuch rainfall capacity is avoided from entering the planting region.

Owner:深圳星蓝德工程顾问有限公司

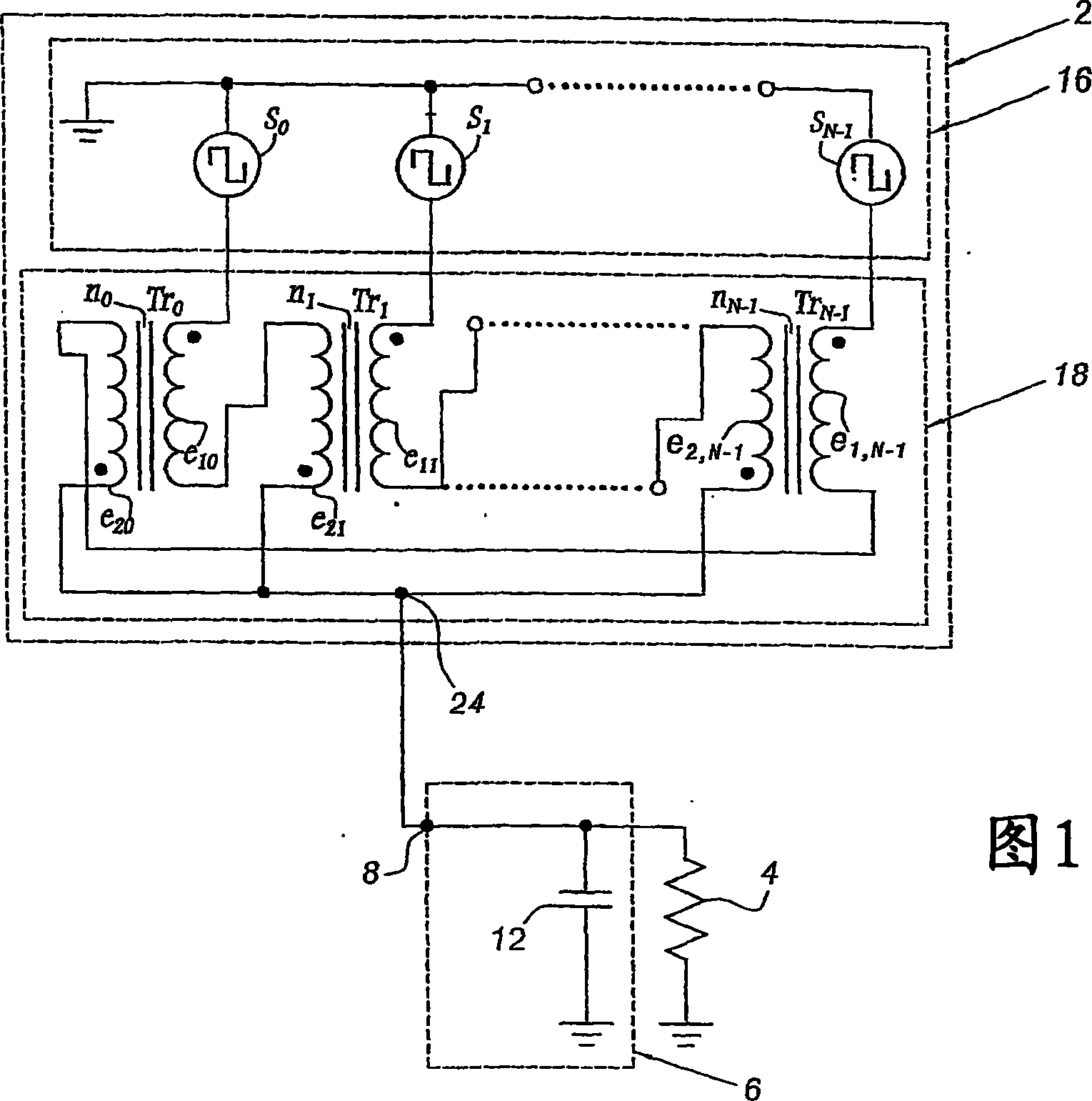

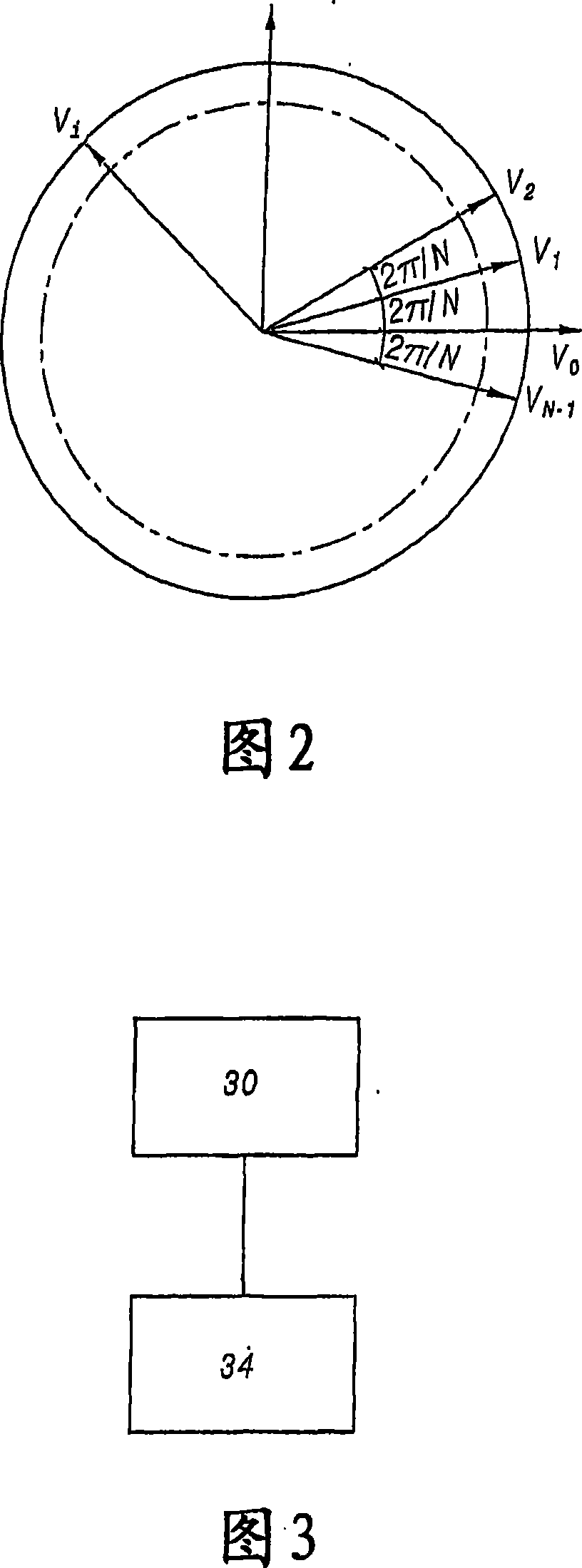

Method and device for supply to a magnetic coupler

InactiveCN101243604ASmall sizeHelp productionDc-ac conversion without reversalEngineeringMechanical engineering

Owner:CENT NAT DE LA RECHERCHE SCI +2

Fermented soybean meal production process suitable for large-scale production

InactiveCN105124136ASolving Nutritional DiarrheaIncrease production capacityAnimal feeding stuffSaccharumBetaine

The invention discloses a fermented soybean meal production process suitable for large-scale production and belongs to the technical field of soybean meal processing. The process comprises the steps of mixing tryptone, glucose, yeast extract and sodium chloride, sterilizing at high temperature, adding less-root rhizopus oryzae into a seed culture medium for culturing and preparing a seed culture medium; mixing bean meal, bran, sucrose and glycine betaine, adding water and uniformly mixing; sterilizing at high temperature and naturally cooling to prepare a fermented culture medium; inoculating the seed culture medium into the fermented culture medium and fermenting for culture; adding a glycine betaine solution in a spraying manner after fermenting, and stopping fermenting after spraying; drying and grinding; drying a fermented product, grinding and sieving to obtain a fermented bean meal finished product. According to the process, seed enlarged cultivation is performed, and stability of a production technology is realized; the glycine betaine is added in fermentation to increase the mixing uniformity of the materials; single less-root rhizopus oryzae strains are adopted to ferment the bean meal, so that the fermentation contamination probability is greatly reduced; the process is mature and stable and suitable for large-scale production.

Owner:山东祥维斯生物科技股份有限公司

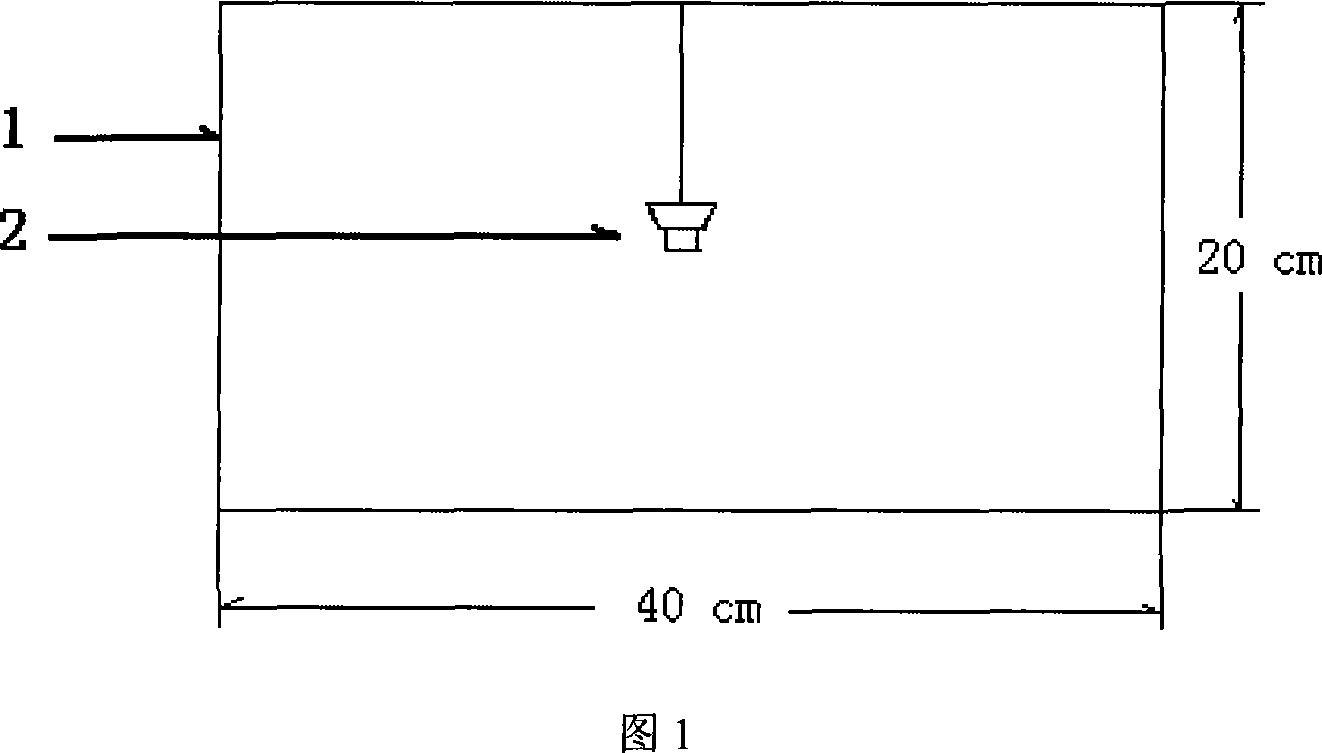

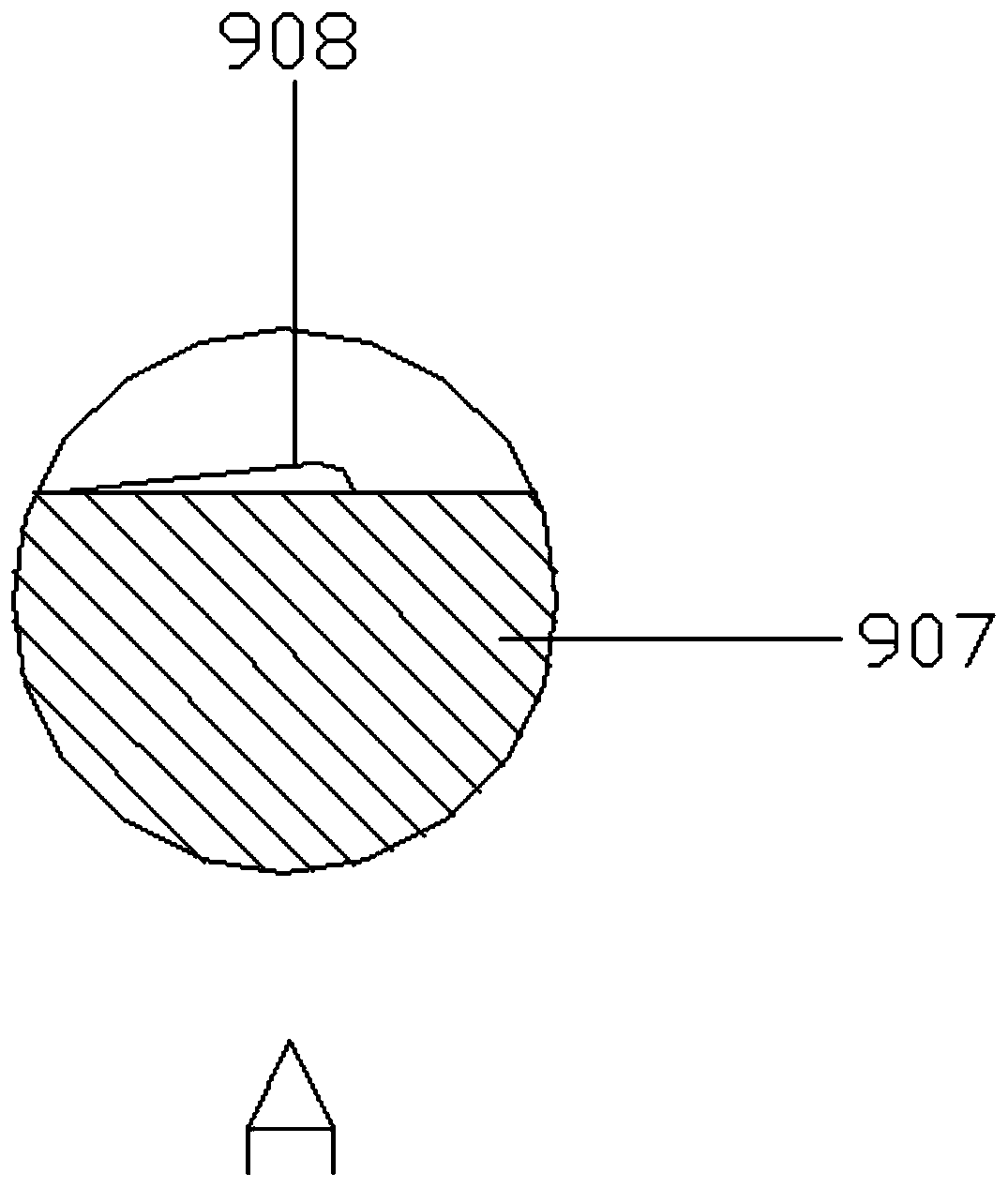

Method for entrapping tea tussock moth male imago

The invention provides an entrapping method for male imagoes of euproctis pseudoconspersa, which selects the euproctis pseudoconspersa sex pheromone 10, 14- dimethyl 15 carbon isobutyric acid ester as the basic component and prepares a euproctis pseudoconspersa gyplure by mixing with the volatile compound. The content of each component is 0.01 to 2.00mg in the gyplure, and by combining the gyplure with a viscose color plate the euproctis pseudoconspersa sex pheromone can be produced for entrapping male moths during the prime time of moth appearance. The trap takes the shape of a plate; the lower hemline is aligned with the tea shoot; the inter-trap distance is 10 to 15 meters. The invention unites for the first time the insect pheromone with the color for entrapping male imagoes of caterpillars, thus the entrapping rate is high and the copulation probability is reduced, preventing the massive eggs from being fertilized, thus the initial population number of the next generation can be depressed. The invention has the advantages of convenient use, low cost, deduction and exemption of pesticide application, non-pollution, and facility for the production of organic tea and pollution tea.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

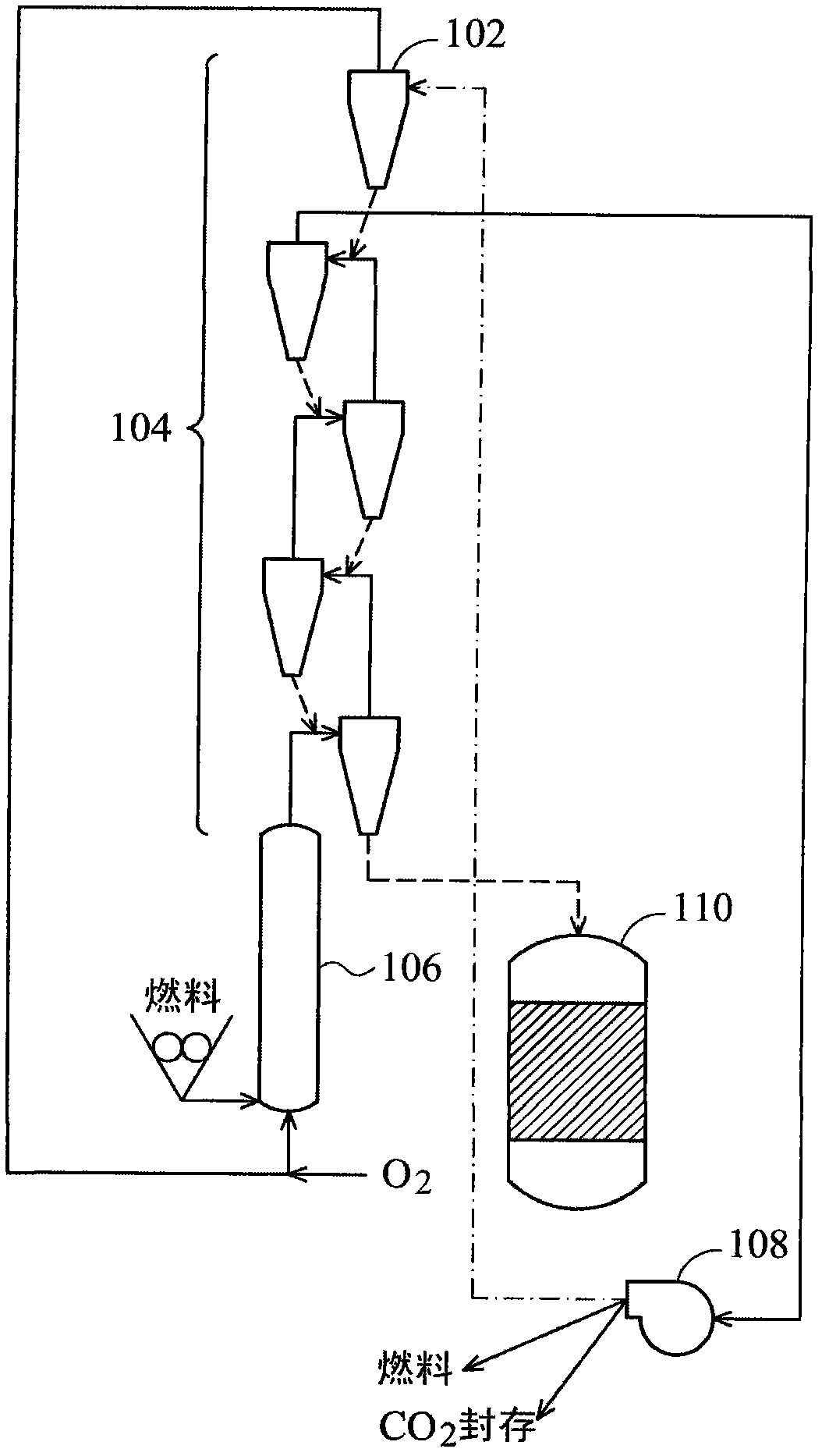

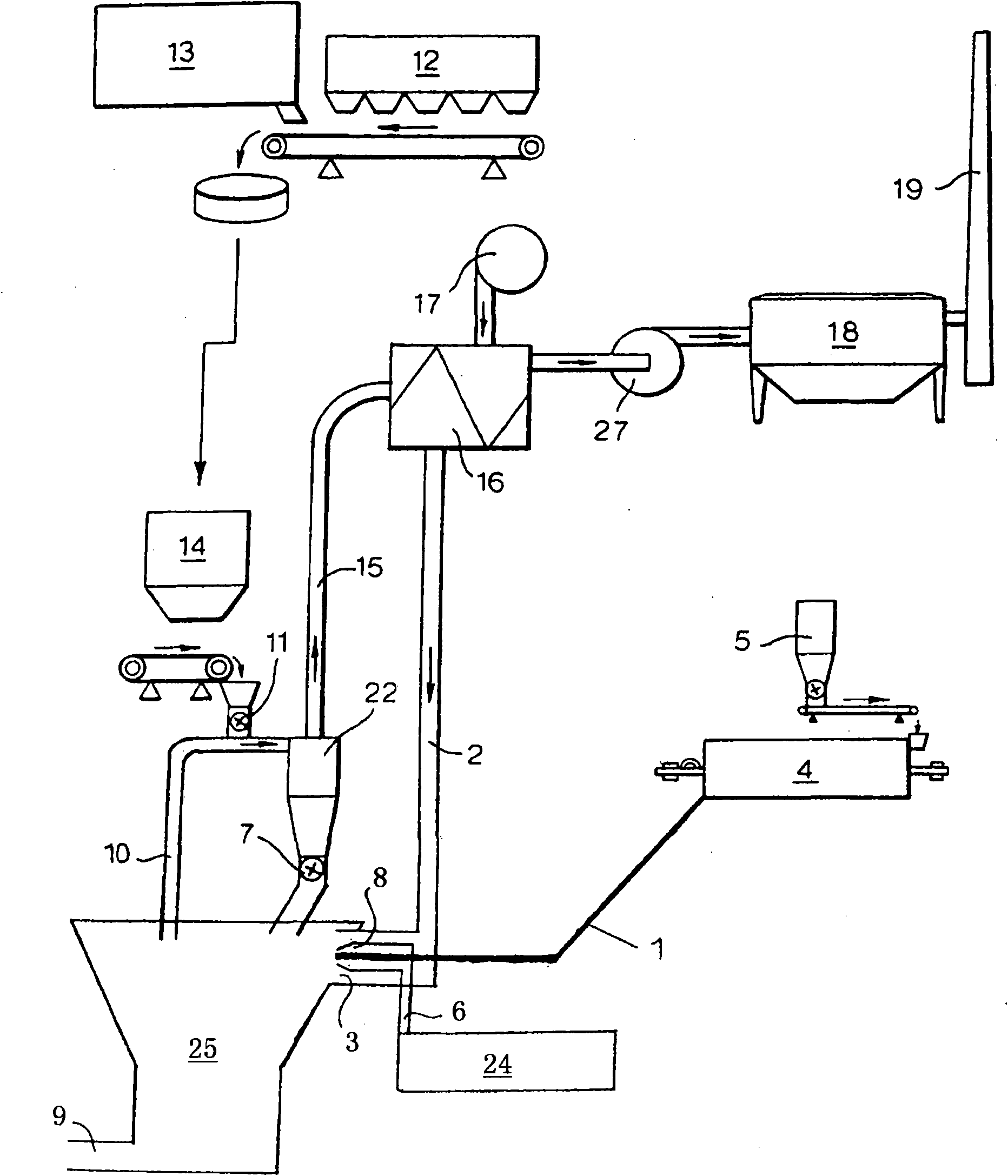

Backflow suspension type calcining furnace system

ActiveCN103175407AImprove energy efficiencyExpand the scope of applicationCarbon compoundsAir quality improvementCarbon dioxideEngineering

Provided is a backflow suspension type calcining furnace system, comprising a plurality of cyclone dust collection devices, wherein a top unit of a cyclone dust collection device is used as a feeder system, a vertical burning kiln, a high temperature windmill and a discharge system. Powder in the feeder system drops into the cyclone dust collection devices; the powder drops and passes through the plurality of cyclone dust collection devices to perform heat exchange with converse high temperature flue gas to generate calcination reaction and release carbon dioxide smoke; the smoke is transmitted to the feeder system pushed by the high temperature windmill and is used as feeder transmission gas of power.

Owner:IND TECH RES INST +1

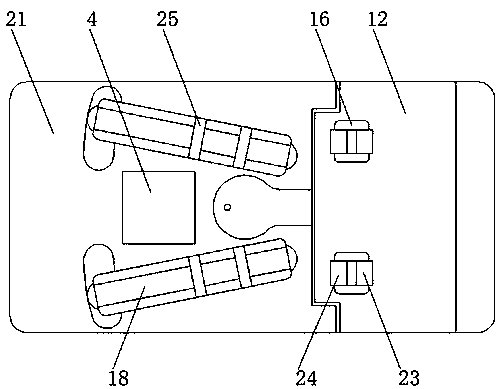

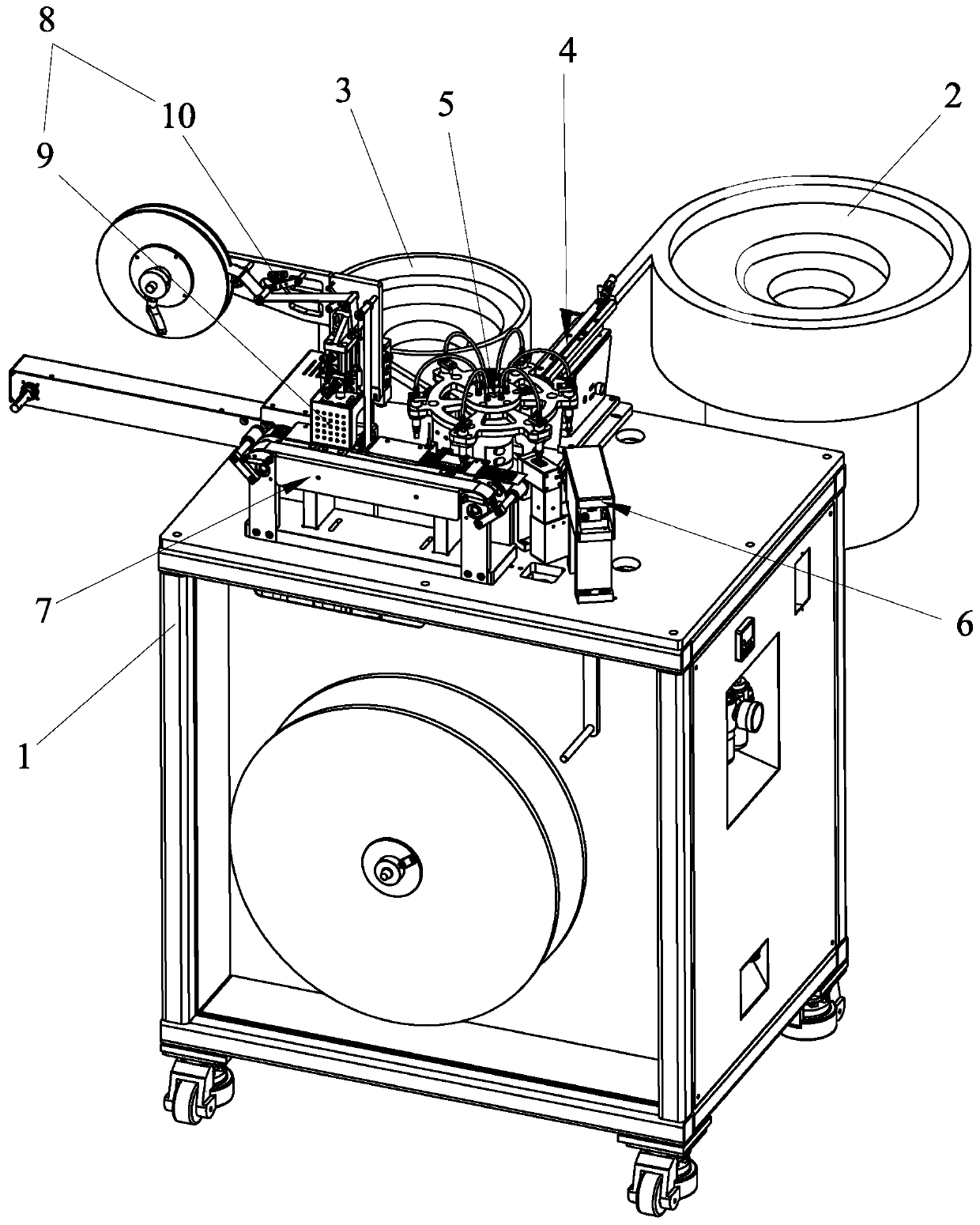

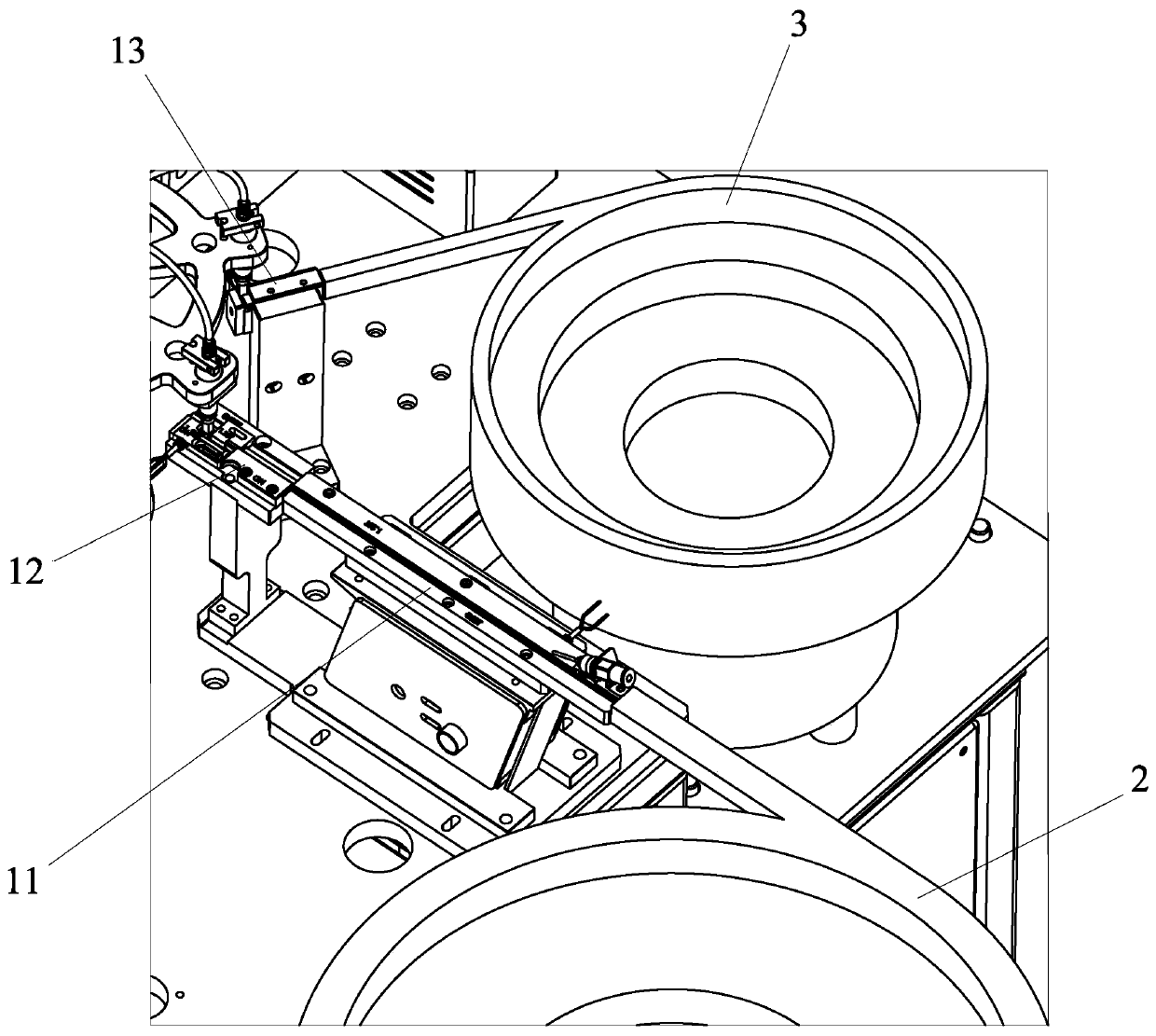

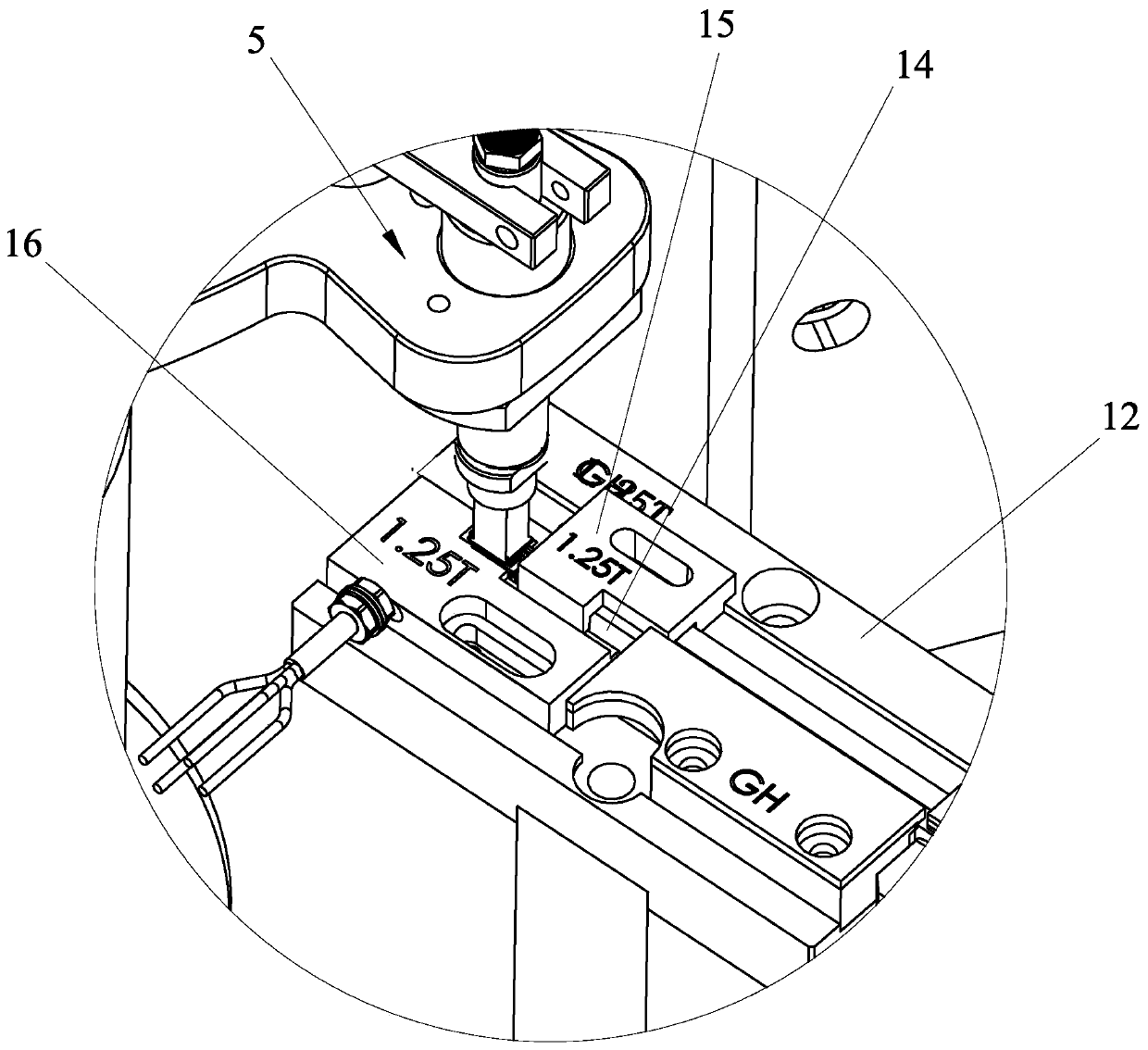

High-efficiency detection packaging machine

ActiveCN111017286AImprove product qualityIncrease productivityContact member cases/bases manufactureWrapping material feeding apparatusHeat sealerIndustrial engineering

The invention discloses a high-efficiency detection packaging machine. The high-efficiency detection packaging machine comprises a rack, a feeding track assembly on the rack comprises a straight vibration track, a product to-be-conveyed track and a cover to-be-conveyed track, products on a product vibration disc are conveyed to the product to-be-conveyed track through the straight vibration track,and covers are sequentially conveyed to the cover to-be-conveyed track through a cover vibration disc; the covers on the cover to-be-conveyed track is conveyed to a product corresponding to the product to-be-conveyed track through a carrying rotary disc mechanism and buckled with the product, and the product buckled with the cover is conveyed to a braid in the braid conveying mechanism through the carrying rotary disc mechanism after being inspected to be qualified by a quality control mechanism; and a heat sealing mechanism comprises a film tape conveying assembly and a heat sealing assembly, the film tape conveying assembly is used for pulling the film tape to the surface of the braid, and the heat sealing assembly is used for heat sealing and attaching the film tape passing through thelower portion of the heat sealing assembly to the braid containing the product. According to the high-efficiency detection packaging machine, the detection and packaging of a connector are automatically completed, the production quality of the connector can be improved, the production efficiency of the connector can be improved, and the production cost is reduced.

Owner:乐清市华宝电子有限公司

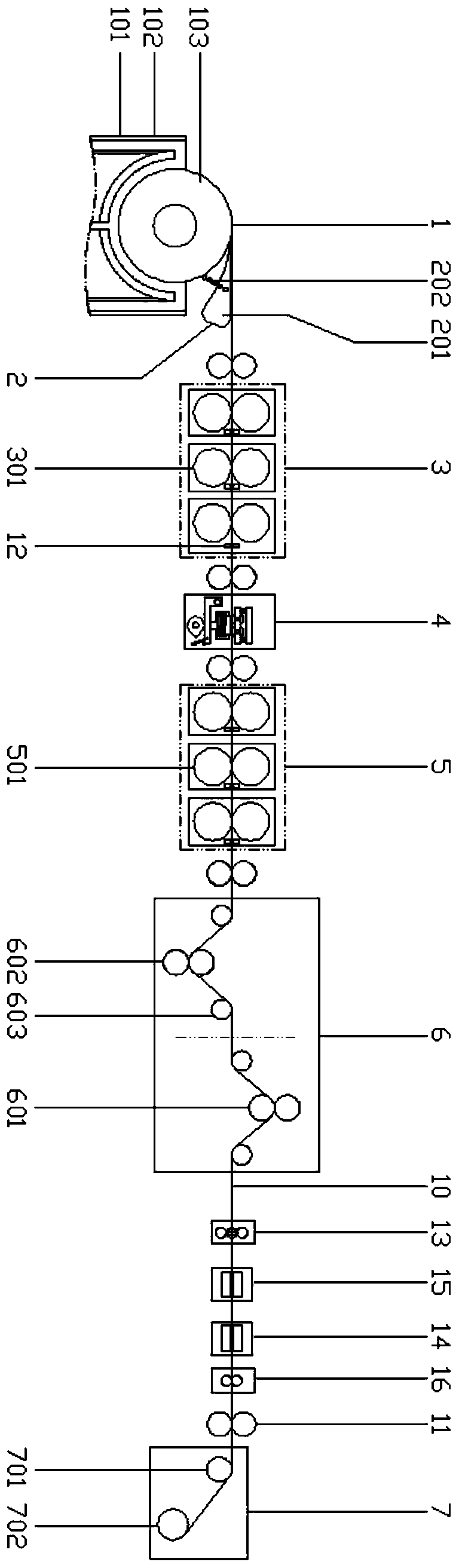

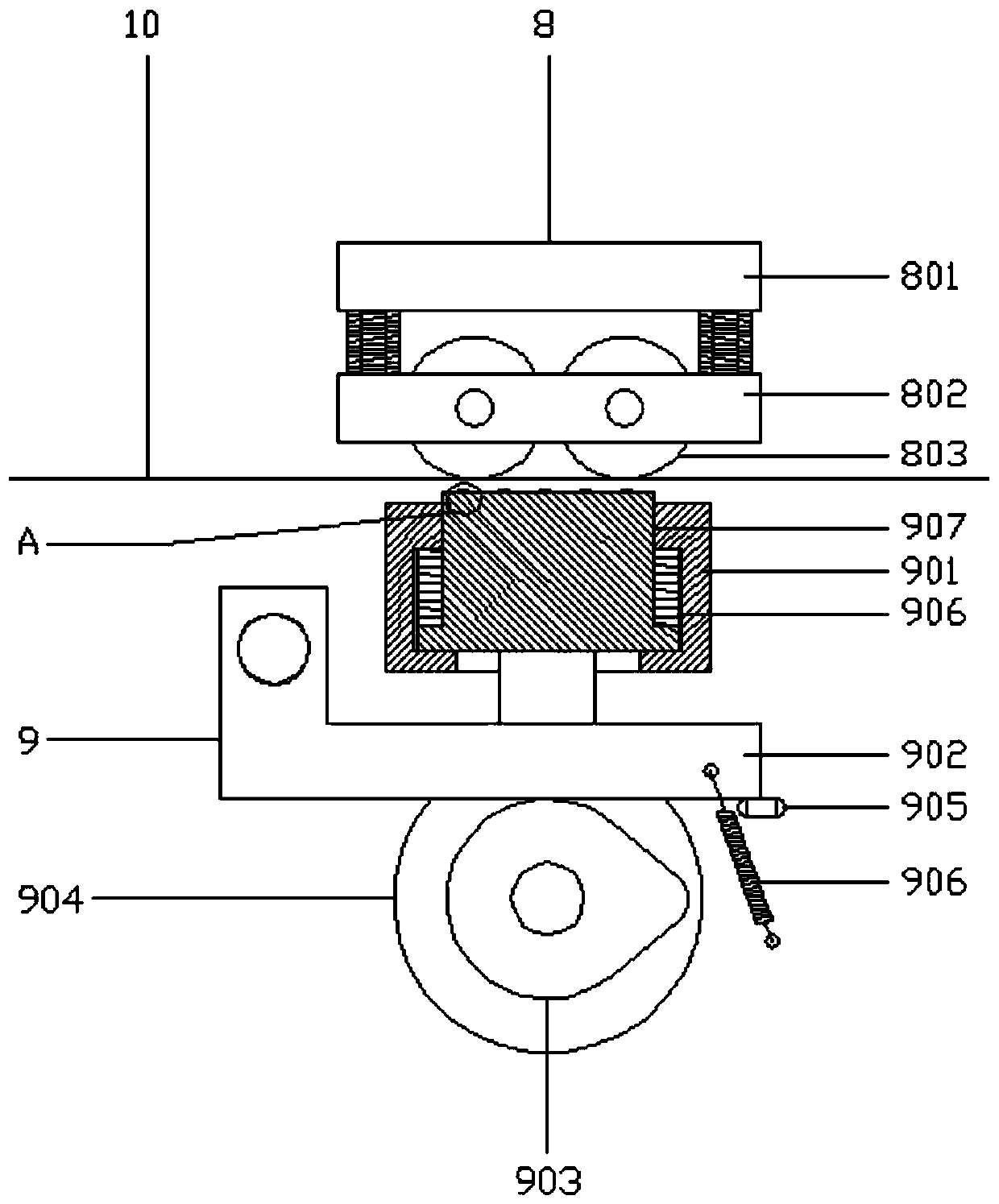

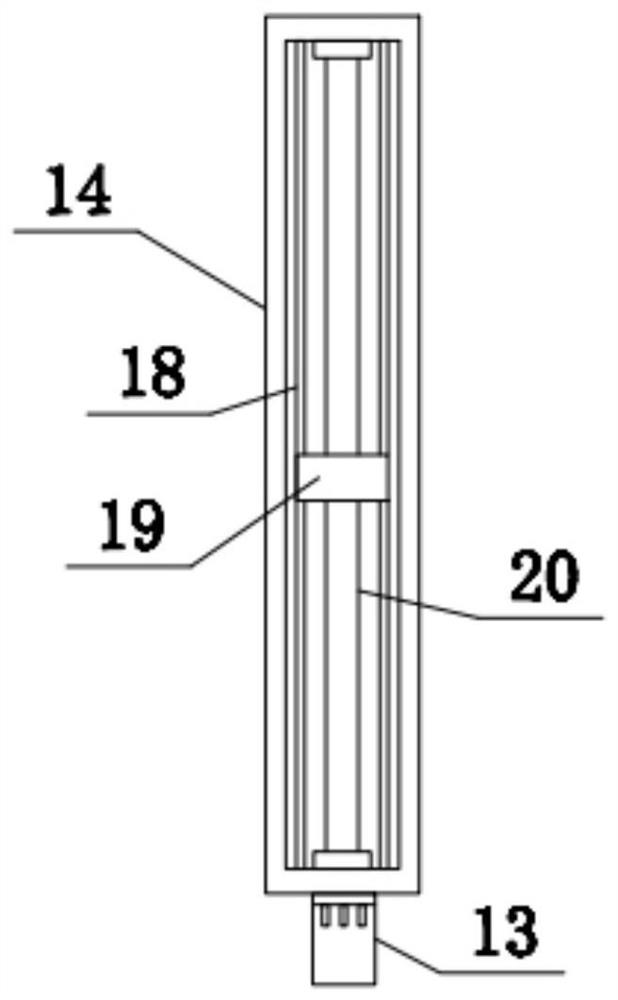

Electrolytic copper foil manufacturing equipment

ActiveCN109778246AHigh surface finishReasonable designPolishing machinesGrinding machine componentsSurface finishHigh density

The invention discloses electrolytic copper foil manufacturing equipment. The electrolytic copper foil manufacturing equipment comprises an electrolytic copper foil mechanism, a stripping mechanism, acoarse roll prepressing mechanism, a high-frequency stamping mechanism, a finish roll rolling mechanism, a polishing and grinding mechanism and a collection mechanism. The high-frequency stamping mechanism comprises an elastic rolling device used for being arranged on one side of copper foil and a high-frequency stamping device used for being arranged on the other side of the copper foil. The polishing and grinding mechanism comprises a front surface polishing and grinding device used for polishing and grinding the front surface of the copper foil and a back surface polishing and grinding device used for polishing and grinding the back surface of the copper foil. The electrolytic copper foil manufacturing equipment provided by the invention is novel in design and reasonable in structure.The electrolytic copper foil manufacturing equipment strips off the electrolyzed copper foil from a cathode electrolytic roll and then conducts prepressing, high-frequency stamping, rolling and polishing to obtain the copper foil with the small mall, high surface smoothness, fewer microdefects and high density. The obtained copper foil has excellent elongation and tensile strength, is suitable forlithium batteries and can improve through quality of the lithium batteries.

Owner:TAIXING SHENGDA COPPER IND CO LTD

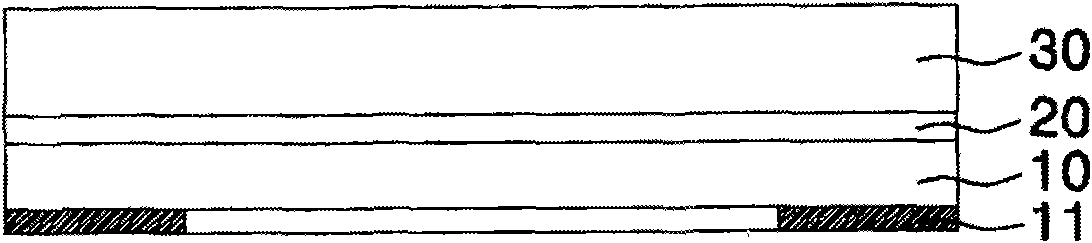

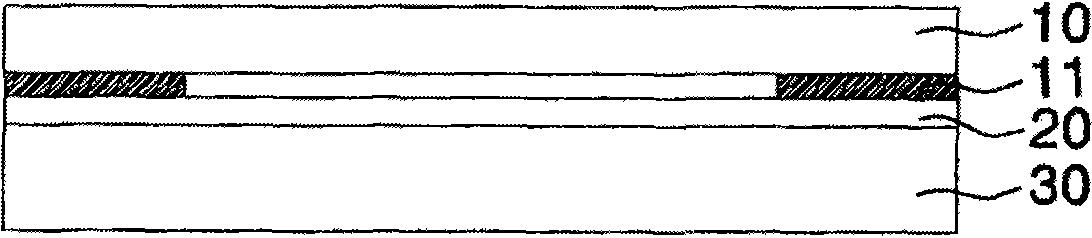

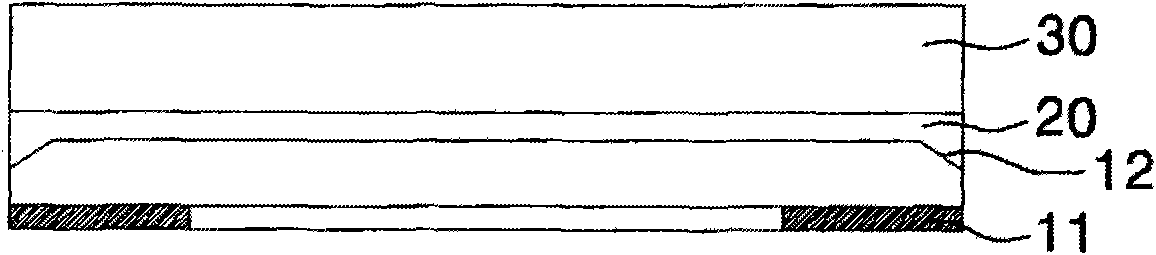

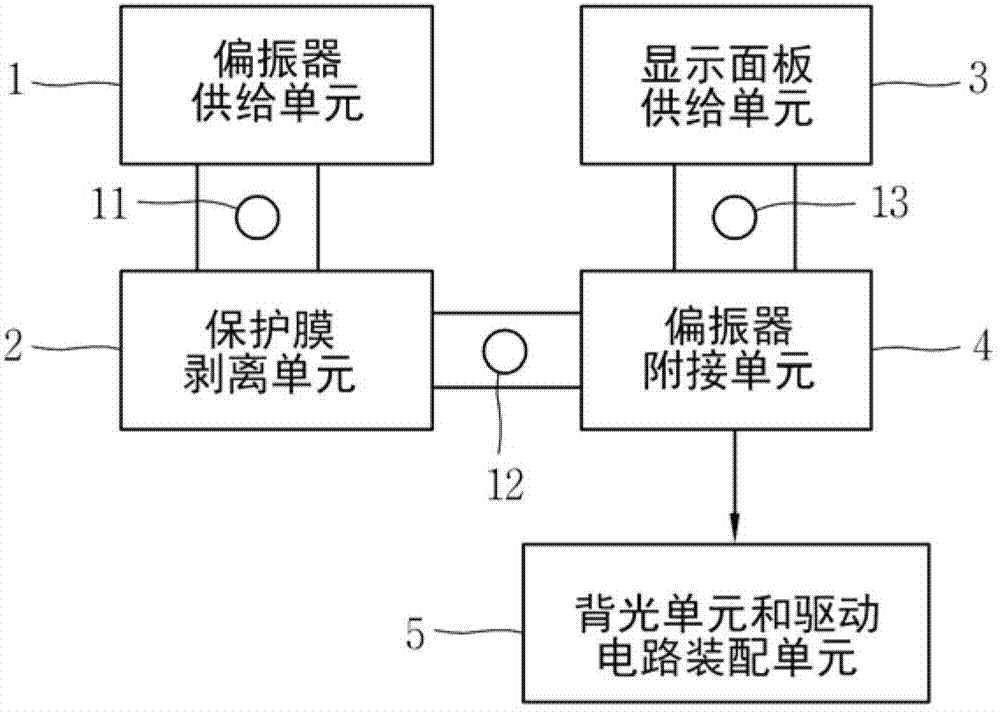

Manufacturing method of window for display device, window for display device and wireless terminal unit comprising the same

InactiveCN101557936AHelp productionGood removal effectLaminationLamination apparatusAdhesiveDisplay device

The present invention provides the characteristic window for display device, and also provides the manufacturing method of window for display device and the wireless terminal unit using the manufacturing method of window for display device, wherein the manufacturing method is characterized by: coating a UV-adhesive to a glass; positioning a synthetic resin substrate on the UV-adhesive coated glass; passing the synthetic resin substrate through a roll press to gradually press from a first end region of the synthetic resin substrate to a last end region of the synthetic resin substrate and to remove gas; and irradiating UV light to cure the UV-adhesive. The present invention provides industrially applicable window for display device whereby decoration is easy on a window, and air bubbles can be easily removed during processes where the synthetic resin substrate and glass are UV-adhesive bonded through a particular method to facilitate a mass production of windows in a short period of time.

Owner:MOGEM

Process and apparatus for making mineral fibres

ActiveCN101558015ASolving inefficienciesUniform dwell timeCharging furnaceGlass furnace apparatusParticulatesCombustion chamber

The present invention provides a process for making a mineral melt comprising: providing a circulating combustion chamber which contains circulating chamber gases, injecting a stream of particulate fuel into the combustion chamber through a fuel feed pipe, injecting combustion gas into the combustion chamber; mixing the stream of particulate fuel with the combustion gas and with the circulating chamber gases by injecting into the combustion chamber secondary gas, through a secondary gas inlet, wherein the secondary gas is injected adjacent to the stream of particulate fuel and the injection speed of the secondary gas is at least 100 m / s greater than the injection speed of the particulate fuel; suspending particulate mineral material in the circulating chamber gases and combusting the fuel, thereby melting the particulate mineral material and forming a mineral melt and hot exhaust gases; and separating the hot exhaust gases from the melt and collecting the melt.

Owner:ROCKWOOL AS

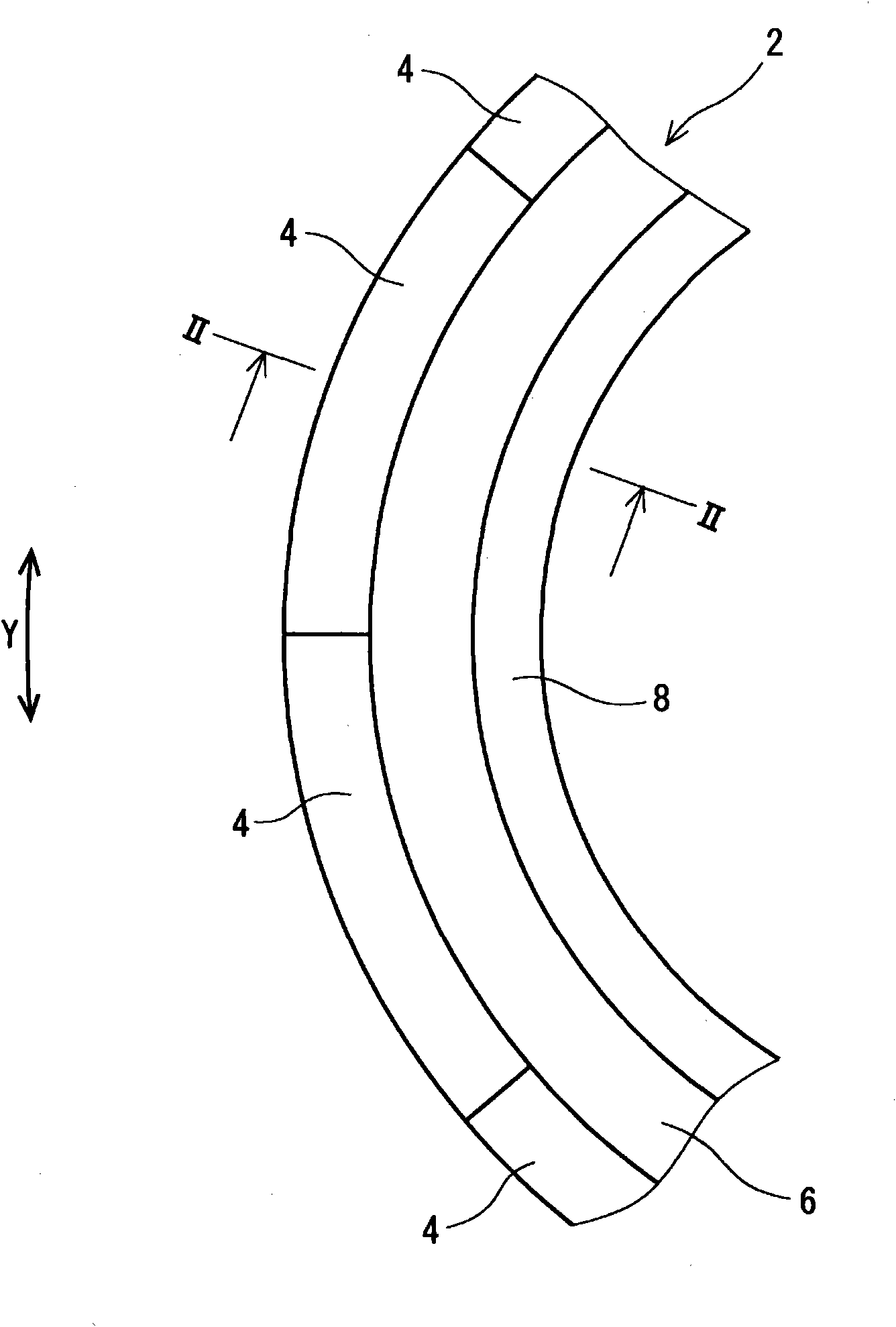

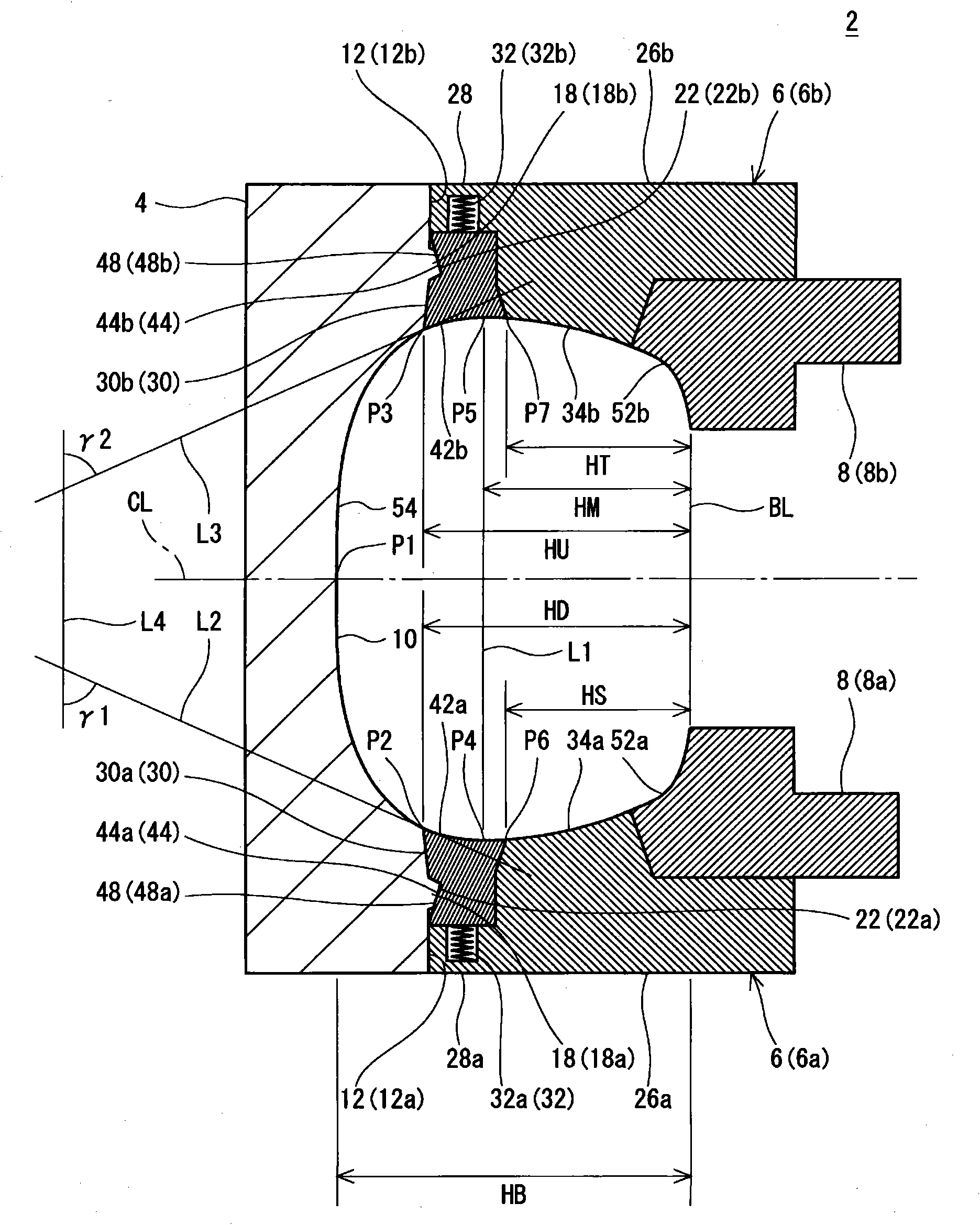

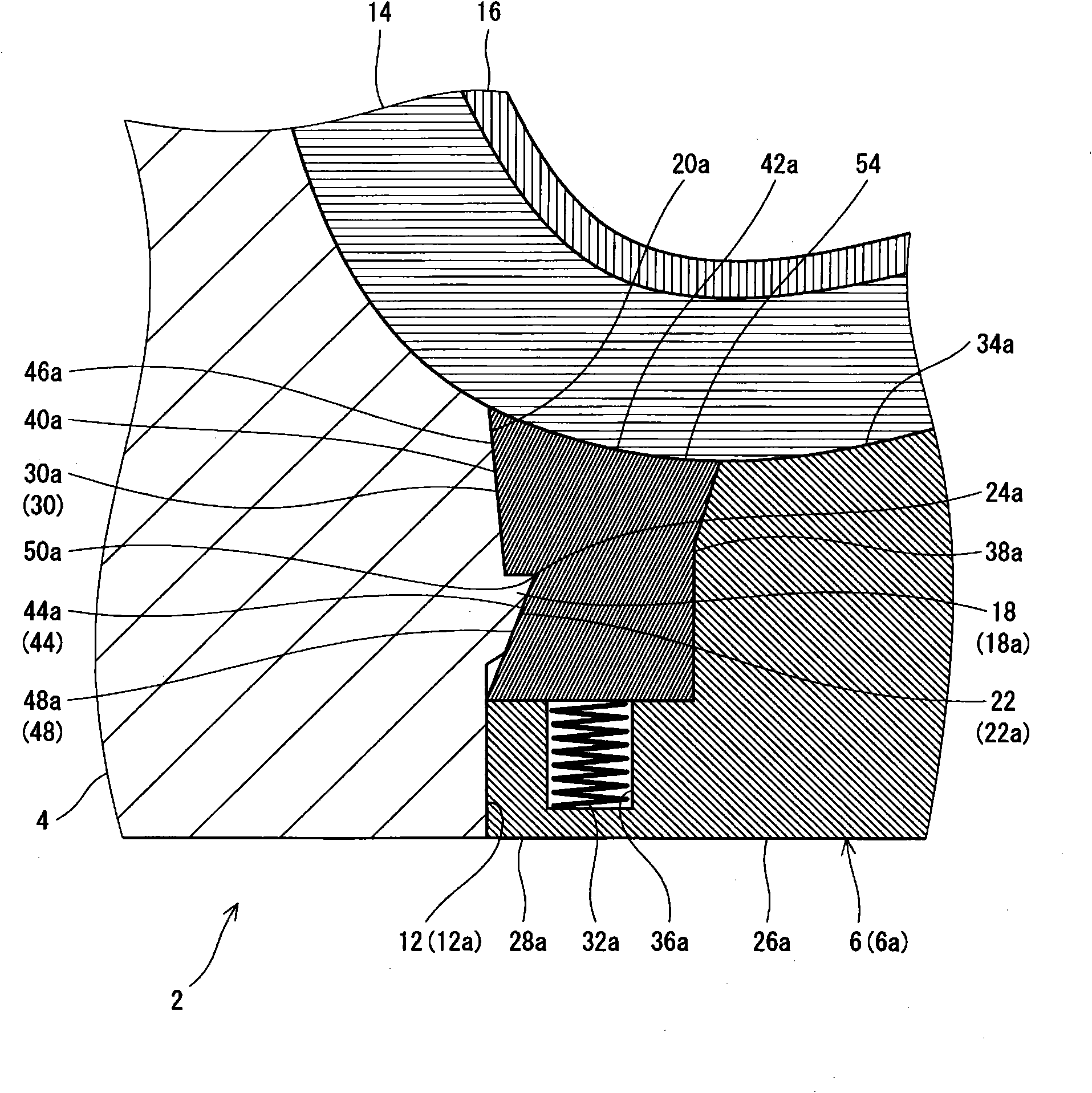

Mold for tyre

The invention discloses a mold (2) for tyre aiming at obtaining tyre with high quality. The mold herein comprises a plurality of combination molds (4), and side plates (6) which are disposed on inner sides in radial direction of each combination mold, wherein each combination mold is provided with a division surface (12) that is oppositely disposed to the side plate (6). The division surface is provided with an inclined plane (22) which inclines from the axis inner side to the outer side and to the radial outer side. The side plate (6) is provided with a movable ring (30) which abuts the division surface, and an actuator (32) which can apply force to the movable ring (30) to the axis inner side. The movable ring (30) is provided with a conical surface (48) which corresponds to the inclined plane (22). If the combination molds (4) depart from the side plates (6), the movable ring (30) will move to the axis inner side. If the combination molds (4) comes close to the side plates (6) and the inclined plate (22) abuts the conical surface (48), the conical surface (48) will slides along the inclined plate (22) and at the same time the movable ring (30) will move to the axis outer side.

Owner:SUMITOMO RUBBER IND LTD

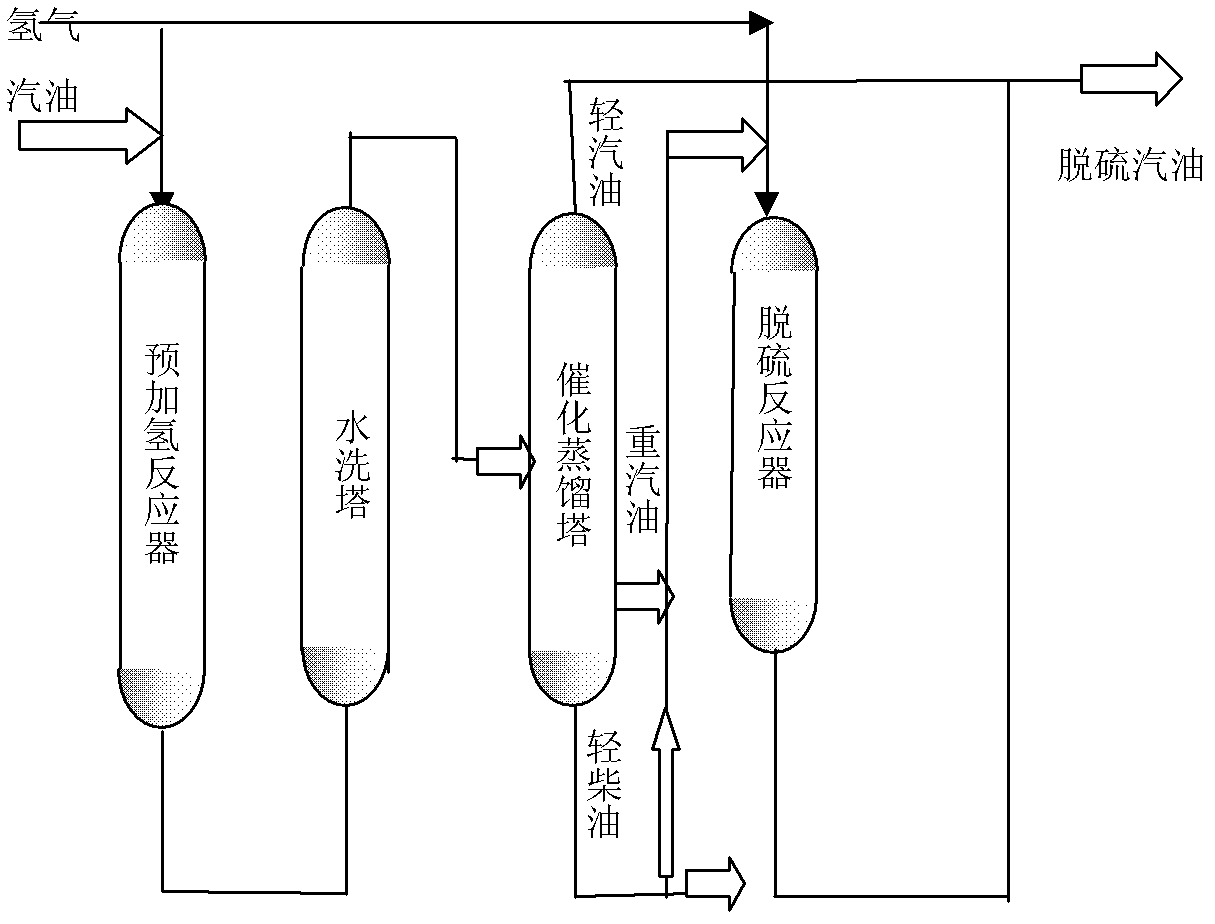

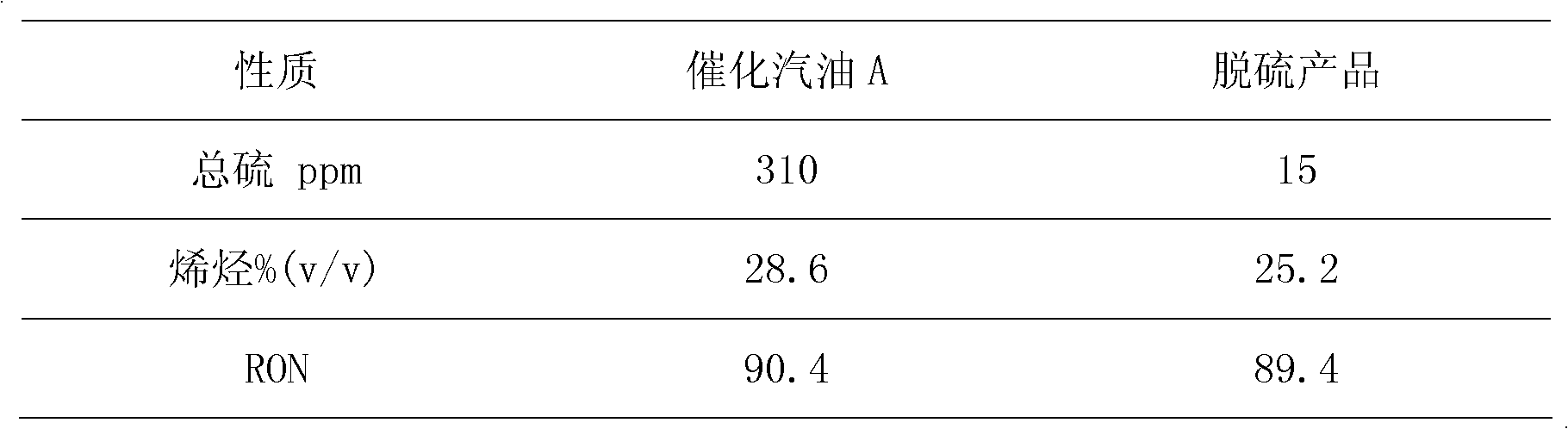

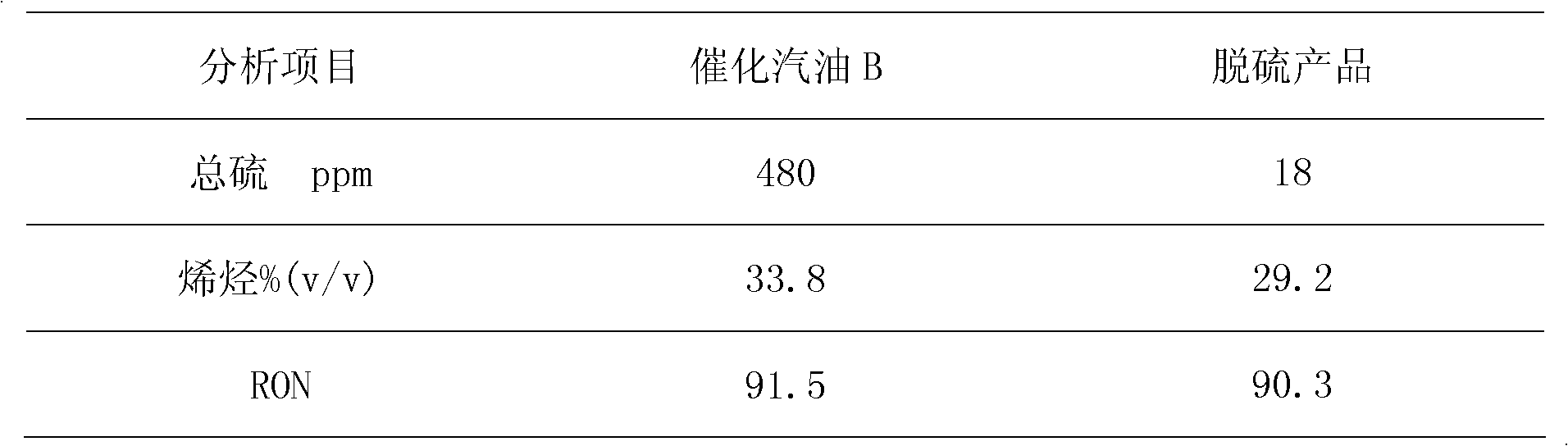

Deep desulfurization method for gasoline

ActiveCN102994148AAdd weight gain stepsHigh yieldTreatment with hydrotreatment processesHydrodesulfurizationCatalytic distillation

The present invention relates to a deep desulfurization method for a gasoline. According to the method, a gasoline raw material and hydrogen are mixed, and then enter a pre-hydrogenation reactor to carry out hydrogenation on diene in catalytic gasoline to obtain mono olefin; the pre-hydrogenation product enters a water washing tower to carry out water washing, partial alkaline nitrides in the gasoline is removed, the obtained material enters a catalytic distillation tower, partial thiophene sulfides in the gasoline is subjected to weight gain under an effect of an olefin thiophene alkylation catalyst on the upper portion of the catalytic distillation tower, and concurrently the gasoline is divided into three components such as light gasoline, heavy gasoline and light diesel oil; the heavy gasoline component enters a selective hydrodesulfurization reactor to carry out deep desulfurization, hydrogen sulfide generated during the reaction is removed from the desulfurization product, and the hydrogen sulfide-removed desulfurization product is mixed with the light gasoline to obtain the deep desulfurization gasoline product; and light diesel oil on the bottom of the tower is adopted as a hydrodesulfurization raw material, or is adopted as low freezing point diesel oil blending component to be subjected to blending producing. With the method, sulfur content in gasoline can be substantially reduced, and octane number loss caused by the deep desulfurization process can be reduced.

Owner:PETROCHINA CO LTD

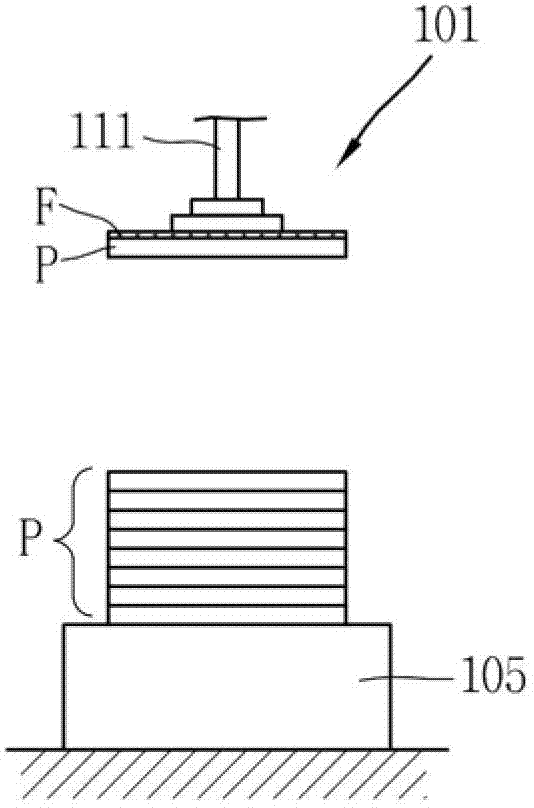

Apparatus and method for peeling protective film and method for fabricating stereoscopic image display device

ActiveCN103129095AReduce processing timeHelp productionLamination ancillary operationsPolarising elementsAir bubbleImage display

An apparatus for peeling a protective film is provided to remove air bubbles in a film member with the protective film peeled, by moving a peeling unit so that the peeling unit performs peeling at a different position for each peeling process. The apparatus includes: a cylindrical plate for rotating a film member attached to the outer peripheral surface thereof, the film member having a protective film attached to the front surface thereof; a peeling unit comprising a peeling roller disposed at a side portion of the cylindrical plate to peel the protective film from the film member and a clamp for holding the peeled portion of the protective film; and a first moving unit for moving the peeling unit backward from the cylindrical plate to peel the protective film, wherein the peeling unit is moved along an axial direction of the cylindrical plate so that the peeling unit is contacted to the a different position of the protection film for each peeling process.

Owner:LG DISPLAY CO LTD

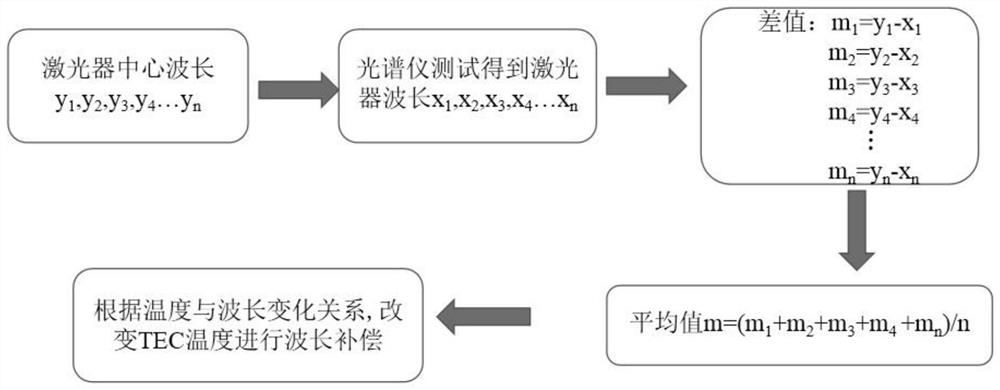

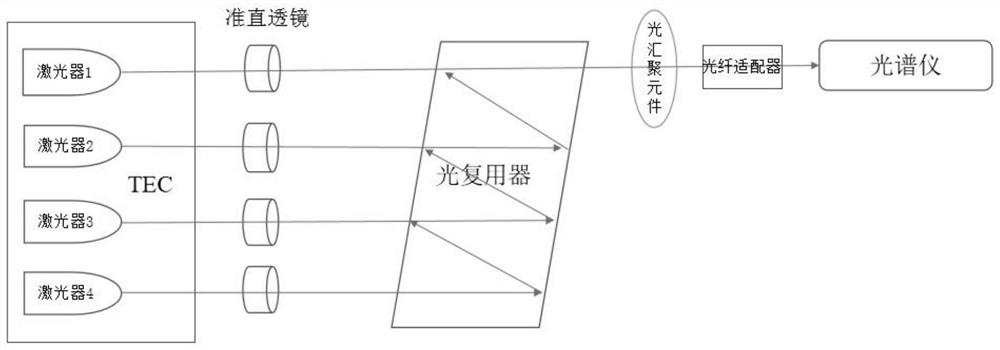

Method for debugging wavelength of optical module by using astigmatism

ActiveCN113050239AIncrease the difficultySimple debugging methodCoupling light guidesOptical ModuleMultiplexer

The invention provides a method for debugging the wavelength of an optical module by using astigmatism. The optical module comprises a plurality of lasers, an optical multiplexer for combining the light of the plurality of lasers into one path and an optical fiber adapter coupled with the optical multiplexer, and the method comprises the following steps of (1) fixing the lasers, the optical multiplexer and the optical fiber adapter; and then obtaining the wavelength of each laser; (2) comparing the obtained wavelength of each laser with the corresponding central wavelength to obtain a difference value between the wavelength and the central wavelength; (3) acquiring an average value of the difference values between the wavelengths of the lasers and the central wavelength, and acquiring a compensation temperature corresponding to the average value of the wavelength difference values according to a change corresponding relation between the temperatures of the lasers and the wavelengths; and (4) compensating the temperature of each laser through a semiconductor cooler according to the compensation temperature. According to the present invention, the repair cost and time are prevented from being increased, the production cost and difficulty are prevented from being increased, and the debugging method is simple.

Owner:武汉英飞光创科技有限公司

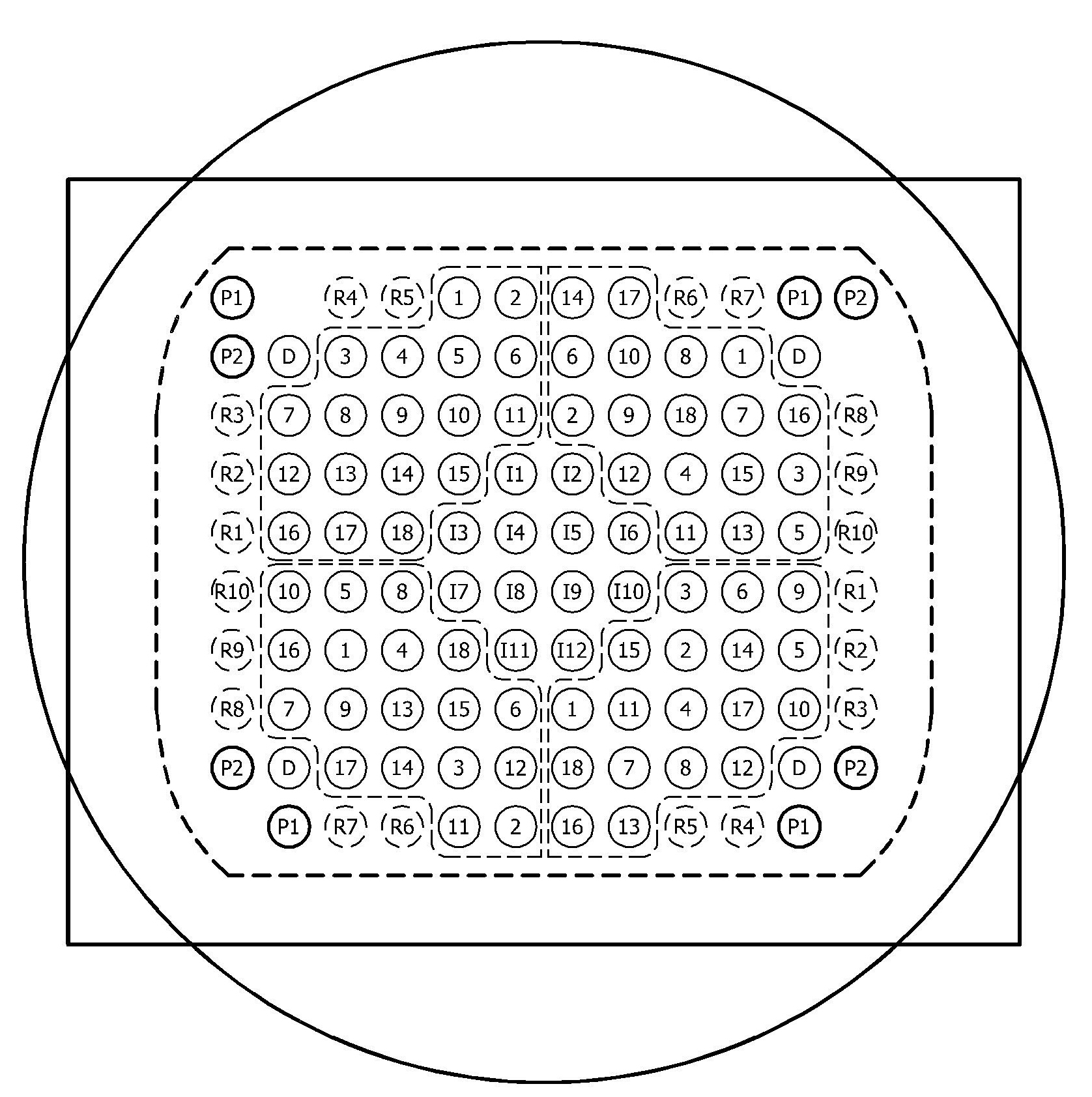

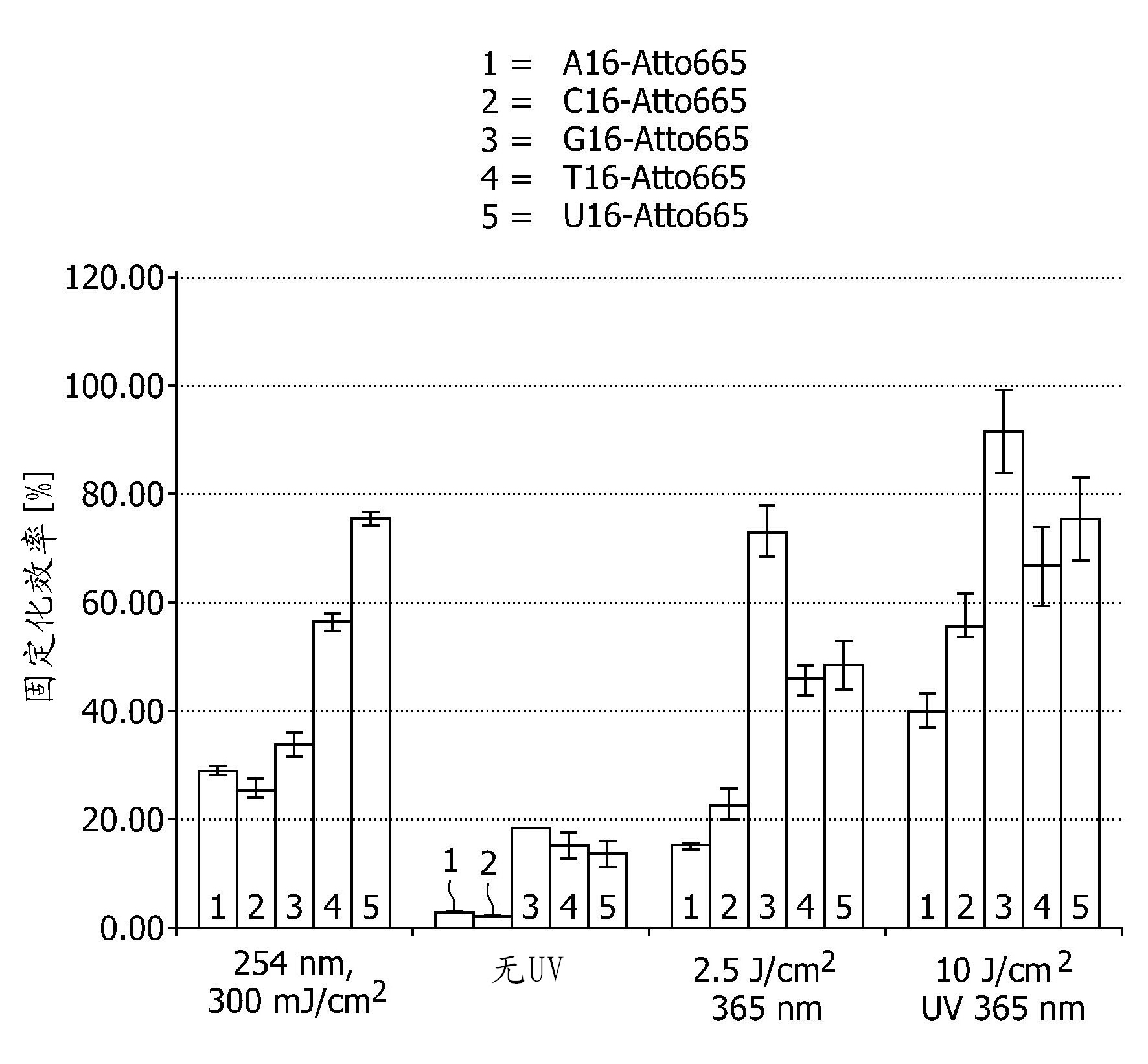

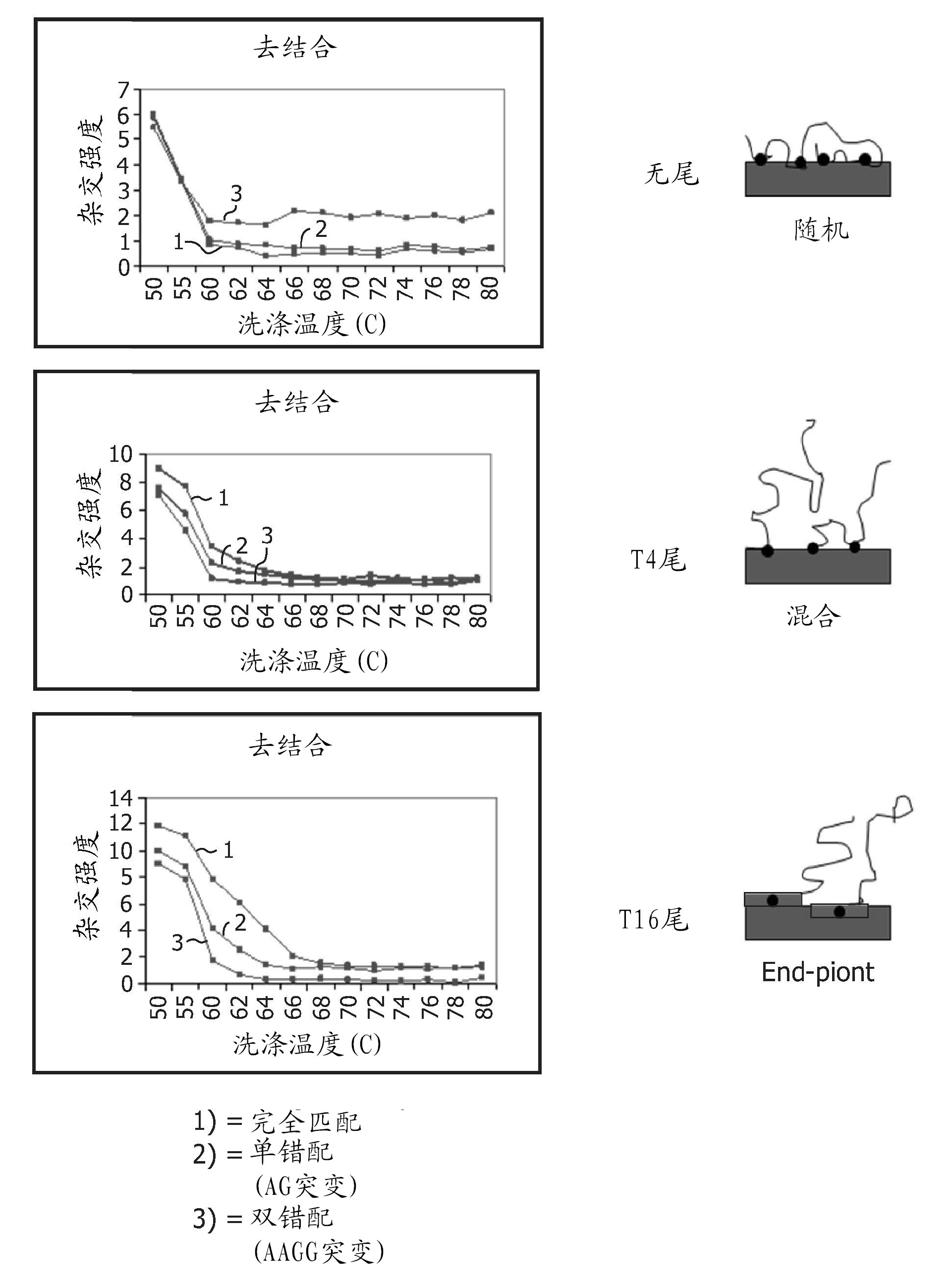

Method for immobilizing nucleic acids on a support

ActiveCN102171368AEffective and stable immobilizationImprove interactive behaviorMicrobiological testing/measurementNucleotideImmobilized Nucleic Acids

The present invention relates to a method for immobilizing nucleic acids on a support, comprising the provision of a nucleic acid with a stretch of nucleotides of only one basetype and the immobilization of said nucleic acid on a support by crosslinking by light, wherein said crosslinking by light is performed at a wavelength of about 300-500 nm, preferably at a wavelength of 365 nm. The present invention further relates to a method for the analysis of nucleic acids immobilized according to the invention, which comprises the hybridization of the immobilized nucleic acid with complementary and mismatch segments. Furthermore, the present invention relates to immobilized nucleic acids obtainable by the method of the invention, the use of accordingly immobilized nucleic acids for the production of nucleic acid arrays and a diagnostic kit, comprising an array of nucleic acids which are immobilized according to the present invention.

Owner:KONINK PHILIPS ELECTRONICS NV

Black film arched shed and flat shed shade net dual-mode planting method for morchella esculenta

InactiveCN113040001APromote early growthHelp productionCultivating equipmentsMushroom cultivationElectric machineryEngineering

The invention discloses a black film arched shed and flat shed shade net dual-mode planting method for morchella esculenta. A flat shed keel is included. The mode that flat shed keels and arched shed keels are combined is adopted when the morchella esculenta is planted, the flat shed keels are adopted firstly after earlier-stage mushroom cultispecies are put into soil, earlier-stage growth of the morchella esculenta can be promoted by means of the good ventilation effect, an arched shed mode is adopted after later-stage mushroom fruiting, a motor is started through a DSP controller and linked with screws to rotate, movable blocks on the outer sides of the screws slide on guide rods, the arched shed keels are dragged to slide on round rods through movement of the movable blocks, after covering of the arched shed keels is completed, the heat preservation and moisture preservation effects can be better achieved through an arched shed mode, meanwhile, a first sunshade net and a second sunshade net are arranged on the outer sides of the flat shed keels and the outer sides of the arched shed keels correspondingly, and direct sunlight can be effectively avoided; and meanwhile, double-layer covering is achieved, the heat preservation effect is good, and fruiting and morchella esculenta production are facilitated.

Owner:巴中永盛农业开发有限公司

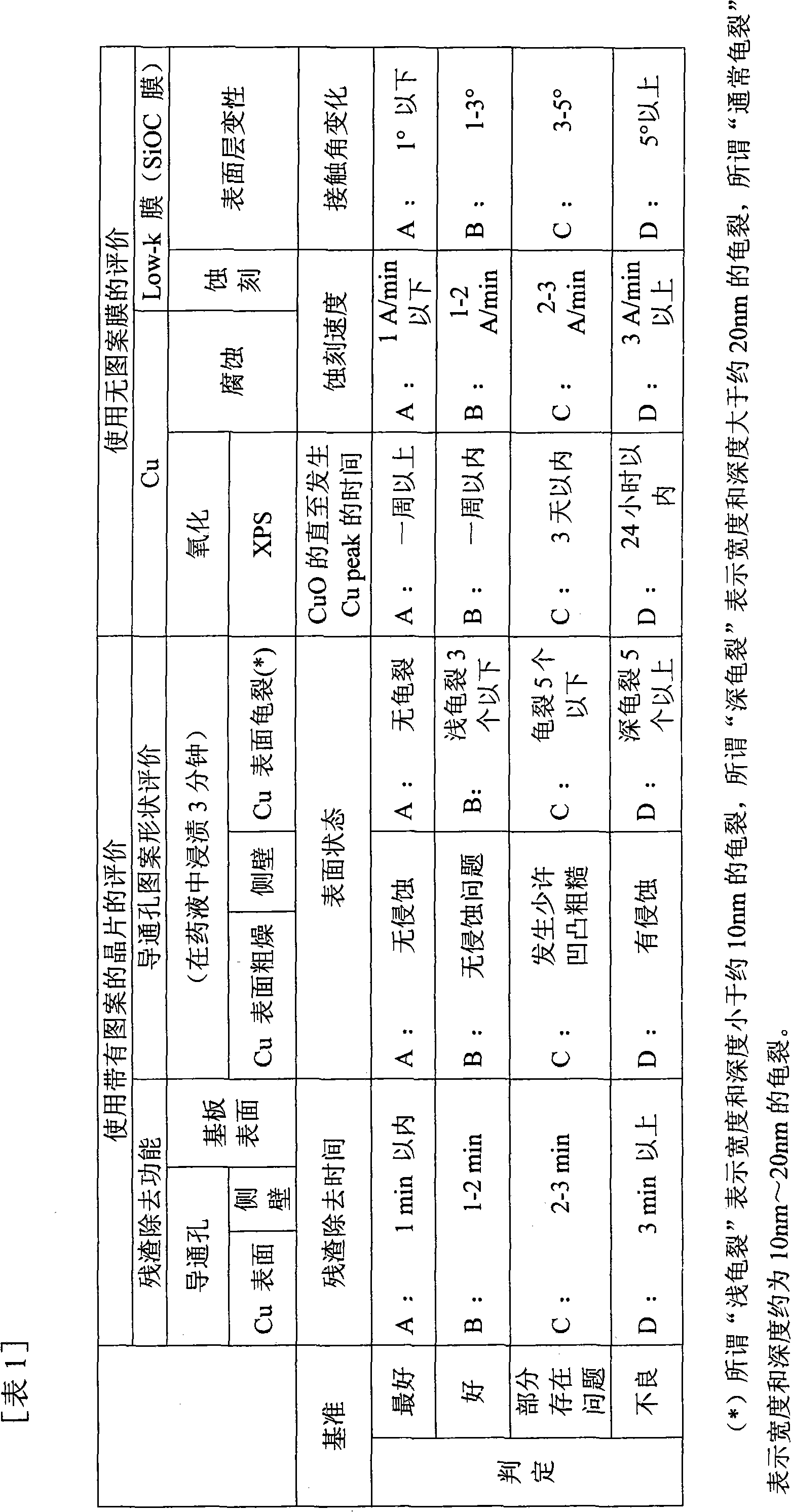

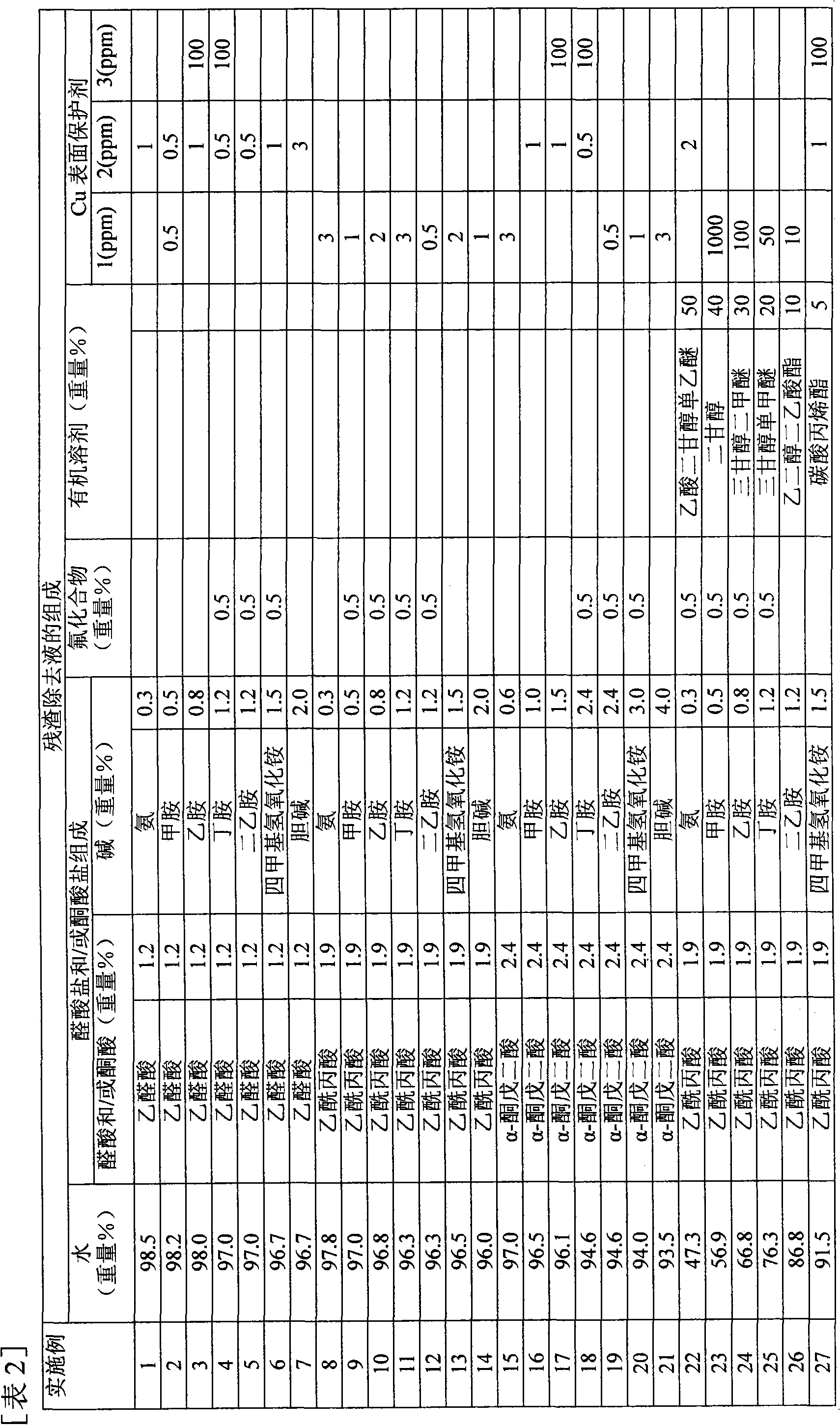

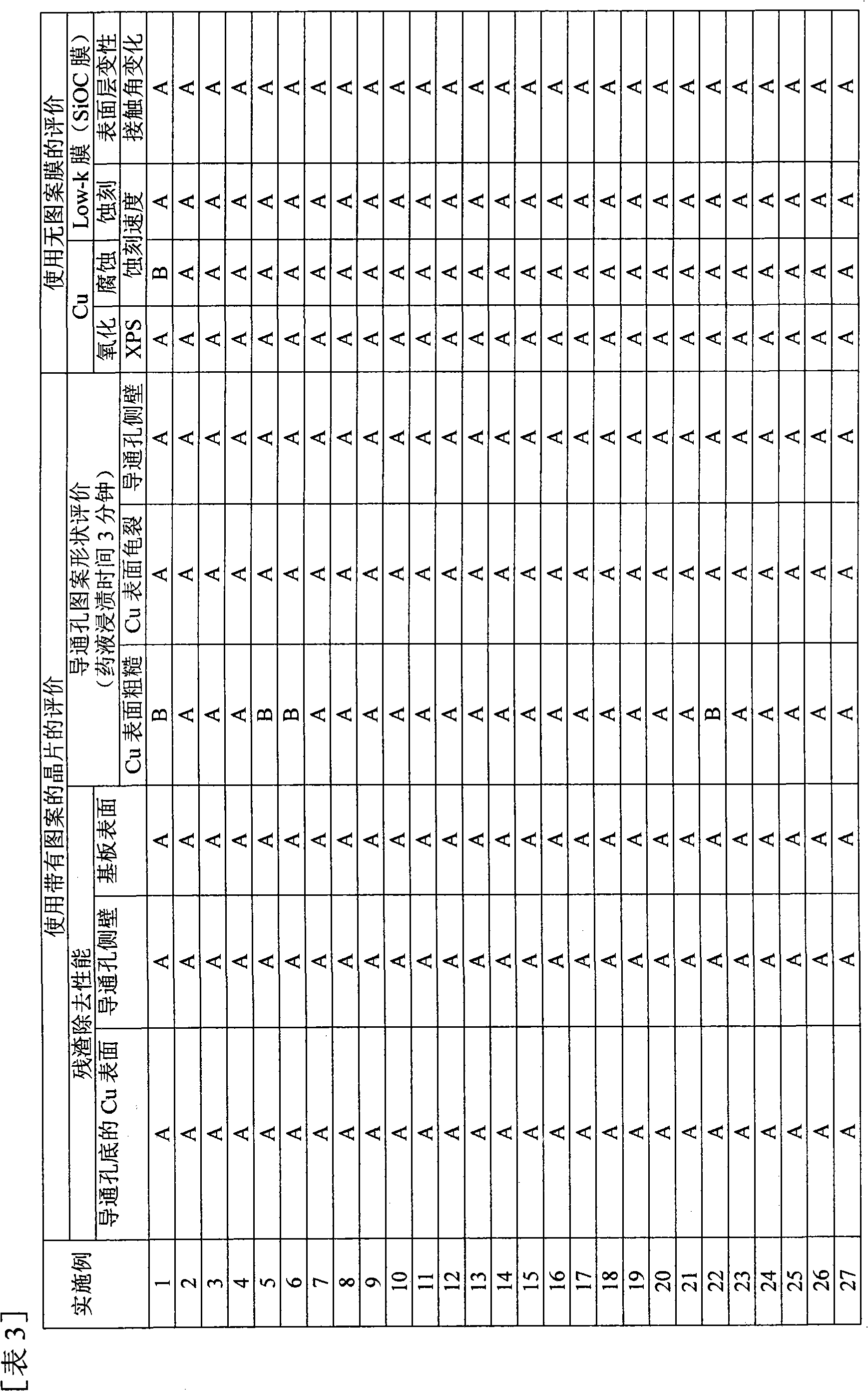

Solution for removal of residue after semiconductor dry processing, and residue removal method using the same

InactiveCN101785087AAvoid crackingAvoid rough surfacesNon-surface-active detergent compositionsDetergent mixture composition preparationNitrogenCopper

Disclosed is a solution for removing a residue after a dry processing, which can prevent the cracking or roughening of a Cu surface which cannot be overcome by a conventional liquid polymer stripper, which can prevent the oxidation of a Cu surface, and which contains a surface-protecting agent. Also disclosed is a method for producing a semiconductor device by using the solution. Specifically disclosed is a solution for removing a residue remaining on a semiconductor substrate after dry etching and / or ashing, which comprises: a Cu surface-protecting agent comprising at least one compound selected from the group consisting of (1) a compound which has, as a basic skeleton, a 5-membered heterocyclic aromatic compound having a structure represented by the formula: =N-NH- (provided that one having three contiguous N atoms is excluded) and which shows a pH value of 7 or less in the form of an aqueous solution (10 ppm, 23 DEG C); (2) a compound which has, as a basic skeleton, a 5-membered heterocyclic compound having a structure represented by the formula: -N=C(SH)-X- [wherein X represents NH, O or S] and which shows a pH value of 7 or less in the form of an aqueous solution (10 ppm, 23 DEG C) and (3) a compound which has, as a basic skeleton, a 6-membered heterocyclic aromatic compound having at least one nitrogen atom (N) and which shows a pH value of 7 or more in the form of an aqueous solution (10 ppm, 23 DEG C); a compound capable of forming a complex or chelate in coordination with Cu (copper); and water. The solution has a pH value ranging from 4 to 9.

Owner:DAIKIN IND LTD

Chinese herbal preparation capable of preventing and curing piglet's yellow-white dysentery and preparation method and application thereof

ActiveCN103349699AGuarantee quality and safetyControl quality safetyAntibacterial agentsDigestive systemHerbal preparationsWhite blood cell

The invention discloses a Chinese herbal preparation capable of preventing and curing piglet's yellow-white dysentery and a preparation method and application thereof, and belongs to the technical field of Chinese herbal preparation. The preparation method comprises the following steps: respectively crushing 30-60 g Chinese pulsatilla root, 20-30 g dianthus superbus, 20-30 g cortex phellodendri, 16-18 g gentian, 20-30 g evodia lepta, 16-18 g kuh-seng, 8-12 g agastache rugosus, 16-18 g costustoot, and 16-20 g ash bark; sieving by a 120-mesh sieve, and uniformly mixing so as to obtain the Chinese herbal preparation. By mass percent, 0.5-1 percent of Chinese herbal preparation prepared is added into fodder for feeding piglets after the two are uniformly mixed, so as to prevent and cure piglet's yellow-white dysentery. Besides, being capable of effectively killing and suppressing pathogenic microorganisms, the Chinese herbal preparation also can stimulate organism immunity, and enhance phagocytic ability of white blood cell and liver reticuloendothelial system so as to suppress devastating reaction for organisms.

Owner:青岛海滨泰康生物科技有限公司

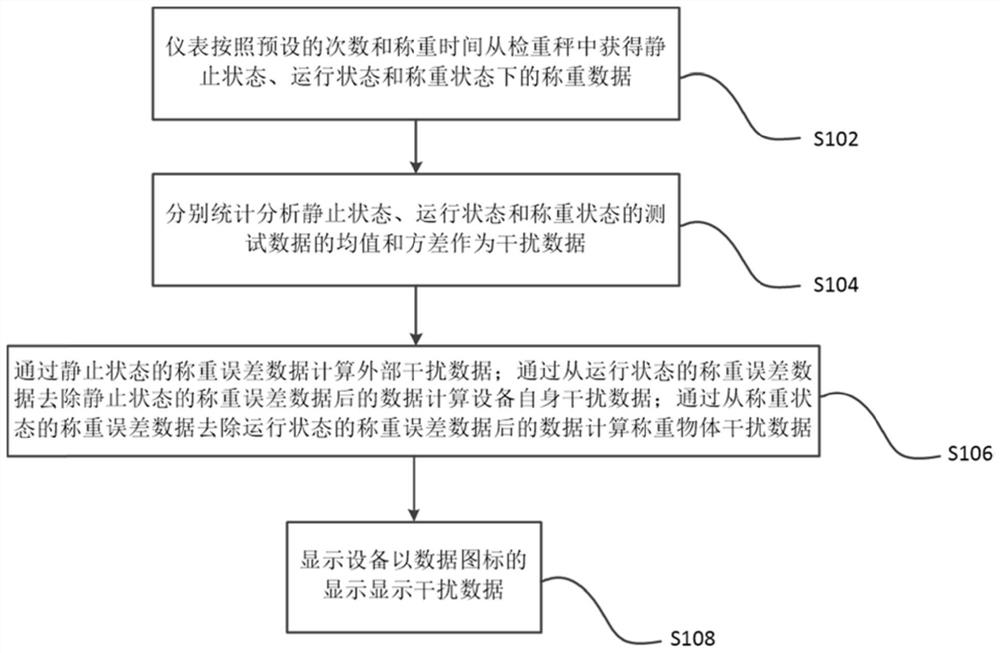

Method and system for measuring interference of weight checking equipment

PendingCN113588062AHelp productionHelp with debuggingWeighing apparatus testing/calibrationOscillations damping for weighingStatistical analysisTested time

The invention discloses a method and a system for measuring interference of weight checking equipment. The method comprises the steps of obtaining weighing test data which are output after preset weighing test time according to preset weighing test times when the weight checking equipment is in a static state, an operation state and a weighing state; obtaining weighing error data of the static state, the operation state and the weighing state through statistical analysis; and calculating or mapping the weighing error data in the static state, the weighing error data in the operation state and the weighing error data in the weighing state to obtain external interference data, equipment self-interference data and weighing object interference data. The interference measuring system for the weight checking equipment comprises an instrument and a processing device; the instrument and the processing device perform an interference measurement and compensation method. According to the invention, the interference intensity of the weight checking equipment in each state and the influence intensity of the weight checking equipment on the weighing performance can be obtained, so that the production, debugging, maintenance and use of a checkweigher are facilitated.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +2

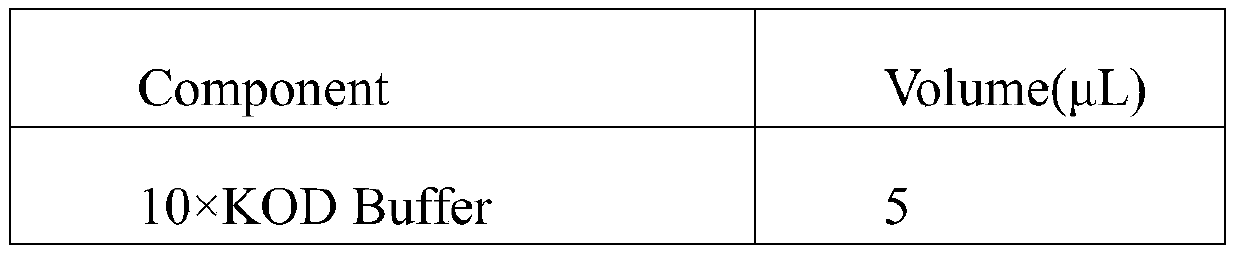

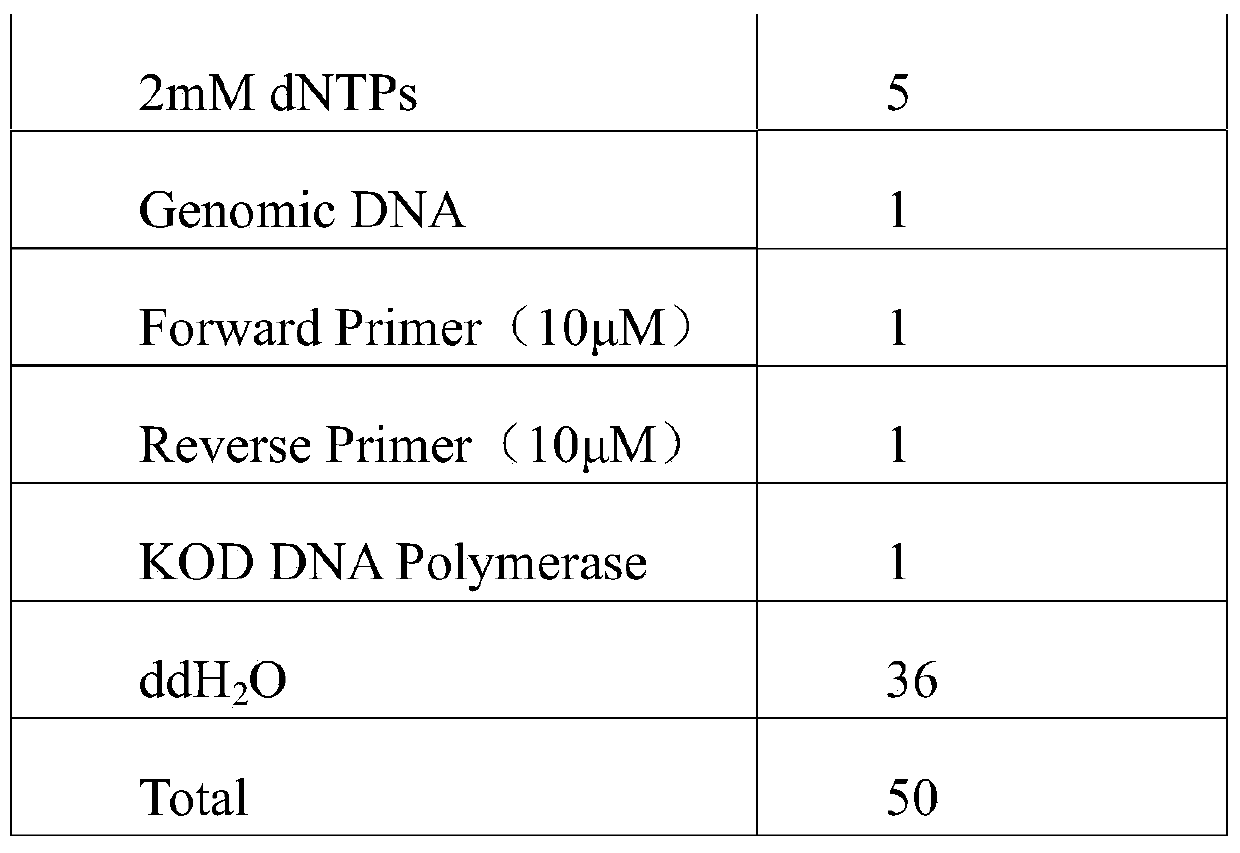

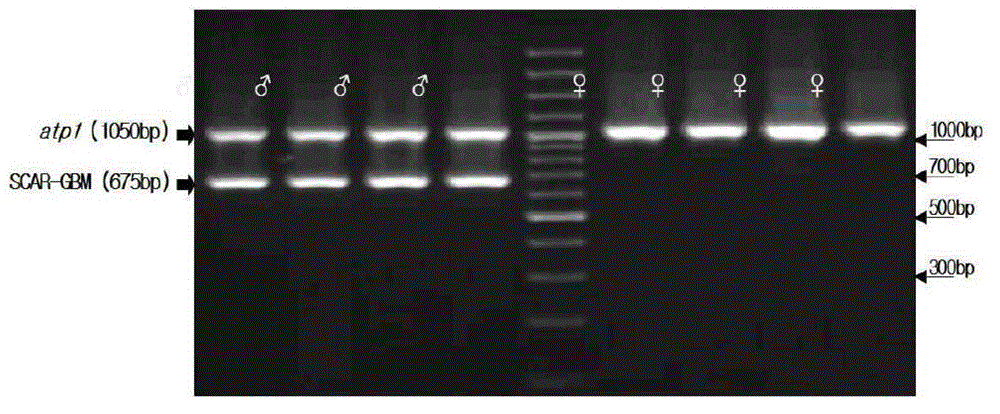

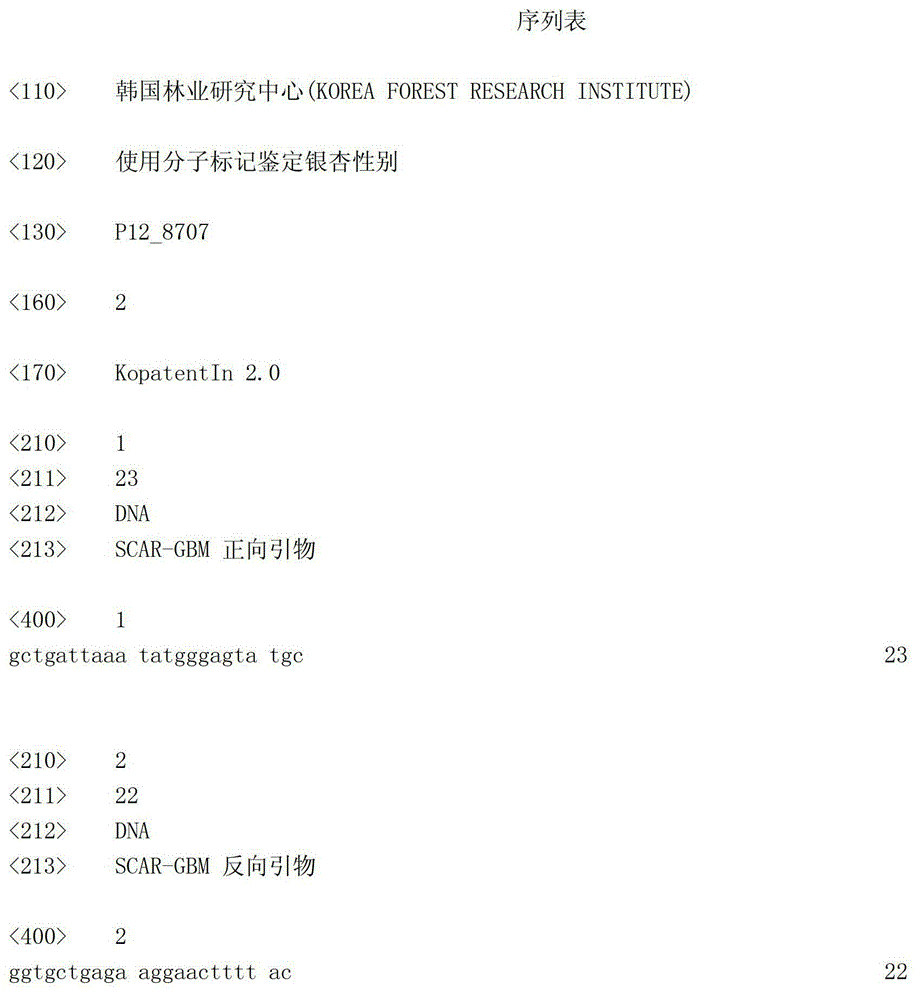

Gender identification of ginkgo biloba using molecular markers

ActiveCN103374568BPrevent plantingHelp productionMicrobiological testing/measurementDNA/RNA fragmentationMultiplex pcrsScars

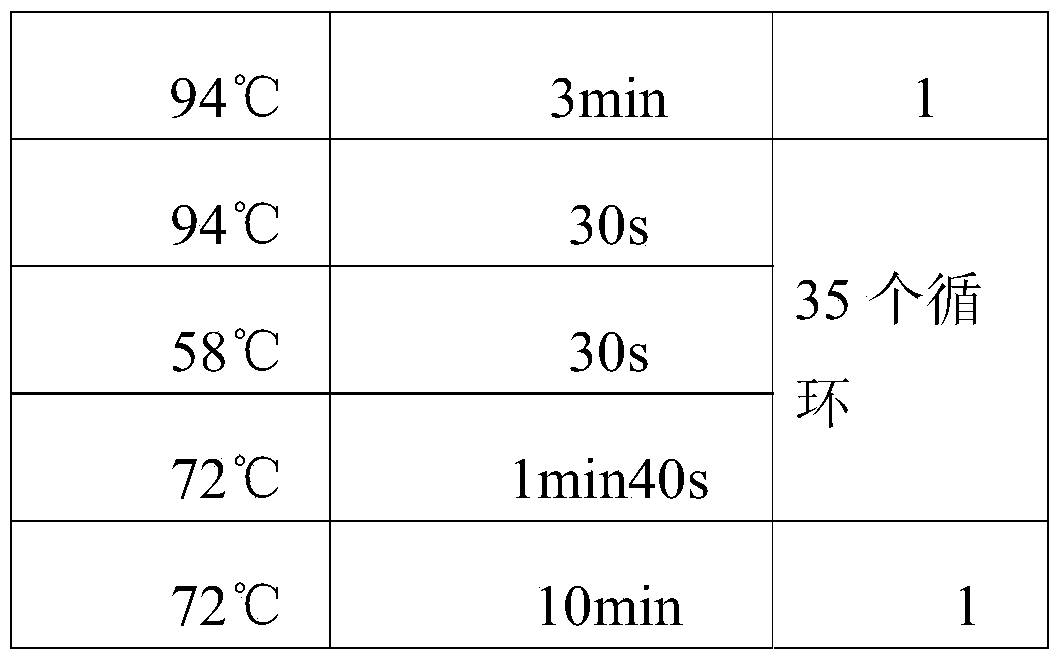

The invention relates to a molecular marker for identifying gemale plant and male plant of gingo, more particularl, the invention relates to a method for identifying gender of gingo. Compared to the usage of random primer, the method has increased stability, and compared to the dominant marker, which can provide limit information, the method is improved. According to the mehtod, the gingo male plant specificity SCAR-GBM primer and the exsisted atp1 primer of the mitochondrial DNA which is developed in the field are used at the same time for performing multiple PCR, wherein, the SCAR-GBM primer is based on the sequence development of RAPD segment which can display the heredity of gingo male plant.

Owner:KERALA FOREST RES INST

Friction welding method for periploca periploca wickerwork material

InactiveCN113319955AHelp productionImprove mildew resistanceWood treatment detailsReed/straw treatmentFiberCross linker

The invention discloses a friction welding method for a periploca periploca wickerwork material, and belongs to the technical field of wickerwork. Periploca periploca stems which are rich in emulsion are utilized, linear vibration friction welding is conducted on the periploca periploca stems through a plastic welding machine, and the welding strength completely meets the use requirement of common wickerwork. In addition, raw materials are low in cost, operation is easy, the mildewing and insect attracting risk is extremely low, the welding strength is high, a welding adhesive interface layer is formed by cross-linking fibers wrapped by melted and flowing periploca sepium lignin cell intercellular layer substances and emulsion contained in periploca sepium, and due to the fact that friction temperature rises in the welding process, the periploca sepium hemicellulose is partially degraded, the contained emulsion is crosslinked through the crosslinking agent to improve the welding strength, an adhesive component added in the prior art is not used in the whole welding process, the friction welding method special for periploca sepium is developed, and the friction welding method is suitable for periploca sepium wickerwork of a complex structure and is low in cost, easy to operate and high in economic added value.

Owner:阜南县铭钰柳木工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com